USER MANUAL, RSS-1000-CVSI

7000-5970 Rev. A

page 5 of 396

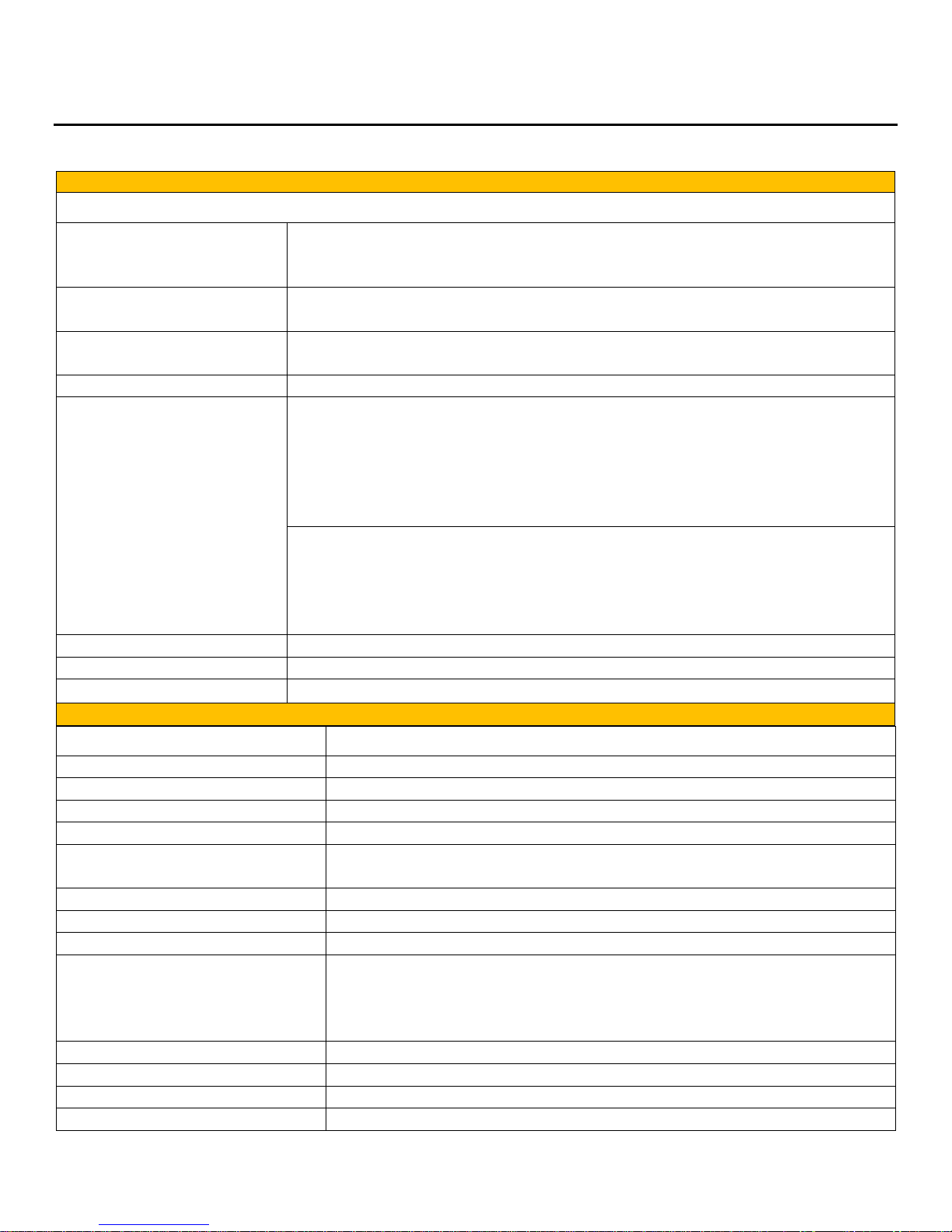

WAY POINTS ............................................................................................................................................ 165

SOLDER WIRE FEEDER ADJUSTMENT ............................................................................................... 166

ADVANCED PROFILE FUNCTIONS ........................................................................................................ 168

EDIT PROFILE .......................................................................................................................................... 168

EDIT PROFILE OVERVIEW ................................................................................................................ 168

SOLDER PARAMETER EDIT .............................................................................................................. 170

PROFILE EDIT ...................................................................................................................................... 175

Edit Transition Speed .......................................................................................................................... 180

Edit Parameter ..................................................................................................................................... 182

Editing a Point Coordinate .................................................................................................................. 183

Editing Line Coordinates .................................................................................................................... 185

Editing Coordinates Using Record Coordinate Function ................................................................... 188

Editing Coordinates Using Offset All Function.................................................................................. 192

Editing Feeder Settings ....................................................................................................................... 197

Edit Order of Features Within a Profile .............................................................................................. 199

Remove a Feature from a Profile ........................................................................................................ 200

MERGE PROFILE ..................................................................................................................................... 201

COMPONENT BASED MERGE........................................................................................................... 201

PRINTED CIRCUIT BOARD ASSEMBLY BASED MERGE ............................................................ 208

GENERATE ARRAY ................................................................................................................................ 216

Examples of Generate Array Settings ..................................................................................................... 218

Single Point Array ................................................................................................................................... 229

Multiple Pattern Array ............................................................................................................................ 232

SET GO-TO LOCATION........................................................................................................................... 238

OFFSET PROFILE ..................................................................................................................................... 239

DRY RUN ................................................................................................................................................... 243

TIP ALIGNMENT .......................................................................................................................................... 245

TIP ALIGNMENT ...................................................................................................................................... 245

CENTER POINT ALIGNMENT ............................................................................................................... 248

CAMERA CALIBRATION & FUNCTIONS ............................................................................................... 256

CALIBRATION ......................................................................................................................................... 256

POSITION VERIFICATION TEST ........................................................................................................... 268

FINE ADJUSTMENT AFTER CAMERA CALIBRATION .................................................................... 270

TAKING A SCREENSHOT....................................................................................................................... 273

OPENING AN IMAGE/SCREENSHOT/ DXF/ GERBER ....................................................................... 277