30

INDEX page

WARNINGS........................................................................................................................................................... 1

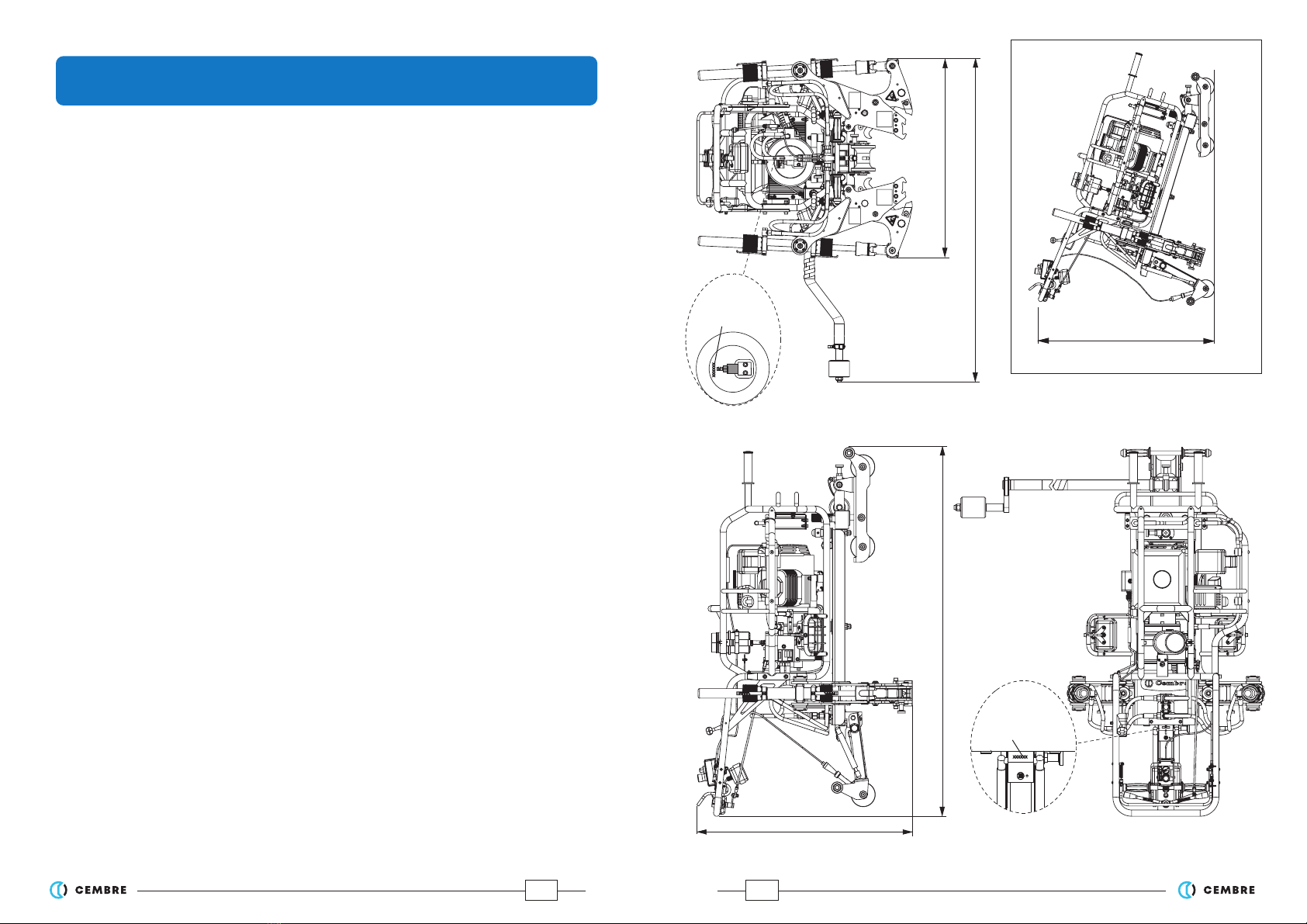

1. GENERAL CHARACTERISTICS.................................................................................................................... 3

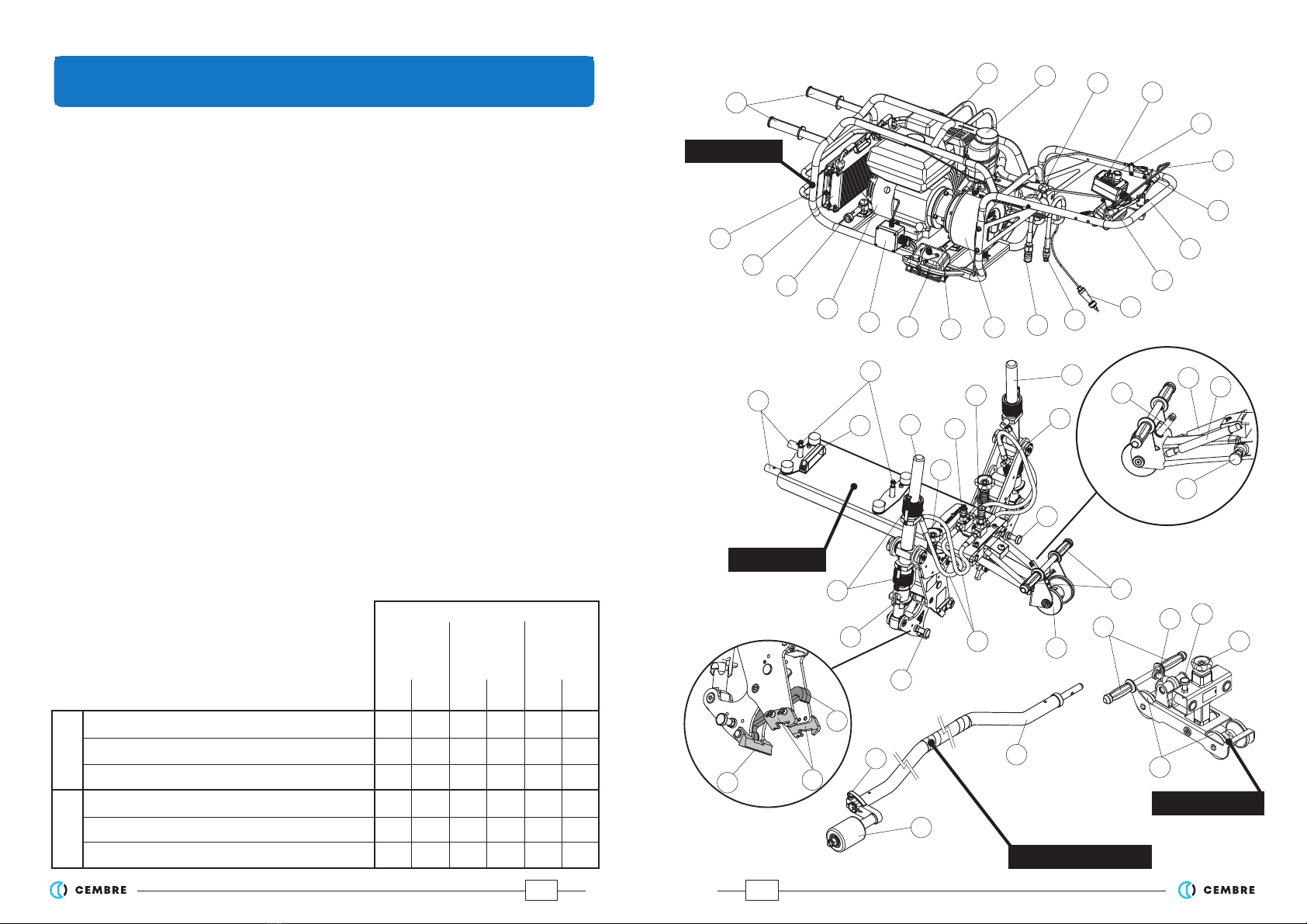

2. MACHINE DESCRIPTION............................................................................................................................... 4

3. UNPACKING .................................................................................................................................................... 6

3.1 Transporting the units ............................................................................................................................... 6

4. INSTRUCTIONS FOR USE.............................................................................................................................. 7

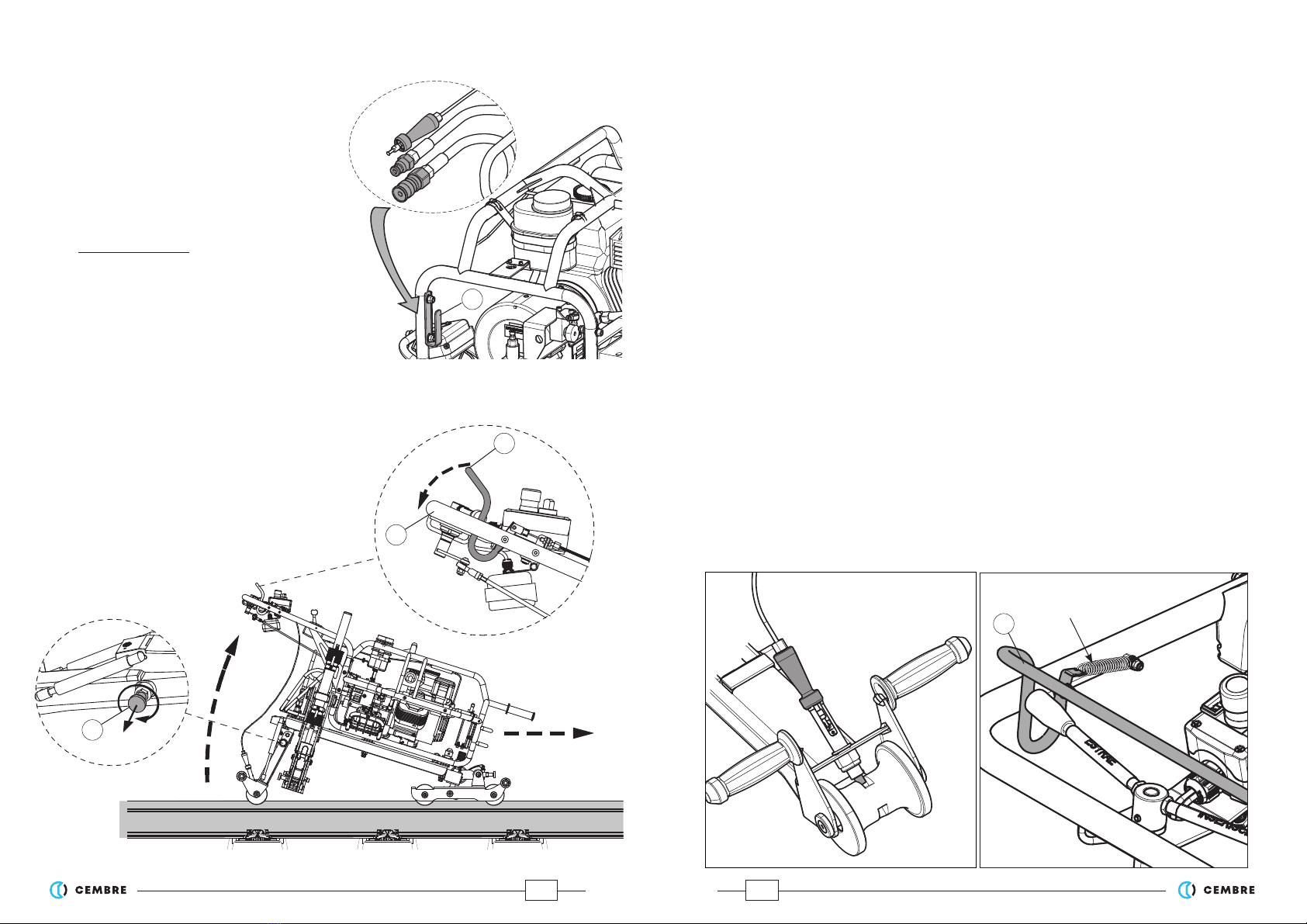

4.1 Assembly of the machine.......................................................................................................................... 7

4.1.1 Braking device.......................................................................................................................................... 8

4.1.2 Disassembly of the machine ................................................................................................................ 9

4.2 Moving the machine.................................................................................................................................. 9

4.3 Controls.......................................................................................................................................................11

4.4 Description of the Pandrol Fastclip ......................................................................................................12

4.5 Preliminary machine adjustments .......................................................................................................13

4.5.1 Centred positioning of contrast jaws ...............................................................................................13

4.5.2 Adjusting horizontal alignment........................................................................................................14

4.5.3 Stable rest of both the contrast jaws................................................................................................14

4.6 Operation ...................................................................................................................................................15

4.6.1 Simultaneous insertion of two Fastclip ...........................................................................................15

4.6.2 Simultaneous extraction of two Fastclip.........................................................................................16

5. ADJUSTING RAM STROKE ........................................................................................................................17

5.1 Adjusting ram stroke for the insertion operations............................................................................17

5.2 Adjusting ram stroke for the extraction operations .........................................................................18

5.1.1 Parking position of the Fastclips........................................................................................................18

5.1.2 Insulatort change position of the Fastclips.....................................................................................19

5.1.3 Complete extraction of the Fastclips from shoulders...................................................................19

6. STARTING THE ENGINE...............................................................................................................................20

7. MAINTENANCE.............................................................................................................................................22

7.1 Routine maintenance of the machine....................................................................................... 22

7.1.1 Maintenance of braking device.........................................................................................................22

7.1.2 Topping up the oil in the hydraulic pump .......................................................................................24

7.1.3 Changing worklight bulbs ..................................................................................................................24

7.1.4 Changing gas springs ..........................................................................................................................25

7.1.5 Maximum pressure valve ....................................................................................................................25

7.2 Routine maintenance of the engine.....................................................................................................25

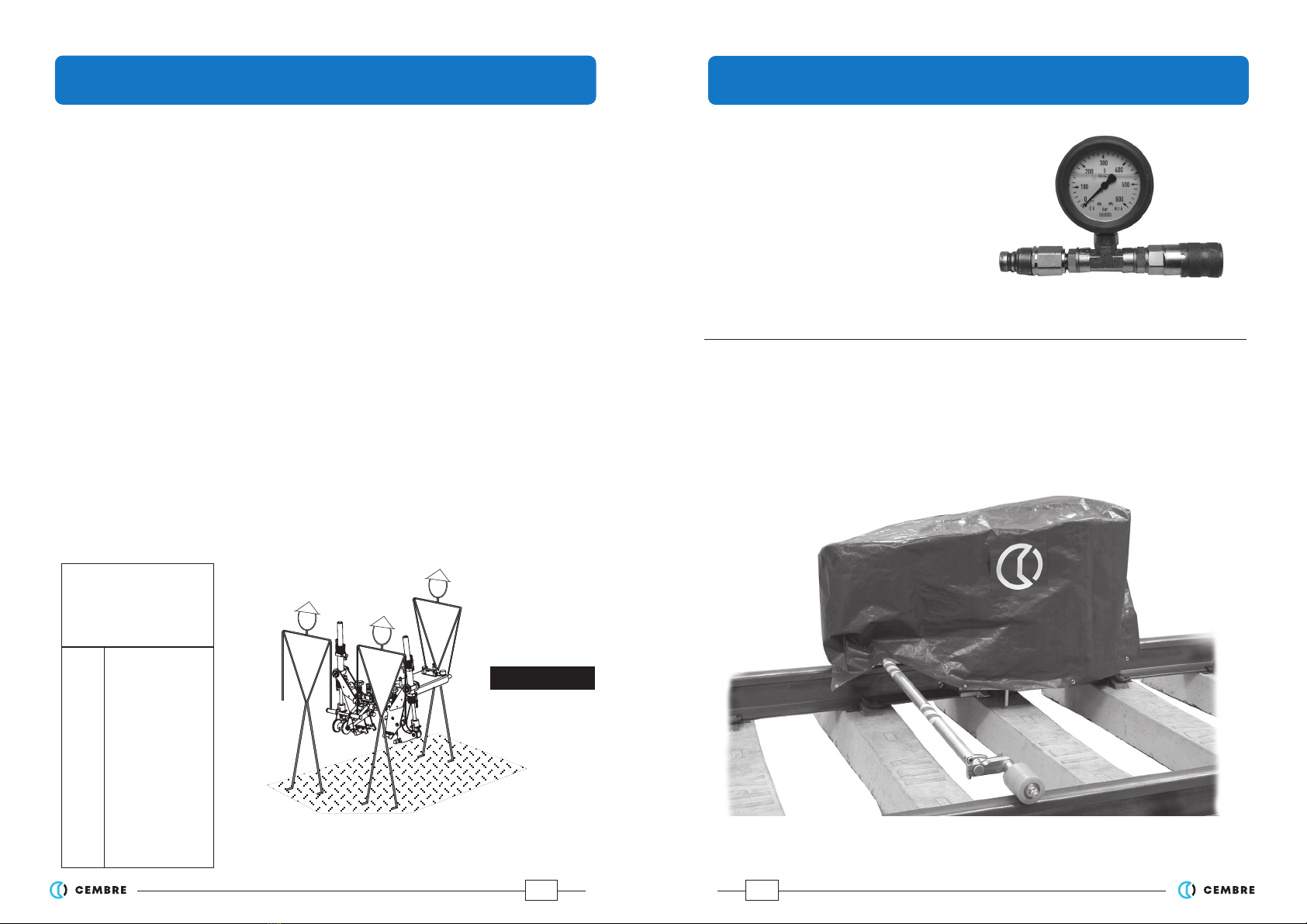

7.3 Long periods of inactivity .......................................................................................................................25

8. ADDITIONAL ACCESSORIES AVAILABLE ON REQUEST........................................................................27

9. RETURN TO CEMBRE FOR OVERHAUL....................................................................................................28

3

– Application range: suitable for inserting and removing Pandrol Fast clips* on standard-

gauge rails (1435 mm).

– Developed force (single clamp): ..................................................................................................29.000 N

– Dimensions: ................................................................................................................. (see Fig. 25, page 29)

– Resistance between rail and wheel: ...............................................................................................≥1 MΩ

– Weight:

– complete machine: ..................................................................................................................................134 kg

– pump unit:

....................................................................................................................................................

55 kg

– clamp unit: .................................................................................................................................................... 65 kg

– carriage: ............................................................................................................................................................9 kg

–

3

rd wheel bar:...................................................................................................................................................5 kg

– Combustion engine:

– type:...............................................................................................4-stroke, overhead valves, one cylinder

– model:.....................................................................................................................

Honda GX200 UT2-SMCR OH

– displacement: ......................................................................................................................................... 196 cm3

– power:............................................................................................................................................ 4.3 kW 5.8 HP

– revs.:.........................................................................................................................................................3600 rpm

– fuel:

.................................................................................................................

unleaded regular grade petrol

– fuel consumption: .............................................................................................. 1.7 litres/hour (3600 rpm)

– fuel tank capacity: .................................................................................................................................3.1 litres

– recommended oil:.....................................................................................................SAE 10W-30 (0.6 litres)

– clutch: ......................................................................................... centrifugal with automatic intervention

– start:......................................................................................................by rope pull with automatic rewind

– Hydraulic pump:

– max. pressure:...........................................................................................................................................42 MPa

– oil supply: .................................................................................................................................5.6 litres/minute

– speed: ..................................................................................................................................................... 3600 rpm

– recommended oil:...................................................................................... ENI ARNICA 32 or equivalents

– Acoustic noise (Directive 2006/42/EC, annexe 1, point 1.7.4.2 letter u)

– The continuous equivalent weighted level (A) of noise pressure

at the working place LpA is equal to ................................................85,2 dB (A), uncertainty KpA ± 4 dB

– The maximum value of instantaneous weighted noise pressure C

at the working place LpCPeak is.....................................................................................................< 130 dB (C)

– The level of noise force produced

by the machine LWA is equal to........................................................ 95,1 dB (A), uncertainty KWA ± 4 dB

–Risks due to vibration (Directive 2006/42/EC, annexe 1, point 2.2.1.1)

Tests carried out in compliance with the indications contained in ISO 5439 Standard, and under

operating conditions much more severe than those normally found, certify that the weighted

root mean square in frequency of the acceleration the upper limbs are exposed to for each

biodynamic reference axis is ahv = 2,44 m/s2uncertainty K ± 0,8 m/s2.

1.

GENERAL CHARACTERISTICS

(*) "Pandrol Fast clip" is a Pandrol Ltd trademark.