OPERATION

FS-2000 Electric Scrubber (06--04) 3

SAFETY PRECAUTIONS

This machine is intended for commercial use. It is

designed exclusively to scrub hard floors in an

indoor environment and is not constructed for any

other use. Use only recommended pads, brushes

and commercially available floor cleaners

intended for machine application.

All operators must read, understand and practice

the following safety precautions.

The following warning alert symbol and the “FOR

SAFETY” heading are used throughout this manual as

indicated in their description:

WARNING: To warn of hazards or unsafe

practices which could result in severe personal

injury or death.

FOR SAFETY: To identify actions which must be

followed for safe operation of equipment.

Failure to follow these warnings may result in:

personal injury, electrocution, electrical shock,

fire or explosion.

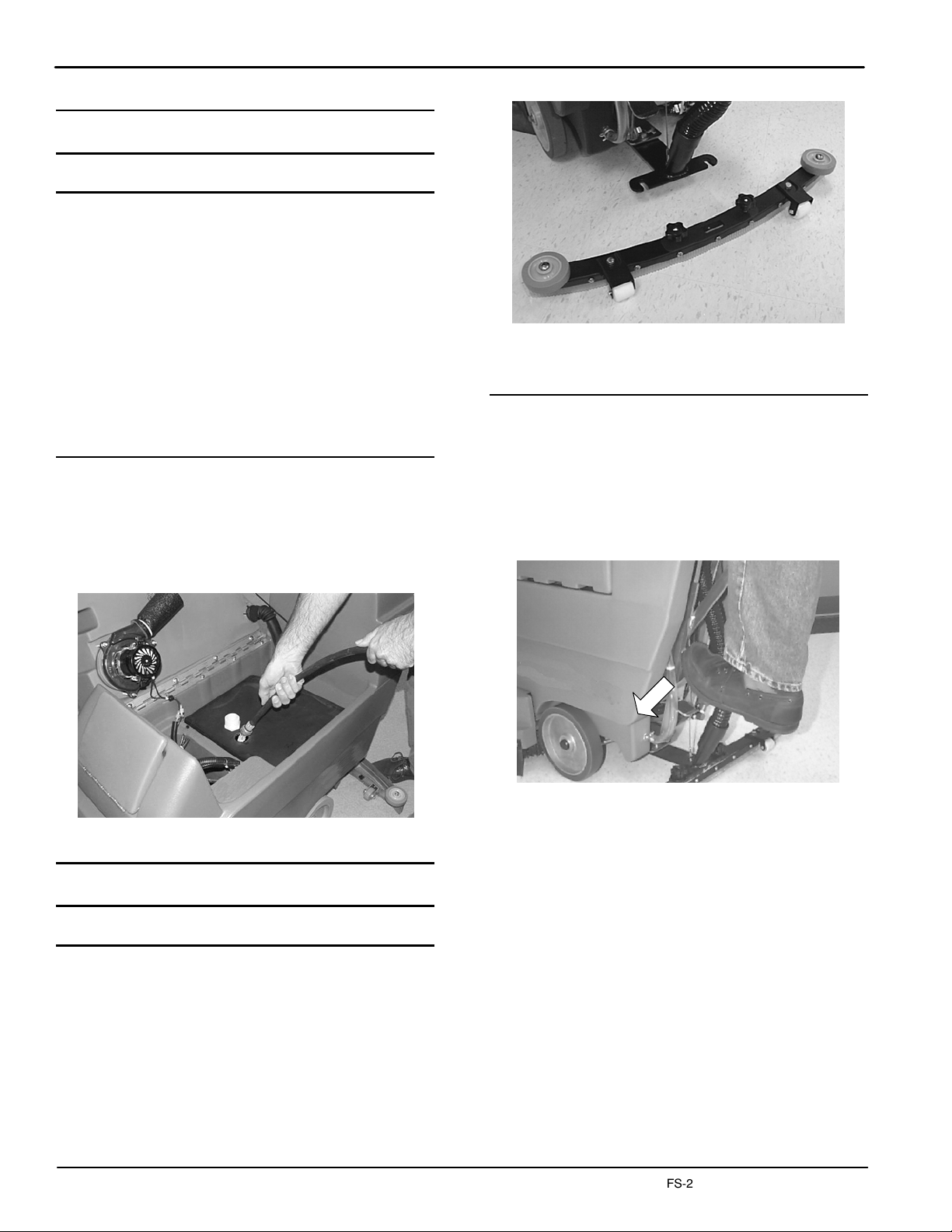

WARNING: Do Not Use Flammable Liquids Or

Operate Machine In Or Near Flammable Liquids,

Vapors Or Combustible Dusts.

This machine is not equipped with explosion

proof motors. The electric motors will spark upon

start up and during operation which could cause a

flash fire or explosion if machine is used in an

area where flammable vapors/liquids or

combustible dusts are present.

WARNING: Do Not Pick Up Flammable

Materials Or Reactive Metals.

WARNING: Do Not Operate With Damaged

Power Cord. Do Not Modify Plug. Unplug power

Cord Before Servicing Machine.

If the supply cord is damaged or broken, it must

be replaced by the manufacturer or it’s service

agent or a similarly qualified person in order to

avoid a hazard.

WARNING: Do Not Use Outdoors. Do Not

Expose To Rain. Store Indoors.

The following information signals potentially

dangerous conditions to the operator or

equipment:

FOR SAFETY:

1. Do not operate machine:

-- With flammable liquids or near flammable

vapors as an explosion or flash fire may

occur.

-- Unless trained and authorized.

-- Unless operator manual is read and

understood.

-- Unless cord is properly grounded.

-- With damaged cord or plug.

-- If not in proper operating condition.

-- In outdoor areas.

-- In standing water.

-- With the use of additional extension cords.

Only use manufacturer’s extension cord

equipped with machine which has proper

capacity and is grounded.

2. Before operating machine:

-- Make sure all safety devices are in place

and operate properly.

3. When using machine:

-- Do not run machine over cord.

-- Do not pull machine by plug or cord.

-- Do not pull cord around sharp edges or

corners.

-- Do not unplug by pulling on cord.

-- Do not stretch cord.

-- Do not handle plug with wet hands.

-- Keep cord away from heated surfaces.

-- Go slow on inclines and slippery surfaces.

-- Wear non--slip shoes.

-- Use care when reversing machine.

-- Report machine damage or faulty

operation immediately.

-- Never allow children to play on or around.

-- Follow mixing and handling instructions

on chemical containers.

4. Before leaving or servicing machine:

-- Stop on level surface.

-- Turn off machine.

-- Unplug cord from wall outlet.