RS232C Communication Kit 10

・To set the age to 30, send the code "A 30 CR", as shown below.

TX$ = "A30"

PRINT#1,TX$

In the same way, other exercise conditions can be changed.

CAUTION: Some computers will express TX$ as "Asp30" when "AGE=30

: TX$="A" (AGE)" is entered. The EC-1500 recognizes this as an

error code and will not return the acknowledged signal "a".

・The setting range of torque is 0.5-4.0 kg•m. The value is multiplied by 10, i.e.

5-40 kg, and transmitted via RS232C interface. To set the torque to 2.5 kg•m

output a character code "E 25".

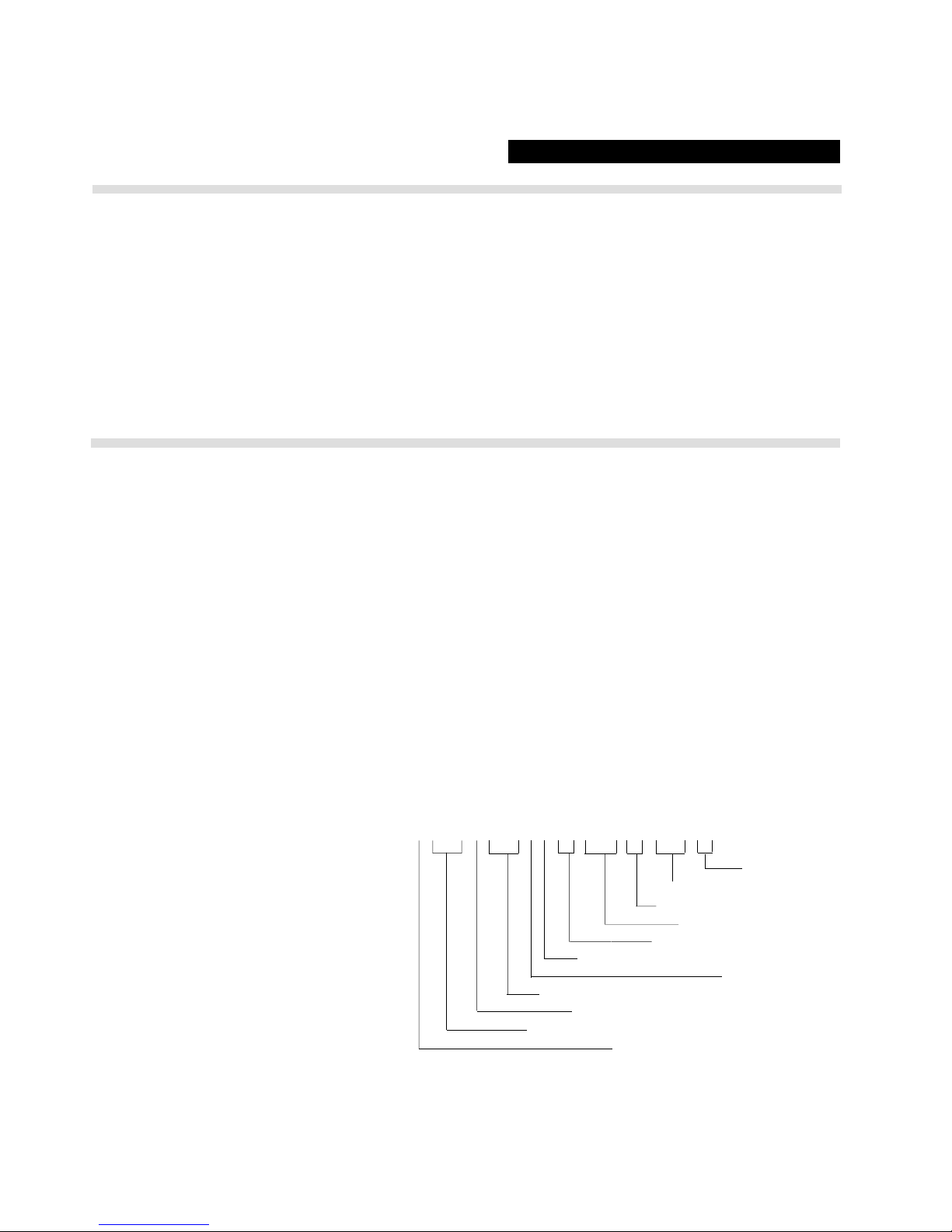

・By sending the following BASIC codes, exercise condition display data can

be obtained from EC-1500, and then decoded.

INPUT#1,RX$

AGE = VAL(MID$(RX$,21,2)) ;Age

LTPLS = VAL(MID$(RX$,18,3)) ;Pulse limit value

TGTM = VAL(MID$(RX$,16,2)) ;Target time

WEIGHT = VAL(MID$(RX$,13,3)) ;Weight (Aerobic Power

Measurement)

TGTQ = VAL(MID$(RX$,11,2))/10 ;Set torque

PROF = VAL(MID$(RX$,10,1)) ;Exercise Pattern (Hill Profile Training)

SEX = VAL(MID$(RX$,9,1)) ;Sex Male="1" Female ="2"

TGPLS = VAL(MID$(RX$,6,3)) ;Target pulse rate (Auto Training)

NTVL0 = VAL(MID$(RX$,5,1)) ;Exercise Pattern (Interval Training)

TGWATT = VAL(MID$(RX$,2,3)) ;Set wattage (Isopower Training)

・Pressing the ADV button puts the EC-1500 into exercise status. As with 2-4-

c), sending the "g CR" code duplicates the ADV button, preparing exercise

conditions.

・When the EC-1500 program starts, transmitted data will change to a set of

exercise data consisting of ten elements beginning with the code B. The data

is transmitted every second, even when the printer is working.

・By sending the following BASIC codes, in-training data can be obtained from

EC-1500, and then decoded.

INPUT#1,RX$

TM = VAL(MID$(RX$,2,4))/100 ;Elapsed time ( min. sec.)

KCAL = VAL(MID$(RX$,6,4)) ;Calorie consumption

WATT = VAL(MID$(RX$,10,3)) ;Wattage

TQ = VAL(MID$(RX$,13,2))/10 ;Pedal torque X.X kgm

HR = VAL(MID$(RX$,15,3)) ;Pulse rate

CDC = VAL(MID$(RX$,18,3)) ;Pedal cadence

PFL = VAL(MID$(RX$,21,1)) ;Aerobic power measurement:PFL

MOU = VAL(MID$(RX$,22,1)) ;Aerobic power measurement:MOU

PWC = VAL(MID$(RX$,24,3)) ;Aerobic power measurement:PWCmax

TGWATT= VAL(MID$(RX$,27,3)) ;Setting wattage (Isopower Training)

Note: Measurements on aerobic (PFL, MOU, PWC) are at zero until the

physical strength test is completed.

2-4-d) Changing exercise conditions

2-4-e) Starting EC-1500 program

(training)

2-4-f) Receiving in-training data