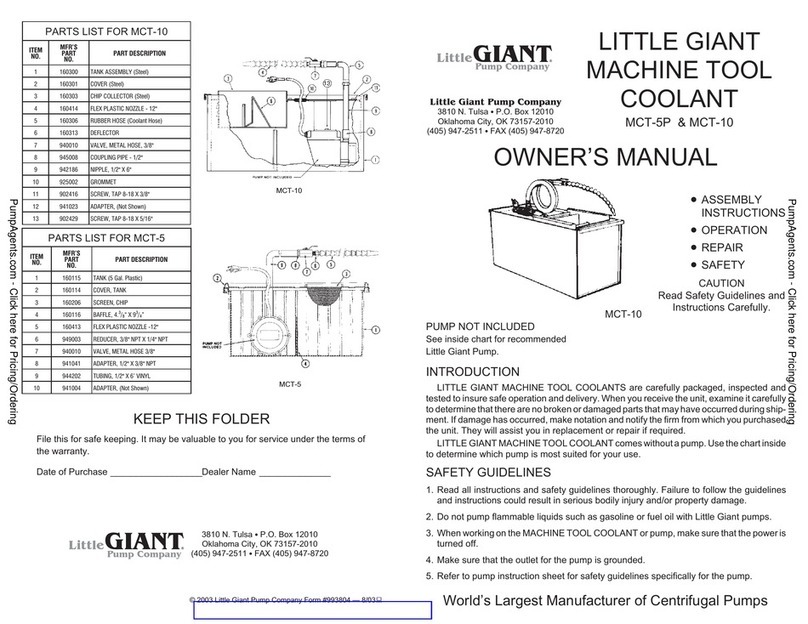

Little Giant RFSN-16 User manual

INTRODUCTION

The Little Giant Model RFSN-16 Liquid Level Control is designed

to be used with Little Giant manual sump, effluent, and sewage

pumps, or other pumps rated within electrical limits noted below.

This control uses a non-mercury switch sealed in plastic float cylin-

der. The switch is activated when the fluid level in the basin causes

the cylinder to float to an approximate 45° angle. This causes the

switch to activate and in turn causes the pump to start.

SAFETY GUIDELINES

READ INSTRUCTIONS AND SAFETY GUIDELINES THOROUGHLY.

FAILURE TO FOLLOW THESE COULD RESULT IN SERIOUS

INJURY OR PROPERTY DAMAGE.

WARNING: Risk of electrical shock! This switch is supplied with a

grounded type attachment plug. The pump used with this switch

must also be equipped with a grounding type attachment plug.

DO NOT REMOVE THE GROUNDING PIN FROM THE PLUG.

To reduce risk of electrical shock, be certain that the switch is

connected only to a properly grounded receptacle. For direct wire

installation (without piggyback plug), refer to Figure 3.

During normal operation the switch and pump are in contact with

water. Also, water may be present in the surrounding area of the

switch and pump. Exercise extreme caution when working near

these areas.

1. Make certain that electrical connections cannot be reached

by rising water. Refer to the National Electrical Code and local

requirements. A separate branch circuit is recommended for

each pump. Do not use an extension cord.

2. Always remove the plug from the receptacle and turn off the

circuit breaker prior to touching, servicing or repairing the

switch or pump.

3. Do not stand in water while changing fuses or resetting circuit

breakers or repairing the switch.

ELECTRICAL

120V AC, 60Hz, SINGLE PHASE

Maximum pump running current: 15 Amp

Maximum pump starting current: 55 Amp

Recommended for use on pumps of 1 HP or less provided pump

draw does not exceed 15 running amps or 55 starting amps.

230V AC, 60Hz, SINGLE PHASE

Maximum pump running current: 15 Amp

Maximum pump starting current: 35 Amp

Recommended for use on pumps of 2 HP or less provided pump

amp draw does not exceed 15 running amps or 35 starting

amps.

NOTE: This pump control should be used only with pumps equipped

with integral thermal overload protection.

INSTALLATION

(in 18" minimum dia. basins)

1. DECIDE ON THE PUMPING RANGE FOR YOUR

INSTALLATION: Refer to the pumping range chart below to

determine the cable length required from mounting point to

float. To insure proper installation, a 3.5" minimum tether length

is recommended.

2. INSTALLATION (refer to Figure 1): Attach float cable to large

mounting strap using the two small cable ties provided. Space

small ties on each side of clear friction pad, a minimum of one

inch apart (see Figure 2). Then fasten the large strap securely

to the discharge pipe or other similar mounting. NOTE: The

large strap and two small cable ties are releasable, which

permits readjustment or removal of either strap or ties.

3. TESTING

a. Without water present, plug pump cord into switch “piggy-

back” plug (refer to Figure 4).

b. Plug piggyback plug into properly grounded outlet.

c. Lift float and listen for pump to operate.

PUMPING RANGE

(approximate measurements, in inches)

PUMPING RANGE (DIM “A”) 3.5 5 7 9 11 13 15 17

TETHER LENGTH (DIM “B”) 5 6.3 8 10 11.7 13.5 15.2 17

RFSN-16

Liquid Level Control

Non-Mercury/Float Type

Catalog No. 599211

Cord Length 20'

Figure 1. Typical Installation

Figure 2. Typical Installation

Little Giant

P. O. Box 12010

Oklahoma City, OK 73157-2010

405.947.2511 • Fax: 405.947.8720

www.LittleGiant.com

PumpAgents.com - Click here for Pricing/Ordering

PumpAgents.com - Click here for Pricing/Ordering

230V AC DIRECT WIRING

FOR 230 VAC DIRECT WIRING INSTALLATION, REFER TO

FIGURE 3 (SCHEMATIC) BELOW.

WARNING: In a 230V direct wire installation, one side of the

line going to the pump is always “HOT”. This condition exists

whether the float switch is “ON” or “OFF”. To avoid hazards

when installing or servicing, install a double-pole disconnect

near pump installation.

Check local electrical and building codes before installing. This

installation must be in accordance with their regulations as

well as the most recent edition of the National Electrical Code

Handbook (NEC).

NOTE: Little Giant Pump Company cannot be responsible for

damages caused by the faulty or negligent installation of this control.

If you feel that you may encounter problems in installing this device,

we respectfully suggest you engage the services of a competent

plumber, electrician, or qualified service person.

ADDITIONAL INFORMATION

CAUTION: To prevent damage to pump, do not set switch turn-off

level below 2 inches above bottom of pump base. Also be sure

that the pump is secured in its position so the float will not become

stuck between the pump and the basin, which could prevent the

pump from turning “ON” or “OFF”. Be sure the cable tie is secure

so the switch cord does not accidentally slip and change the

pre-set ON/OFF levels.

©Copyright 2003 Little Giant

Form 994885 — 11/2003

Little Giant Print Services

For Warranty or Repair, please contact. . . . . . . . . . . . 1.888.572.9933

For Technical Assistance, please contact. . . . . . . . . . 1.888.956.0000

www.LittleGiant.com

Figure 3. 230V Direct Wire Installation Figure 4. Piggyback Plug Installation

Manual pump operation possible by plugging pump directly into outlet.

LIMITED WARRANTY

Your Little Giant product is guaranteed to be in perfect condition when it leaves

our Factory. It is warranted against defective materials and workmanship for a

period of 12 months (90 day warranty on Models: 1-AA-O.M., GKPK-SC, PP-1,

PPS-1, PP-12, PPS-12 , PP-230 and Cooler King) from date of purchase by

the user. No warranty on brush wear in Model 35-O.M. and impeller or cam in

Models PP-1, PP-12, and PP-230.

Any product that should fail for either of the above two reasons and is still within

the warranty period will be repaired or replaced at the option of Little Giant as

the sole remedy of buyer. For our customers in the CONTINENTAL UNITED

STATES: Please return the defective unit, postage paid, to the factory at 301

N. MacArthur, Oklahoma City, OK 73127-6616. All defective product returned

under warranty will be fully inspected to determine the cause of failure before

warranty is approved.

For our customers located elsewhere; it is not economical, due to duties and

freight, to return the pump to the factory for inspection. Please return the defective

unit to any authorized distributor or dealer with a brief written explanation of the

problem. If there are no apparent signs of customer abuse, unit will be repaired

or replaced. If dispute arises over replacement of the pump, the distributor or

dealer is to segregate such items and hold for inspection by a representative of

Little Giant Pump Company or notify factory with details of the problem for factory

disposition and settlement of warranty claim.

DISCLAIMER: THE FOREGOING WARRANTY IS AN EXCLUSIVE WARRANTY

IN LIEU OF ANY OTHER EXPRESS WARRANTIES. ANY IMPLIED WARRANTIES

(INCLUDING, BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE) TO THE

EXTENT EITHER APPLIES TO A PUMP SHALL BE LIMITED IN DURATION TO THE

PERIODS OF THE EXPRESS WARRANTIES GIVEN ABOVE.

Warranty will be VOID if any of the following conditions are found:

1. Sealed motor housing opened.

2. Product connected to voltage other than indicated on nameplate.

3. Cord cut off to a length less than three feet.

4. Pump allowed to operate dry (fluid supply cut off).

5. Pump used to circulate anything other than fresh water, light oils, or other

mild liquids at approximately room temperature.

6. Product abuse by customer.

Any oral statements about the product made by the seller, the manufacturer, the

representatives or any other parties, do not constitute warranties, shall not be

relied upon by the user and are not part of the contract for sale. Seller’s and man-

ufacturer’s only obligation, and buyer’s only remedy, shall be the replacement

and/or repair by the manufacturer of the product as described above. NEITHER

SELLER NOR THE MANUFACTURER SHALL BE LIABLE FOR ANY INJURY,

LOSS OR DAMAGE, DIRECT, INCIDENTAL OR CONSEQUENTIAL (INCLUDING,

BUT NOT LIMITED TO INCIDENTAL OR CONSEQUENTIAL DAMAGES FOR

LOST PROFITS, LOST SALES, INJURY TO PERSON OR PROPERTY, OR ANY

OTHER INCIDENTAL OR CONSEQUENTIAL LOSS), ARISING OUT OF THE USE

OR THE INABILITY TO USE THE PRODUCT AND THE USER AGREES THAT

NO OTHER REMEDY SHALL BE AVAILABLE TO IT. Before using, the user shall

determine the suitability of the product for the intended use, and user assumes

all risk and liability whatsoever in connection therewith.

Some states and countries do not allow limitations on how long an implied war-

ranty lasts or the exclusion or limitation of incidental or consequential damages,

so the above limitations or exclusions may not apply to you. This warranty gives

you specific legal rights, and you may also have other rights which vary from

state to state and country to country.

The National Electric Code (in the USA) and similar codes in other countries require

a Ground Fault Circuit Interrupter (GFCI) to be installed in the branch circuit sup-

plying fountain equipment rated above 15 volts. 115 volt GFCIs (with various cord

lengths) are in stock, and we recommend each pump be used with a GFCI.

PumpAgents.com - Click here for Pricing/Ordering

PumpAgents.com - Click here for Pricing/Ordering

This manual suits for next models

1

Other Little Giant Industrial Equipment manuals