OPERATION

7.

Plug

machine's

powercordinto

a

groundedwall

outlet

(Figure

4).

Grounded

3

HoleOutletGroundedOutlet

Ground

Pin

Grounding

Edge/hole

V

(120V)

(230V/240V)

FIG.

4

FOR

SAFETY:

Donot

operatemachine

unless

cord

is

properlygrounded.

FOR

SAFETY:

Donot

operatemachinewith

the

useofan

extensioncord.

FIG.

6

3.

Releasetriggers

atendof

path

and

continue

to

pullmachine

to

pick

up

excess

solution.

4.

Tip

machineback

on

wheels

and

pushmachine

forward

to

beginnextpath.

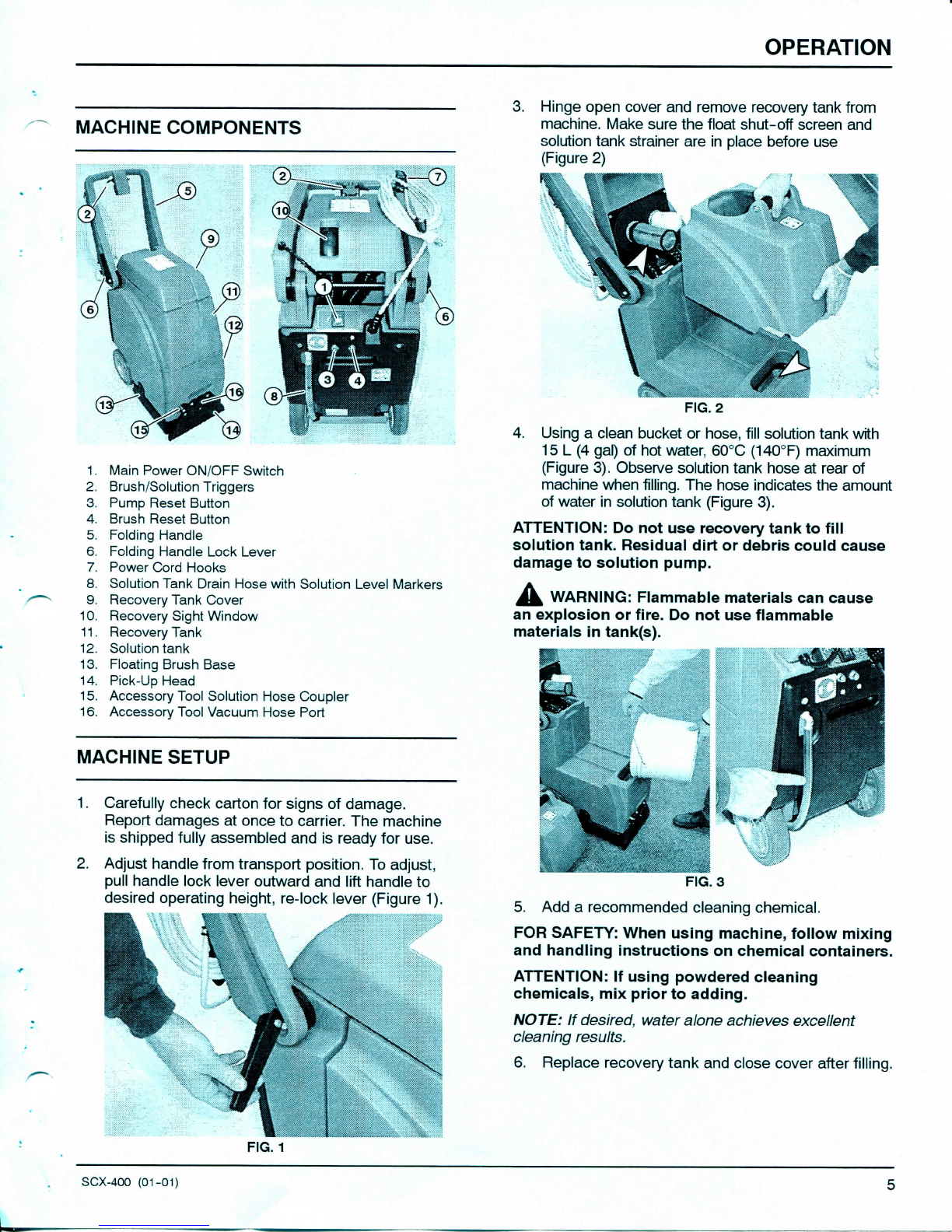

MACHINEOPERATION

FOR

SAFETY:

Donot

operatemachineunless

operator

manual

is

read

and

understood.

PRE-OPERATION

1.

Vacuumcarpet

and

removeotherdebris.

2.

PerformMACHINESETUPprocedures.

3.

Inspectpowercord

for

damage.

CLEANING

CARPETS

1.

Turnmainpowerswitch

on

(Figure

5).

2.

FIG.

5

To

begincleaningcarpets,pulltriggers

and

slowly

pullmachinebackwards(Figure

6).

WHILE

OPERATING

1.

Overlapeachpath

by50mm(2

in).

mm.

WARNING:Flammablematerials

or

reactive

metals

can

cause

an

explosion

or

fire.

Donot

pick

up.

2.

Workawayfromwalloutlet

and

powercord

to

preventcorddamage.

3.

Periodicallycheck

for

excessivefoambuildup

in

recovery

tank.

Usea

recommendedfoamcontrol

solution

to

preventvacuummotordamage.

ATTENTION:Excessive foambuildupwill

not

activate

the

floatshut-offscreen.

4.

If

brushstops,

the

circuit

breaker

may

havebeen

tripped.Unplugpowercord,checkbrush

for

obstruction.Pushbrushresetbutton

to

resume

(Figure?).

5.

6.

FIG.

7

To

cleanheavilysoiledareas,repeatcleaningpath

fromdifferentdirection.

Observerecoverysitewindow,whenrecovery

appears

to

stop,drainrecoverytank

(See

DRAININGTANKS).

SCX-400

(01-01)