TROUBLESHOOTING

86073955-R3

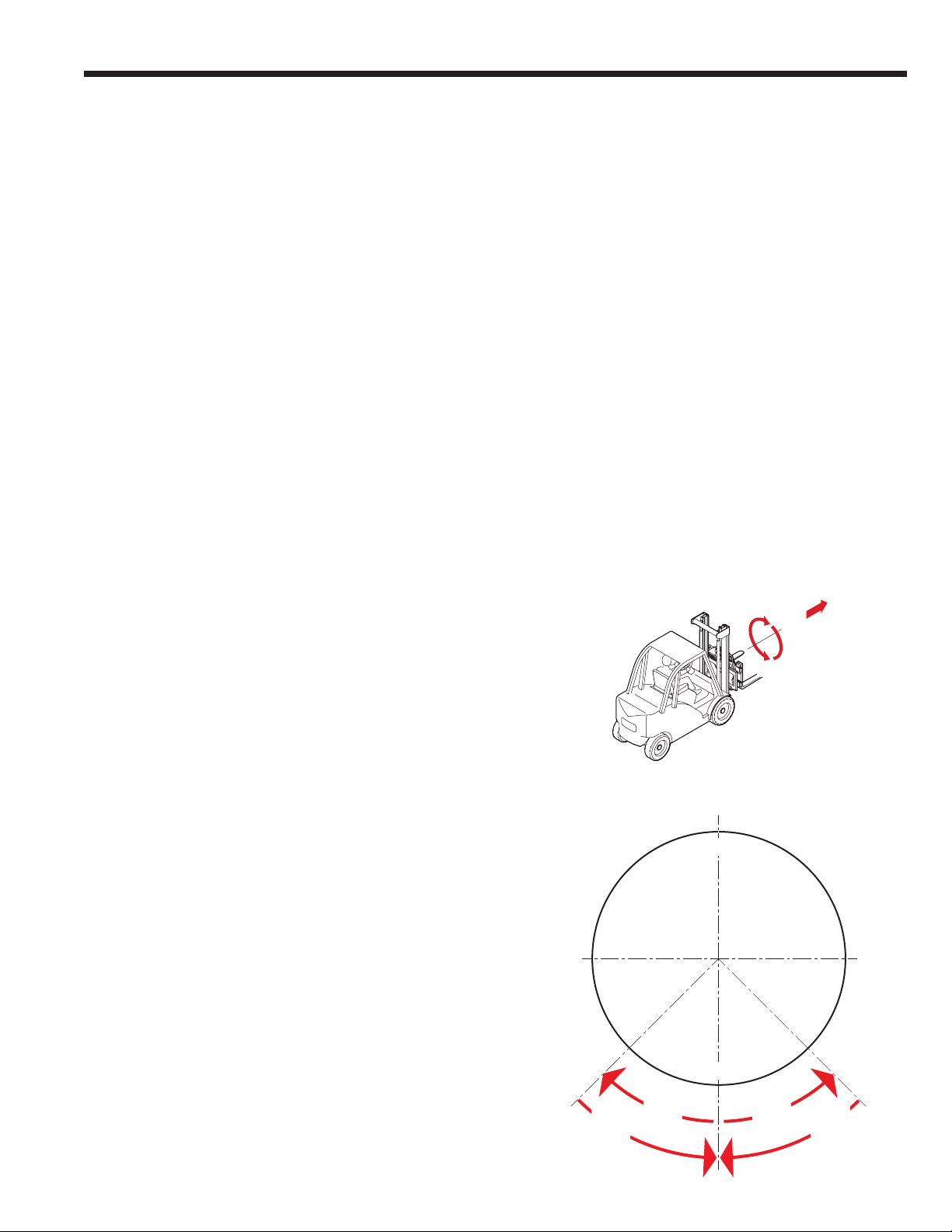

3.3-3 Rotation With Load

1 Attachments with Single Drive –Rotate a load

requiring approximately 3/4 of attachment maximum

torque capacity. Note gauge readings during rotation:

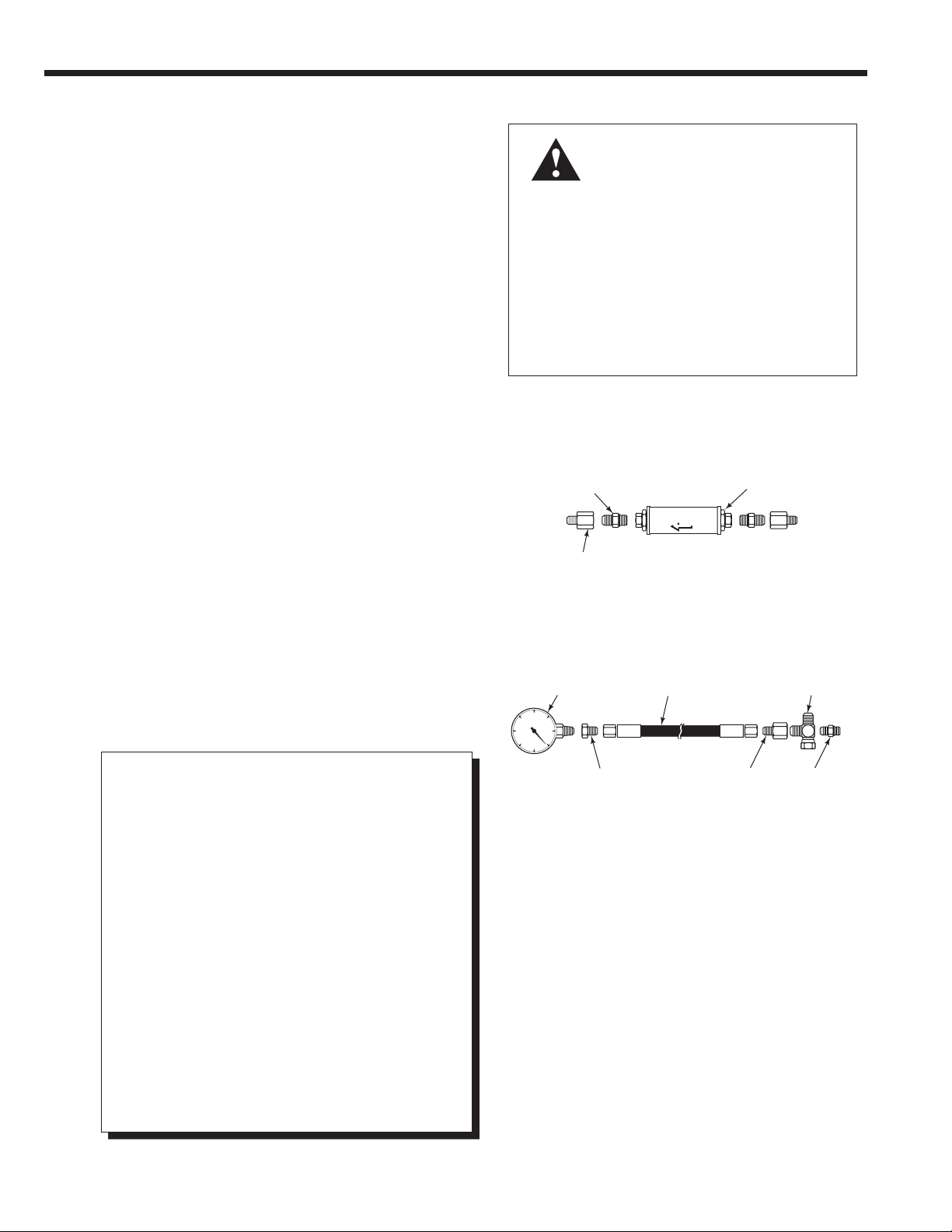

• If the higher gauge reading is substantially less than

the truck pressure as measured at the carriage hose

terminal, the rotator motor gerotor/geroler set may

need repair. Refer to Section 4.3.

• If the higher gauge reading is close to truck pressure

as measured at the carriage hose terminal and no

rotation occurs, the rotator motor output shaft or drive

box may need repair. Continue troubleshooting.

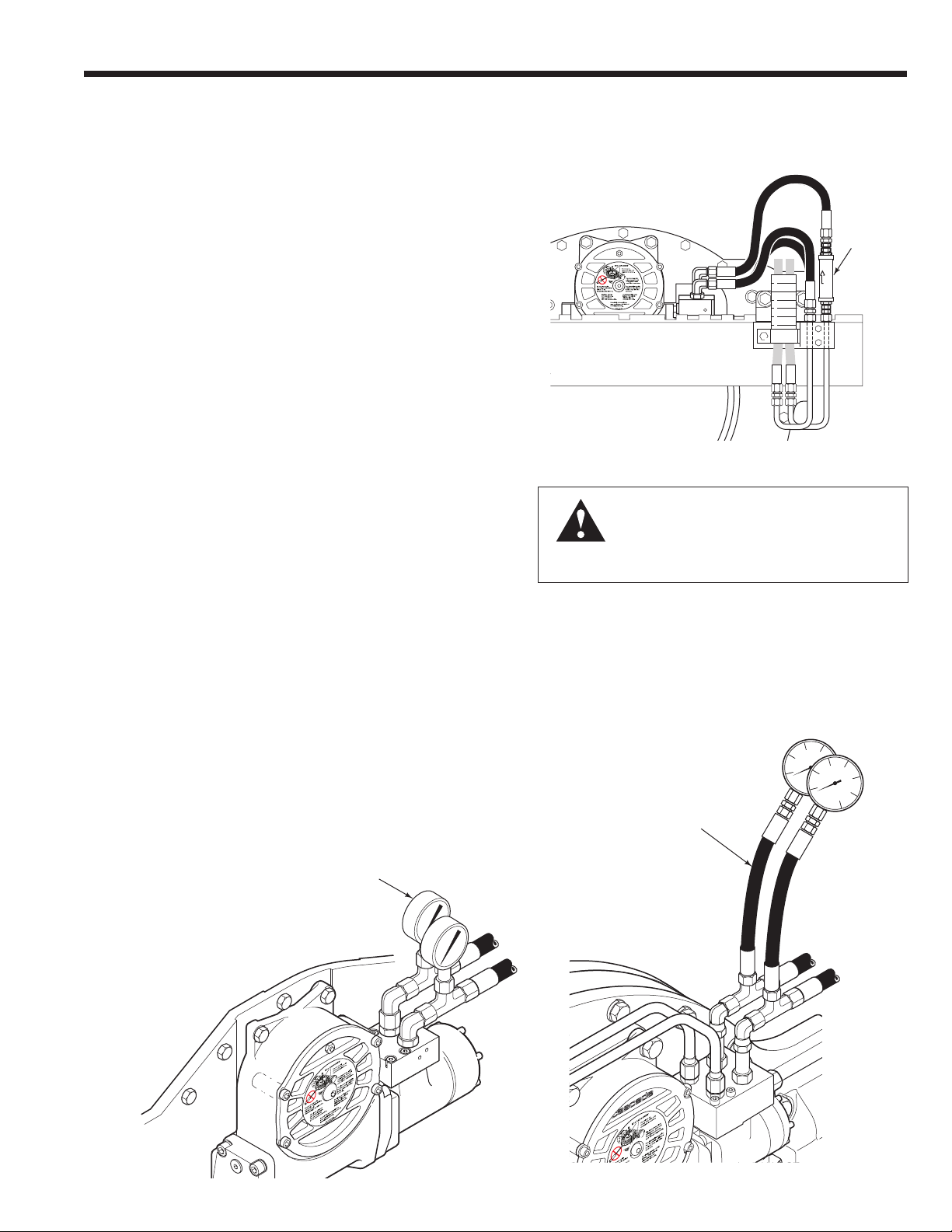

Attachments with Dual Drive – Remove the left drive

group from the attachments as described in Section

4.2-1. Cap the connector fittings on the right hand drive

group. Rotate a load requiring approximately 1/3 of

attachment maximum torque. Note gauge readings

during rotation:

• If the higher gauge reading is substantially less than

truck pressure measured at the junction block/hose

terminal, the RH motor may need repair.

• If the higher gauge reading is close to truck pressure

measured at the junction block/hose terminal, and

no rotation occurs, the RH motor output shaft or drive

may need repair. Continue troubleshooting.

• If the higher gauge is close to truck pressure,

measured at the junction block/hose terminal, and

rotation occurs, the LH motor output shaft or drive

may need repair. Continue troubleshooting.

2 Remove the motor from the drive box assembly as

described in Section 4.3-1.

3 Reinstall the hoses to the rotator fittings. Actuate the

ROTATE circuit.

• If the rotator motor shows rotational output, the drive

box may require service. See Section 4.2.

• If the rotator motor shows little or no rotational output,

the rotator motor requires service. See Section 4.3.

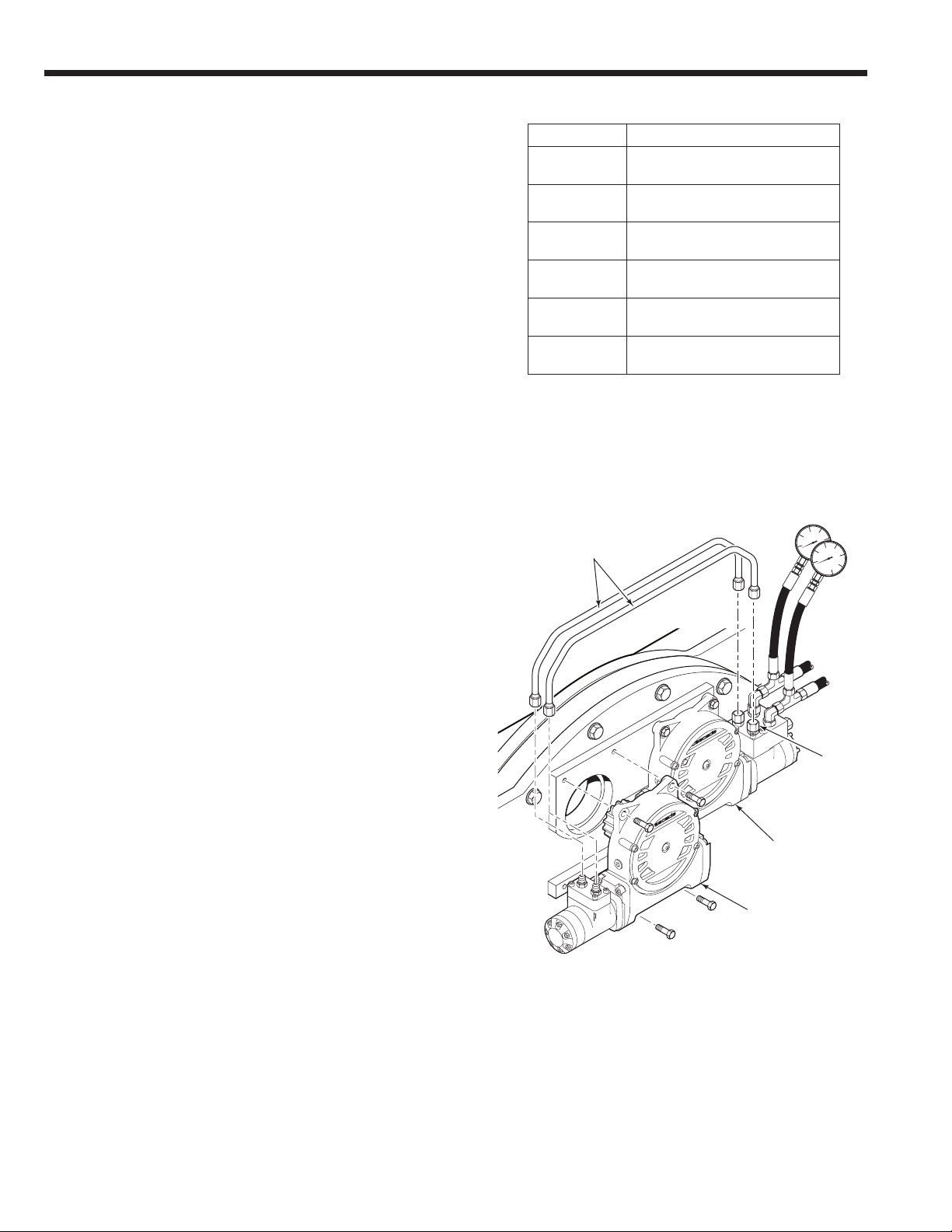

Disconnect the

crossover tubes

Cap fittings

Right hand

drive group

Left hand

drive group

Model Maximum Torque Capacity

45G, 55G 63,000 in.–lbs. @ 2300 psi

(7,118 Nm @ 160 bar)

65G 80,000 in.–lbs. @ 2300 psi

(9,039 Nm @ 160 bar)

80G 73,000 in.–lbs. @ 2,300 psi

(8,248 Nm @ 160 bar)

100G 98,000 in.–lbs. @ 2,300 psi

(11,037 Nm @ 160 bar)

130G ★128,000 in.–lbs. @ 2,300 psi

(14,462 Nm @ 160 bar)

160G ■145,000 in.–lbs. @ 2,300 psi

(16,383 Nm @ 160 bar)

★Rated at 15 GPM (56L/min.) flow.

■Rated at 20 GPM (75L/min.) flow.