You must shut off the power when:

?The temperature protector is in trouble

?You don't want to continue the work

?You want to leave the station.

2. Be careful. It is high temperature. Never use this rework station when it is close to flammable gas or

other material like paper. Both the nozzle and the air are in high temperature. Never touch the hot

nozzle or blow the body skin directly. It smokes a little bit when you switch on power. But after a while

the smoke will disappear.

3. After you shut the station off, it will cool down automatically. When temperature decrease to 50°C, it

will stop. During this time, don't unplug the plug.

4. Dropping down or shaking violently.

Heating tube contains quartz. Dropping down or shaking violently would break the glass.

5. Don't dismantle the pump.

6. If the machine will mot be used for along time, unplug the plug. If the machine if plugged, there will be

some current input even if it is switched off.

7. Advise other people in the work area that the unit can and should be considered potentially

dangerous.

CAUTION

1. Before use pump securing screw (M5*10) under the base of the soldering station must be removed.

Otherwise it will cause serious problem.

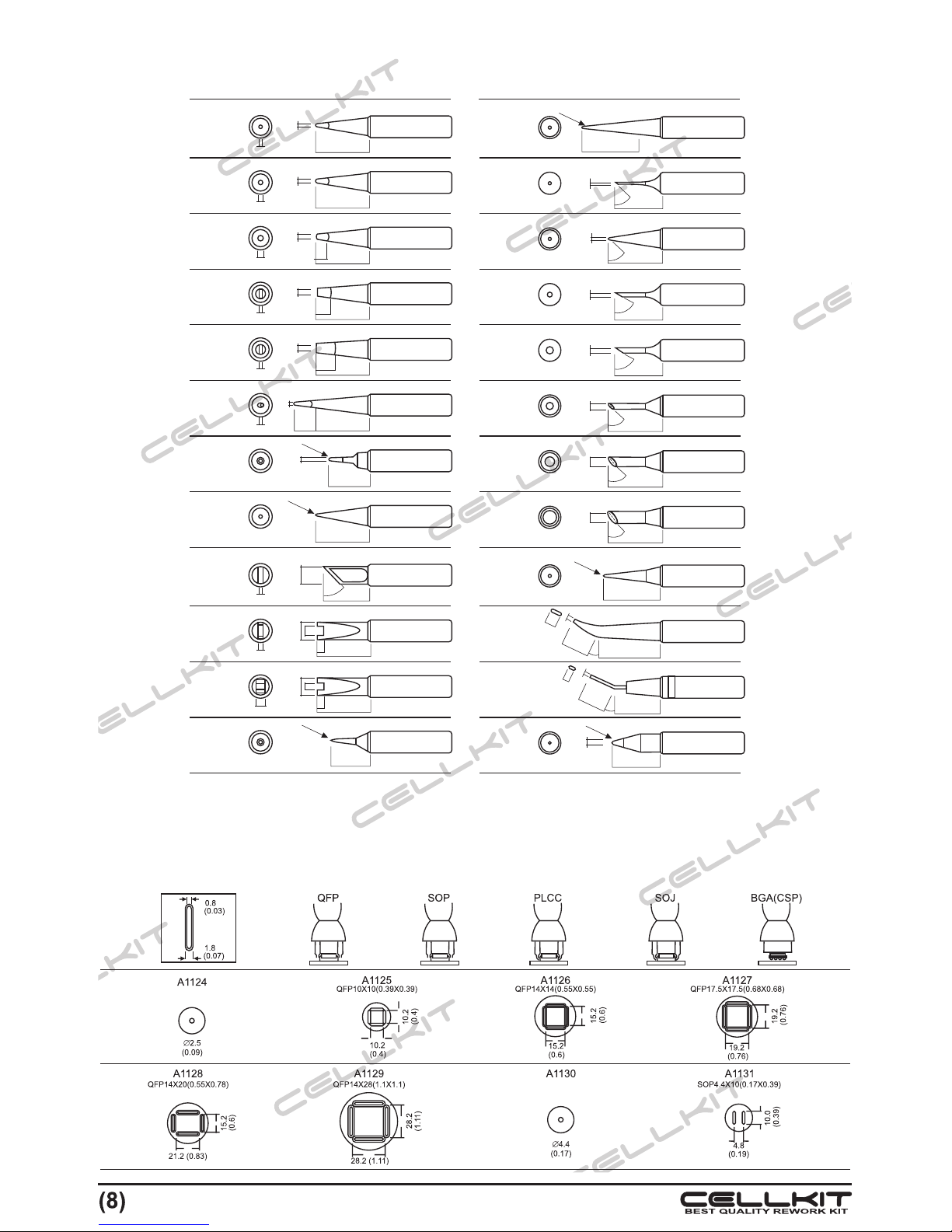

2. Select the nozzle in comploiant with the size of integrated circuit unit. When both the heater and the

nozzle are cool, install the nozzle if one of them is still hot, installation should be done after it is cool for

safety of people.

3. Before use please read the User Guide in detail.

4. Before use please joint the wire connected with ground which is used to avoid transmitting static.

5. Don't damage the piece against removal. Otherwise the guaranteed w service will be invalid.

6. It is forbidden to put other metal articles in the net hole on the top of the soldering iron. This action will

damage the heating installation and make people get an electric shock.

7. When in case the soldering station cannot work normally because of fault, please contact with

supplier. Before transportation, Please lock well the red screw under the base of the rework station.

Applications:

?It is suitable for disassembling soldering for the most of part an the surface for example SOIC, CHIP,

QFP, PLCC, BGAand so on

?It is suitable for contractive flexible tube.

?Design of static electricity proof: prevent from damaging PCB caused by static electricity and creepage.

?Adapting soldering methods that unnecessary touching soldering joint, it can avoid the elements

displacement from heat shocking.

1. Installation of the nozzle

1. Release the screw of the nozzle.

2. Insert the nozzle into position and fasten the screw.

Don't install the nozzle with too much strength, neither installs it pulling the edge with a force, nor too

much strength to drive the screw.

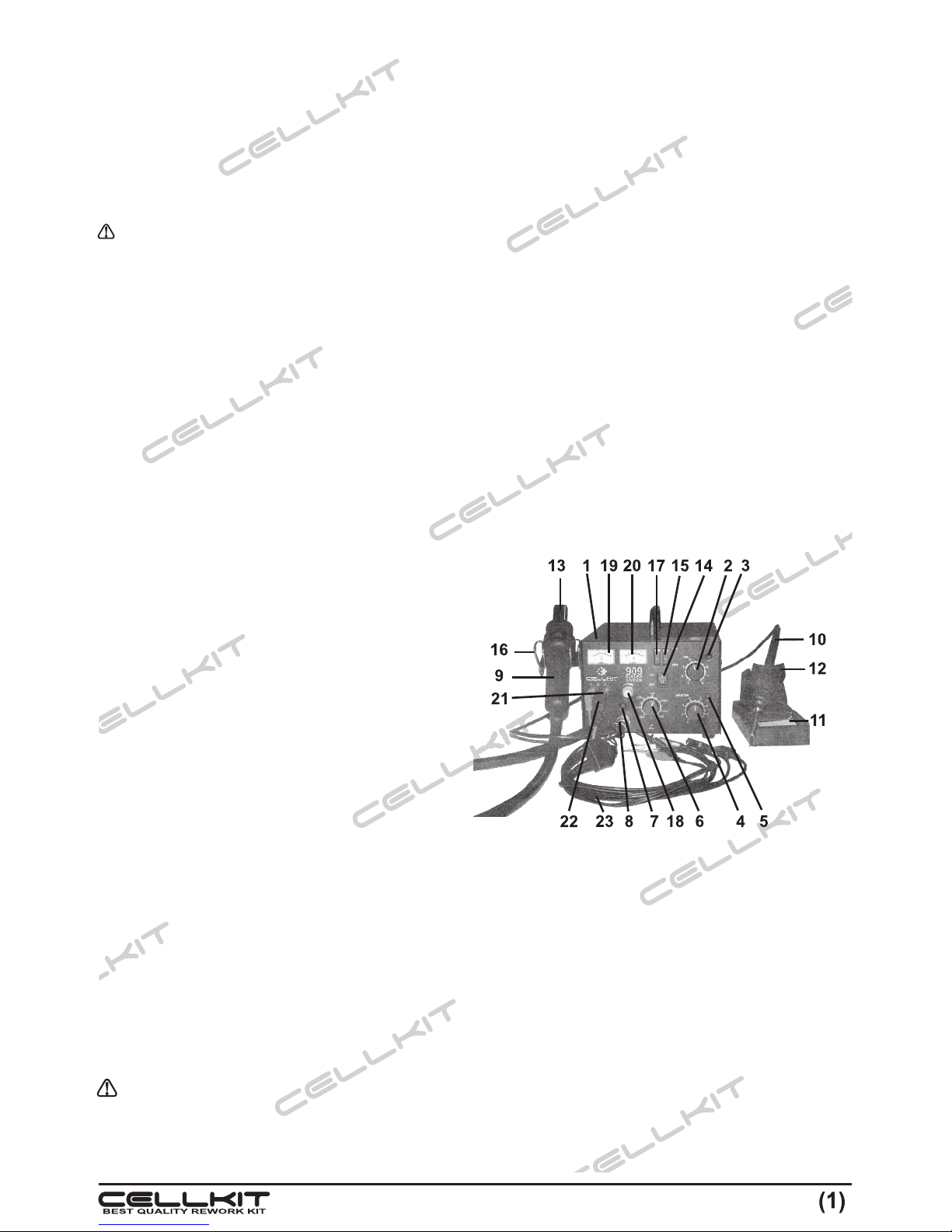

2. Setting up & Operating the 909

2.1. QFP tin removal process

1. Plug for power

2. Switch on the power