2

Foreword

This manual provides all the specic information you need to fa-

miliarize yourself with and correctly operate your unit.

Read it very carefully when you purchase the instrument and

consult it whenever you have doubts regarding use and before

performing any maintenance operations.

Safety precautions

Using the unit improperly and performing repairs or modications

personally will void the warranty.

The producer declines any responsibility for damages due to

inappropriate use of the product and due to any use other than

the use the product was designed for.

The producer declines any responsibility for consequential da-

mages except civil liability for the products.

The automation is conformed to the european laws: EN 60204-1,

EN 12445, EN 12453

It is compulsory to be conformed to the automatic gates: EN

12453, EN 12445, EN 12978 and national laws.

The force of the door should be measured and adjusted accor-

ding the maximum values of the norm EN 12453.

Environmental protection

measures

Information regarding the environment for custom-

ers within the European Union. European Directive

EC 2002/96 requires that units bearing this symbol

on the unit and/or on the packaging be disposed of

separately from undierentiated urban wastes.

The symbol indicates that the product must not be disposed of

with the normal household wastes. The owner is responsible

for disposing of this product and other electrical and electronic

equipment through specic waste collection facilities indicated

by the government or local public agencies. Correct disposal

and recycling help prevent any potentially negative impact on

the environment and human health. To receive more detailed

information regarding disposal of your unit, we recommend that

you contact the competent public agencies, the waste collec-

tion service or the shop where you purchased the product.

1Introduction 3

1.1 Description of the produc

1.2 Technical caracteristics

2Premises

2.1 Preliminary checks

2.2 Type of cable 4

2.3 Installation

2.4 Notes of connections

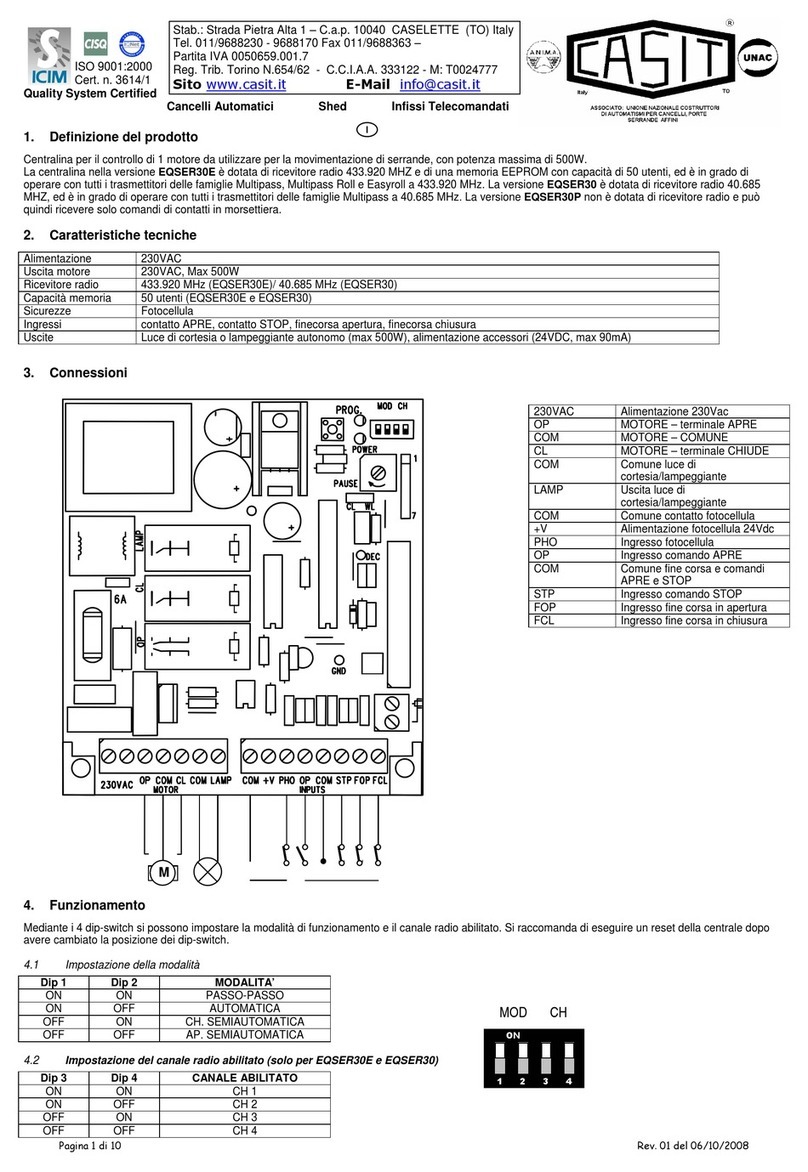

2.5 Scheme of the control unit and electrical connections 5

3Installation of the control unit 6

3.1 Connection of the POWER SUPPLY

3.2 Connections of the MOTORS

3.3 Connection of the ANTENNA

3.4 Power supply of the ACCESSORIES

3.5 Connection of the STOP

3.6 Connection of the COURTESY LIGHT 7

3.7 Connection of the SIGNAL LIGHT

3.8 Set up of the PRE-LIGHTING

3.9 Connection of the LIGHT

3.10 Connection of the LIMIT SWITCHES 8

3.11 Connection of the START and PEDONALE

3.12 Connection of the PHOTO-BEAM A (only closing) 9

3.13 Conneciton of the PHOTOBEAM A with TEST

3.14 Connection of the PHOTOBEAM B

(when opening and closing) 10

3.15 Connection of the PHOTO-BEAM B with TEST

3.16 Connection of the NEW LOCK SYSTEM 11

3.17 Connection of the MECHANICAL EDGE

3.18 Connection of the motor with electro-magnetic bloc

3.19 Check of the connections

4Functions and adjustment 12

4.1 Function

4.2 Activation of the OUTPUTS 13

4.3 Watch the tension of the BATTERIES

4.4 SPEED and SLOW DOWN of the motors 14

4.5 Level of the OBSTACLE DETECTION

4.6 Function of the OBSTACLE DETECTION

5Installation of the radio receiver and remote controls 15.

5.1 Cancellation of the MEMORY

5.2 Cancellation of a SINGLE CODE

5.3 Activation of the ROLLING CODE COUNTER

5.4 Memorization of the code of the REMOTE CONTROLS 16

6Learning and programm of the working time with

START

6.1 Working time learning with START

6.2 Working time learning with START or

PARTIAL OPENING 17

7RESET of the control unit with standard values

8Table with all START FUNCTIONS of S10 19

9CE declaration of conformity 23

Index chapter

PiccolSmall dictionary

OLS Opening Limit Switch

CLS Closing Limit Switch

START START control

PEDESTRIAN Partial Opening

Vac (alternate current)

Vdc (direct current)

NC Normally closed

NA o NO Normally open

Contatto pulito Isolated contact