196

DPG1000DR Series Instructions

© 01-08

Cecomp maintains a constant effort to upgrade and improve its products. Specifications

are subject to change without notice. Consult factory for your specific requirements.

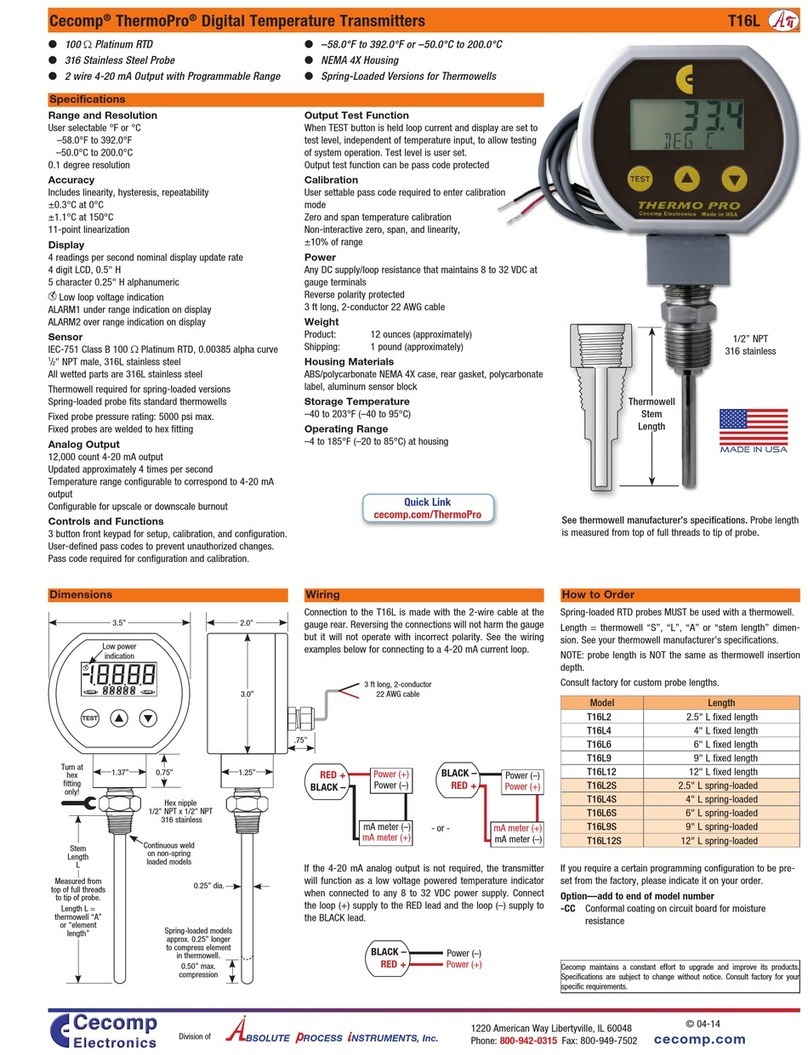

INSTALLATION AND PRECAUTIONS

Install or remove the gauge using wrench on hex fitting only. Do not attempt to tighten by

turning housing or any other part of the gauge. Use fittings appropriate for the pressure

range of the gauge. Do not apply vacuum to gauges not designed for vacuum operation.

Due to the hardness of 316 stainless steel, it is recommended that a thread sealant be used

to ensure leak-free operation. NEVER insert objects into the gauge port or blow out with

compressed air. Permanent damage not covered by warranty will result to the sensor.

NEVER connect the gauge wires directly to 115 VAC or permanent damage not covered

by warranty will result!

ELECTRICAL CONNECTION

The DPG1000DR series can be powered by any 9 to 32 VDC or 8 to 24 VAC 50/60 Hz

power source. An inexpensive unregulated low voltage source can be used. The magnitude

of the supply voltage has negligible effect on the gauge calibration as long as it is within the

stated voltage ranges. Do not allow the gauge supply voltage fall below 9 VDC or 8 VAC

RMS. Operation below these values may cause erratic or erroneous readings or output.

Models with 4-20 mA output power the current loop. Use a power source with sufficient volt-

age to operate the current loop.

Connection is made with the 4-conductor cable at the gauge rear. This cable accommo-

dates both the gauge power supply and retransmission output. If using a 9 to 32 VDC

power source, connect the (+) supply to the RED lead and the (–) supply to the BLACK

lead. If using a 8 to 24 VAC 50/60 Hz power source, connect to the RED and BLACK leads.

When using low voltage AC power, there is of course, no polarity consideration.

The (+) retransmission output appears on the WHITE lead, and the (–) retransmission out-

put appears on the GREEN lead. Use of the shield (drain) wire of the retransmission out-

put is optional. It is not generally needed for 4-20 mA current loops unless very long cable

lengths are used in electrically noisy environments.

Power – BLACK

Power + RED

Output – GREEN

Output + WHITE

The output is a continuous analog signal based on the transducer output rather than the

display. This output is filtered to improve noise immunity and has a response time of about

50 milliseconds.

The power supply (–) lead is tied to the retransmission output ground. Therefore, if a DC

supply is used, the power supply (–) lead should be considered common with regard to the

retransmission output (–) connection.

USING THE RETRANSMISSION OUTPUT

NEVER connect retransmission output wires together or to an external power source or

permanent damage not covered by warranty will result.

For 4-20 mA output models, be sure to observe the output compliance (voltage drive) capa-

bilities of the gauge. The compliance, and therefore the maximum loop resistance the out-

put can drive, is a function of the supply voltage to the gauge. Consult the graph shown

below for maximum loop resistance vs. gauge supply voltage. Too large a loop resistance

will cause the gauge output to “limit” or saturate before reaching its full 20 mA output.

When using the 0-2 volt retransmission output, do not allow the resistive load on the out-

put to fall below 5K ohms. Avoid large capacitive loads (greater that 1000 pF) such as those

caused by long runs of shielded cable. For long cable runs, use a 4-20 mA output model.

OPERATION

The gauge is powered on whenever a supply voltage is applied. Warm-up time is negligi-

ble. In normal operation, the system pressure is displayed on the LCD and an output sig-

nal will be present. DPG1000DRBL model display backlighting will be on whenever power

is on. The display backlighting will not be apparent under bright lighting conditions.

TEST BUTTON

When the front-panel TEST button is held depressed, the display and retransmission out-

put are switched, independent of the system pressure, to a test level determined by the set-

ting of the Test potentiometer. This test mode will allow setup and testing of the output and

any external device(s) connected to it by switching to this test level whenever desired with-

out having to alter the system pressure.

To set the test output level, see gauge label for location of Test potentiometer. Press and

hold the front-panel TEST button and adjust the Test potentiometer to set the display and

retransmitted output to the desired test level.

CALIBRATION

The gauge is calibrated at the factory using equipment traceable to NIST. There is no need

to calibrate the gauge before putting it in service. Complete calibration instructions can be

downloaded from www.cecomp.com. Gauges may be returned to Cecomp Electronics for

factory certified recalibration. NIST traceability is available.

Span calibration should only be attempted if the user has access to a pressure reference

of known accuracy. The quality of the calibration is only as good as the accuracy of the cal-

ibration equipment and ideally should be at least four times the gauge accuracy.

Absolute reference gauges require vacuum generation and atmospheric pressure meas-

urement equipment for accurate calibration and are more difficult to calibrate in the field.

The calibration system must be able to generate and measure pressure/vacuum over the

full range of the gauge. A vacuum pump able to produce a vacuum of 10 microns (0.01 torr

or 10 millitorr) or lower is required for vacuum and absolute gauges.

1. Low-voltage powered gauges must be connected to 8-24 VAC 50/60 Hz or 9-32 VDC

during the calibration procedure. The supply voltage has negligible effects on the gauge

calibration as long as it is within the stated voltage ranges.

2. Allow the gauge to equalize to normal room temperature before calibration.

3. Access the individual controls to adjust the zero and span of the display.

4. Zero calibration must be done before span calibration.

5. Zero for gauge reference pressure or vacuum gauges: Gauge reference units may

be re-zeroed without affecting the span calibration. The gauge port must be open to the

ambient with no pressure or vacuum applied. Adjust the Zero potentiometer for a display

indication of zero with the minus (–) sign occasionally flashing.

Zero for absolute reference gauges: Apply full vacuum to the gauge. Adjust the Zero

potentiometer for a display indication of zero with the minus (–) sign occasionally flashing.

6. Span for gauge reference pressure gauges and absolute reference gauges: Apply

full-scale pressure and adjust the Span potentiometer for a display indication equal to

full-scale pressure.

Span for gauge reference vacuum gauges: Apply full vacuum to the gauge. Adjust the

Span potentiometer for a display indication equal to full-scale vacuum.

7. Verify pressure indications at 0%, 25%, 50%, 75%, and 100% of full scale and repeat

calibration as needed to achieve best accuracy over desired operating range.

Calibration of the retransmission output coordinates the retransmission output to the dis-

play indication, and normally does not need to be adjusted. It requires a direct physical

measurement of the retransmission output. This calibration procedure can be downloaded

from www.cecomp.com.

DIMENSIONS AND WIRING EXAMPLE

1/4" NPT

Cecomp Electronics Inc./Made in USA

2.88"

3.38"

0.75" 0.75"

1.65"

Turn at

hex

fitting

only!

PSIG

Max Loop Resistance (Ohms)

8121620242832

Supply Voltage (DC or AC RMS)

Voltage Compliance for

4-20 mA Current Retransmission Output

DC Backlit &

non-Backlit

Gauge power supply

9-32 VDC

or

8-24 VAC 50/60 Hz (–)BLACK

(+)RED

(+)WHITE

(–)GREEN

Remote Device Optional

shield

connection

3 ft long, 4-con-

ductor 22 AWG

cable

Span Zero

Test

TEST

1400

1200

1000

800

600

400

200

0

AC 3000 & 5000 psi

DC 3000 & 5000 psi

Zero, Test, Span pots for

3000 & 5000

psi ranges

AC Backlit

AC

BSOLUTE ROCESS NSTRUMENTS, Inc.

1220 American Way Libertyville, IL 60048

Phone: 800-942-0315 Fax: 800-949-7502

For latest product information or to contact

your local representative visit api-usa.com

Pressure