1

TE15 - TE25 - TE35 - TE50 - TE65/L

PRE-MIX

1 - Safety .....................................................................................................................3

1.1 Intended use ..................................................................................................................... 3

1.2 Improper use .................................................................................................................... 3

1.3 List of hazards ................................................................................................................... 4

1.4 Residual risks .................................................................................................................... 6

2 - General information ............................................................................................... 7

2.1 Manufacturer’s details ........................................................................................................ 7

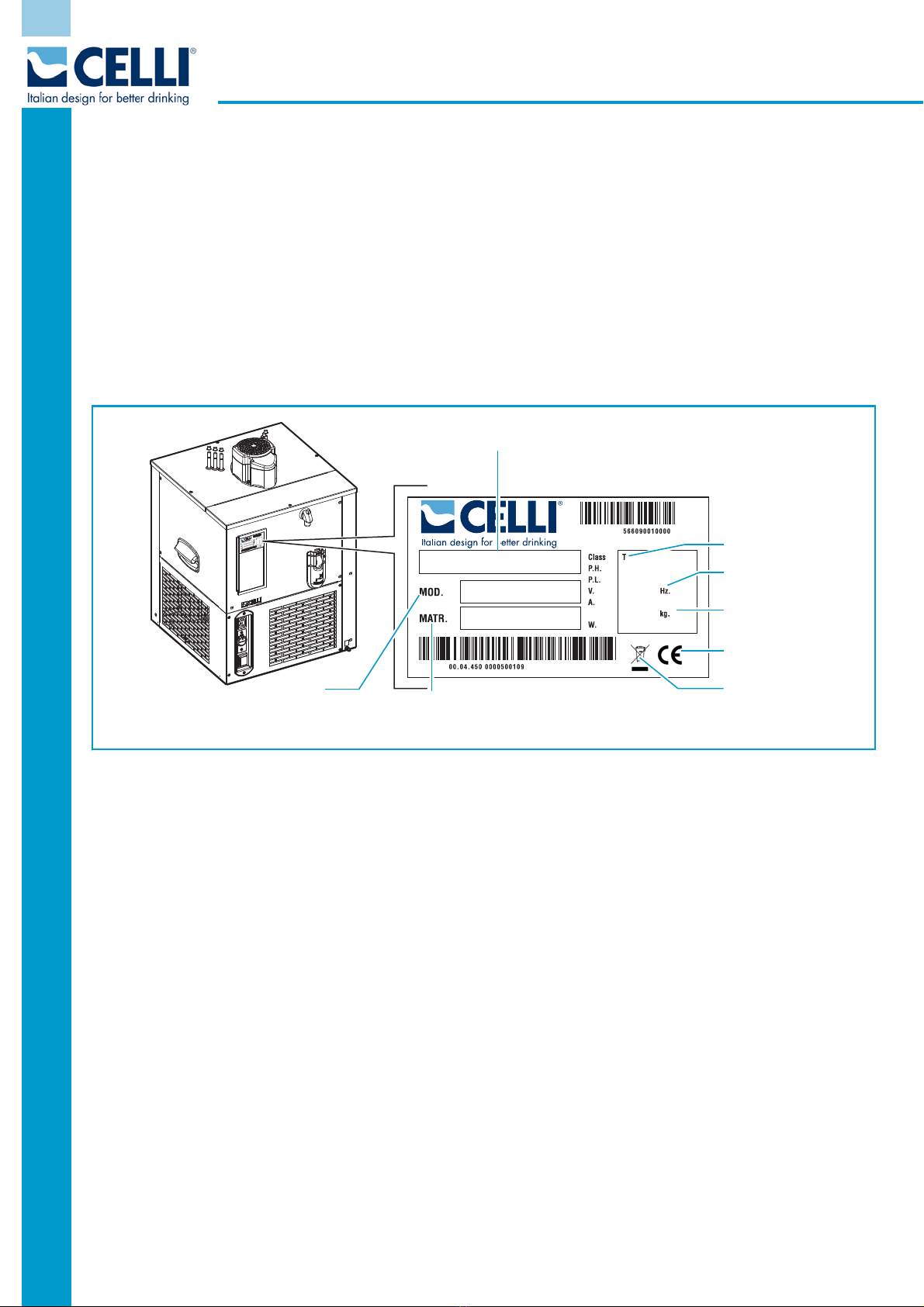

2.2 Machine identification......................................................................................................... 8

2.3 Warranty........................................................................................................................... 8

2.4 Symbols used in the manual ............................................................................................... 9

2.5 Staff qualification............................................................................................................... 9

3 - Description of the machine .................................................................................. 10

3.1 Main components of the TE/L Range with mechanical thermostat.........................................11

3.2 Main components of the TE15/L Range with mechanical thermostat .....................................13

3.3 Main components of the TE/L Range with electronic thermostat ...........................................15

3.4 Main components of the TE/L Range with digital thermostat ................................................17

3.5 Main components of the TE/L Range with water-cooled condensing .....................................19

3.6 Operating principle............................................................................................................21

3.6.1 Water stirring and recirculation..................................................................................22

3.7 Unit with electronic thermostat ..........................................................................................22

3.8 Unit with digital thermostat to function with glycol ..............................................................23

3.8.1 To obtain an ICE effect on the towers........................................................................23

3.8.2 ICE tower connection diagram - TE Glycol ..................................................................24

3.8.3 To dispense extra cold beer ......................................................................................25

3.8.4 Diagram with primary and secondary cooler for extra COLD beer .................................26

3.8.5 To obtain the ICE effect on the towers and dispense extra COLD beer .........................26

3.9 Water cooled condensing unit ............................................................................................27

3.10 Technical data ................................................................................................................29

3.10.1 Sound emissions.....................................................................................................29

3.11 Dimensions in mm (inches)..............................................................................................30

3.11.1 TE15/L...................................................................................................................30

3.11.2 TE25/L...................................................................................................................30

3.11.3 TE35/L...................................................................................................................30

3.11.4 TE50/L...................................................................................................................31

3.11.5 TE65/L...................................................................................................................31

3.12 Differential-switch power cord (optional)...........................................................................32

4 - Installation ........................................................................................................... 33

4.1 Checks and Unpacking ......................................................................................................33

4.2 Positioning .......................................................................................................................34

4.3 Environmental conditions...................................................................................................35

4.4 Electrical requisites ...........................................................................................................35

4.5 Connections .....................................................................................................................36

4.5.1 Preparing the machine..............................................................................................36

4.5.2 Connection to the drinks kegs ...................................................................................37