OPERATION

PX-1500LPH (11–99) 3

SAFETY PRECAUTIONS

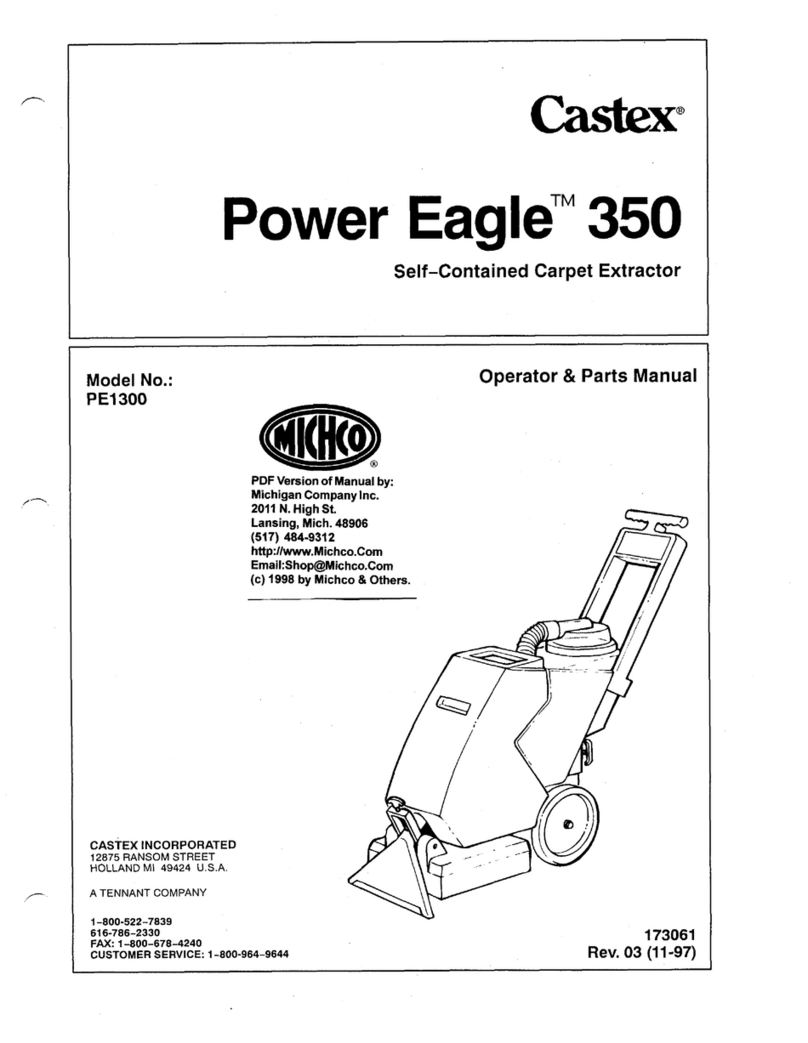

This machine is suited to clean carpet and upholstery

in an indoor environment and is not constructed for

any other use. Use only recommended accessory

tools and cleaning solutions.

All operators must read, understand and exercise the

following Important Safety Instructions.

The following safety alert symbols are used throughout

this manual as indicated in their description.

WARNING: To warn of hazards or unsafe

practices which could result in severe personal

injury or death.

FOR SAFETY: To identify actions which must be

followed for safe operation of equipment.

The following information signals potentially dangerous

conditions to the operator or equipment:

FOR SAFETY:

1. Do not operate machine:

– Unless trained and authorized.

– Unless operator manual is read and

understood.

– In flammable or explosive areas unless

designed for use in those areas.

– With the use of additional extension cords.

Only use manufacturer’s extension cord

equipped with machine which has proper

capacity and is grounded.

– With damaged cord or plug.

– If not in proper operating condition.

– In outdoor areas.

– In standing water.

2. Before operating machine:

– Make sure all safety devices are in place

and operate properly.

3. When using machine:

– Do not run machine over cord.

– Do not pull machine by plug or cord.

– Do not pull cord around sharp edges or

corners.

– Do not unplug by pulling on cord.

– Do not stretch cord.

– Do not handle plug with wet hands.

– Keep cord away from heated surfaces.

– Report machine damage or faulty

operation immediately.

– Follow mixing and handling instructions

on chemical containers.

4. Before leaving or servicing machine:

– Turn off machine.

– Unplug cord from wall outlet.

5. When servicing machine:

– Unplug cord from wall outlet.

– Avoid moving parts. Do not wear loose

jackets, shirts, or sleeves.

– Use manufacturer supplied or approved

replacement parts.

WARNING: Hazardous Voltage. Shock or

electrocution can result. Always unplug machine

before servicing.

WARNING: Flammable materials can cause

an explosion or fire. Do not use flammable

materials in tank(s).

WARNING: Flammable materials or reactive

metals can cause an explosion or fire. Do not pick

up.

GROUNDING INSTRUCTIONS

Machine must be grounded. If it should

malfunction or breakdown, grounding provides a

path of least resistance for electrical current to

reduce the risk of electrical shock. This machine

is equipped with a cord having an

equipment–grounding conductor and grounding

plug. The plug must be plugged into an

appropriate outlet that is properly installed in

accordance with all local codes and ordinances.

Do not remove ground pin; if missing, replace

plug before use.

GROUNDED OUTLET

(3 HOLE)

GROUNDING PIN