Contents

1 Introduction ....................................................................................................................................... 1

Purpose of this document.......................................................................................................... 1

Obligations and liability ............................................................................................................. 1

2 Safety information ............................................................................................................................. 2

Operating personnel.................................................................................................................. 2

Intended use .............................................................................................................................. 2

Improper use.............................................................................................................................. 2

EC Declaration of Conformity .................................................................................................... 3

Radio Approval........................................................................................................................... 5

3 Glossary.............................................................................................................................................. 6

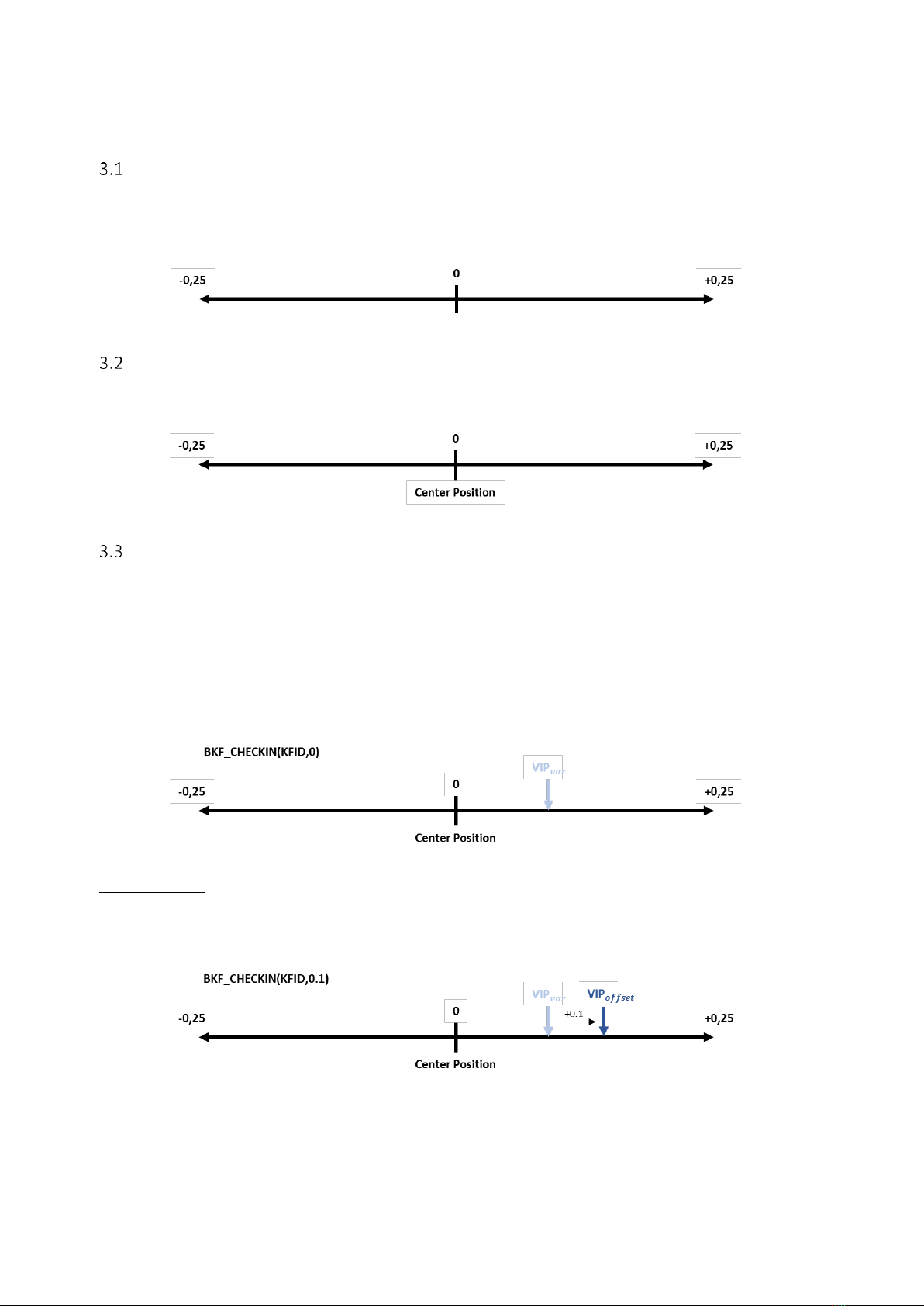

KOMflex adjustment range........................................................................................................ 6

Centre position definition.......................................................................................................... 6

VIP definition.............................................................................................................................. 6

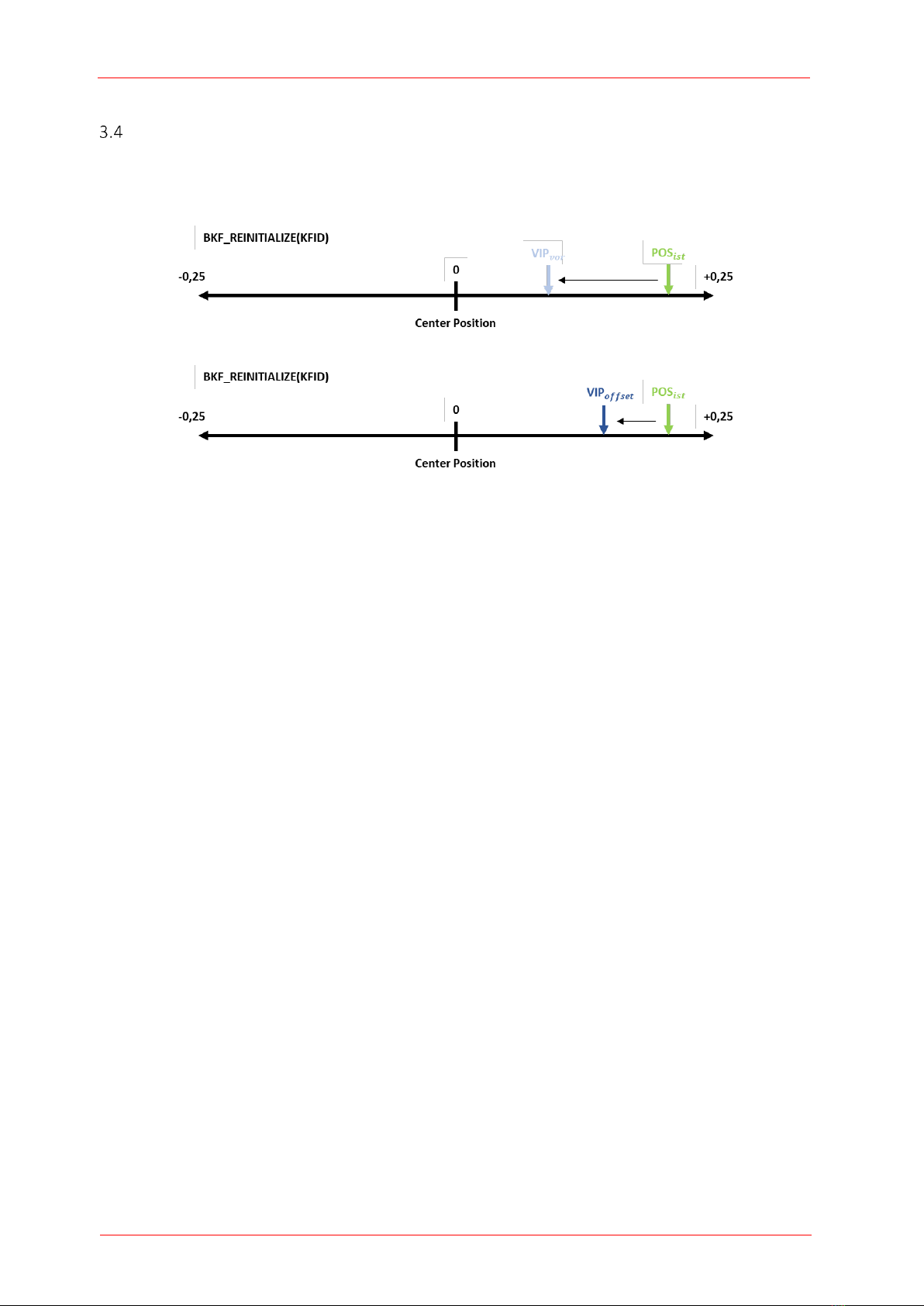

Reinitialisation ........................................................................................................................... 7

4 System overview................................................................................................................................ 8

5 Description of the RC66 wireless receiver......................................................................................... 9

RC66 standby mode................................................................................................................... 9

KOMflex mode ........................................................................................................................... 9

Pairing mode............................................................................................................................ 10

6 Description of the KOMflex precision spindle head ........................................................................ 11

Technical data.......................................................................................................................... 11

KOMflex system description.................................................................................................... 12

Required accessories ............................................................................................................... 12

Description of the KOMflex modes.......................................................................................... 13

6.4.1 Manual adjustment with magnetic pen........................................................................... 13

6.4.2 Automatic adjustment via NC cycle................................................................................. 14

Emergency shutdown .............................................................................................................. 15

If the KOMflex is in an active state, but does not receive any commands from the interface IF20, the

head is deactivated after a timeout of 5 minutes and goes into standby mode................................. 15

Possible scenarios in which an emergency shutdown may occur....................................................... 15

•Switch-off command does not reach the KOMflex, e.g. problems with radio connection ......... 15

•The emergency stop or reset of the NC is activated.................................................................... 15

7 Getting started and tool mounting.................................................................................................. 15

Initial commissioning of the KOMflex...................................................................................... 15

Indicating the basic settings..................................................................................................... 16