Contents

1About this document

1.1Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2Target group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3Symbolism used. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2For your safety

2.1Authorised personnel . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2Appropriate use . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3Warning about misuse . . . . . . . . . . . . . . . . . . . . . . . 5

2.4General safety instructions . . . . . . . . . . . . . . . . . . . . 5

2.5Safety approval markings and safety tips . . . . . . . . . . 6

2.6CE conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.7Compatibility according to NAMUR NE 53 . . . . . . . . . 6

2.8Safety instructions for Ex areas . . . . . . . . . . . . . . . . . 6

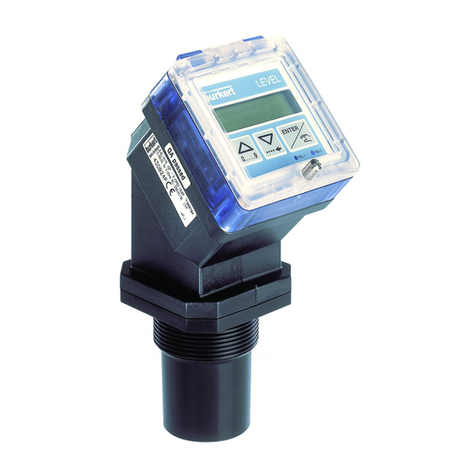

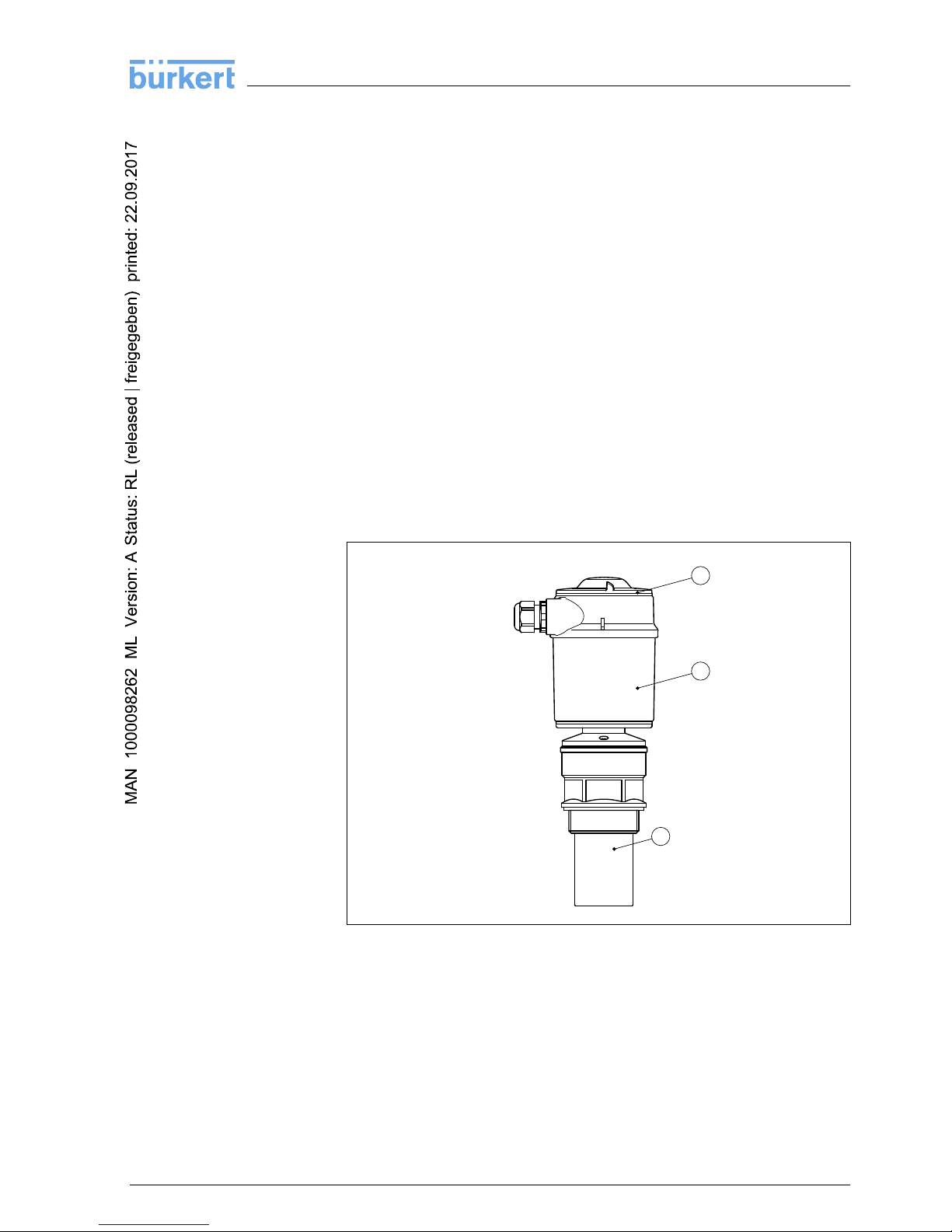

3Product description

3.1Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2Principle of operation . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.4Packaging,transport and storage . . . . . . . . . . . . . . . 8

4Mounting

4.1General instructions . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.2Mounting instructions . . . . . . . . . . . . . . . . . . . . . . . . 12

5Connecting to power supply

5.1Preparing the connection . . . . . . . . . . . . . . . . . . . . . 18

5.2Connection procedure. . . . . . . . . . . . . . . . . . . . . . . . 19

5.3Wiring plan,single chamber housing . . . . . . . . . . . . . 20

5.4Switch on phase. . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6Set up with the indicating and adjustment module

6.1Short description . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.2Insert indicating and adjustment module. . . . . . . . . . . 22

6.3Adjustment system . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.4Setup procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.5Menu plan ultrasonic sensor . . . . . . . . . . . . . . . . . . . 31

6.6Saving the parameter adjustment data. . . . . . . . . . . . 33

7Maintenance and fault rectification

7.1Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.2Remove interferences. . . . . . . . . . . . . . . . . . . . . . . . 34

8Dismounting

8.1Dismounting steps . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8.2Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2LEVEL TRANSMITTER 8177 •4…20 mA/HART

Contents

32059-EN-081121