TSM-35 Screw Pocket Machine Troubleshooting

35.15 Motor starts, but cycle does not initiate:

•Confirm machine is receiving air.

!*** ALWAYS DISCONNECT POWER AND AIR WHEN CHECKING SWITCHES ***!

•Check the stock sense switch (E10850) and safety blade (C35101)

oCheck switch for continuity: (Also See 35.16)

Remove one wire from the switch

Check for continuity at the switch by placing probes on the screws

and moving the stock sense lever out of the way, then back

oCheck safety blade to make sure it swings and moves out of the way of the

magnet when safety buttons are depressed

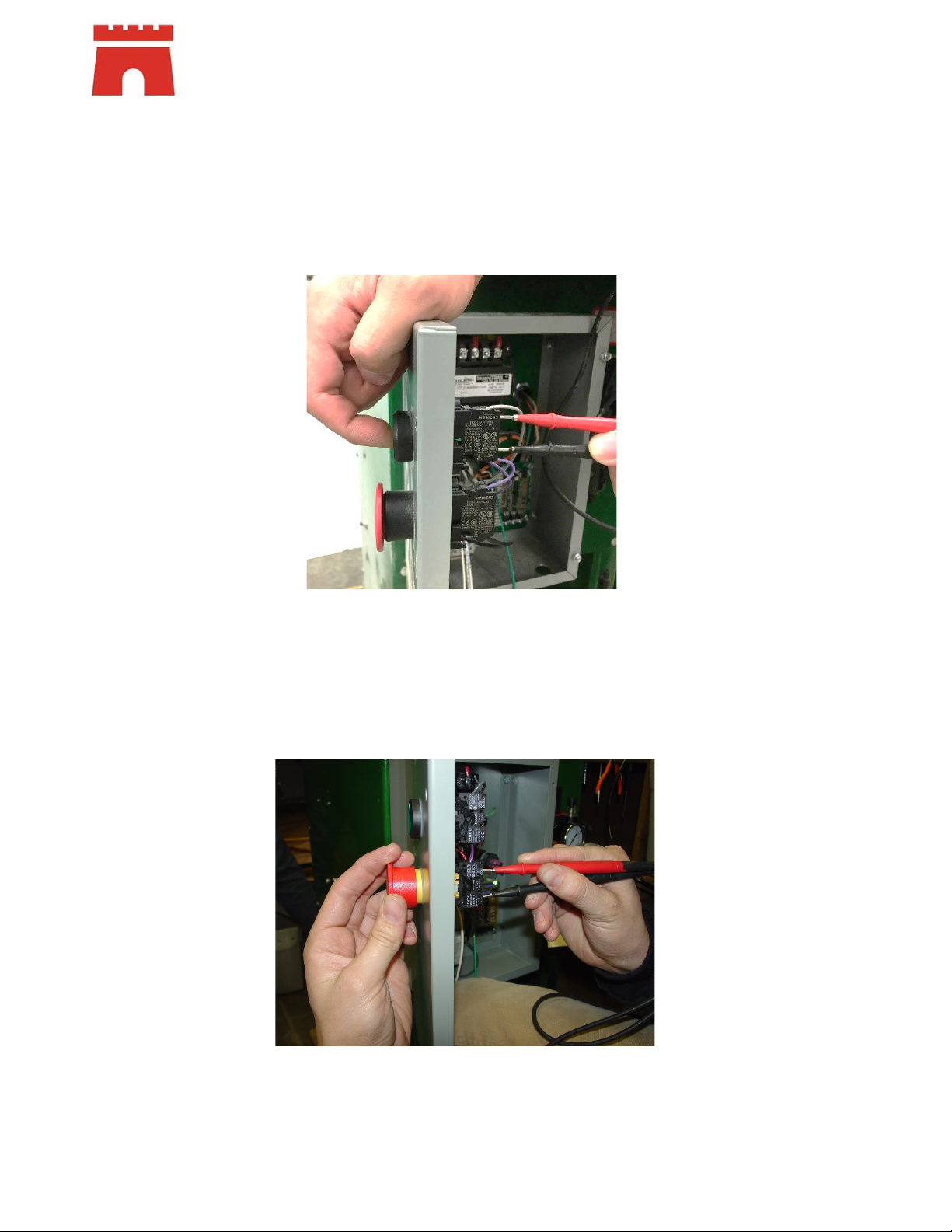

•Check the foot pedal switch (E07041 Switch only / E00491 Foot Pedal with Cord)

(Also See 35.17)

oCheck for continuity change when depressed – can check at the switch or

at terminals 3 & 4 on the terminal strip

oJust switch can be changed. Buy from Castle or Grainger part 6X283

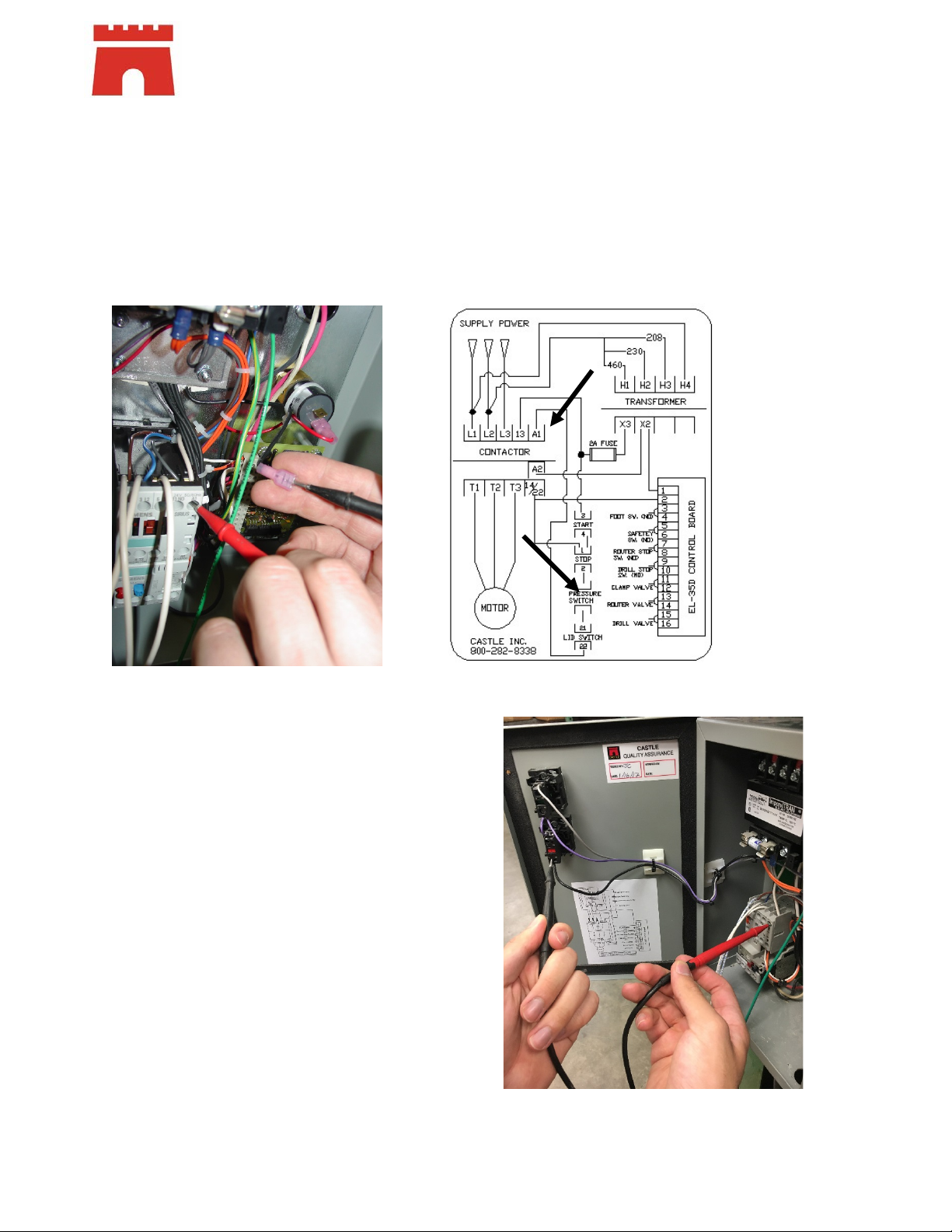

•Check to make sure there is power (24V AC) going into the board at terminals 1 & 2

o*** CAUTION: ONLY A QUALIFIED ELECTRICIAN SHOULD PERFORM THE

FOLLOWING STEPS. POWER MUST BE SUPPLIED TO THE MACHINE TO CHECK THE

TRANSFORMER AND CONTROL BOARD. THIS PRODUCES A SHOCKING HAZZARD. DO NOT

TOUCH THE CONTROL BOX COMPONENTS WITH ANYTHING OTHER THAN ELECTIRCAL

TESTING PROBES. ***

oCheck the transformer if no power (E35713)

oThere should be 230V 3ph or 480V 3ph going into the transformer (Check H1 (480V) or H2

(230V) AND H4 at top of transformer)

If no power into the transformer, check main power to the machine

oThere should be 24V AC coming out of the transformer and entering the board at terminals

1 and 2

oCheck to make sure the fuse is intact (E16224)

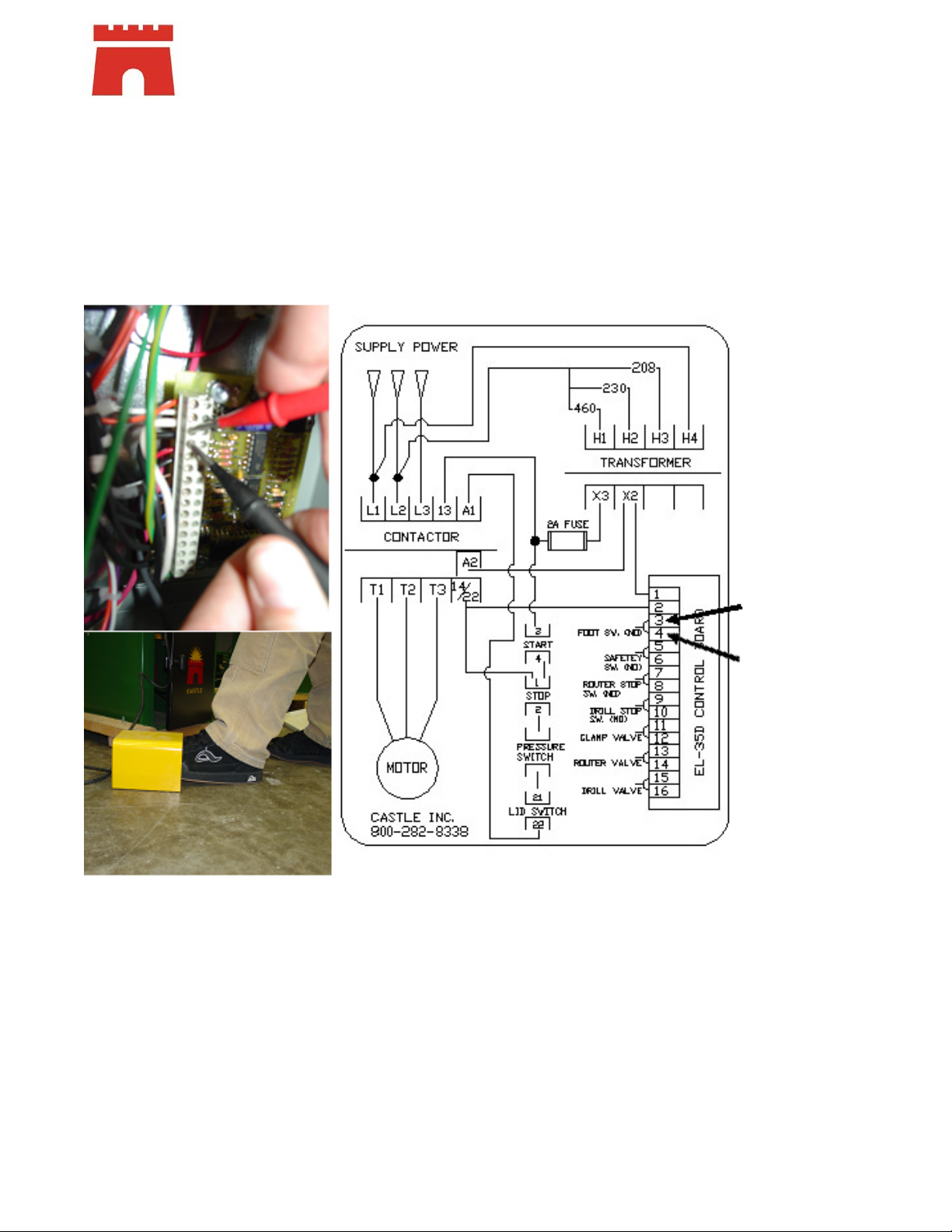

•Check to make sure that when a cycle is initiated, that there is 24V DC coming from the board to the

clamp solenoid at terminals 11 & 12

o*** CAUTION: ONLY A QUALIFIED ELECTRICIAN SHOULD PERFORM THE

FOLLOWING STEPS. POWER MUST BE SUPPLIED TO THE MACHINE TO CHECK THE

CONTROL BOARD. THIS PRODUCES A SHOCKING HAZZARD. DO NOT TOUCH THE CONTROL

BOX COMPONENTS WITH ANYTHING OTHER THAN ELECTIRCAL TESTING PROBES. ***

oRun a cycle on the machine (put the stock in place, depress the safety buttons, and press the

foot pedal), then check the pins at terminals 11 & 12, then the screws at 11 & 12

If there is no power at the pins, change the board (E35424)

If there is power at the pins, but not at the screws, change the terminal strip

(E21016)