TABLE OF CONTENTS

GENERAL

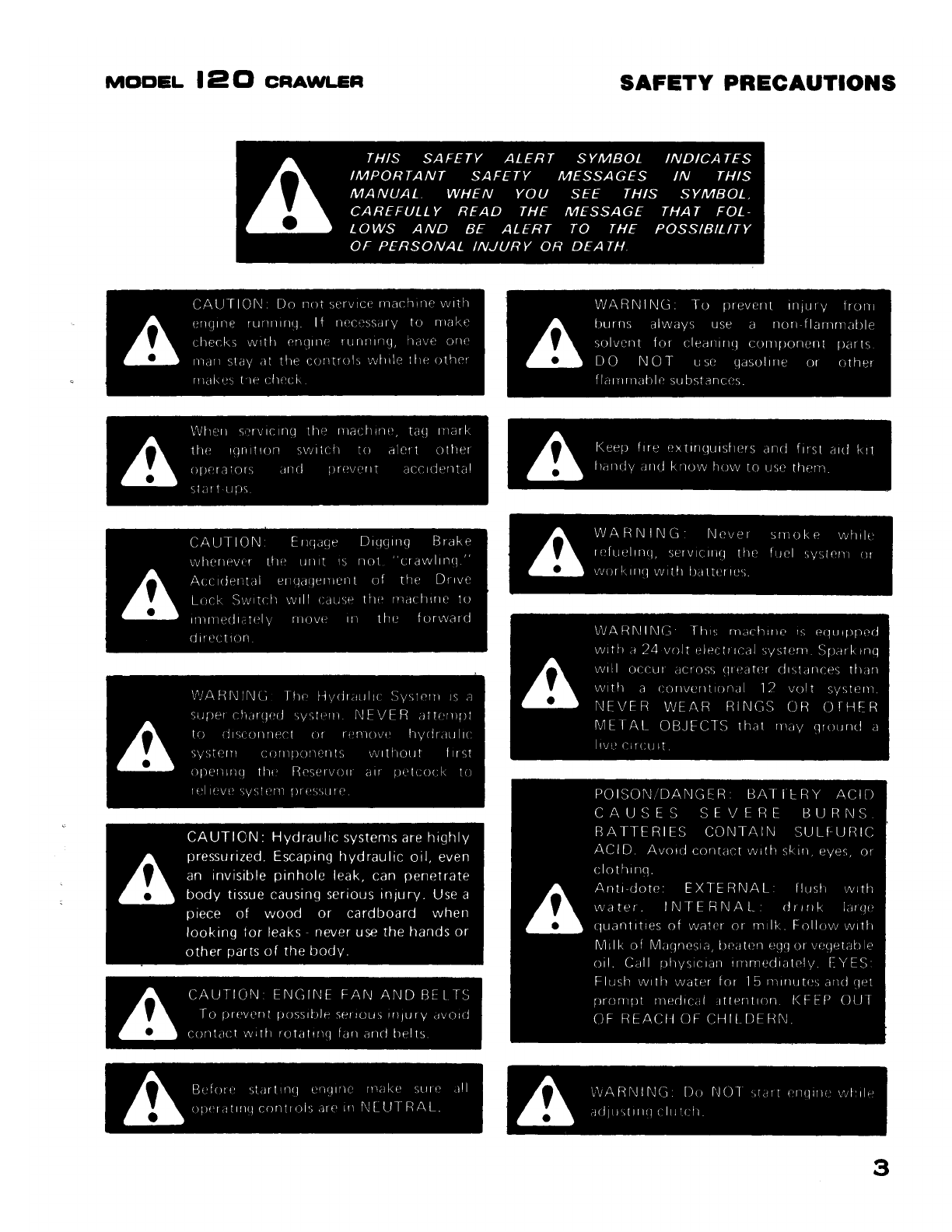

SafetyPrecautions

.............................................................................

3,4

Introduction

.....................................................................................

5

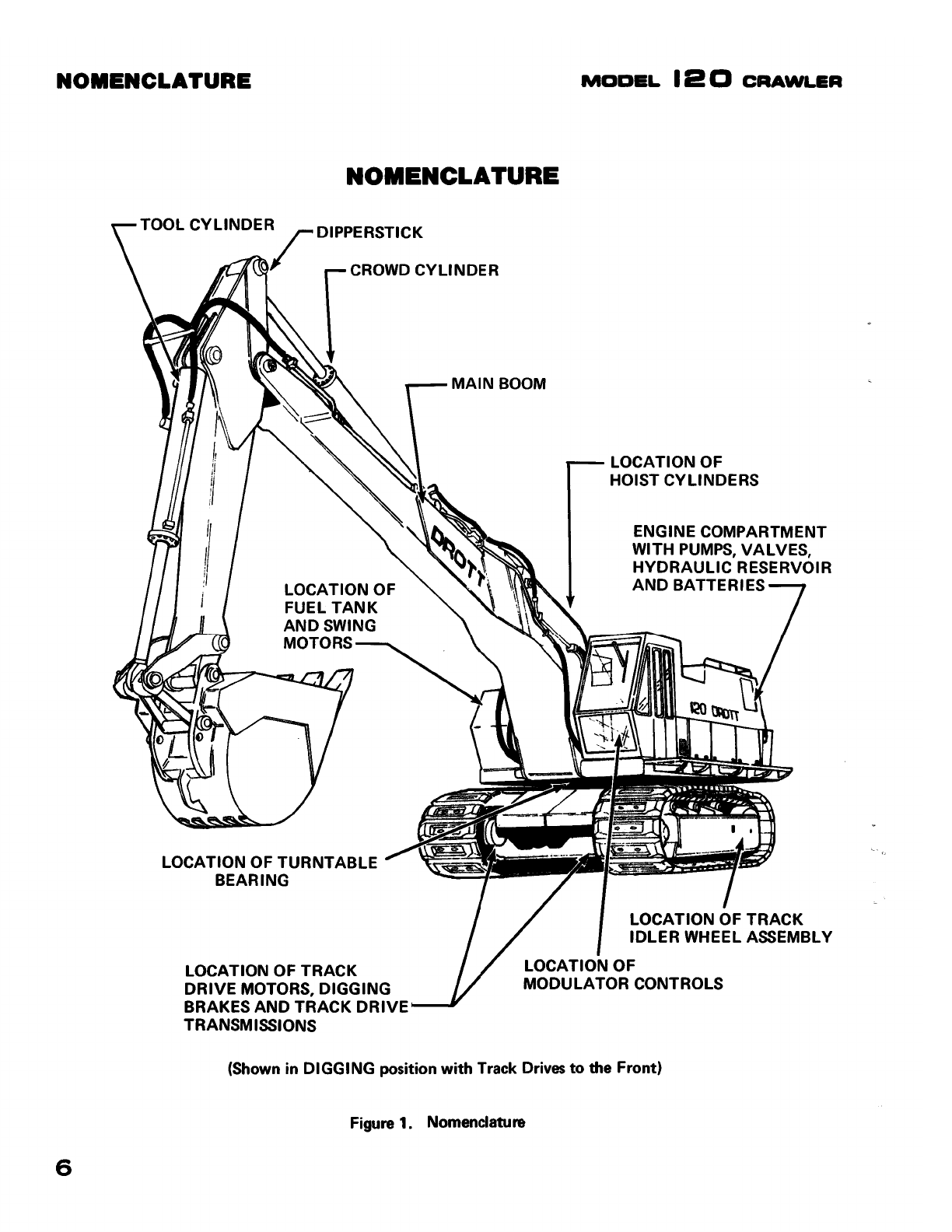

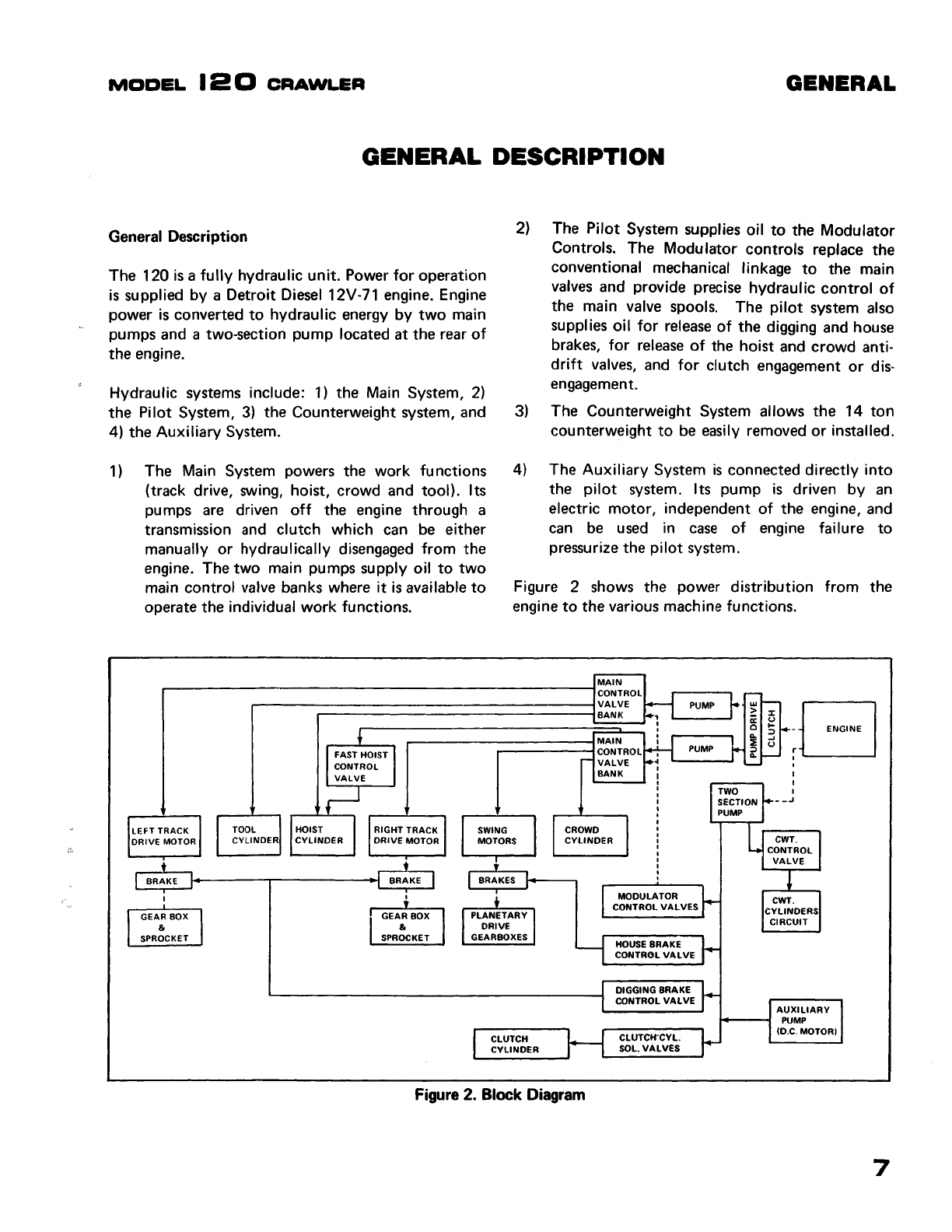

Nomenclatureand MachineGeneral Description

.................................................

6,7

Directional Reference

............................................................................

8

Partsand Service

................................................................................

8

SECTION

1 •

SCHEDULED

PREVENTIVE

MAINTENANCE

Lubricantand Fluid Recommendations

............................................................

9

ComponentCapacities

..........................................................................

10

PressureSettings

...............................................................................

10

MaintenanceSchedule

..........................................................................

11

Service Chart

................................................................................

12,

13

Pictorial Listing

of

Grease

Fitting

Locations

...................................................

14,

15

SECTION

2•

THE

UNDERCARRIAGE

Description, Maintenanceand Troubleshooting

............................................

16 thru

26

Carbodyand Turntable Bearing

................................................................

17

Track Assemblies

......................................................................

18

thru

22

Track Drive Assemblies

................................................................

22

thru

26

Disassemblyand Repair

..................................................................

27

thru

42

General Cleaning Instructions

.................................................................

27

UpperTrack Rollers

........................................................................

28,29

LowerTrack Rollers

........................................................................

30,31

IdlerWheel Assembly

..................................................................

31

thru 33

Digging

Brake

............................................................................

34-35B

Track DriveTransmission

..............................................................

36 thru 42

SECTION

3•

THE

UPPERSTRUCTURE

Description, Maintenanceand Troubleshooting

............................................

43

thru 54

Pump Drive System

....................................................................

43 thru 48

Swing System

.........................................................................

49 thru 53

Boom

Assembly.

. ... . .. .. . .. .. ... .. . .. ... .. . .. ... .. . ... .. .. ... . .. .. . .. . .. .. . ... . . .

..........

54

Disassemblyand

Repair

.

.................................................................

55

thru 67

Pump Drive Transmission and Clutch

...................................................

56 thru 59

House

Brakes

................................................................................

59

Swing Gearbox

........................................................................

59 thru 65

Turntable Bearing Replacement

........................................................

65 thru 67

Boom Removal

..........................................................•....................

67

SECTION

4•

THE

ELECTRICAL

SYSTEM

Description, MaintenanceandTroubleshooting

............•..•.•.............••....•.....•

68 thru

79

The

Charging

System

..................................................................

69thru

74

Control

Circuits

.•........•..............................................•...•...•..•..

74

thru

77

Lightsand Instrument

Circuits

.........................................•......................

78

Disassembly

and

Repair

.

........................................................................

79

1

Find manuals at https://best-manuals.com