CCI Thermal Technologies Inc. 2721 Plymouth Drive, Oakville, ON L6H 5R5 Tel. (905) 829-4422 Fax (905) 829-4430

www.ccithermal.com

MI291 REV.3 Page 3 of 4

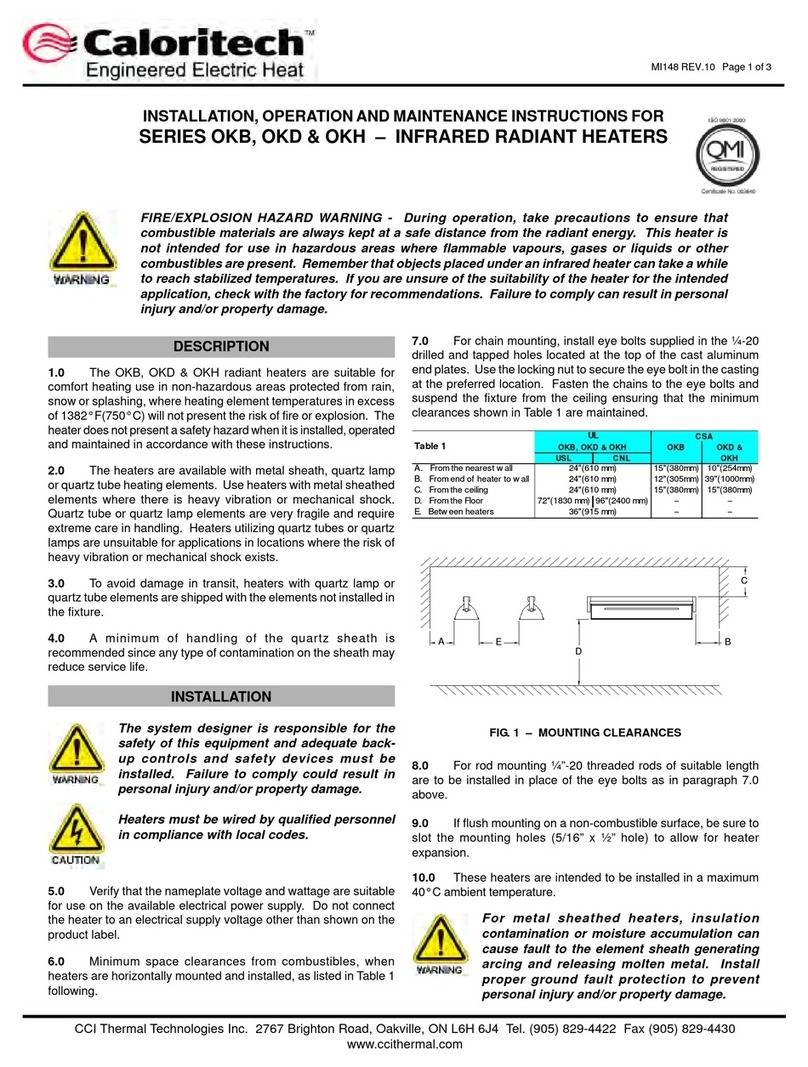

6.0 WIRING

Whenever hazardous materials are present,

ensure that the terminal housing covers,

plugs, etc., are secured (but not over-

tightened) before energizing the heater.

All circuits must be in the open position before

removing junction or terminal box covers.

Use supply wires suitable for 90°C. Supply

wires are to be fused with appropriately sized

HRC fusing.

Use approved conduit and conduit seals as

required by hazardous location standards.

Ensure that no power is connected to the

equipment prior to making any connections.

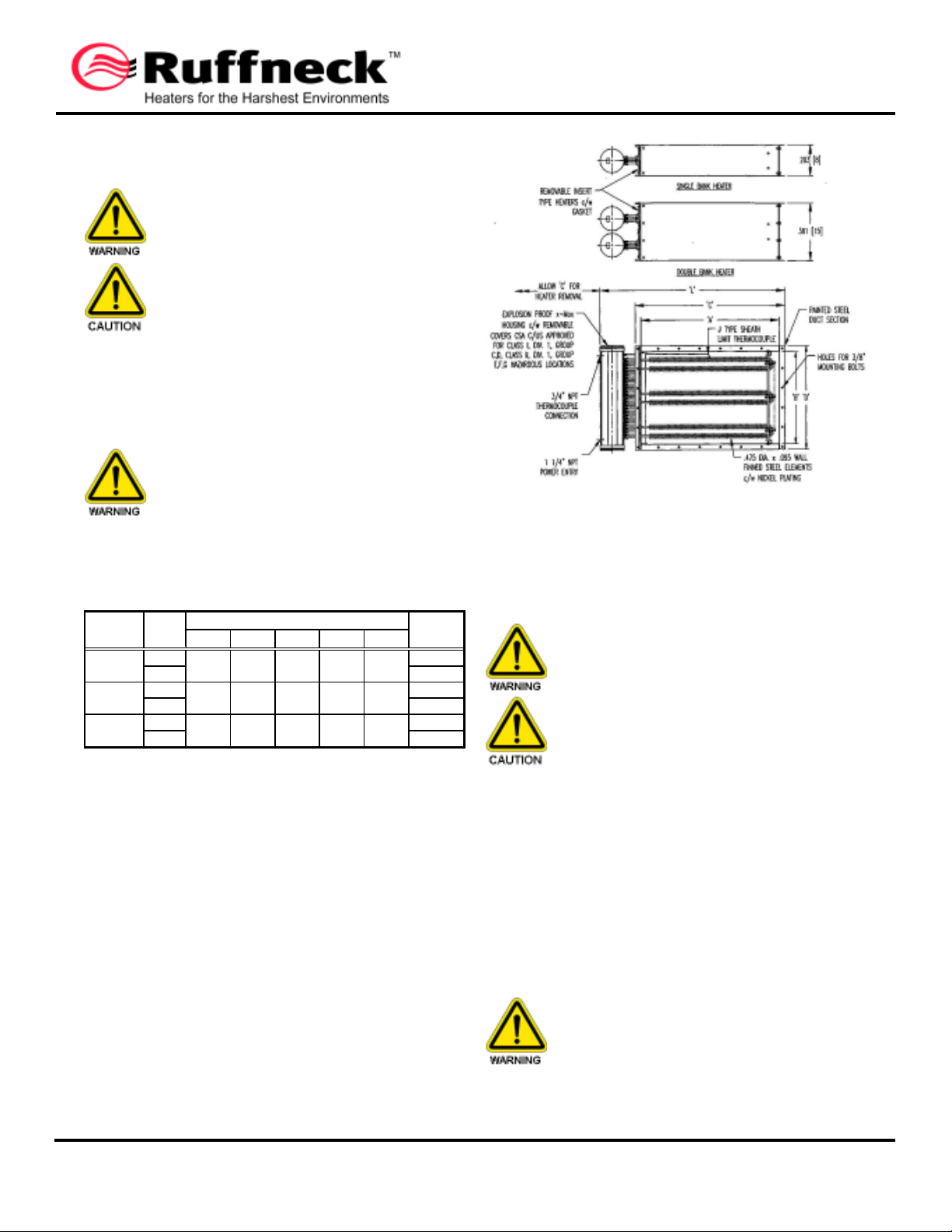

6.1 The heater is factory prewired to supply terminal blocks in

the heater terminal housing ready for direct connection to the power

supply. The heater also contains one (1) high limit thermocouple

per heating bank that must be wired to the control equipment.

For double bank heaters, Heater Bank #1 is

defined as the inlet bank and Heater Bank #2

is defined as the outlet bank. This distinction

is important in order to ensure proper high

limit set limit set points must be set in the

field. Table 2 gives the maximum high limit

set points for safe operation of the heater. For

initial start-up, set the high limit controllers

to the values indicated in Table 2 and lock in

place.

6.2 To wire the heater to the control equipment, make the

following connections at the connection points indicated on the

assembly drawing:

a) 1¼" NPT conduit entries have been provided in each heater

terminal housing for wiring the power supply and ground to

the heaters. Connect the heating bank(s) to the contactor(s)

in the control panel.

b) ¾" NPT conduit entries have been provided on each heater

bank for wiring the J type high limit thermocouple(s) to

Certified, manual-reset high limit controller(s) in the control

panel. Using appropriate thermocouple extension wire,

connect the thermocouple(s) to the high limit controllers,

ensuring proper connection of the positive and negative

leads.

c) Connect the "Normally Open" contacts of the supplied

pressure differential switch to the interlocks in the control

circuit.

After all connections have been made and

before starting up the system, ensure that all

housings, plugs, covers, etc. have been

installed.

7.0 STARTUP AND OPERATION

TO ENSURE SAFE AND RELIABLE

OPERATION, DO NOT EXCEED THE MAXIMUM

OUTLET TEMPERATURE OF 40°C AND DO

NOT ALLOW THE AIRFLOW TO DROP BELOW

THE MINIMUM AIRFLOW AS SHOWN ON THE

PRODUCT NAMEPLATE.

7.1 Turn on the airflow through the duct heater. Ensure that

the minimum airflow, as shown on the product nameplate, is

maintained at all times.

7.2 The field installed explosion-proof differential pressure

switch may require field adjustment. Consult manufacturer's

operation instructions included with this manual.

THE PRESSURE DIFFERENTIAL SWITCH IS A

CRITICAL SAFETY COMPONENT. IMPROPER

SETTING OF THE SWITCH MAYRESULT IN

HAZARDOUS CONDITIONS.

7.3 Apply power to the control panel.

7.4 Turn the control on/off switch to "On".

7.5 Set the temperature controller to the desired set point. Do

not exceed the maximum outlet temperature of 40°C.

7.6 Ensure that the temperature controller is working properly.

Consult the manufacturer's operation instructions supplied with the

temperature controller.

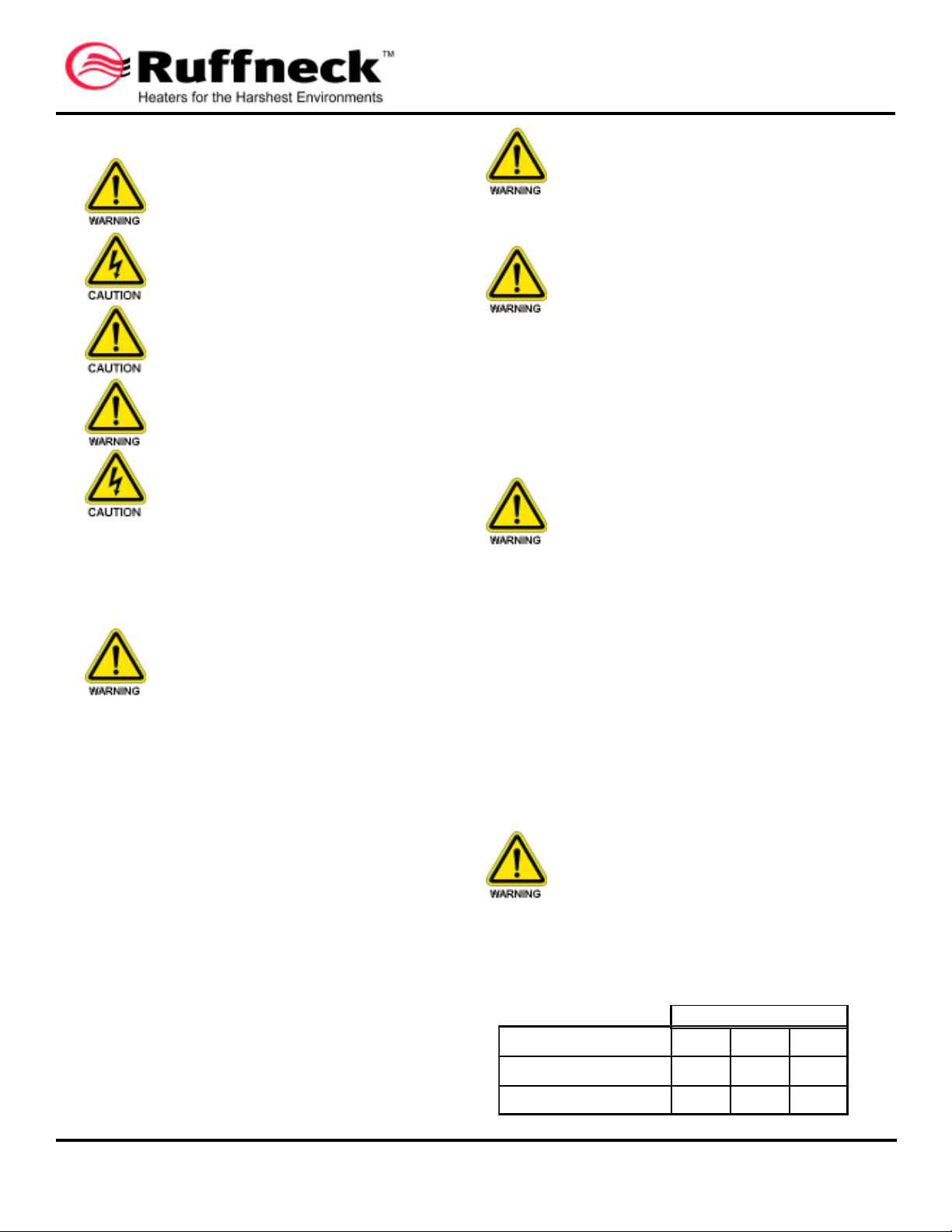

7.7 Except when purchasing a control panel to accompany your

RXDF heater, the high limit set points must be set in the field. Table

2 gives the maximum high limit set points for safe operation of the

heater. For initial start-up, set the high limit controllers to the values

indicated in Table 2.

TO PREVENT UNSAFE OPERATION OF THE

HEATER, DO NOT EXCEED THE MAXIMUM

HIGH-LIMIT SET POINTS. OPERATION OF

THE HEATER WITH HIGH LIMIT SET POINTS

GREATER THAN THOSE SHOWN IN TABLE 2

CREATES ASIGNIFICANT RISK OF

EXPLOSION.

Table 2 - Maximum High Limit Set Points

Temperature Code T2D T3A T3B

Heater Bank #1 (Inlet) 94 78 65

Heater Bank #2 (Outlet) 125 100 83

High Limit Set-Point (°C)