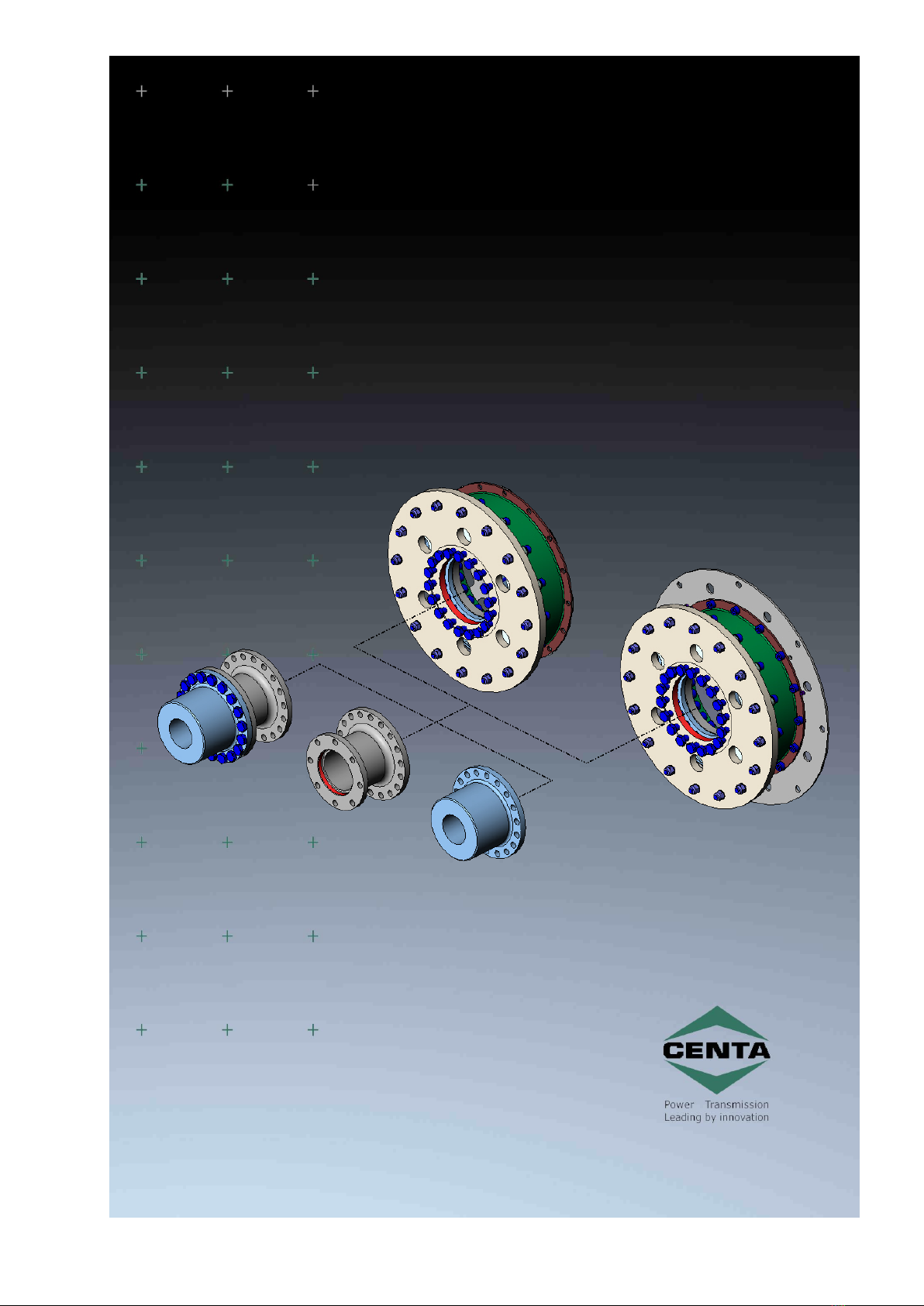

Assembly and operating instructions

CENTAX-N

033N-00035…00075-F.00

CENTA Antriebe Kirschey GmbH 2 / 47

Contents

1General remarks ..................................................................................... 5

2Safety ..................................................................................................... 6

2.1 Safety remarks.................................................................................. 6

2.1.1 Signal words ......................................................................... 6

2.1.2 Pictograms ............................................................................ 7

2.2 Qualification of deployed personnel ...................................................... 7

2.3 Intended application........................................................................... 7

2.4 Application not in compliance with the intended use ............................... 9

3Delivery, transport, storage and disposal ............................................. 10

3.1 Delivery...........................................................................................10

3.2 Transport.........................................................................................10

3.3 Storage ...........................................................................................10

3.3.1 Storage location....................................................................11

3.3.2 Storage of couplings / flexible elements ...................................11

3.4 Disposal...........................................................................................11

4Technical Description............................................................................ 12

4.1 Characteristics..................................................................................12

4.2 Specifications ...................................................................................12

5Alignment of the units being connected................................................ 13

5.1 Axial alignment.................................................................................14

5.2 Radial alignment...............................................................................16

5.3 Angular alignment.............................................................................18

6Mounting .............................................................................................. 20

6.1 General assembly instructions ............................................................20

6.2 Sequence of mounting.......................................................................22

6.3 Mounting the hub (if necessary) .........................................................24

6.3.1 Mounting the hub with keyway ...............................................24

6.3.2 Mounting the hub with conical oil interference fit.......................26

6.3.3 Mounting the CENTA-conical clamping hub ...............................29

6.4 Mounting the adapter (10; if necessary) ..............................................31

6.5 Aligning the units..............................................................................31

6.6 Mounting the pre-mounted rubber element assembly (C/D) to the

flywheel...........................................................................................32

6.6.1 Mounting the pre-mounted rubber element assembly (C) and

sheet to the flywheel .............................................................32

6.6.2 Mounting the pre-mounted rubber element assembly (D) with

adapter to the flywheel ..........................................................34

6.7 Mounting the adapter (1.4) ................................................................36