2 3

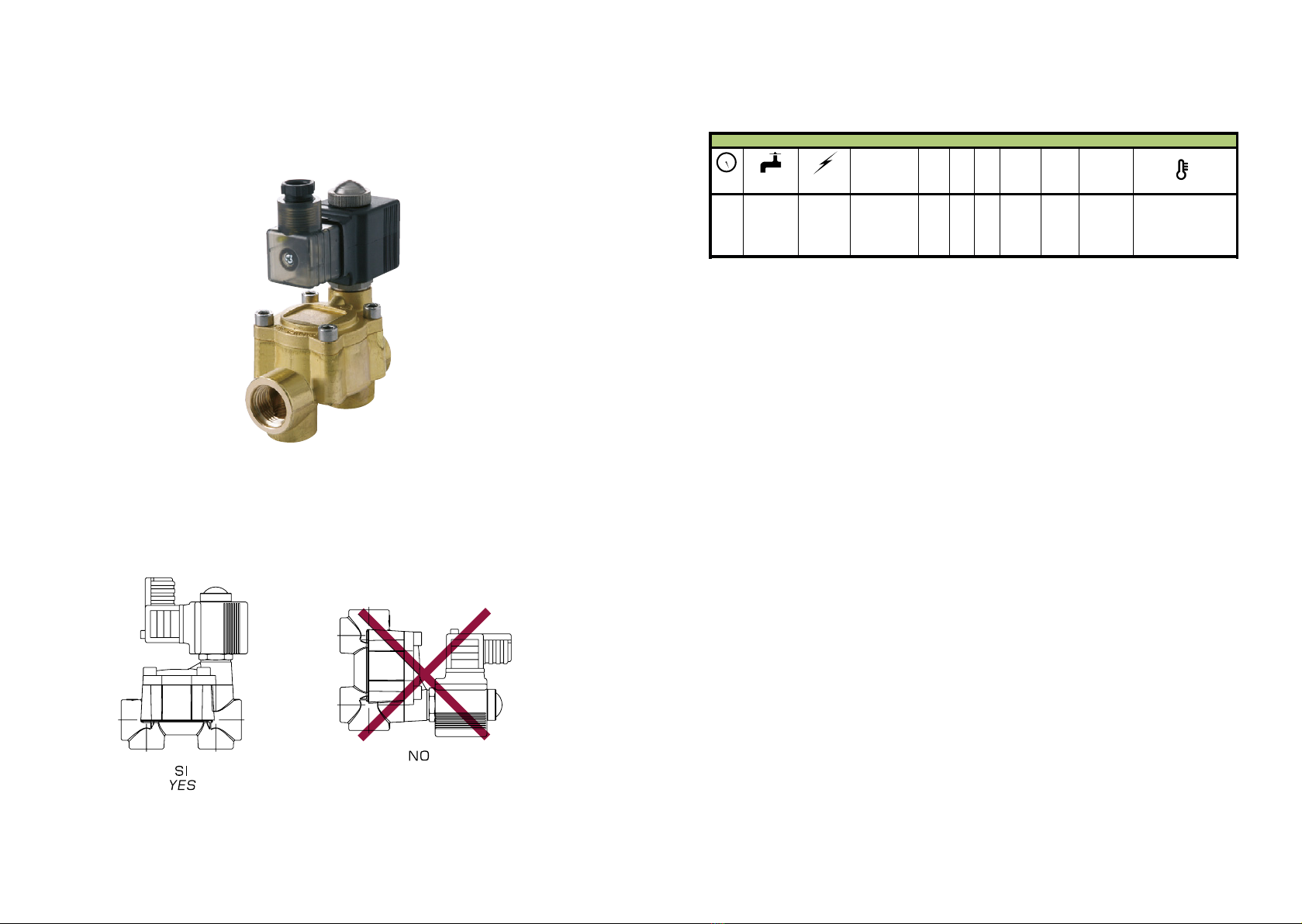

AQUILOTTO 2 SIDES is an electronic device designed and

engineered to cut the liquid flow in-between two subsequent trees.

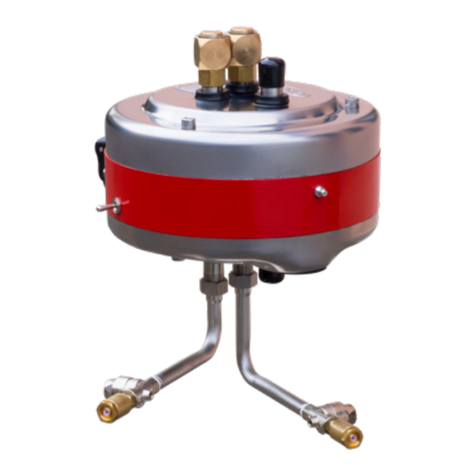

It can be mounted very easily to any type of sprayers: air blast

sprayers, equipments with DUPIGET OLIVO or 2 ELECTROGET

OLIVO.

AQUILOTTO 2 SIDES consists of 3 parts:

Control unit with double timer and 2 optical readers with solenoid

valve.

The function of the optical reader is to find the presence of the

trunk or leaves and give the impulse for the fluid opening.

The Control unit allows accurately controlling all functions of

AQUILOTTO 2 SIDES.

WHAT IS AQUILOTTO 2 SIDES

• Electronic control unit

• 2 optical readers with solenoid valve and installation bracket

• Electrical connection cables

• Hydraulic pipes and connections

• Frame to install the optical reader

WHAT IS INCLUDED

WHAT IS NOT INCLUDED

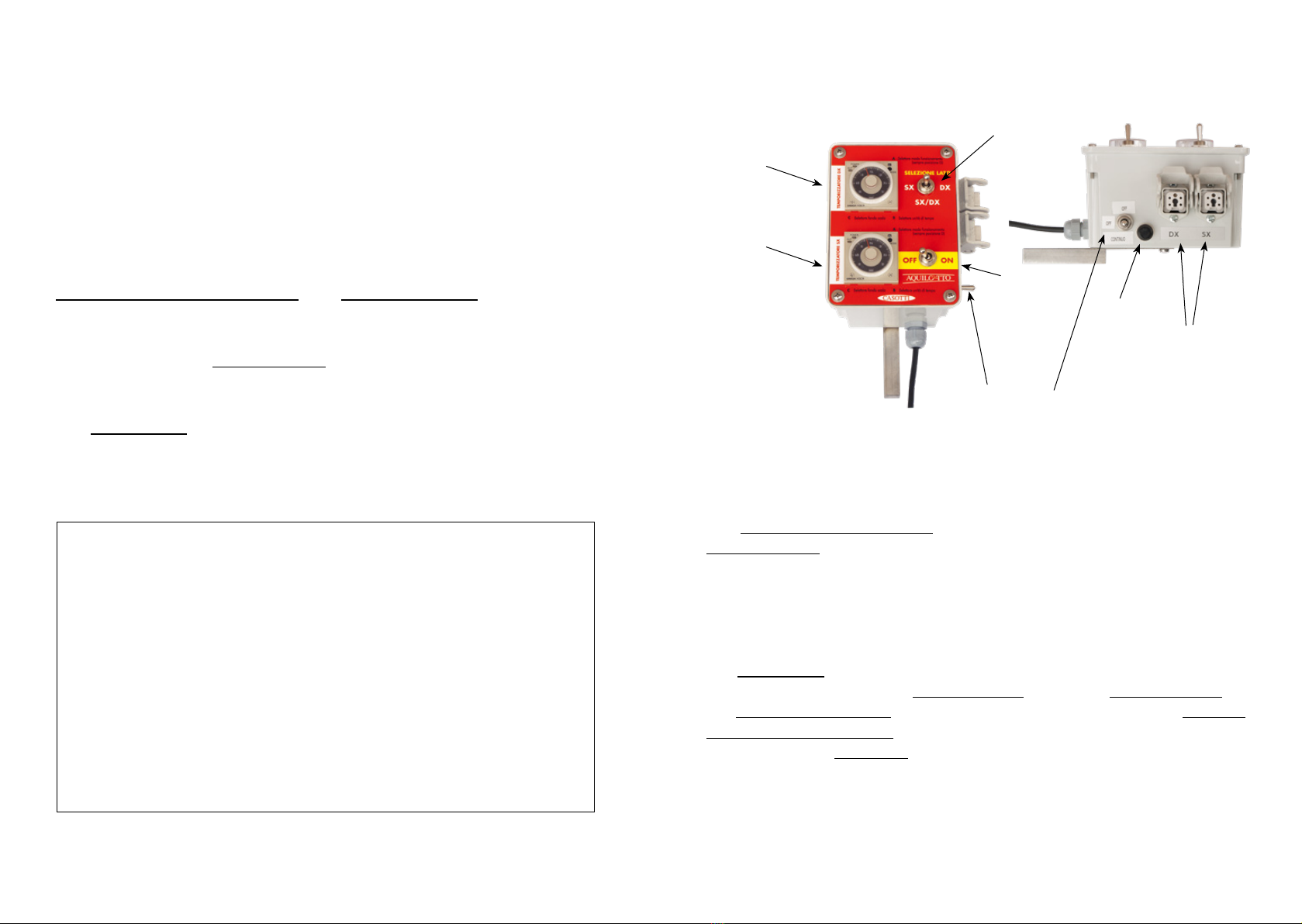

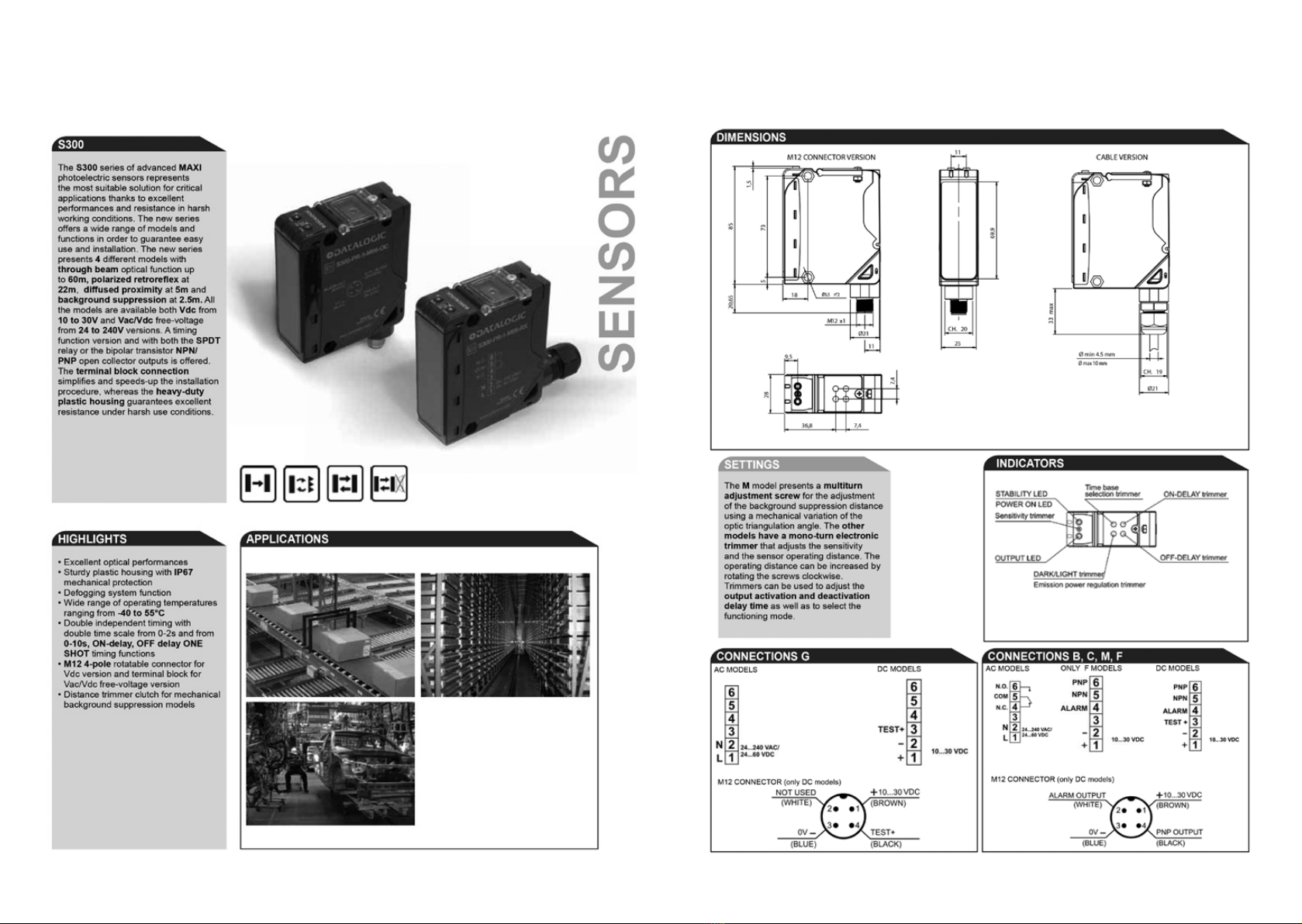

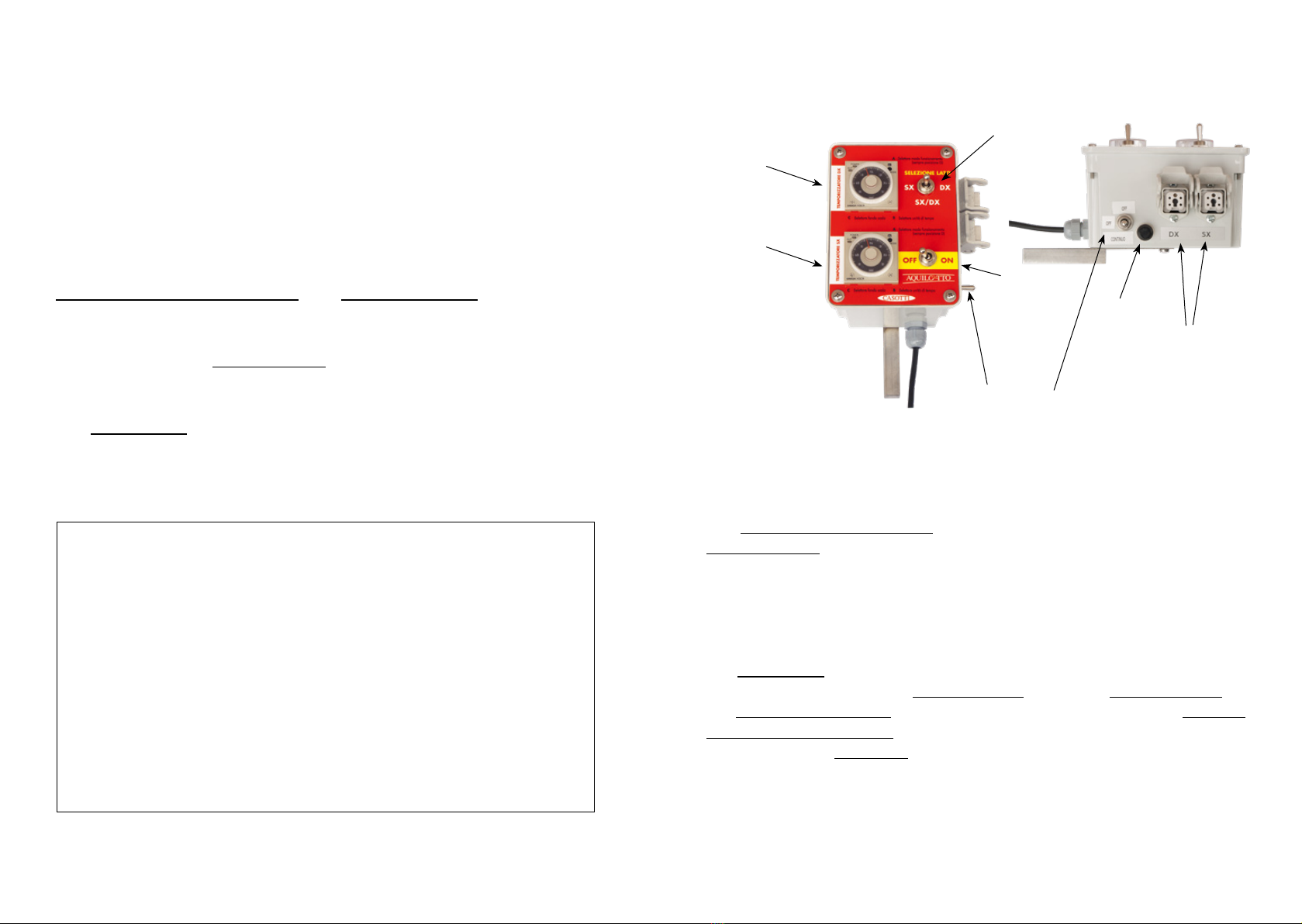

Continuous

operation switch

Working

side selector

Fuse

Main

switch

ON/OFF

5-pole sockets

to connect

the OPTICAL

READERS

Right timer

Left timer

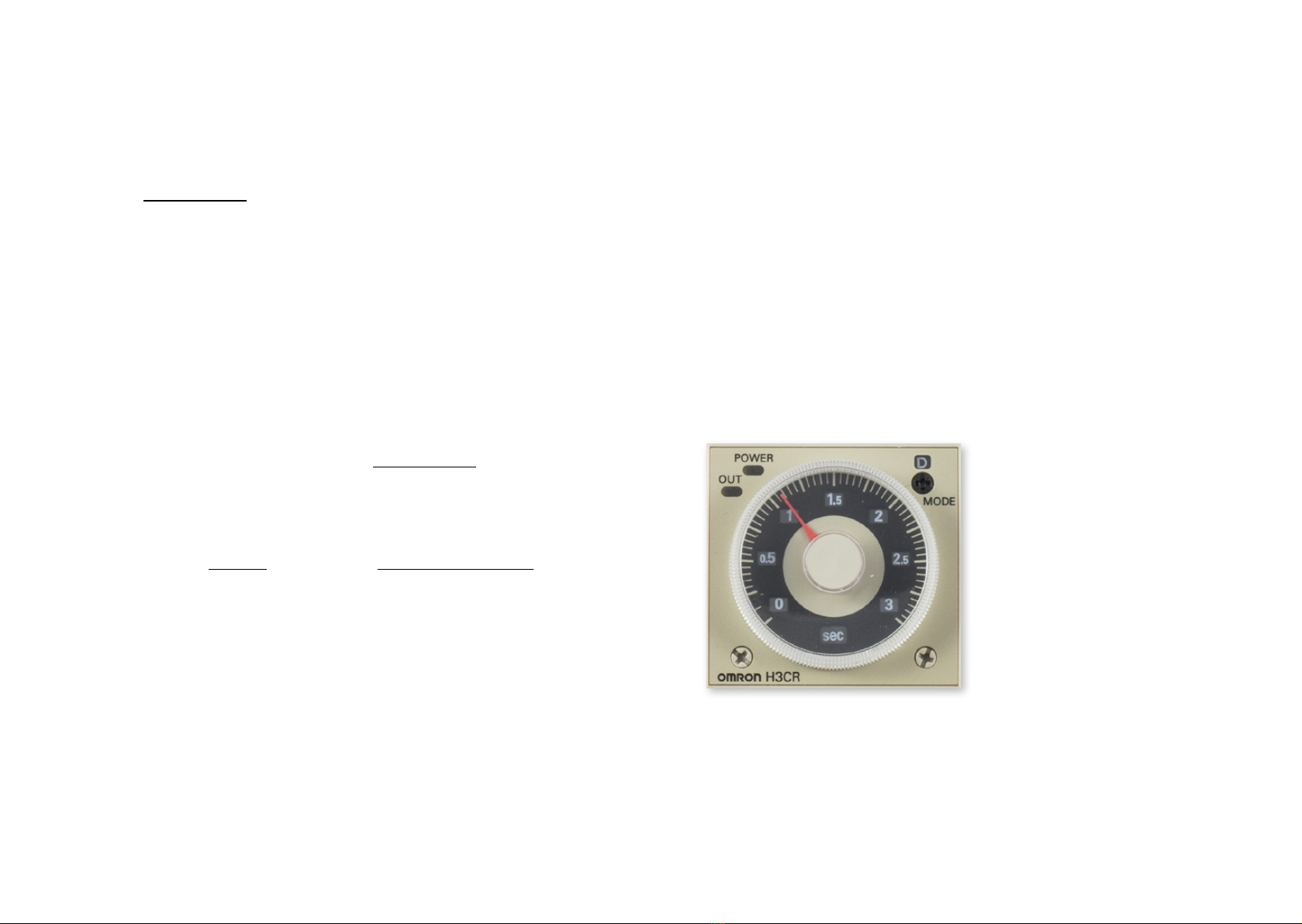

The control unit with 2 timers is used to adjust the closing time of the

solenoid valves (energisation delay), allowing the fluid to be discharged

accurately.

A magnet is installed on the back of the control unit, in order to place it

comfortably in the cab.

AQUILOTTO 2 SIDES is supplied power by connecting the control unit

plug to the 12V power outlet of the tractor.

The main switch turns the entire device on and off; in OFF position, it also

cut off power supply to the optical readers and to the solenoid valves.

The continuous operation switch in ON position is used to keep the solenoid

valve of the selected side always open, effectively bypassing the impulse

coming from the Photocells and discharging the fluid continuously.

CONTROL UNIT WITH 2 TIMERS