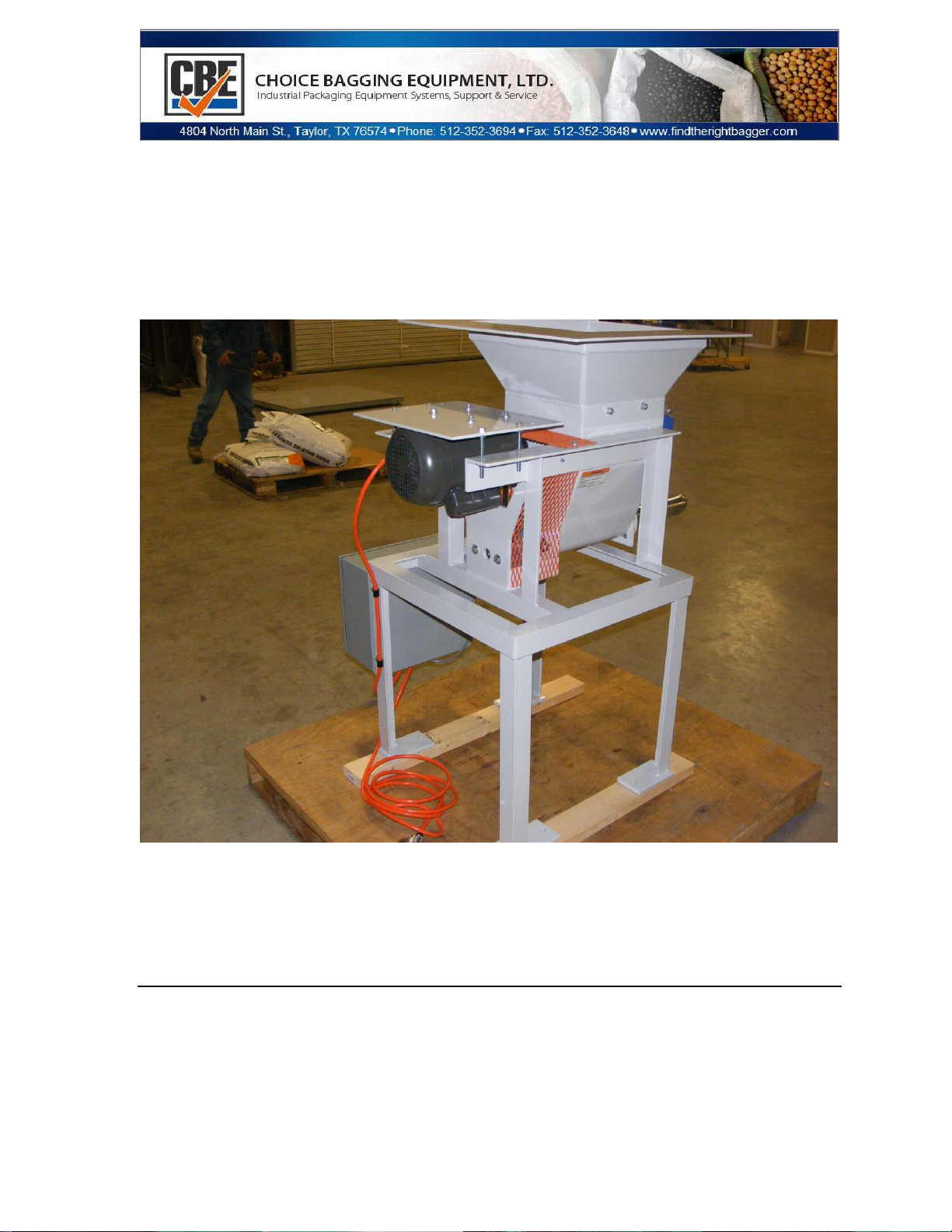

250 Rebagger Auger Packer 2014

4OF10

WARNINGS

NEVERoperatebaggerwithsafetygrate removed.Thiscould leadtoinjurybygetting caughtinauger.

OSHAregulations pertainingto theelectricalwhen maintenanceisperformed mustbefollowed.

DONOTOPERATEMACHINEWITHGUARDSREMOVED.

The purpose of this section is to alert operating and maintenance personnel to the possible dangers of this

type of equipment. Serious injury and/or equipment damage could result from not heeding these safety

precautions.

BEFOREOPERATINGEQUIPMENT:

1) Any personnel working directly with or on this equipment should read this manual before

proceeding with equipment use.

2) Electricians should familiarize themselves with the electrical drawings before initial start-up

of equipment.

3) Other appropriate operating and maintenance personnel should familiarize themselves

with mechanical layout and general arrangement drawings before start-up of equipment.

4) Determine location of all emergency switches.

5) Be sure all guards are in place and observe all warning signs.

6) Check oil level in all motors.

7) Be sure electrical equipment is free of anyaccumulation of water.

8) Be sure all personnel are clear of operating mechanisms before connecting air.

9) Never start equipment without first checking for loose objects, tools and trash. All persons

in the immediate area of the equipment should be alerted prior to starting.

WHENOPERATINGEQUIPMENT:

1) Observe extreme caution when switches are turned on. Operation may begin

automatically after a time delay.

2) Do not open junction boxes or control panels unless you are a qualified electrician. Be

sure power is off. Except when electricians are performing maintenance, electrical

enclosures and junction boxes should always be securely closed.

3) Stop machine and disconnect power supply before servicing or repairing. Maintenance

and adjustments must be performed with all power supply disconnected unless otherwise

specified in this manual.

4) Do not attempt to defeat any safetyswitches. Serious injurycould result.

5) While machine control power is on, do not activate limit switches manually. Serious injury

and/or machine damage could result. Disable machine before attempting any

maintenance or manual testing of components.