3

Starting the CaviBlasterTM unit:

1. When using the feed pump, start the feed pump by moving the feed pump switch located on

the cart handle (Figure 9) to the “on” position. When using a supplied water source, open the

valve to supply water to the system.

2. Ensure that the system is primed with water and that there are no leaks in the system. The

pressure pump is a positive displacement pump and water must be supplied under pressure.

Failure to pump feed water to the pressure pump will result in damage to the pump.

3. Once the system is primed, turn the feed pump off.

4. Connect the ½” high-pressure hose to the quick-connect plug on the pressure-regulating

unloader (Figure 10). The high-pressure hose has a brass female quick-connect fitting on the

end. The HG-1222 CaviBlasterTM can deliver the required pressure utilizing up to 300 feet of

½” diameter hose. Using greater lengths or smaller diameters of hose may degrade

performance. If hose lengths over 300 feet are required, ¾” diameter hose must be used.

Figure 9 Figure 10

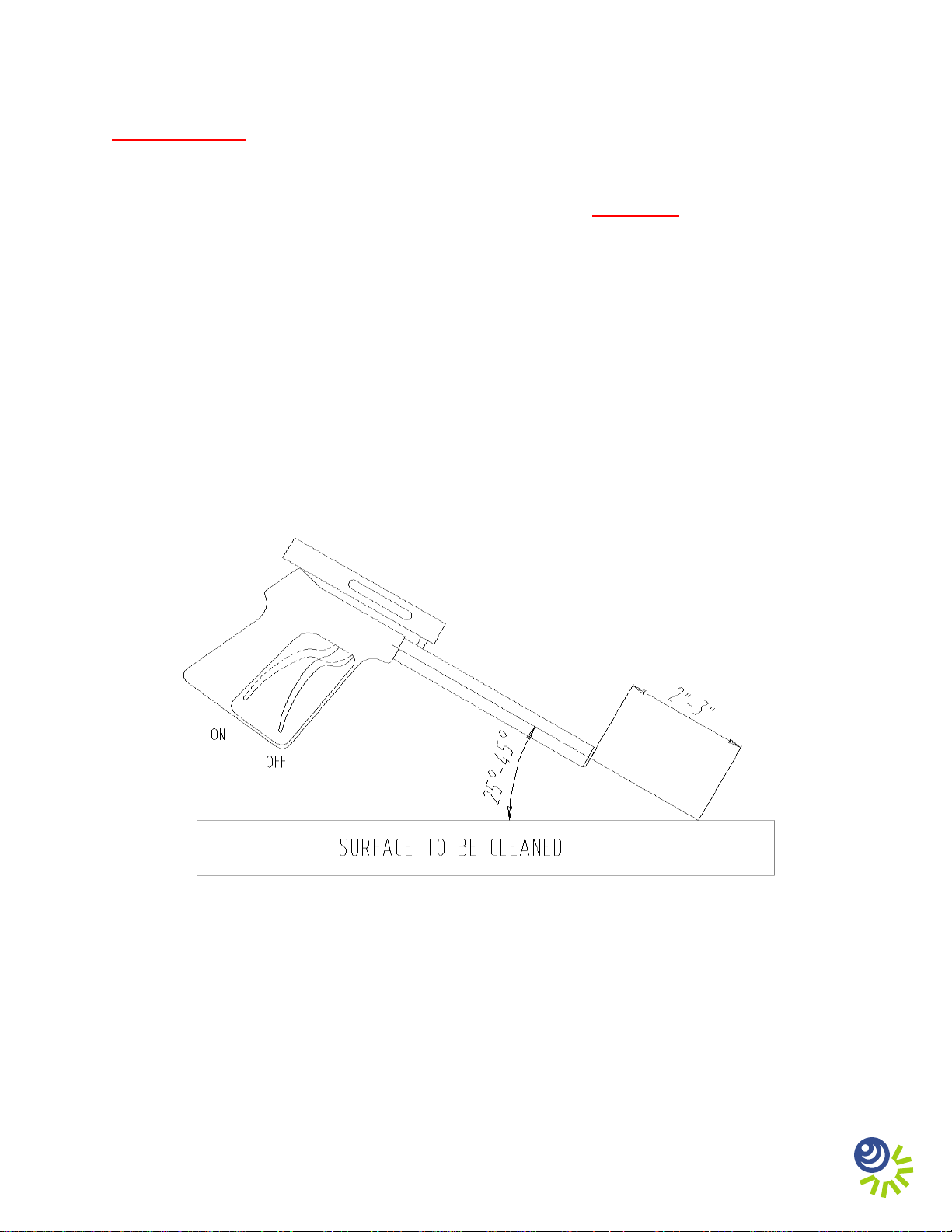

5. Connect the lance to the high-pressure hose

(Figure 11) and submerge the lance in water.

6. Restart the feed pump.

7. It is recommended that the lance trigger be

in the open or “on” position (Figure 12)

when starting the engine.

8. Insert the key into the ignition switch on the

side of the engine. Adjust the choke and turn

the key to the start position to start the

engine. When engine starts, close choke.

9. The system is now ready to operate (refer to

photo on cover for overall system view). Figure 11