7

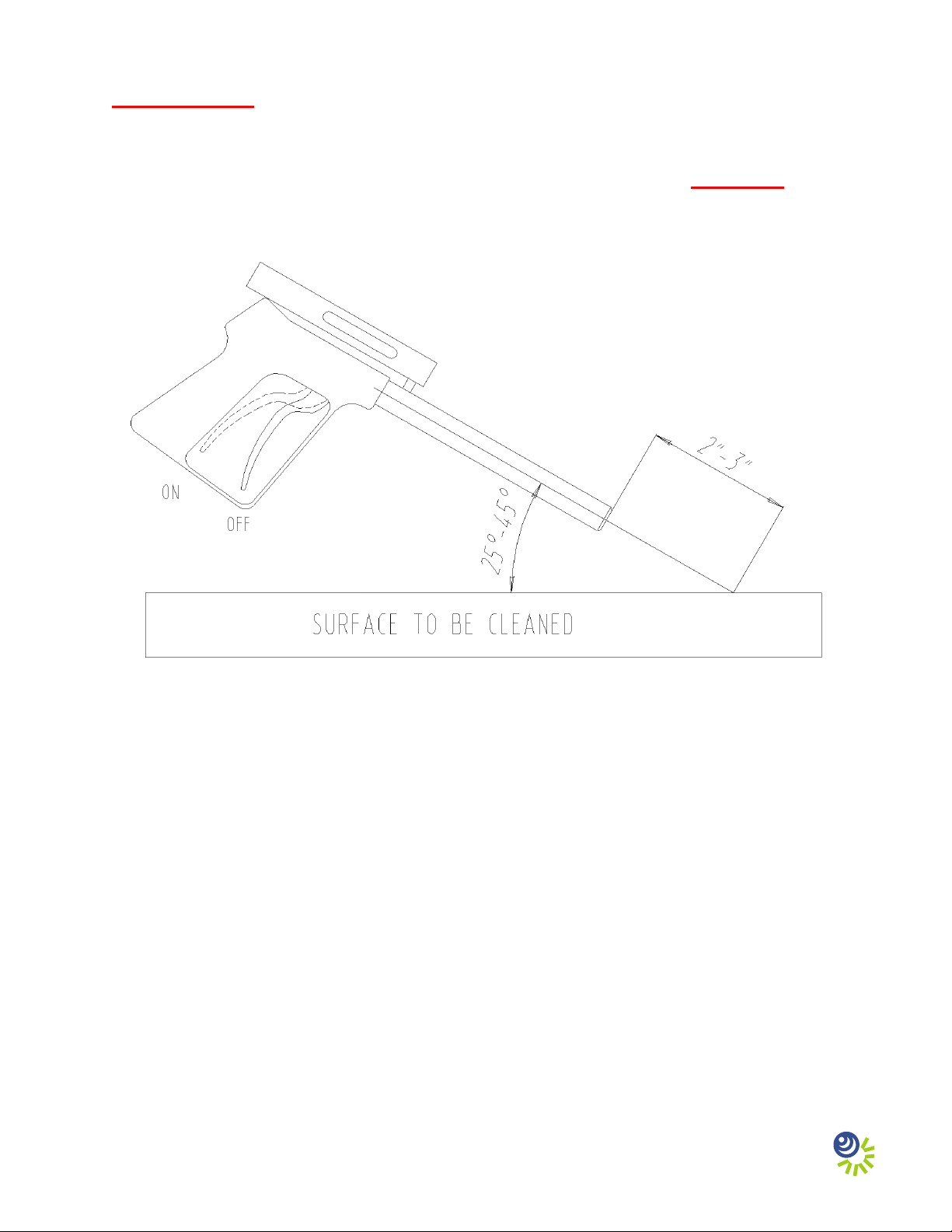

5. If the diver operating the unit must be replaced or the cleaning operation must be interrupted

or terminated, shut down the engine by moving the throttle lever down to adjust engine RPM

to “MIN” (Figure 18) and turning the key to the “OFF” position (Figure 16). Turn off the

feed pump (Figure 13), and then release the water pressure in the hose(s) by squeezing the

gun trigger to the open or “ON” position (Figure 19) while under water. Revert back to step

1 of the operating instructions when the replacement diver is ready to continue cleaning.

6. Ensure that the gun is submerged any time the engine and pressure pump are operating.

Adjusting the CaviBlaster®system for maximum performance:

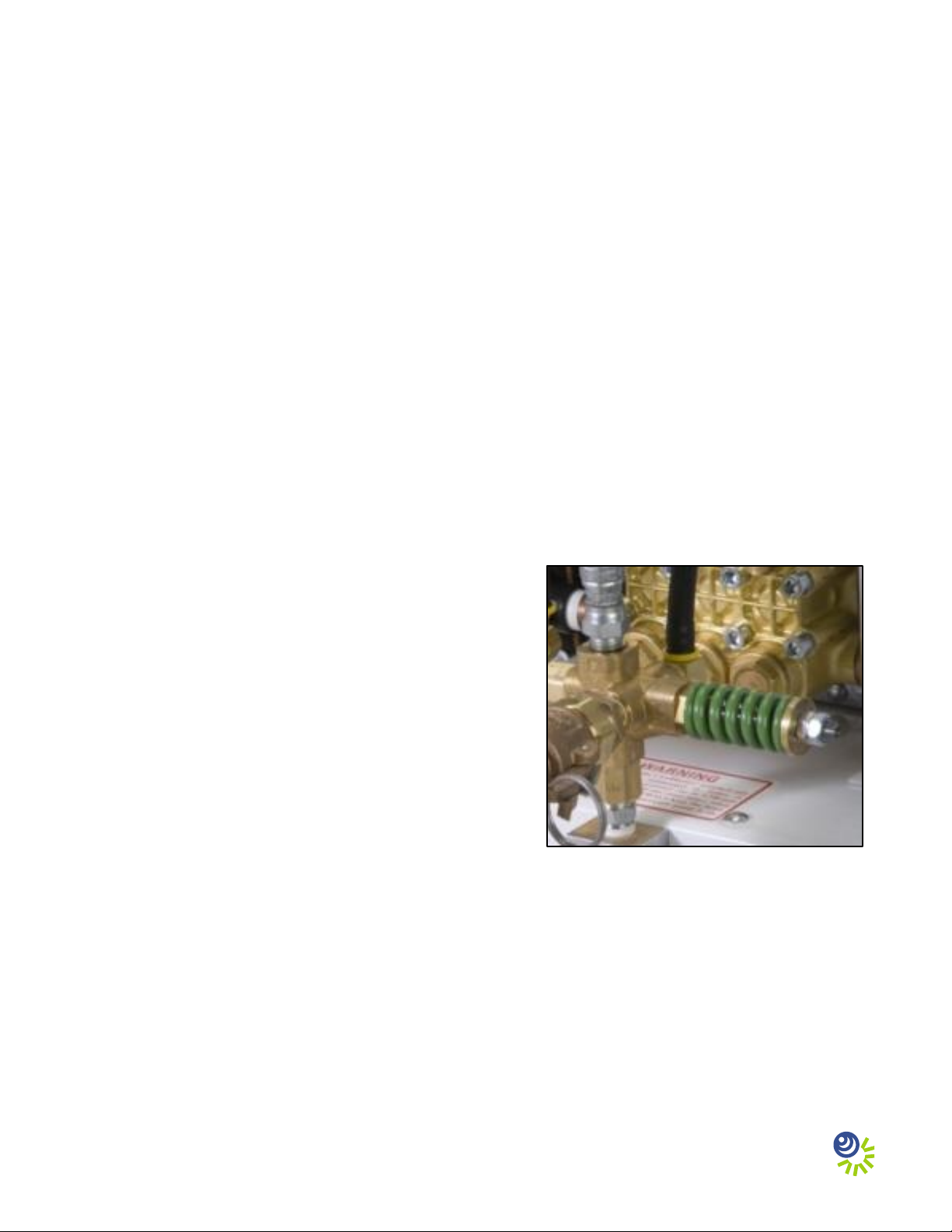

1. If using a calibration pressure gauge situated between the pressure hose and the CaviBlaster®

gun, the water pressure should be 2,200-psi with the gun submerged and the gun trigger in

the open or “ON” position. The pressure is adjusted by turning the nuts on the end of the

pressure-regulating unloader (Figure 20). This adjustment increases or decreases the flow of

water through the bypass hose when the CaviBlaster®gun trigger is in the open or “on”

position. The flow of water through the bypass hose, in turn, determines the flow of water

through the pressure hose and the gun. Less flow through the bypass hose means more flow

through the gun which translates to higher velocity and pressure. There should always be a

trickle of water through the bypass when the gun trigger is in the open or “ON” position. This

ensures that the bypass will open without a pressure shock wave damaging the pump when

the gun trigger is released to the closed position.

2. If using a pressure gauge located on the

CaviBlaster®power unit, the water pressure

will need to be higher to account for sidewall

friction loss in the pressure hose. The pressure

at the pump should be 2,200-psi plus 0.75-psi

per foot of pressure hose. For example, if using

the CaviBlaster®with 100 feet of pressure

hose, the pressure gauge located next to the

pump should indicate 2,275-psi. Pressure

adjustments are made in the same manner as

described above. There should always be a

trickle of water through the bypass when the

gun trigger is in the open or “ON” position.

Figure 20

3. If adjusting the CaviBlaster®without a pressure gauge, close the pressure-regulating

unloader until there is just a trickle of water (less than ¼ gallon per minute) coming out of

the bypass with the gun trigger in the open or “ON” position.

Shutting down the CaviBlaster®power unit:

1. Adjust engine RPM to “MIN” (Figure 18).

2. Shut off the engine by turning the key to the “OFF” position (Figure 16).