0-4

TABLE OF CONTENTS

Use and warning instructions

TABLE OF CONTENTS

4. MACHINE DESCRIPTION .................................................................................................................43

4.1 Proper intended use.............................................................................................................................................................................................4-3

4.2 Reasonably foreseeable misuse......................................................................................................................................................................4-3

4.3 Obligations and prohibitions...........................................................................................................................................................................4-4

4.3.1 Users’obligations..........................................................................................................................................................................................................4-4

4.3.2 Operators’ obligations.................................................................................................................................................................................................4-4

4.3.3 Operators’ prohibitions...............................................................................................................................................................................................4-4

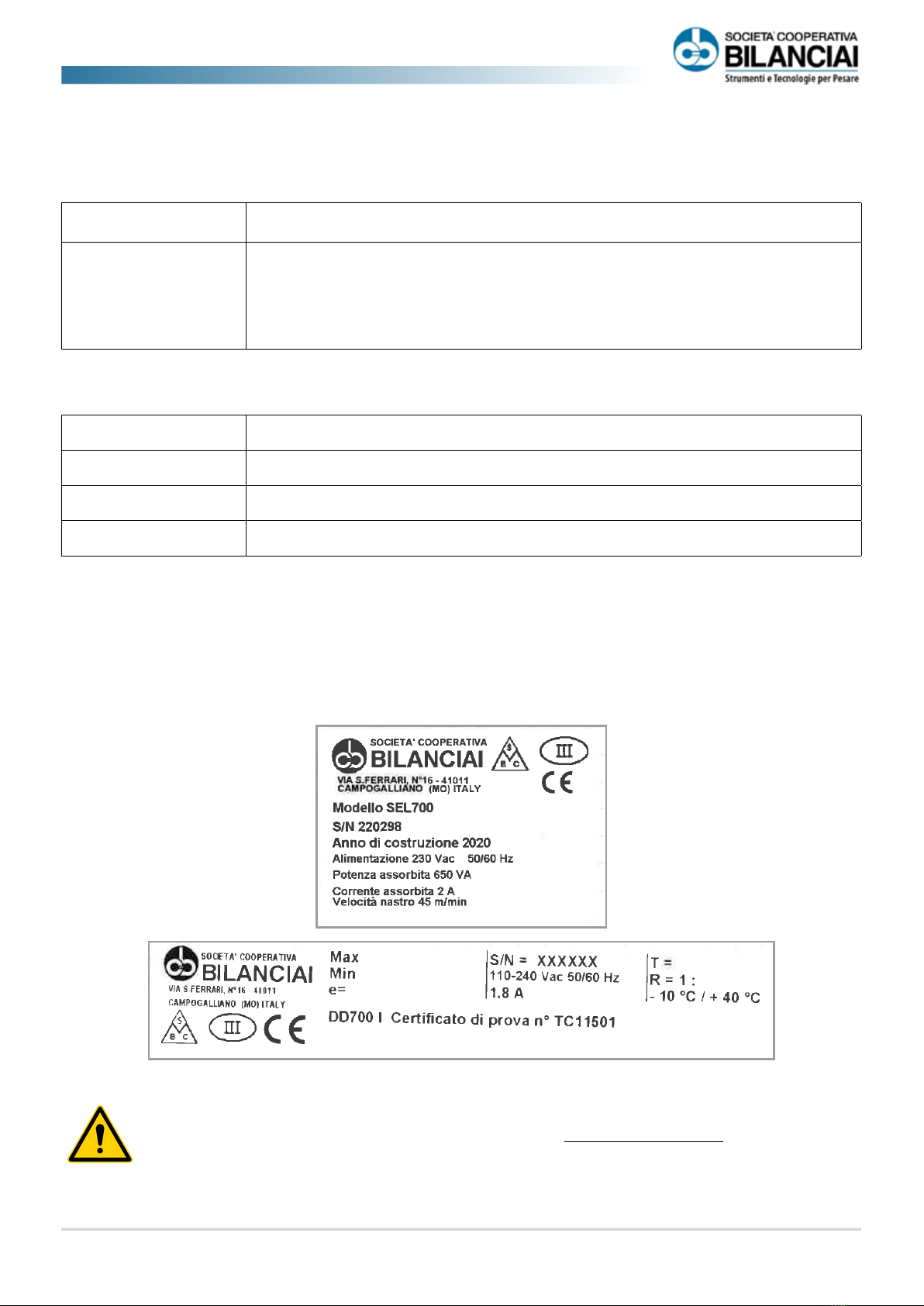

4.4 Technical data.........................................................................................................................................................................................................4-5

4.5 Layout measurements ........................................................................................................................................................................................4-6

4.6 Main components.................................................................................................................................................................................................4-7

4.7 Operating cycle......................................................................................................................................................................................................4-8

5. TRANSPORT AND INSTALLATION...................................................................................................53

5.1 Packaging..................................................................................................................................................................................................................5-4

5.1.1 Packaging removal.......................................................................................................................................................................................................5-4

5.1.2 Disposal of packaging ................................................................................................................................................................................................5-4

5.2 Transport and handling......................................................................................................................................................................................5-5

5.2.1 Unit and weight division table ...............................................................................................................................................................................5-5

5.2.2 Transport operations...................................................................................................................................................................................................5-5

5.3 Installation................................................................................................................................................................................................................5-7

5.3.1 Set-ups to be provided by the customer...........................................................................................................................................................5-7

5.3.2 Permitted environmental conditions...................................................................................................................................................................5-7

5.3.3 Installation place...........................................................................................................................................................................................................5-8

5.3.4 Positioning......................................................................................................................................................................................................................5-9

5.3.5 Installation .......................................................................................................................................................................................................................5-9

5.3.6 Levelling.........................................................................................................................................................................................................................5-10

5.3.7 SEL700 + 4 I/O terminal installation..................................................................................................................................................................5-11

5.3.7.1 Scale parameters (path: \\ Setup\ Scale\ Congurations\ General\ )................................................................................5-12

5.3.7.2 Weighing management parameters (path:\\ Setup \ Customisations \ Work modes \ Operation \ Single weigh-

ing \ Standard\)..........................................................................................................................................................................................5-12

5.3.7.3 Parameters for input contacts (path: \\ Setup\ Customisations\ Outputs\ Inputs) ....................................................5-14

5.3.7.4 Parameters for output contacts (path: \\ Setup\ Customisations\ Outputs\ Output) ...............................................5-16

5.3.7.5 Parameters for analogue output (path: \\ Setup\ Customisations\ Outputs\ Analogue Output\) ......................5-17

5.3.7.6 Default programming .............................................................................................................................................................................5-17

5.3.8 Data available from user menu ...........................................................................................................................................................................5-19

5.3.8.1 How to calculate the piece time to associate to the product...............................................................................................5-22

5.3.9 Main page....................................................................................................................................................................................................................5-23