Cateye Ergociser EC-5000 Service Manual

2

EC-5000

INDEX

INTRODUCTION

• How to Use This Service Manual --------------------------------------------------------------------------------------- 3

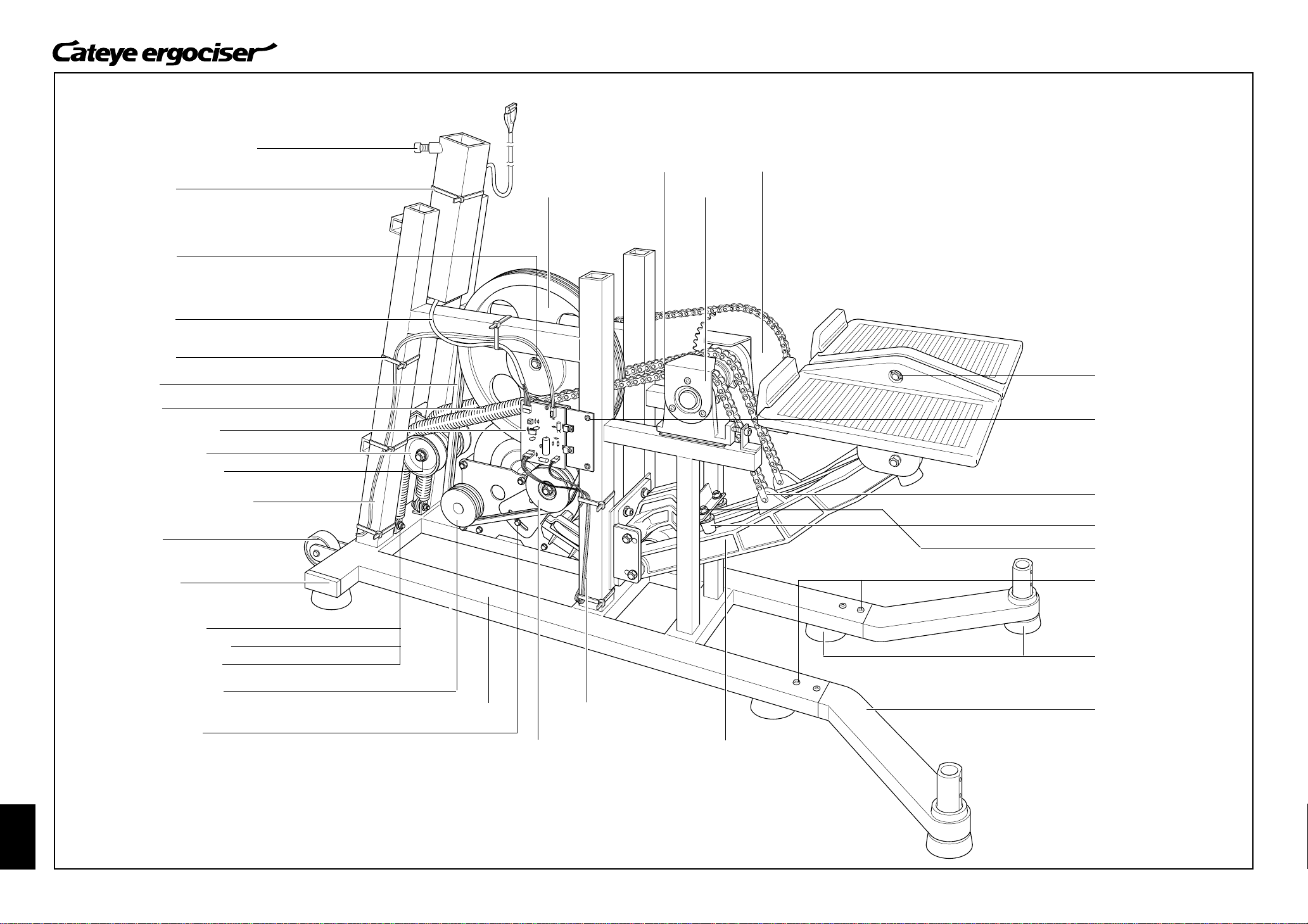

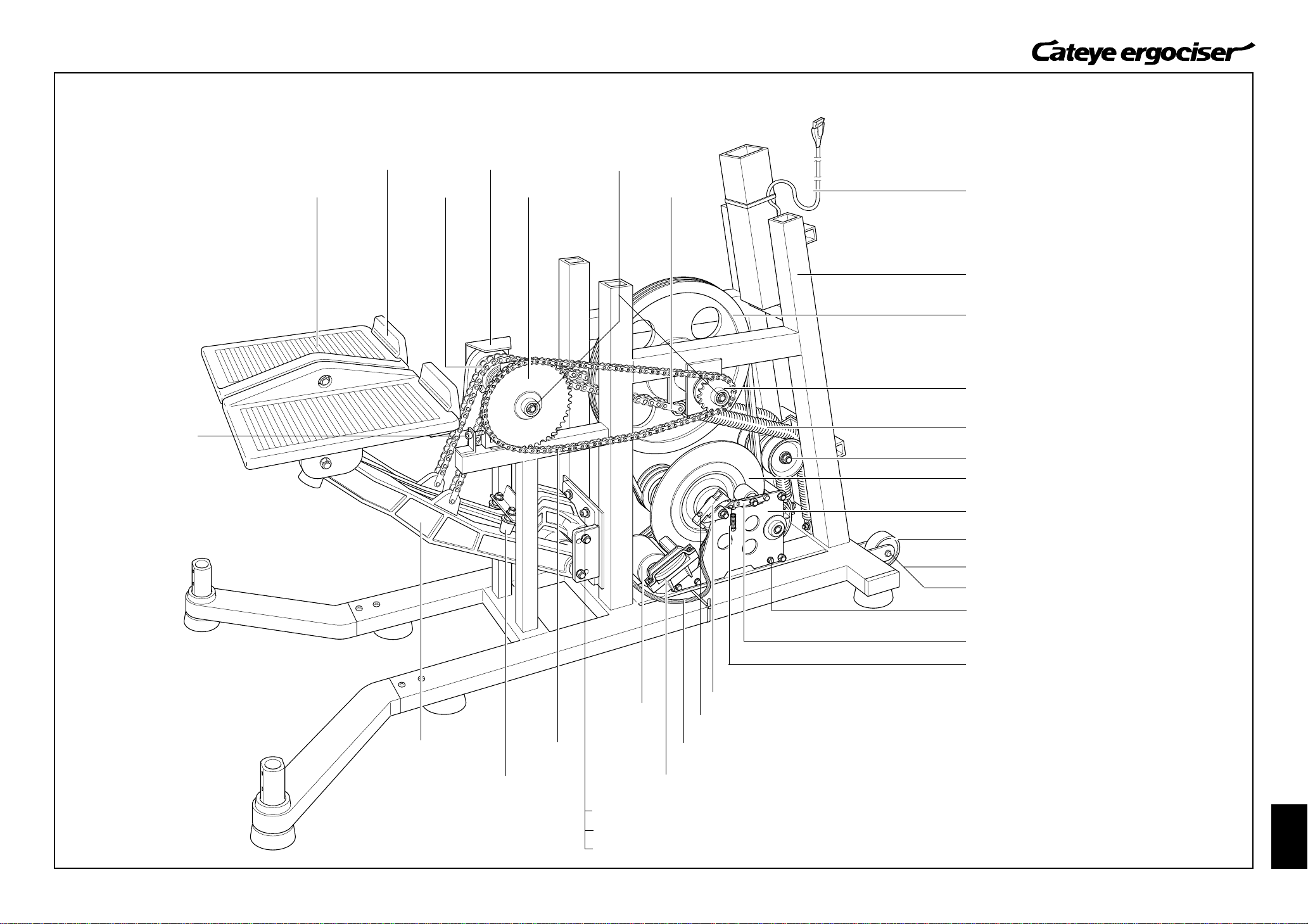

• Name of Parts ------------------------------------------------------------------------------------------------------------- 4~5

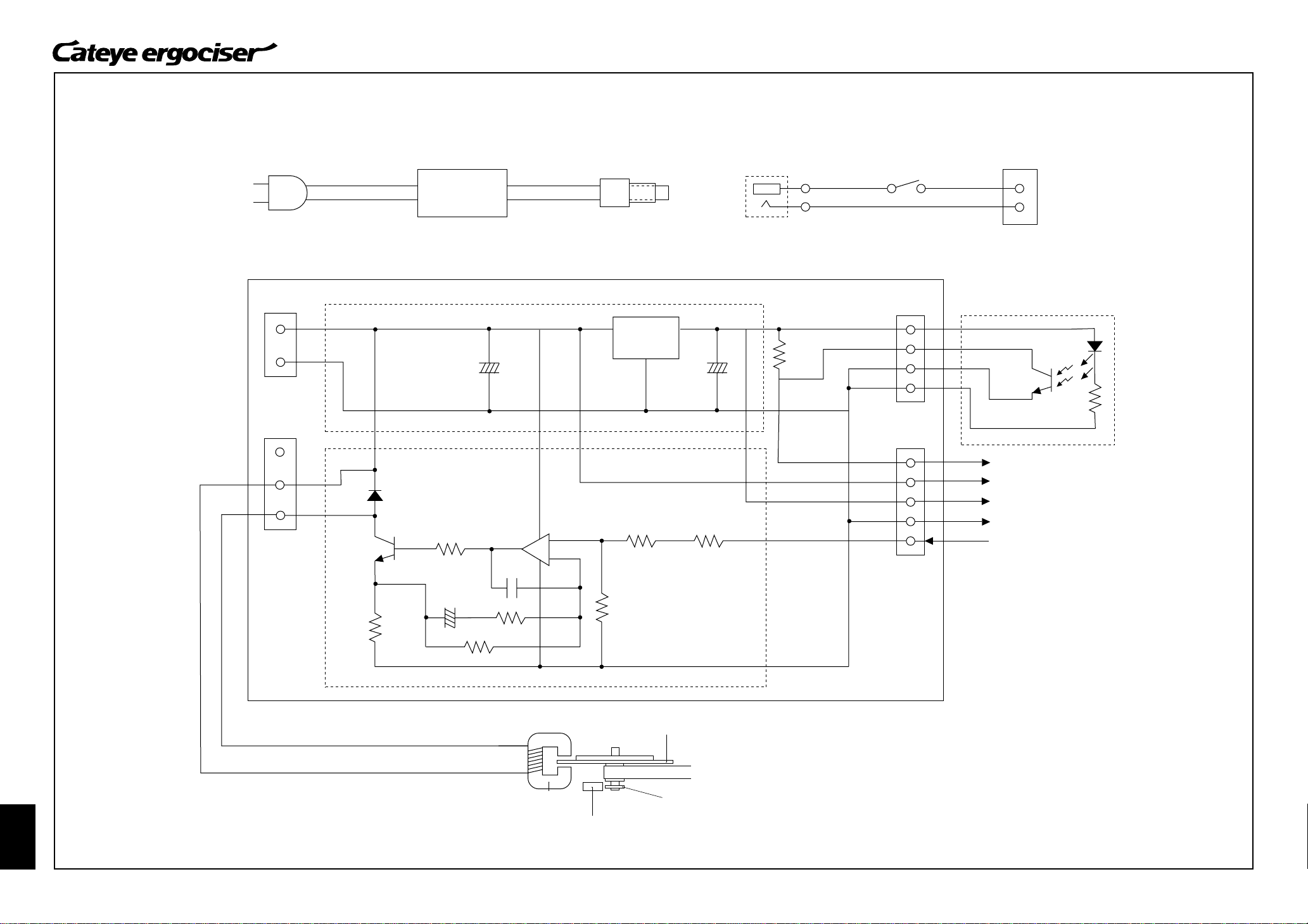

• Circuit Diagram -------------------------------------------------------------------------------------------------------------- 6

Part A

Symptoms of Problems & Causes

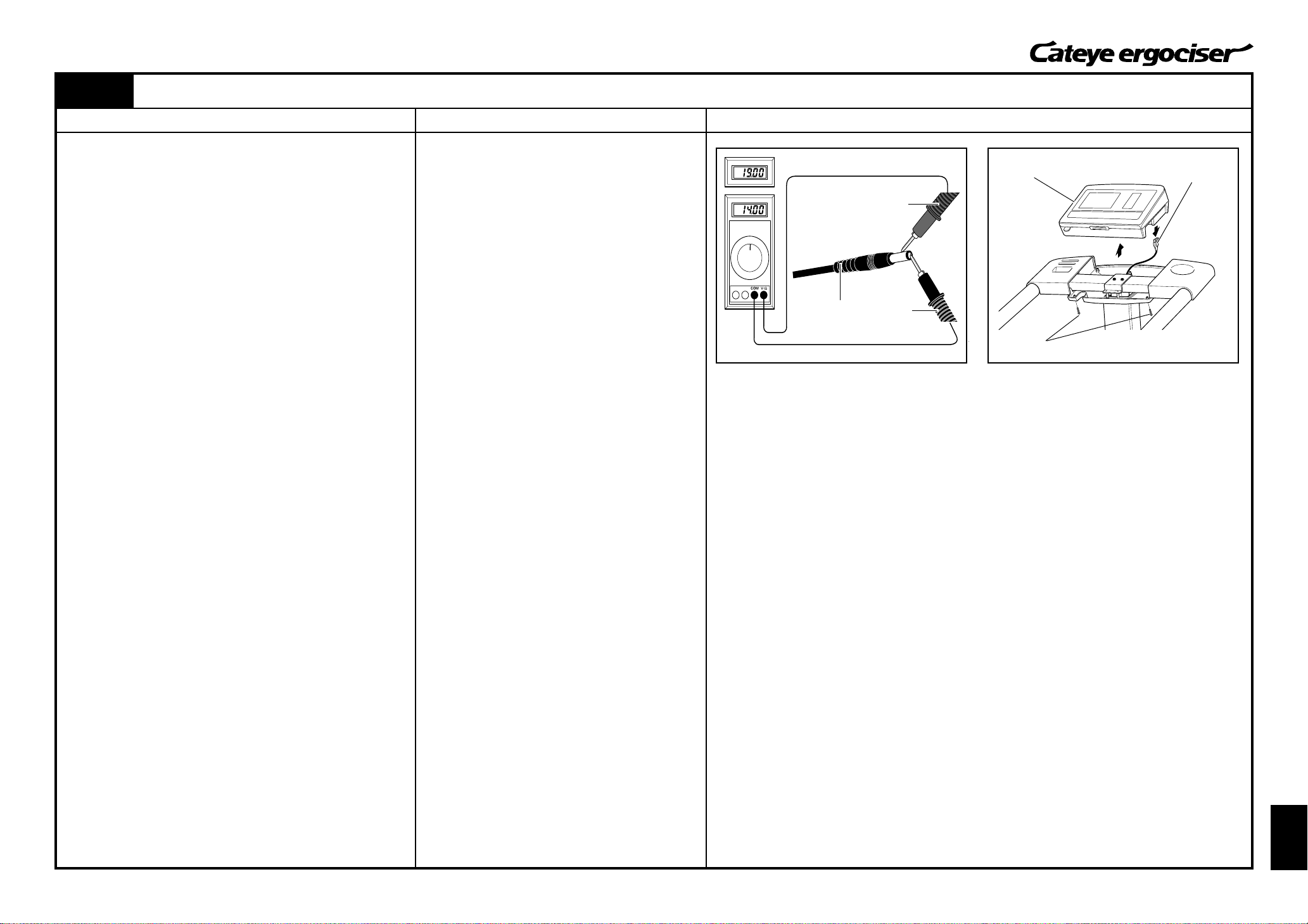

T-1: No Display on Control Unit after Power ON

1. Back light does not turn on--------------------------------------------------------------------------------- 7~8

2. Back light turns on----------------------------------------------------------------------------------------------- 9

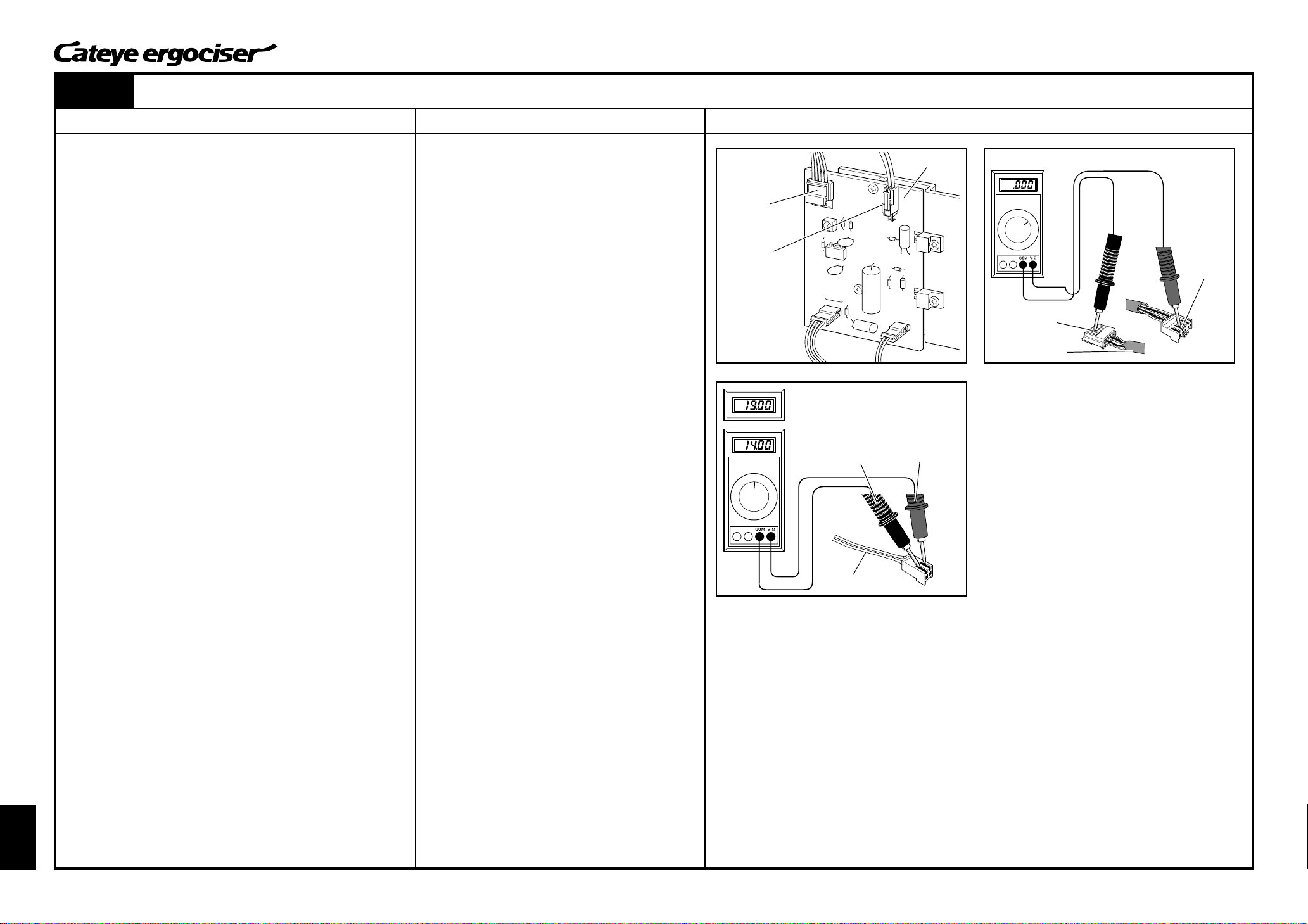

T-2: No Display of Cadence when the Pedal is Rotated --------------------------------------------------10~13

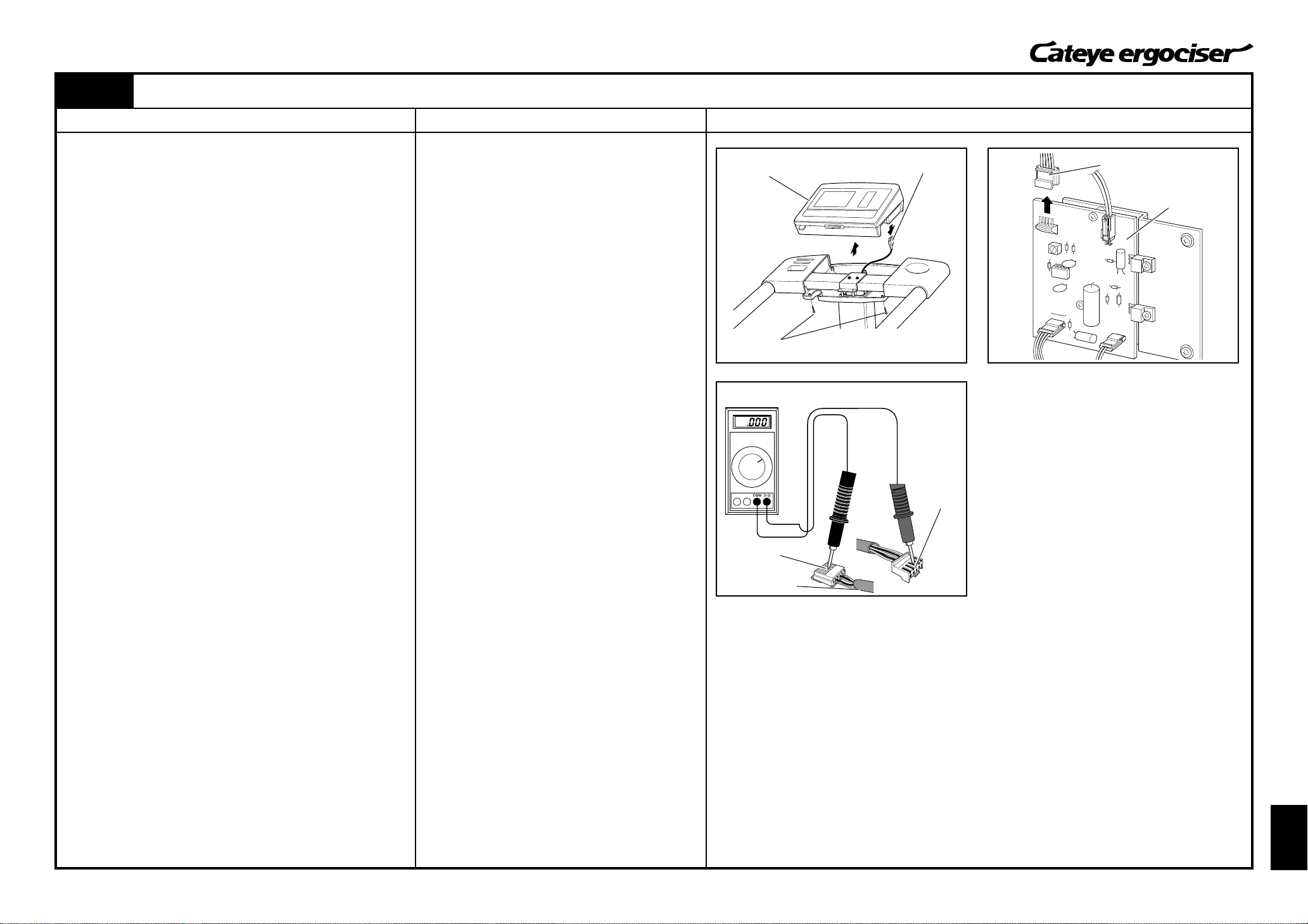

T-3: No Display of Pulse Rate -----------------------------------------------------------------------------------------14

T-4: No Display of Heart Rate (The Case with Wireless Chestbelt Pulse Sensor Kit) ------------15~16

T-5: Improper Display on Control Unit-------------------------------------------------------------------------------17

T-6: No Cadence Control

1. Slower cadence control is not possible--------------------------------------------------------------18~19

2. Faster cadence control is not possible --------------------------------------------------------------20~23

T-7: Pedal will not be Restored to Original Position -------------------------------------------------------------24

T-8: Unusual Noise

1. Continuous and Increasing -----------------------------------------------------------------------------25~26

2. Unusual Noise Synchronized with Pedal Rotation ----------------------------------------------------27

INDEX

Part B

Removing / Mounting the Frame Covers

D-1: Removing the Frame Covers ----------------------------------------------------------------------------- 28

D-2: Mounting the Frame Covers------------------------------------------------------------------------------- 29

Repair Methods

ES-1: Replacing the Wiring within Frame (Inlet Metal Base Set) -------------------------------------------30

ES-2: Replacing the 5P Cable ----------------------------------------------------------------------------------------31

ES-3: Replacing the Power Supply Board-------------------------------------------------------------------------32

ES-4: Correcting the Postion of Solenoid Coil--------------------------------------------------------------------33

ES-5: Replacing the Slenoid Coil Set -------------------------------------------------------------------------------34

ES-6: Replacing the CDC Sensor set-------------------------------------------------------------------------------35

ES-7: Replacing the CDC Sensor Cable---------------------------------------------------------------------------36

ES-8: Correcting the Postion of CDC Sensor---------------------------------------------------------------------37

ES-9: Replacing the Control Unit ------------------------------------------------------------------------------------38

ES-10: Replacing the Button Panel -----------------------------------------------------------------------------------39

MS-1: Replacing the Workload Unit ---------------------------------------------------------------------------------40

MS-2: Replacing the Accelerating Chain ---------------------------------------------------------------------------41

MS-3: Replacing the Pedal Chain ------------------------------------------------------------------------------------42

MS-4: Replacing the V-Belt --------------------------------------------------------------------------------------------43

MS-5: Replacing the Idler Set -----------------------------------------------------------------------------------------44

MS-6: Replacing the Pulley A -----------------------------------------------------------------------------------------45

MS-7: Replacing the V-Belt tension Pulley ------------------------------------------------------------------------46

MS-8: Replacing the Sprocket (Gear for Chains) ----------------------------------------------------------------47

MS-9: Replacing the Shaft Set A -------------------------------------------------------------------------------------48

MS-10: Replacing the Spring--------------------------------------------------------------------------------------------49

MS-11: Replacing the Spring Pulley Set -----------------------------------------------------------------------------50

MS-12: Replacing the Linkstep Set-------------------------------------------------------------------------------51~52

MS-13: Replacing the Pedal Stopper ---------------------------------------------------------------------------------53

MS-14: Replacing the BB Set -------------------------------------------------------------------------------------------54

MS-15: Replacing the Front Reg Cover ------------------------------------------------------------------------------55

MS-16: Replacing the Caster--------------------------------------------------------------------------------------------56

MS-17: Replacing the Rubber Stopper -------------------------------------------------------------------------------57

MS-18: Replacing the Tray-----------------------------------------------------------------------------------------------58

Part C

List of Genuine Parts --------------------------------------------------------------------------------------------------- 59~62