© 2014 Power-Tronics, Inc.

Introduction and Functional Description

Caution: Read This Installation

Manual Carefully and Entirely!

Warning: Do not use digital equipment to read voltage, Hz, or amperage

during this installation. Use only Analog sensing equipment! Failure to do so

may result in damage to equipment or in personal injury!

ALWAYS perform all setup procedures off-line

ALWAYS wear eye protection

ALWAYS strip wire insulation properly or use insulated connectors

ALWAYS use analog metering equipment when setting up the regulator

ALWAYS ensure the static exciter receives ample airflow

ALWAYS use adequate fusing

NEVER hold the static exciter in your hand or lap when energized

NEVER install the static exciter in a place it can get wet or is exposed to the elements

NEVER mount the static exciter over a screw, bolt, rivet, seam, or other fastener

NEVER remove the regulator cover while the unit is in operation

NEVER insert a screwdriver or other object under the regulator cover

NEVER touch any exposed part of the SE6000B-3P during operation (LIVE HEATSINKS)

NEVER install a switch in the DC portion of the static exciter’s wiring

NEVER USE A DIGITAL FREQUENCY METER (It can give a false reading!)

Functional Description

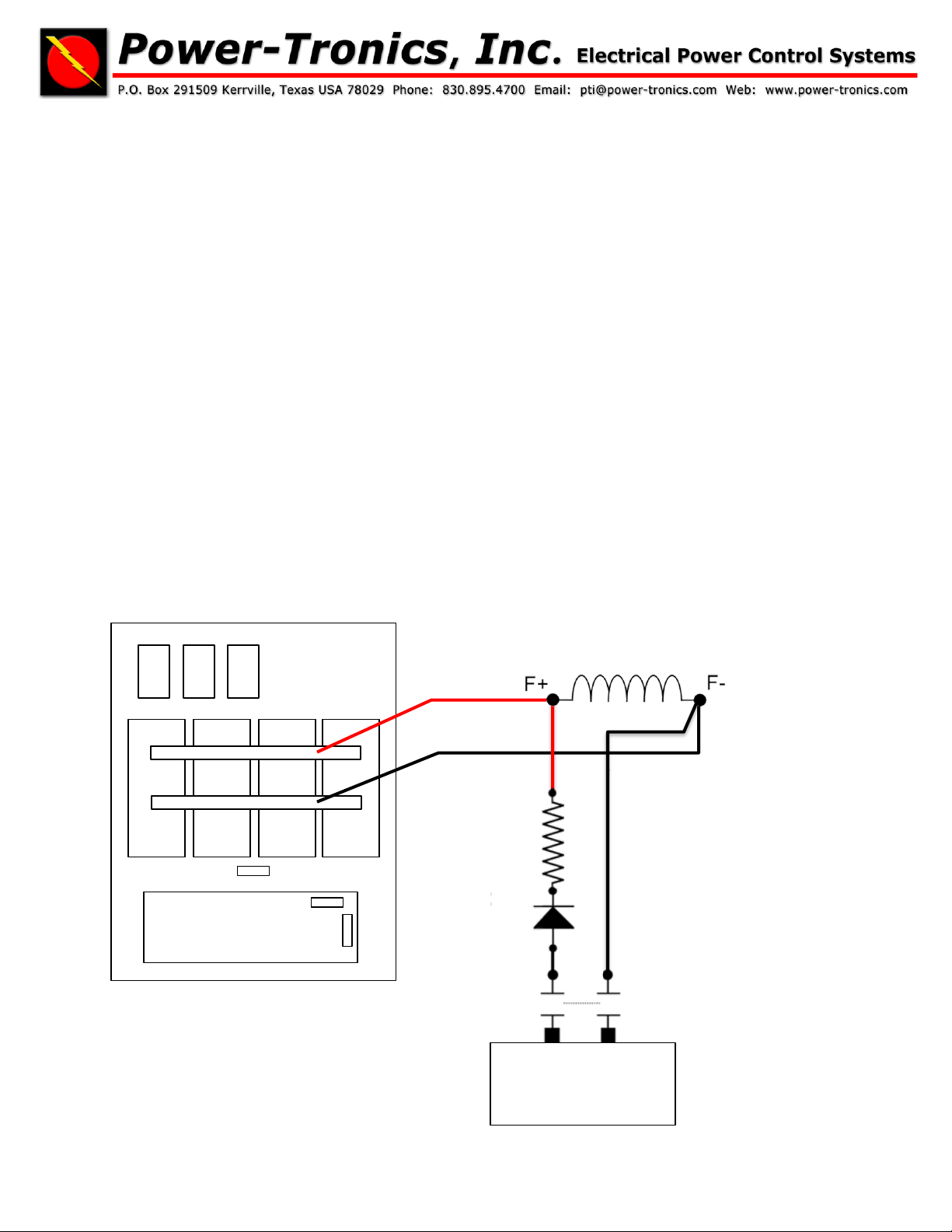

The SE6000B-3P 3-Phase Static Exciter is the result of over 20 years of engineering efforts and offers

high-demand features at a competitive price point. The SE6000B-3P is a proven design and is

engineered to greatly simplify setup while offering extreme reliability. When properly installed, the

SE6000B-3P 3-Phase Static Exciter is designed to provide a lifetime of service.

A Generator voltage regulator has several automated tasks it must perform in order to provide reliable,

clean, and regulated electricity. It must regulate the terminal voltage within its design specifications

and protect both itself and the generator should a fault situation arise.

The SE6000B-3P 3-Phase Static Exciter is designed to replace older obsolete static exciters or

rotating exciters with a minimum of connections and a minimum of required installation space. The

SE6000B-3P 3-Phase Static Exciter contains an internal filter for voltage sensing, internal field-

replaceable 600A fusing, and internal DC field noise suppression. The SE6000B-3P is also designed

to be user-serviceable should a problem arise. Fuse or rectifier replacement in the field takes only

minutes, thanks to the unique modular design of the SE6000B-3P.

The SE6000B-3P features loss of sensing protection and will shut down if sensing voltage is lost. This

feature prevents a runaway condition prevalent in many separate-sensing designs and will result in a

fail-safe shutdown!

Due to its extreme simplicity, the SE6000B-3P 3-Phase Static Exciter is uncommonly reliable and

offers features and regulation accuracy usually only offered by much more complicated and often

much more expensive static exciters.