6905873

TROUBLESHOOTING

3

3.1 General Procedures

IMPORTANT: Troubleshooting the SIDESHIFT or CLAMP

circuits can be found in D-Series Carton Clamp Service

Manual 228156.

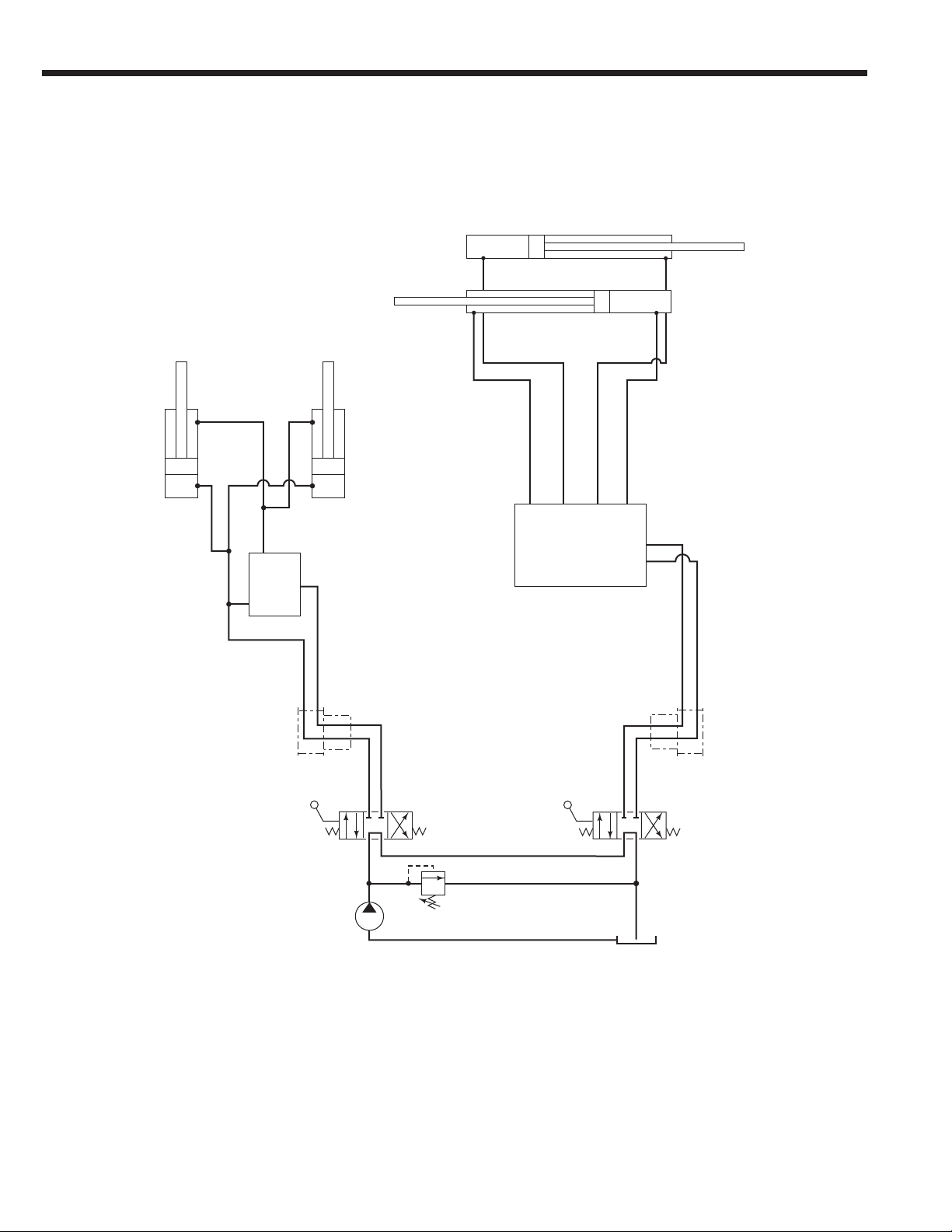

3.1-1 Truck System Requirements

• Truck hydraulic pressure should be within the range

shown in Specifications, Section 5.1. Pressure to the

attachment must not exceed 2300 psi (160 bar).

• Hydraulic flow should be within the volume range as

shown in Specifications, Section 5.1.

• Hydraulic fluid supplied to the attachment must meet the

requirements as shown in Specifications, Section 5.1.

3.1-2 Tools Required

In addition to a normal selection of hand tools, the following

will be required:

• Inline Flow Meter Kit:

20 GPM (75 L/min.) - Cascade Part No. 671477.

• Pressure Gauge Kit:

5000 psi (345 bar) - Cascade Part No. 671212. Two kits

are required.

OR

Wireless Pressure Monitor Kit:

Pressure transducers monitor the hydraulic pressure

and wirelessly transmit the data to the receiver display.

• Assorted fittings and hoses to adapt the gauge and flow

meter to the components being tested.

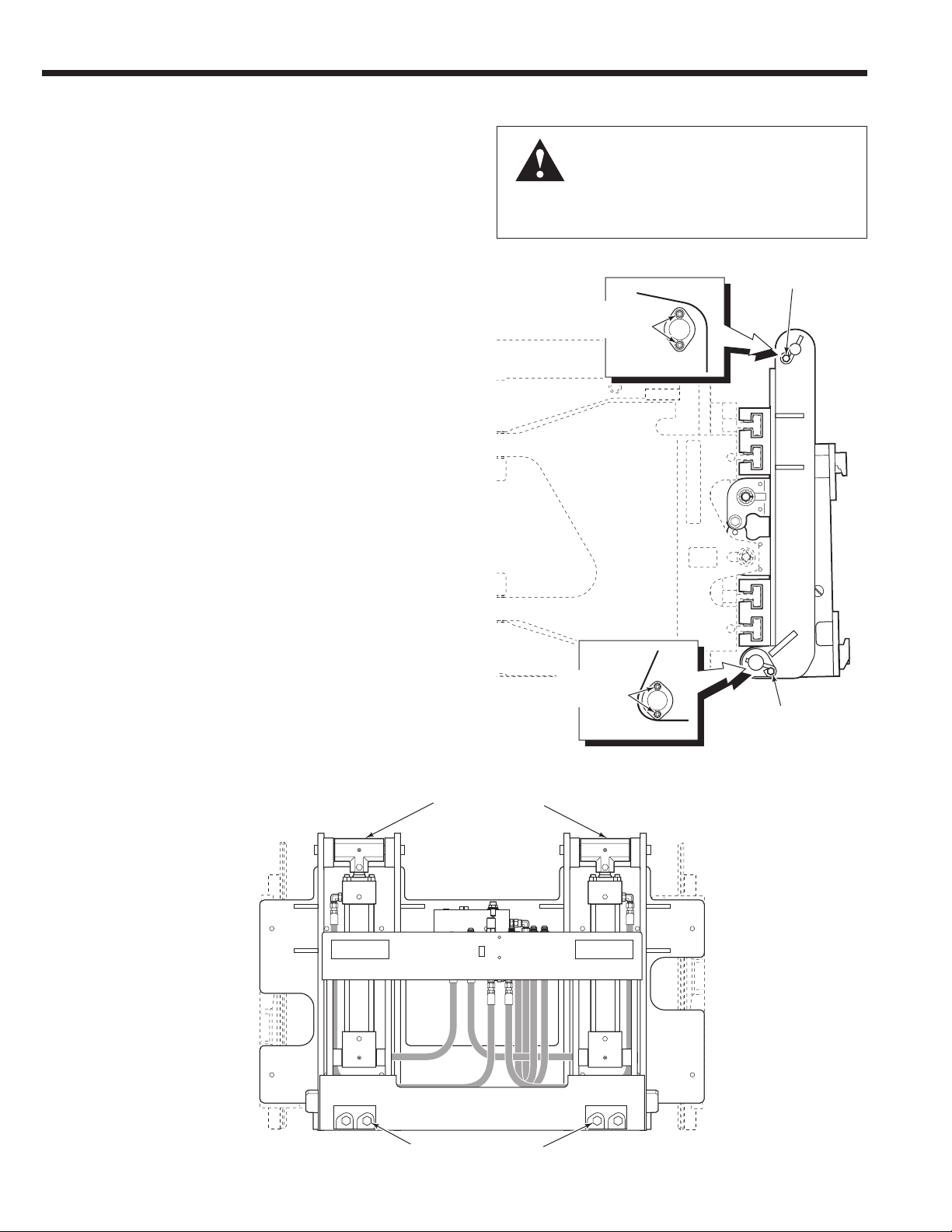

WARNING: Before servicing any

hydraulic component, relieve pressure

in the system. Turn the truck off and

move the truck auxiliary control valves

several times in both directions.

After completing any service procedure, test the

attachment through several cycles. First test

the attachment empty to bleed any air trapped

in the system to the truck tank. Then test the

attachment with a load to be sure it operates

correctly before returning to the job.

Stay clear of the load while testing. Do not raise

the load more than 4 in. (10 cm) off the floor while

testing.

Pressure

Gauge ▲

No. 6 and No. 8

JIC Swivel Tee

No. 4-6 Pipe/JIC ▲

No. 6-6 Hose ▲

(2) No. 6-8 JIC Reducer

Flow Meter

No. 4, No. 6 ▲

and No. 8

JIC/O-Ring

No. 6-8 JIC

Reducer

(2) No. 8-12 JIC/

O-Ring

Diagnostic Quick-Disconnects

Male Straight Thread

O-Ring Coupler:

No. 4 (Part No. 212282) ▲

No. 5 (Part No. 210378)

No. 6 (Part No. 678592)

Female JIC Thread Coupler:

No. 4 (Part No. 210385) ▲

No. 6 (Part No. 678591)

▲Included in Diagnostics Kit 394382.

GA0014.eps

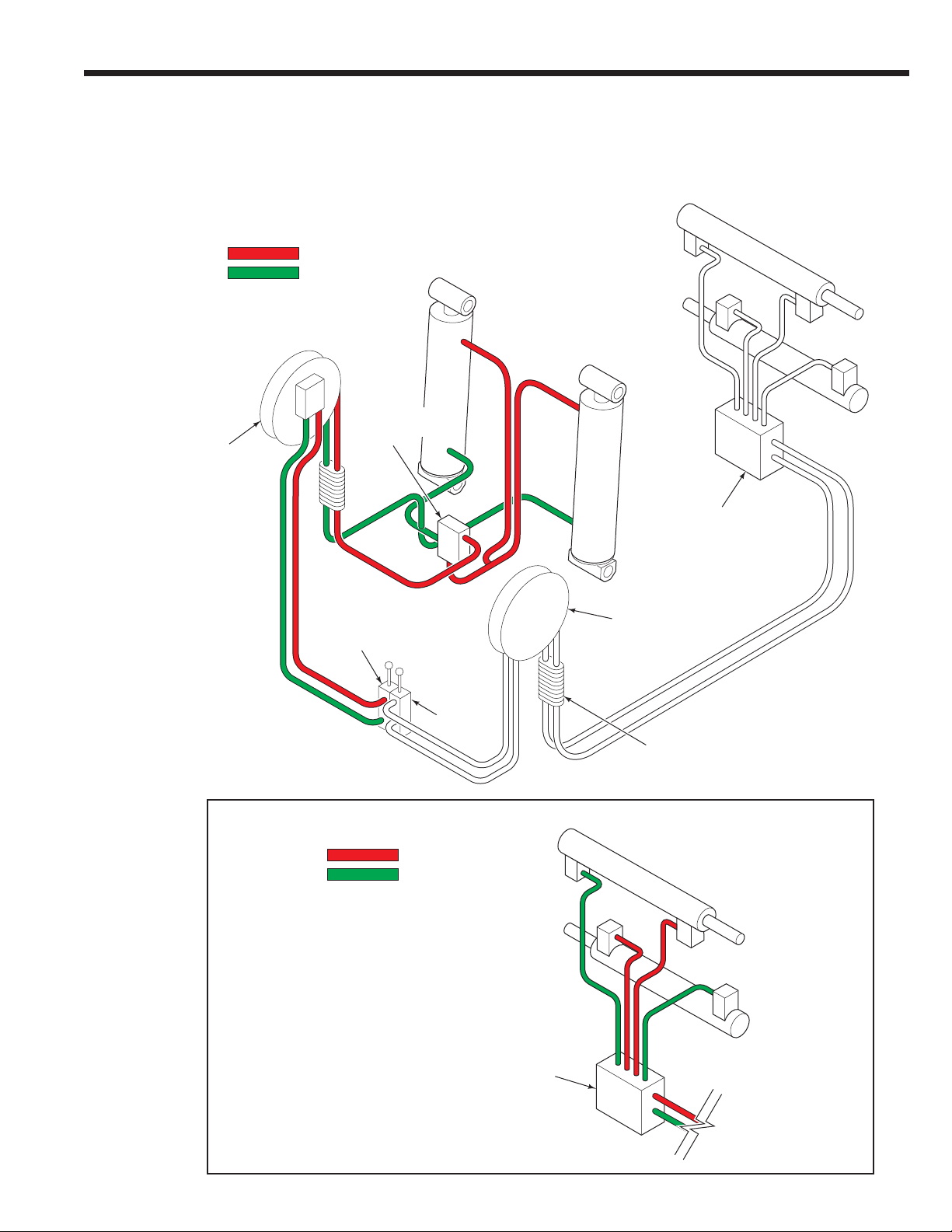

Receiver/Display

Transmitter

Pressure

Transducer

Alarm

(if equipped)

Flow Meter Kits:

671476 – 37 L/min (10 GPM)

671477 – 75 L/min (20 GPM)

Pressure Gauge Kit:

671212

Wireless Pressure Monitor Kits

6803614 – 12V Kit

6815672 – 12V Kit, includes alarm

6803617 – 24V-48V Kit

6815675 – 24V-48V Kit, includes alarm