OPERATION

2SCX-2800 (08–03)

This manual is furnished with each new model. It

provides necessary operation and maintenance

instructions and an illustrated parts list.

Read this manual completely and understand the

machine before operating or servicing it.

When ordering replacement parts, use the Parts Lists

in this manual. Before ordering parts or supplies, be

sure to have your machine model number and serial

number handy. Parts and supplies may be ordered by

phone or mail from any authorized Service Center or

Distributor.

This machine will provide excellent service. However,

the best results will be obtained at minimum costs if:

SThe machine is operated with reasonable care.

SThe machine is maintained regularly - per the

machine maintenance instructions provided.

SThe machine is maintained with manufacturer

supplied or equivalent parts.

MACHINE DATA

Pleasefill out at time of installation for future reference.

Model No.-

Install. Date -

Serial No.-

E1999, 2003 Tennant Company

Castex is a registered United States trademark of Tennant Company.

Specifications and parts are subject to change without notice.

TABLE OF CONTENTS

SAFETY PRECAUTIONS 3. . . . . . . . . . . . . . . . . . . .

GROUNDING INSTRUCTIONS 4. . . . . . . . . . .

WARNING LABEL 4. . . . . . . . . . . . . . . . . . . . . . . . . .

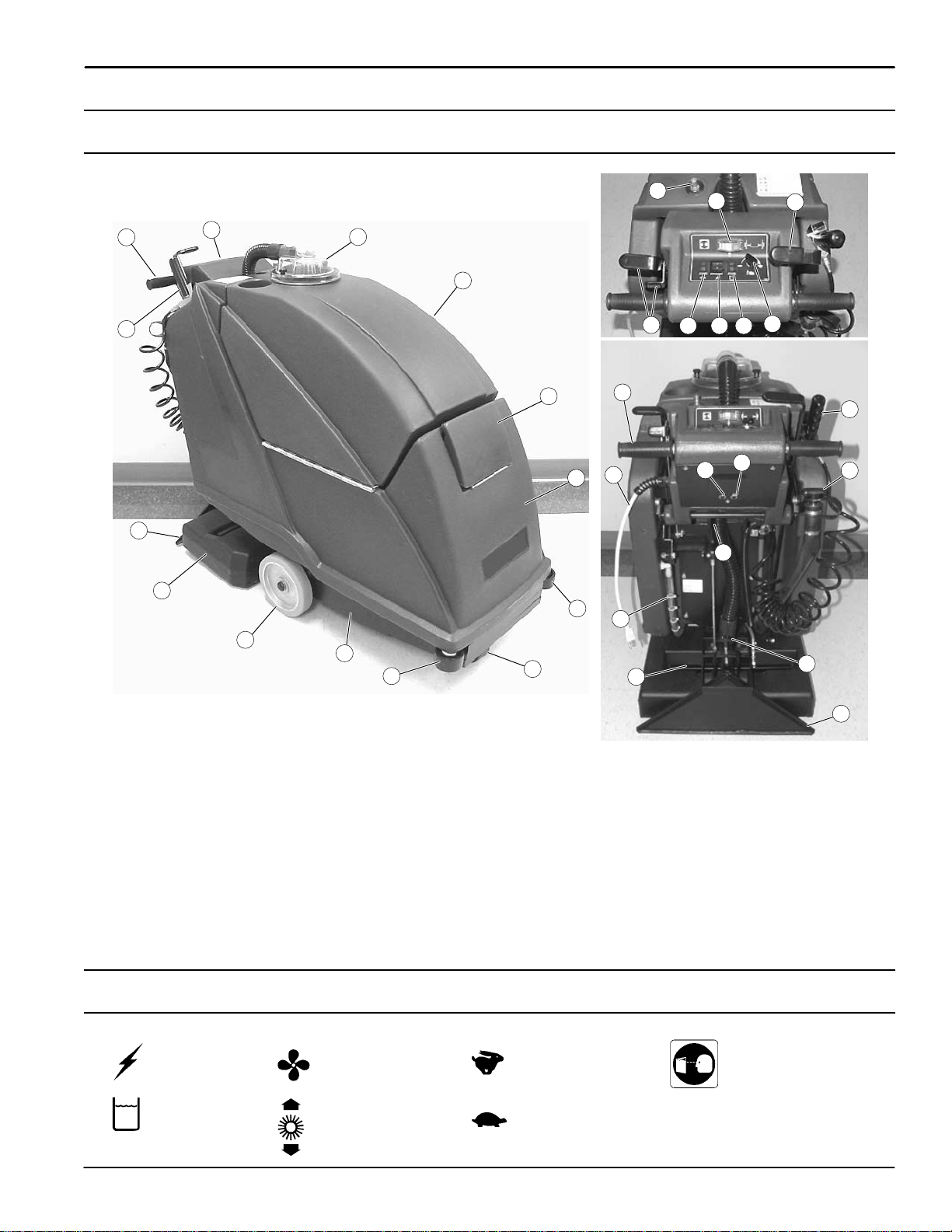

MACHINE COMPONENTS 5. . . . . . . . . . . . . . . . . . .

CONTROL PANEL SYMBOLS 5. . . . . . . . . . . . . . .

SETUP AND OPERATION 6. . . . . . . . . . . . . . . . . . .

MACHINE INSTALLATION 6. . . . . . . . . . . . . . . .

MANEUVERING MACHINE WITHOUT

USE OF POWER 6. . . . . . . . . . . . . . . . . . . . . . . .

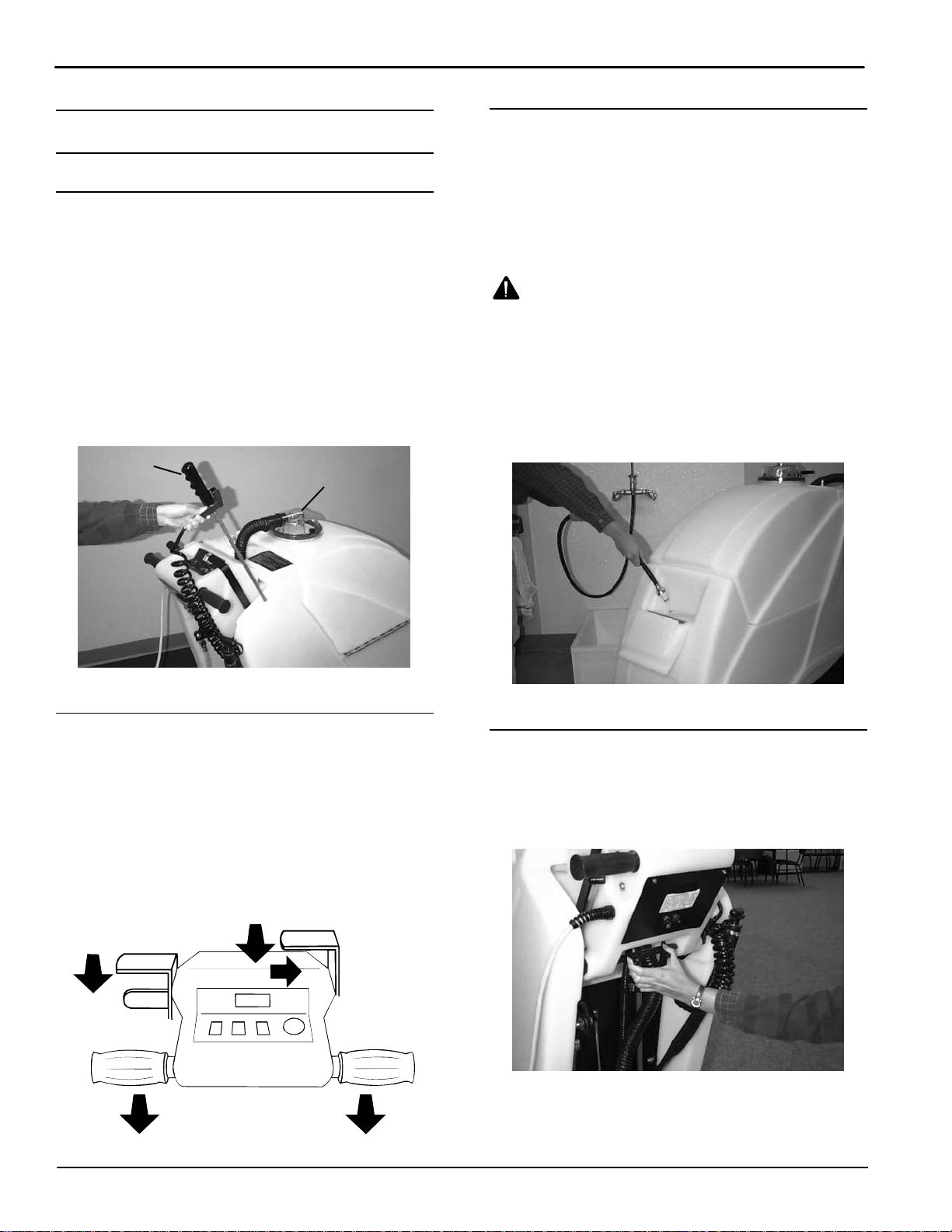

FILLING SOLUTION TANK 6. . . . . . . . . . . . . . .

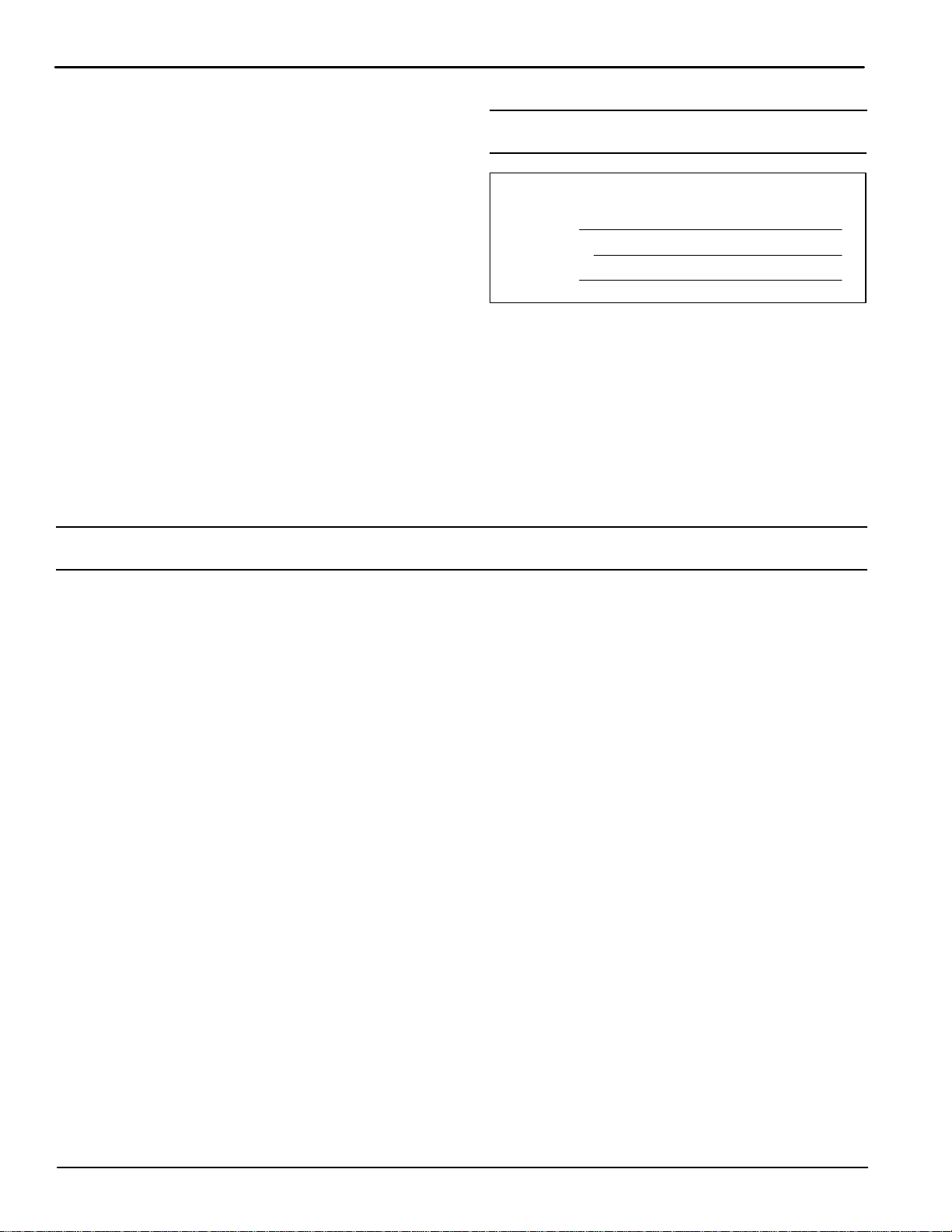

ADJUSTING CONTROL GRIP HEIGHT 6. . . .

CONNECTING MACHINE TO

POWER SOURCE 7. . . . . . . . . . . . . . . . . . . . . . .

PRE–OPERATION CHECKS 7. . . . . . . . . . . . . .

CLEANING CARPET 7. . . . . . . . . . . . . . . . . . . . .

OPERATING PRE–SPRAY WAND 8. . . . . . . . .

ADJUSTING BRUSH HEIGHT 9. . . . . . . . . . . .

CIRCUIT BREAKERS 9. . . . . . . . . . . . . . . . . . . .

ACCESSORY TOOL SETUP AND

OPERATION (OPTION) 9. . . . . . . . . . . . . . . . . . . . . .

DRAINING TANKS 10. . . . . . . . . . . . . . . . . . . . . . . . . .

MACHINE MAINTENANCE 10. . . . . . . . . . . . . . . . . .

DAILY MAINTENANCE 10. . . . . . . . . . . . . . . . . . .

WEEKLY MAINTENANCE 11. . . . . . . . . . . . . . . .

MONTHLY MAINTENANCE 11. . . . . . . . . . . . . . .

QUARTERLY MAINTENANCE 12. . . . . . . . . . . .

ADJUSTING DRIVE BELT 12. . . . . . . . . . . . . . . .

TRANSPORTING MACHINE 12. . . . . . . . . . . . . . . . .

STORING MACHINE 13. . . . . . . . . . . . . . . . . . . . . . . .

RECOMMENDED STOCK ITEMS 13. . . . . . . . . . . . .

TROUBLE SHOOTING 13. . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS 15. . . . . . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL DIAGRAMS 16. . . . . . . . . . . . . . . . . . .

PARTS LIST 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RECOVERY TANK GROUP 18. . . . . . . . . . . . . . .

SOLUTION TANK GROUP 20. . . . . . . . . . . . . . . .

DRIVE WHEEL GROUP 22. . . . . . . . . . . . . . . . . .

REAR PANEL GROUP 24. . . . . . . . . . . . . . . . . . .

CONTROL CONSOLE GROUP 26. . . . . . . . . . .

PICK-UP HEAD GROUP 28. . . . . . . . . . . . . . . . .

BRUSH BASE GROUP 30. . . . . . . . . . . . . . . . . . .

PLUMBING GROUP 32. . . . . . . . . . . . . . . . . . . . .

PUMP BREAKDOWN 34. . . . . . . . . . . . . . . . . . . .

OPTIONS 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SOLUTION AND VACUUM HOSES 35. . . . . . . .

330mm (13 in) LOW PRESSURE

FLOOR TOOL 36. . . . . . . . . . . . . . . . . . . . . . . . . . .

406mm (16 in) LOW PRESSURE

FLOOR TOOL 38. . . . . . . . . . . . . . . . . . . . . . . . . . .

127 mm (5 in) HAND TOOL 40. . . . . . . . . . . . . . .

76 mm (3 in) CREVICE TOOL 40. . . . . . . . . . . . .

LOW PRESSURE UPHOLSTERY TOOL 41. . .