1 - WARNINGS AND IMPORTANT ADVICE .............................5

2 TECHNICAL DATA ...............................................................11

2.1 - Identication plate.........................................................11

2.2 - Load limits.....................................................................11

2.2.1 Maximum load of the internal structure .......................11

2.2.2 Tray capacity ...............................................................11

2.3 Refrigerant ......................................................................11

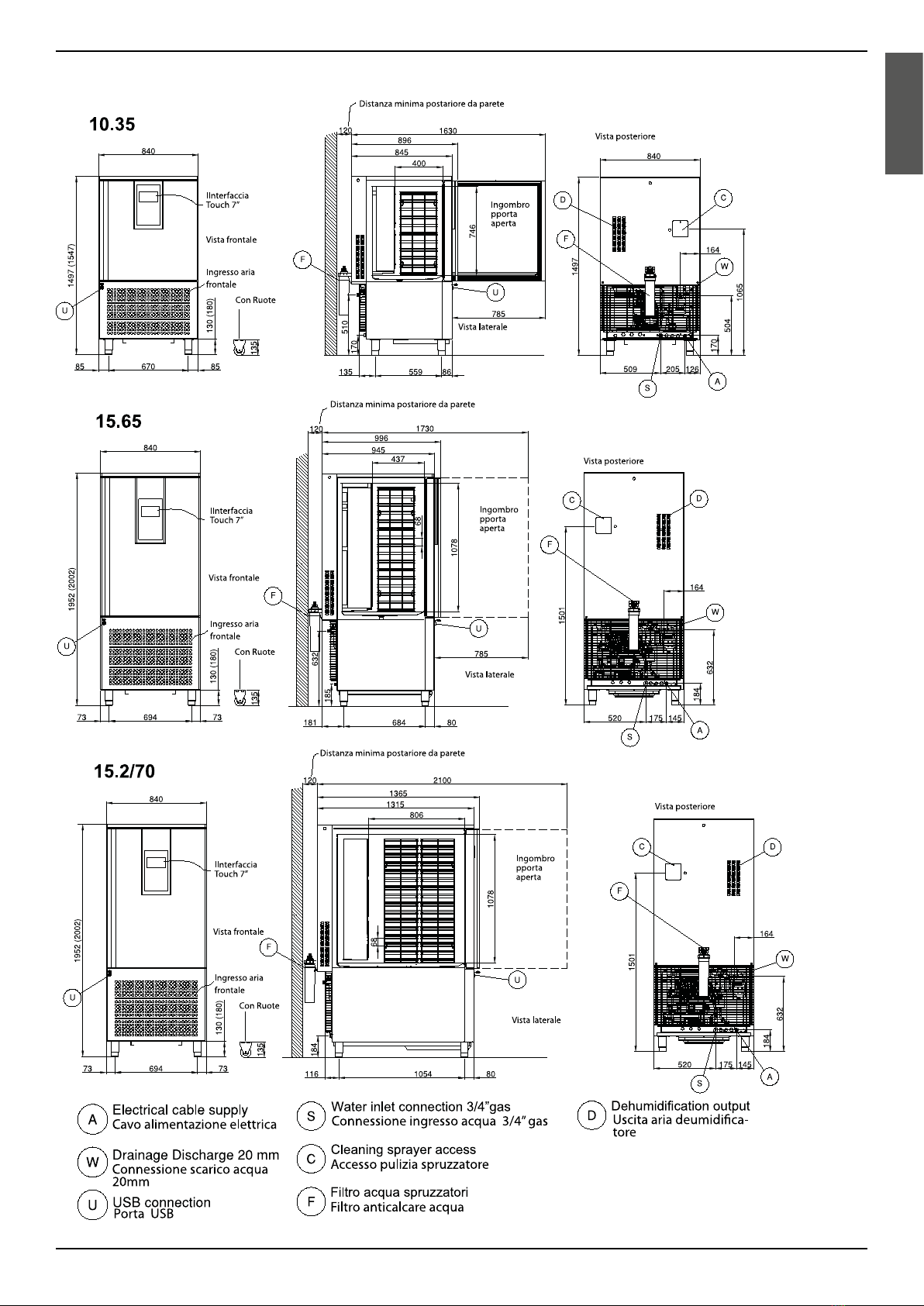

3 INSTALLATION.....................................................................12

3.1 Transportation and handling...........................................12

3.2 Unpacking and disposal.................................................12

3.3 Positioning......................................................................12

3.4 Ambient temperature and air exchange ..........................13

3.5 Hydraulic connection for water cooled condensing units13

3.6 Electrical connection ......................................................13

3.7 Remote group refrigerator connection ...........................13

3.8 Condensate drainage connection (if applicable)............13

3.9 Notes for the installer .....................................................13

.............................................................................................13

3.10 Commissioning.............................................................14

3.11 Safety and control systems ..........................................14

3.12 Stop modes..................................................................14

3.13 Signalling/reports of malfunctioning .............................14

3.14 Waste electrical and electronic equipment - WEE (not

valid for xed installations)....................................................14

4 - ORDINARY MAINTENANCE..............................................14

4.1 Operations by the user (that do not require the assistance

of a qualied technician) .......................................................14

4.1.1 Room cleaning ...........................................................14

4.1.2 Outer casing cleaning ................................................14

4.1.3 Defrost water drainage ...............................................14

4.1.4 Ozone sanitation (optional).....................................15

4.2 Operations that must be performed by an authorised installer

..............................................................................................15

4.2.1 Condenser cleaning ...................................................15

4.2.2 Condenser lter cleaning ...........................................15

4.2.3 Evaporator cleaning ...................................................15

4.2.4 Ozonator maintenance ...............................................15

5 ADVICE FOR PROPER OPERATION ..................................16

5.1 Operating instructions .....................................................16

5.2 Pre-cooling......................................................................16

5.3 Loading of the machine..................................................16

6 MACHINE START-UP AND SHUT DOWN .........................17

6.1 General information........................................................17

6.2 Entry and exit from Stand-by..........................................17

7 INITIAL SETTINGS .............................................................17

7.1 Language .......................................................................17

7.2 Unlocking the display ......................................................18

7.3 Date and time setting ......................................................18

7.4 Setting the 24-48-72 H cycle duration............................19

8 CHILLING / FREEZING CYCLES.........................................20

8.1 Summary of Positive chilling cycles ................................20

8.2 Starting the MANUAL Positive Chilling ..........................21

8.3 Summary of Negative chilling cycles...............................22

8.4 Starting the MANUAL Negative Chilling..........................23

8.5 Saving the Positive / Negative chilling cycle ..................24

8.6 Change the preservation cell set point...........................24

8.7 Needle probe removal....................................................24

9 THAWING CYCLE ...............................................................25

9.1 Manual Thawing..............................................................25

9.2 Programmed Thawing.....................................................26

INDEX

10 RETARDER PROVING CYCLES........................................28

10.1 Manual retarder proving cycle.......................................28

10.2 Programme retarder proving cycle................................29

11 LOW TEMPERATURE COOKING CYCLES .....................31

11.1 Timed Manual Cooking Cycle........................................31

11.2 Manual Temperature cooking cycle...............................32

11.3 Programme Cooking Cycle ...........................................33

12 ICE CREAM CYCLE ...........................................................35

12.1 Ice Cream Manual cycle................................................35

13 PRESERVATION CYCLE....................................................36

13.1 Manual preservation cycle ............................................36

14 PROGRAMME WRITING...................................................37

14.1 Access to programme set-up .......................................37

14.2 Creation of a Chilling Programme.................................38

14.3 Creation of a Thawing programme................................39

14.4 Creation of a retarder proving programme....................40

14.5 Creation of an ice cream programme............................41

14.6 Creation of a cooking programme.................................41

14.7 Creation of a preservation programme .........................43

15 STARTING UP STORED PROGRAMMES.........................44

15.1 Access to stored programmes......................................44

15.2 Starting up from stored programmes ...........................44

16 STARTING THE UTILITY FUNCTIONS..............................45

16.1 Access to UTILITY window ...........................................45

16.2 Display LOCK function..................................................45

16.3 List/Export of alarms .....................................................45

16.4 Starting the manual defrosting ......................................46

16.5 Starting the Drying cycle ...............................................46

16.6 Starting the OZONO cycle (optional) ............................46

16.7 Conguration of the main menu...................................47

17 Alarm statuses .................................................................48

17.1 Alarm warnings.............................................................48

17.2 Warnings for SERIOUS alarms...................................48

17.3 Warnings for AVERAGE alarms ...................................48

17.4 Pre-alarm warnings......................................................48

17.5 Machine information/data.............................................48

17.6 Alarm list.......................................................................49

ENGLISH