GENERAL

TABLE OF CONTENTS

GENERAL

Safety Precautions

...................................................................

3,4

Introduction

..........................................................................

5

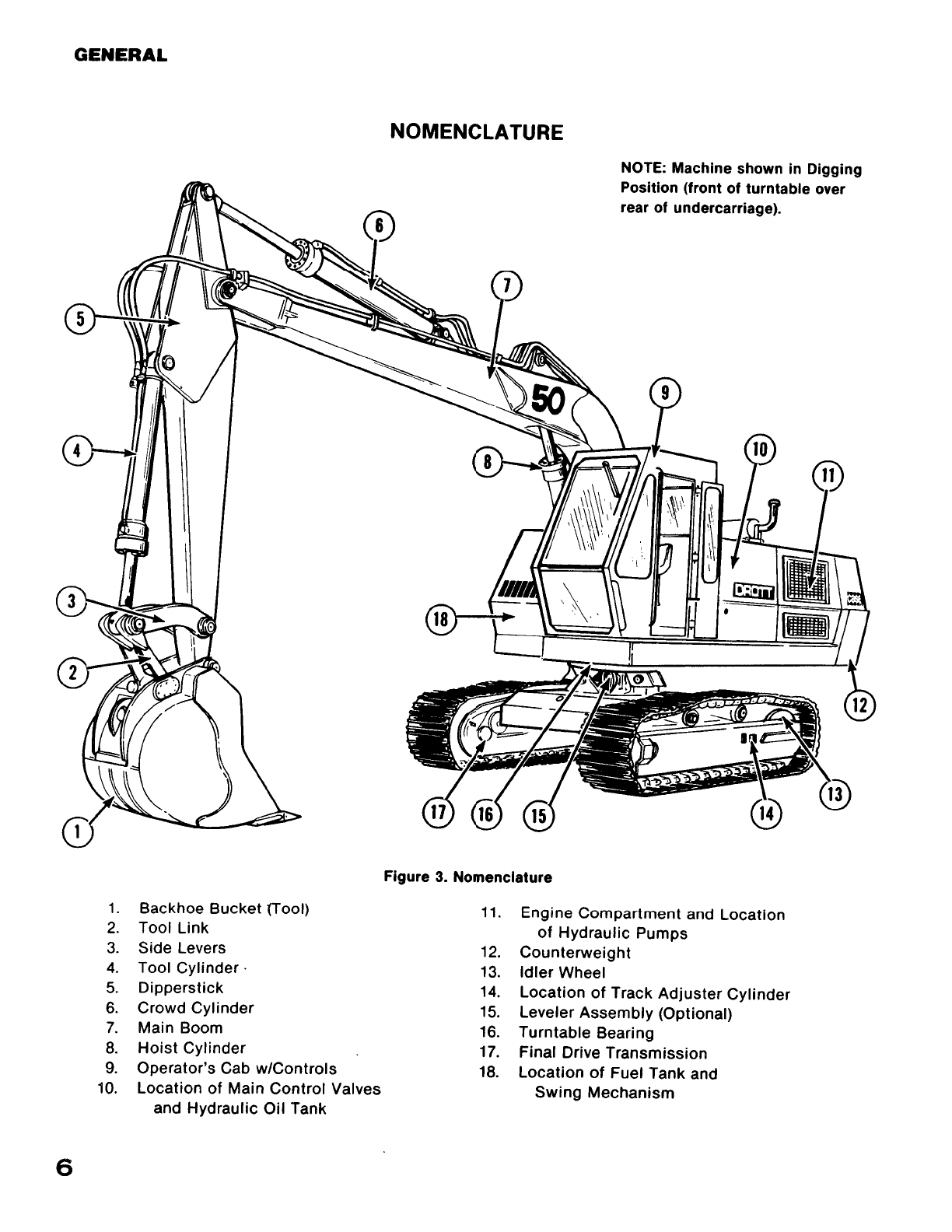

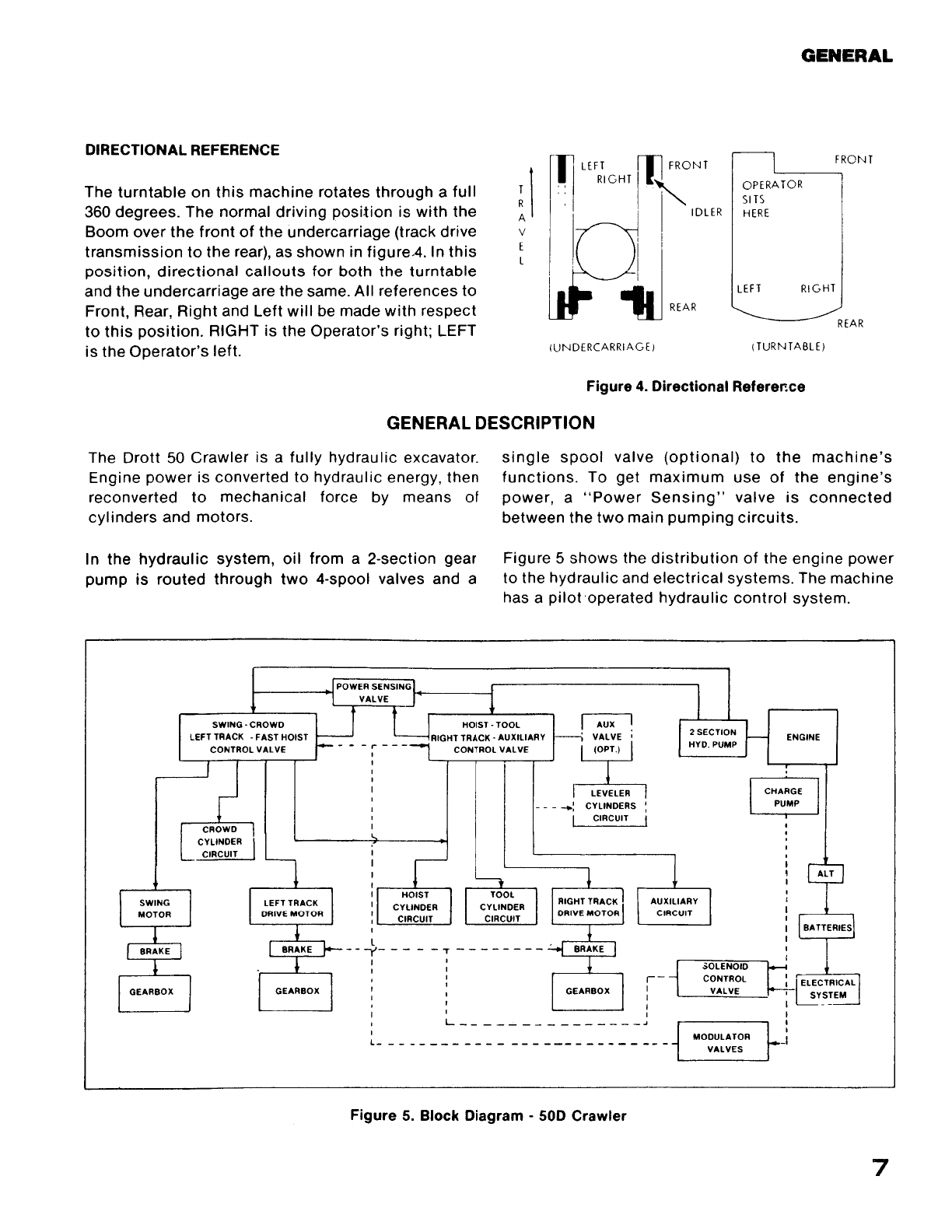

Nomenclatureand General Description

..................................................

6,7

Specifications

........................................................................

8

SECTION 1 • SCHEDULED PREVENTIVE MAINTENANCE

Introduction

..........................................................................

9

Hydraulic Oil Recommendations

........................................................

10

Hydraulic System Operating Pressures

..................................................

10

Component Capacities

................................................................

11

Rated Pump Output

...............................

·

....................................

11

Maintenance Chart

.................................................................

12,

13

Illustrated

Listing

of Grease

Fittings

..................................................

14,15

Itemized Maintenance

Instructions

................................................

16 thru

21

SECTION 2 · MECHANICAL SYSTEM

Undercarriage

.........................

:

.......................................

22

thru

30

Engine and Related Parts

...................................

:

....................

31

thru

34

Turntable Swing

..............

,

.......................

;

.......

,

..........

,

......

34

thru

39

aoom

and

Attachments

........................................

:

................

39

thru

42

SECTION 3 • ELECTRICAL SYSTEM

Introduction

,;

........................................................................

43

12/24 Volt System (Machines through PIN 6280344)

...

,

..............................

44 thru

52

24

Volt System (Machines

with

PIN 6280345 and After)

................................

53

thru

60

Control

Circuits

...

·

...................................................................

61

Lights and Instrumentation

Circuits

.....................................................

62

SECTION 4 · HYDRAULIC SYSTEM (For pressures, see page

10)

Introduction

.........................................................................

63

System Maintenance

...........................................................

64

thru

66

Main Hydraulic System

..........................................................

66

thru

80

General Description

.................................................................

66

Hydraulic Pump

....................................................................

68

Main Control Valves

.................................................................

70

Port Relief Valves

...................................................................

73

Explanation

of

"Summated"

System

...................................................

76

Power Sensing Valve

..............................................................

76

Main Relief Valves

................................................................

78

Track Drive Hydraulics

..........................................................

81

thru

87

Drive

Motor

Circuits

.................................................................

81

Digging Brake Release

Circuit

........................................................

85

Solenoid Control Valve

..............................................................

85

Hydraulic Swivel

...................................................................

86

Swing Hydraulics

.....................................................................

88

Hoist

Hydraulics

.....................................................................

90

Hydraulic

Circuits

to Crowd Cylinderand Tool Cylinder

.....................................

92

Leveler Hydraulics

....................................................................

93

PilotControl System

............................................................

94

thru

97

1

Find manuals at https://best-manuals.com