0-6-1

Table of Contents

To the Owner ..................................................... 0-1

Safety Labels .....................................................0-2

For Safe Driving.................................................0-3

Safety Section.....................................0-7

Precaution Identification Plates (DECALS)........0-8

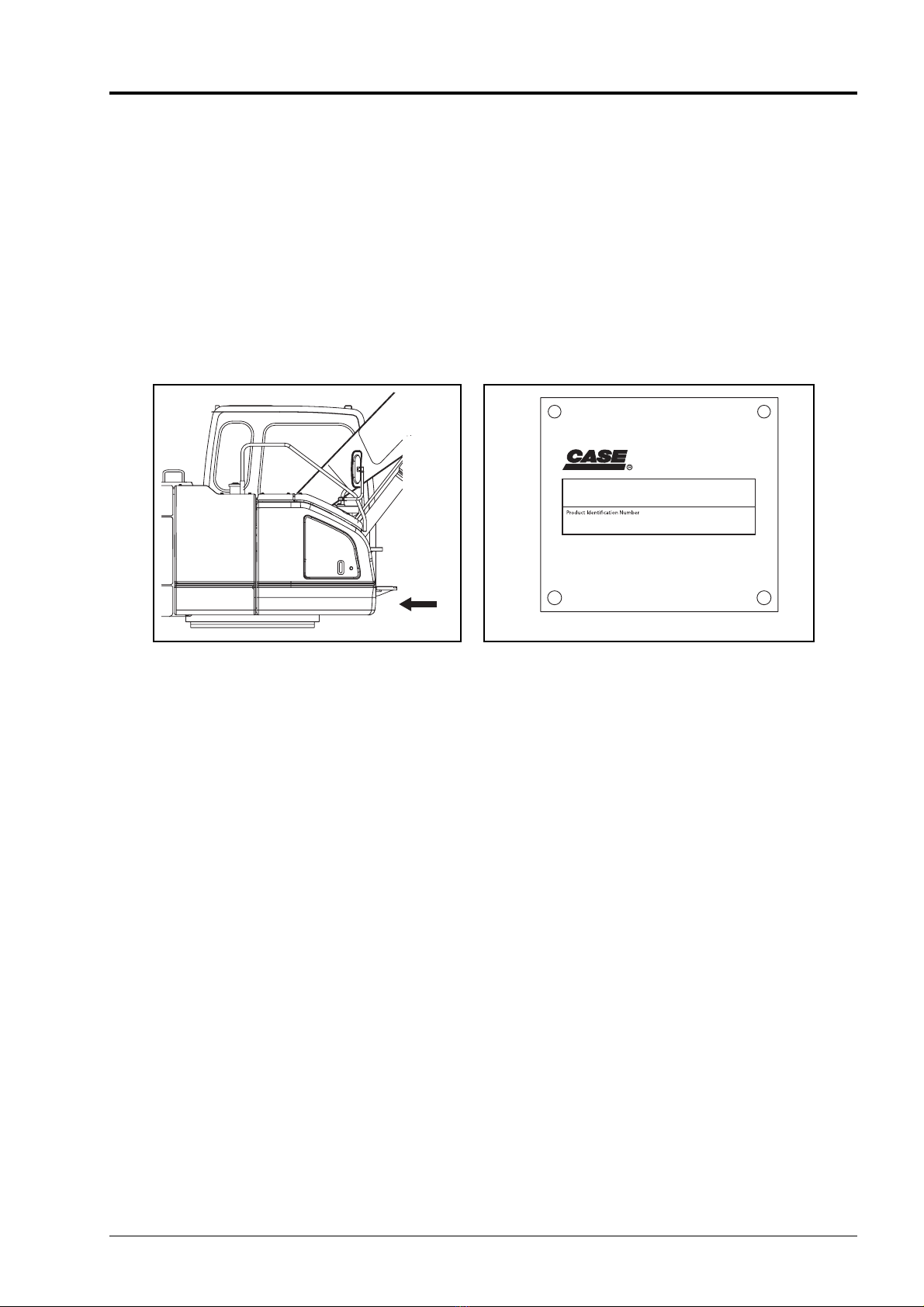

Identification Plates inside the Cabin.......................0-8

Outside Identification Plate....................................0-13

Precaution Identification Plates on Parts (Examples)

...........................................................................0-17

Prior to Operation.............................................0-18

Confirmation of Safety items............................0-20

During Operation..............................................0-23

While Traveling ................................................0-27

After Operating.................................................0-28

While Transporting........................................... 0-29

Before Regular Inspection & Maintenance.......0-30

Inspection and Maintenance............................ 0-31

Instruments and Controls..................1-0

Location of Components ....................................1-1

Overall View ............................................................1-1

Operator’s Cab........................................................1-2

Right Console.....................................................1-4

Right Console..........................................................1-4

Monitor & Switch Panel......................................1-5

Monitor & Switch Panel ...........................................1-5

Moniter Display ..................................................1-6

Switch Panel ......................................................1-7

Left Console.......................................................1-9

Left Console ............................................................1-9

Switch....................................................................1-10

Air Conditioner .................................................1-11

Air Conditioner (If equipped)..................................1-11

Explanation of device.......................................1-13

Radio.....................................................................1-13

Operation Levers..............................................1-15

Operation Levers...................................................1-15

Operator’s Seat................................................ 1-18

Operator’s Seat .....................................................1-18

Operator’s Cab.................................................1-20

Fuses ...............................................................1-22

Fuses.....................................................................1-22

Explanation of device.......................................1-23

Battery...................................................................1-23

Starting the Engine by Using Booster Cables .......1-24

Operating Instructions.......................2-0

Operation of New Machine.................................2-1

Using a New Machine..............................................2-1

Daily Inspections................................................2-2

Daily Inspections .....................................................2-2

Starting and Stopping the Engine ......................2-4

Inspections before Starting the Engine....................2-4

Starting the Engine..................................................2-5

Inspections after Starting the Engine.......................2-6

Stopping the Engine (Normal Operation) ................2-7

Warm-up Operation............................................2-8

Warm-up Operation................................................. 2-8

Operations (Traveling)......................................2-10

Operations (Swing)...........................................2-19

Swing Operation....................................................2-19

Operations (Attachment) ..................................2-20

Operations (Attachment).......................................2-20

Operations........................................................2-21

Blade Operation ....................................................2-21

Characteristics of Hydraulic Excavator..................2-21

Cautions for operations.........................................2-22

Cautions for Interference.......................................2-22

Operating Instructions (Cautions).....................2-24

Operating Instructions (Procedures) ................2-25

Bucket: Turning Over and Replacement..........2-27

Bucket: Turning Over and Replacement...............2-27

On Completion of Daily Operations..................2-29

On Completion of Daily Operations.......................2-29

Operating in Cold Climates ..............................2-31

Operating under Extreme Conditions...............2-32

Transportation..................................................2-33

Loading and Unloading ......................................... 2-33

Switch settings during loading and unloading.......2-33

Transportation.......................................................2-33

Storing..............................................................2-37

Inspections and Maintenance............3-0

General Cautions ...............................................3-1

Periodic Maintenance Check List.......................3-2

Daily Inspections (Prior to Operation) .....................3-2

Periodic Maintenance Check List............................ 3-3

Fuel / Lubricants for Different Ambient Temperature

Settings ............................................................... 3-4

Genuine CASE Company LLC Parts and Elements 3-5

Disposable Items.....................................................3-6

Grease / Oil and Elements.................................3-7

Inspection Prior to Operation..............................3-9

Inspections Prior to Operation.................................3-9

Greasing Attachments......................................3-13

Greasing Front Attachment Pins ...........................3-13

Fuel System .....................................................3-15

Fuel .......................................................................3-15

Fuel Refilling and Fuel Level Checking.................3-18

Drainage of Water and Sediments in the Fuel Tank

..........................................................................3-18

Draining Water from the Pre Fuel Filter.................3-19

Pre Fuel Filter Replacement..................................3-20

Draining Water from the Fuel Filter (Main)............3-21

Fuel Filter (Main) Replacement.............................3-21

Engine..............................................................3-23

Engine Oil Replacement........................................ 3-23

Engine Oil Filter Replacement...............................3-23

Cooling System.....................................................3-25

Inspecting and Refilling Coolant............................3-25

Replacing the Coolant...........................................3-26

Cleaning and Inspecting the Radiator Net and Fin

..........................................................................3-27

Cleaning and Replacing the Air Cleaner (double ele-

ments) ...............................................................3-28

Inspection and Adjustment of Fan Belt..................3-30

Find manuals at https://best-manuals.com