Ceyear 1465 Series User manual

1465 Series

Signal Generator

Quick Start Guide

China Electronics Technology Instruments Co., Ltd

This manual applies to the following types of signal generators, based on firmware version 1.0 and

above.

1465A Signal Generator (100kHz ~ 3GHz)

1465B Signal Generator (100kHz ~ 6GHz)

1465C Signal Generator (100kHz ~ 10GHz)

1465D Signal Generator (100kHz ~ 20GHz)

1465F Signal Generator (100kHz ~ 40GHz)

1465H Signal Generator (100kHz ~ 50GHz)

1465L Signal Generator (100kHz ~ 67GHz)

1465A-V Signal Generator (100kHz ~ 3GHz)

1465B-V Signal Generator (100kHz ~ 6GHz)

1465C-V Signal Generator (100kHz ~ 10GHz)

1465D-V Signal Generator (100kHz ~ 20GHz)

1465F-V Signal Generator (100kHz ~ 40GHz)

1465H-V Signal Generator (100kHz ~ 50GHz)

1465L-V Signal Generator (100kHz ~ 67GHz)

Edition: A.3 September 2018, China Electronic Technology Instruments Co., Ltd

Address: No. 98, Xiangjiang Road, Qingdao City, China

Tel.: (86) 0532-86896691

Web: www.ceyear.com

E-mail: sales@ceyear.com

Postcode: 266555

Preface

Thank you very much for

choosing 1465 series signal

generator developed and

produced by China Electronics

Technology Instruments Co.,

Ltd. Our products, high-tech,

precise and sophisticated, are

highly cost effective among

similar products.

Pursuing to maximally meet

your demands, we will provide

you with quality measuring

instruments and first-class

after-sales services. Adhering

to our consistent tenet of "good

quality and considerate

service", we promise to provide

you with satisfactory products

and services.

Manual Number

2.827.1202 SKCN

Edition

A.3 2018.9

CHINA ELECTRONICS

TECHNOLOGY

INSTRUMENTS CO., LTD

Manual Authorization

The content of this manual is

subject to changes without

prior notice. The right of final

interpretation of the content

and terminology used in this

manual belongs to China

Electronic Technology

Instruments Co., Ltd.

The copyright of this manual

belongs to China Electronics

Technology Instruments Co.,

Ltd. Without authorization of

the company, no organization

or individual is allowed to

modify the content of this

manual or copy and

disseminate it for profit. China

Electronics Technology

Instruments Co., Ltd. reserves

the right to seek legal liabilities

of infringers.

Product Warranty

This product is under warranty

for 18 months from the date of

delivery. During the warranty

period, the manufacturer will

repair or replace the damaged

parts according to the actual

situation. Please refer to

related contracts for specific

maintenance and operation

matters.

Product Quality

Certification

We guarantee that this product

meets the specifications in the

manual as from the date it is

manufactured. The calibration

and measurement have been

completed by organizations of

metrology with national

qualifications, and relevant

information has been provided

for your reference.

Quality / Environmental

Management

This product has complied with

the quality and environmental

management systems in the

process of R&D, manufacturing

and testing. The company has

required qualification and has

passed ISO 9001 and ISO

14001 management systems.

Safety Precautions

A Warning sign indicates the

existence of danger. It prompts

users to pay attention to a

certain operation process,

operation method or similar

situation. Failure to comply with

the rules or correct operation

may cause personal injury. Do

not proceed to the next step

after completely understanding

and meeting the warning

conditions.

A Caution sign prompts some

important information, which

will not cause danger. It

prompts users to pay attention

to a certain operation process,

operation method or similar

situation. Failure to follow the

rules or operate correctly may

result in instrument damages or

loss of important data. Do not

proceed to the next step after

completely understanding and

meeting the conditions.

Caution

Be careful

Warning

1465 Series Signal Generator

Contents

1

Contents

1 Manual Navigation................................................................................................................................... 1

1.1 About the Manual.......................................................................................................................... 1

1.2 Related Documents ...................................................................................................................... 1

2 Getting Prepared..................................................................................................................................... 3

2.1 Preparations before Operation ..................................................................................................... 3

2.2 Operating System Configuration................................................................................................. 12

2.3 Appearance of Instrument........................................................................................................... 16

3 Typical Applications............................................................................................................................... 21

3.1 Setting CW RF Output Frequency at 500 MHz and Power Level at 0 dBm............................... 21

3.2 Generating AM Signals: LO Frequency of 3.5 GHz, Modulation Rate of 1 kHz, and AM Depth of

30%................................................................................................................................................... 24

3.3 Generating Pulse Modulation Signals: LO Frequency of 3.5 GHz, Pulse Width of 50 us, and

Period of 1 ms................................................................................................................................... 26

3.4 Configuring Step Sweep: Start Frequency of 1 GHz, Stop Frequency of 3 GHz, and 5 Step

Points ................................................................................................................................................ 27

3.5 Configuring List Sweep: Start Frequency of 1 GHz, Stop Frequency of 3 GHz, and 5 List Points29

3.6 Configuring Ramp Sweep: Start Frequency of 1 GHz, Stop Frequency of 3 GHz .................... 31

3.7 Configuring Baseband: Data Source PN Sequence, Modulation Type QPSK, and Code Element

Rate of 4 Msps.................................................................................................................................. 32

3.8 Sequence Playback Function ..................................................................................................... 34

3.9 Arbitrary Wave Playback Function.............................................................................................. 36

3.10 Selecting ALC Bandwidth ......................................................................................................... 38

3.11 Setting Reset State................................................................................................................... 39

3.12 Storing / Calling a User State ................................................................................................... 40

3.13 Copying / Moving / Deleting Files............................................................................................. 42

4 Getting Help........................................................................................................................................... 43

4.1 Basic Checks .............................................................................................................................. 43

4.2 Help Information.......................................................................................................................... 44

4.3 Repair.......................................................................................................................................... 45

1465 Series Signal Generator

Contents

2

1 Manual Navigation

1.1 About the Manual

1

1 Manual Navigation

This chapter introduces the function, chapters and main contents of the Quick Start Manual for 1465

Series Signal Generator, as well as instrument-related documents provided to users.

About the Manual ………………………………………………………………………………………1

Relevant Documents …………………………………………………………………………………1

1.1 About the Manual

This manual introduces the basic functions and operation methods of 1465 series signal generator.

It describes such information as the operations before startup, system settings, features of front and rear

panels, basic operation methods and examples, simple fault diagnosis and repair methods, so as to help

you get familiar with and master the operations and key points of this instrument as soon as possible. In

order to facilitate your proficiency in using the instrument, please read this manual carefully before

operating the instrument, and follow this manual for correct operation.

This Quick Start Manual contains the following chapters:

Getting Prepared

This chapter introduces such information as the pre-operation inspection, operating system

configuration, initialization configuration and appearance of 1465 series signal generator with the

purpose of helping users make early preparations for correct and safe operation of this instrument.

Typical Applications

This chapter gives a detailed description of the operation with examples, such as setting up RF CW

(continuous wave), modulation, sweep, data storage / calling, according to the frequency and

importance of the functions of the instrument so as to help users get familiar with the use of 1465 series

signal generator as soon as possible.

Getting Help

This chapter includes basic methods for fault diagnosis, solutions and repair of the instrument.

1.2 Related Documents

The product documentation of 1465 series signal generator includes:

Quick Start Manual

Online Help

User's Manual

Programmer’s Manual

Quick Start Manual

This manual introduces the configuration of the instrument and basic operations for startup

configuration with the purpose of allowing users to quickly understand the characteristics of the

instrument, master basic settings and basic local and programmable operations. It contains the following

chapters:

Getting Prepared

Typical Applications

Getting Help

User's Manual

This manual gives a detailed introduction of the functions and operations of the instrument,

including configuration, program control and maintenance information, with the purpose of instructing

users to comprehensively understand the features of the product and master common testing methods

1 Manual Navigation

1.2 Related Documents

2

of the instrument. It mainly contains the following chapters:

Manual Navigation

Summary

Getting Started

Operation Guide

Menus

Remote control

Fault Diagnosis and Repair

Technical Indicators and Testing Methods

Appendixes

Programmer’s Manual

This manual gives a detailed introduction of programming foundation, SCPI foundation, SCPI

commands, programming examples and I / O driver function library with the purpose of instructing users

to quickly and comprehensively master the program control commands and methods of the instrument. It

mainly contains the following chapters:

Remote Control

Program Control Commands

Programming Examples

Error Description

Appendixes

Online Help

The online help is integrated into the instrument for providing quick help via text navigation so as to

facilitate the local and remote operations of users. Both the hard keys on the front panel or the toolbar in

the user interface provide shortcuts to activate this function. Its main chapters are the same as that of

the User’s Manual.

2 Getting Prepared

2.1 Preparations before Operation

3

2 Getting Prepared

Preparations before Operation ………………………………………………………………………3

Operating System Configuration ……………………………………………………………………12

2.1 Preparations before Operation

This chapter introduces the precautions before setting and using the 1465 series vector signal

generator for the first time.

Unpacking ………………………………………………………………………………………………4

Instrument Placement and Installation ………………………………………………………………5

Power on / off ……………………………………………………………………………………………5

Correct Use of Connectors ……………………………………………………………………………7

User Check ……………………………………………………………………………………………9

Online Help ……………………………………………………………………………………………10

Avoid damaging the instrument

To avoid electric shock, fire and personal injury:

Do not open the chassis without authorization.

Do not attempt to disassemble or modify any part not specified in this manual. Disassembly

without permission may lead to decrease in the electromagnetic shielding efficiency and damage of

internal parts, which will affect the reliability of the product. If the product is under warranty, we will no

longer provide free maintenance.

Read carefully the section of "2.2 Safe Use Guide" of the User’s Manual and the following

operation safety precautions. Attention should also be paid to specific operating environment

requirements mentioned in the data pages.

Electrostatic protection

Please pay attention to the anti-static measures in the workplace to avoid damages to the

instrument. Please refer to the section "2.2 Safe Use Guide" of the manual for details.

Caution

Warning

!

2 Getting Prepared

2.1 Preparations before Operation

4

When operating the instrument, please note:

Improper operating position or measurement settings may damage the instrument or instruments

connected to it. Please pay attention to the following before power-on of the instrument:

Ensure that the fan blades are not blocked, the radiator holes are unobstructed, and the

distance between the instrument and the wall is at least 10 cm.

Keep the instrument dry.

Place the instrument flat and reasonably.

The ambient temperature meets the requirements specified in the data pages.

The input signal power of the port meets the specified range.

The signal output port is connected correctly without overloading.

Influence of electromagnetic interference (EMI):

EMI will affect the measurement results, therefore:

Please select suitable shielded cables, double shielded RF / network connection cables, for

instance.

For opened cable connection ports, please close temporarily unused output ports or connect

matching loads to the ports in time.

Pay attention to refer to the EMC level specified in the reference data page.

2.1.1 Unpacking

2.1.1.1 Visual Examination

Step 1. Check the packing box and shock-proof package of the instrument for damages. If there are

no damages, keep the outer package for future use and proceed with the following steps.

Step 2. Unpack the instrument and check it and enclosed items for damages.

Step 3. Check the above items carefully according to Table 2.1.

Step 4. In case of any damages or mistakes of the packing box, the instrument and enclosed

articles, it is strictly forbidden to turn on the power! Please contact our Customer Service Center

according to the contact information provided in the inside front cover or "4.3 Repair", and we will repair

or replace it as soon as possible according to the actual situation.

Handling: Because the instrument and the packing box are heavy, they should be handled by two

people together with care.

Caution

Tip

Caution

2 Getting Prepared

2.1 Preparations before Operation

5

2.1.1.2 Model Confirmation

Table 2.1 List of enclosed items for 1465 signal generator

Name

Qty

Function

Generator:

1465

1

—

Standard:

Three-core power cord

1

User's Manual

1

—

Programmer’s Manual

1

—

Packing List

1

—

Product Qualification Certificate

1

—

2.1.2 Instrument Placement and Installation

In order to ensure normal functionality of 1465 series signal generator, please note:

The operating site should meet: The operating environment requirements, heat dissipation

requirements, and correct electrostatic protection measures should be taken with reference to the

section "3.1.1.2 Environmental Requirements" in the User's Manual.

The operating requirements of a vertical instrument should be met: The instrument can be

placed horizontally on a worktable equipped with an anti-static table mat or supported by its own legs.

For details, please refer to the section "2.2.2 Operational Status and Location" in the User’s Manual.

Attention should be paid when deploying legs of the instrument:

To ensure instrument stability and personal safety, please fully deploy or retract the legs.

When the legs are deployed, do not move the instrument or operate or place articles under the

instrument.

In case of overload, the legs may break. When the legs are deployed, the maximum load shall

not exceed 500 N.

2.1.3 Power on / off

Methods and precautions for switching on / off the instrument are as follows:

2.1.3.1 Connecting Power Supply

Before the first power-on, please confirm the power supply parameters and the power cord. For

details, please refer to precautions before power-on in section 3.1.1.3 in the User’s Manual.

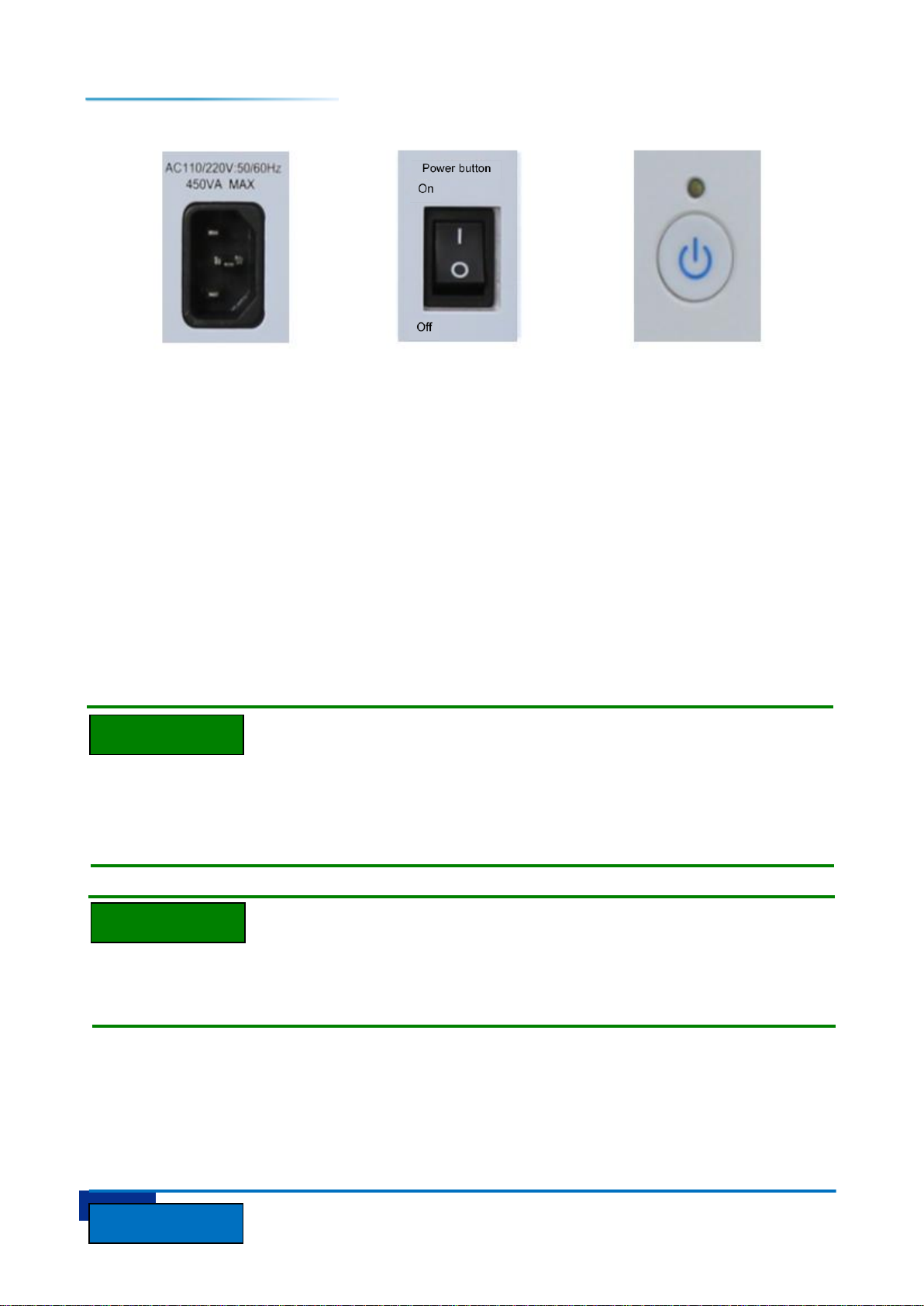

Step 1. Connect the power cord: Connect one end of the power cord delivered with the signal

generator in the packing box or a three-core power cord conforming to the requirements to the power

socket on the rear panel of the signal generator (Figure 2.1), and the other end to a conforming AC

power supply.

Step 2. Turn on the power switch on the rear panel: As shown in Figure 2.2, observe the standby

indicator above the front panel power switch (Figure 2.3) till it turns yellow.

Step 3. Turn on the power switch on the front panel: As shown in Figure 2.3, do not connect any

device to the signal generator before startup. If everything is normal, you can turn it on, and then the

indicator above the front panel power switch will turn green.

Be Careful

!

2 Getting Prepared

2.1 Preparations before Operation

6

Figure 2.1 Power socket Figure 2.2 Rear panel power switch Figure 2.3 Front panel power switch

2.1.3.2 Turning on / off the Instrument

1) Turning on the instrument

Step 1. Turn on the back panel power switch ("|").

Step 2. Turn on the power switch in the lower left corner of the front panel (Figure 2.3), and then the

power indicator above the power switch will change from yellow to green.

Step 3. The user interface on the front panel of the signal generator will gradually display the

relevant information of the start-up process of the instrument: Firstly, the manufacturer's information is

briefly displayed, and then the operating system menu will be displayed. There are two options in the

menu, and users need not operate the menu during normal operation. Windows 7 will be started

automatically after the timer shows 0.

Step 4. After Windows 7 is started successfully, the system will automatically run the initialization

program of the signal generator and displays the main operation menu of the signal generator.

The instrument is now in an operational state.

10MHz Time Base and Preheating

In order to keep the 10 MHz time base of 1465 series signal generator at the operating temperature

during cold start, it is necessary to preheat it for a period of time. The signal generator does not need

time for preheating when it is started from the standby state. The instrument needs to be preheated for

two hours when testing indicators. (Refer to relevant instructions in the data indicators for details).

Attenuator Initialization

After entering the host program, when the attenuator is initialized, you will hear the sound of the

attenuator for setting ranges, so do not mistake it as an error of the signal generator.

Caution

Tip

Tip

2 Getting Prepared

2.1 Preparations before Operation

7

System Startup

This instrument adopts the control platform of Windows + x86 computers. In the process of BIOS

self-test and Windows loading, no user intervention is required, so do not cut off the power halfway or

modify the settings in BIOS.

2) Turning off the instrument

Step 1. Turn off the power switch in the lower left corner of the front panel (Figure 2.3). At this time,

the instrument enters the shutdown process (some processing of the hardware and software is required

before the power can be turned off). After more than ten seconds, the instrument is powered off, when

the color of the power indicator above the power switch changes from green to yellow.

Step 2. Turn off the back panel power switch ("O") or disconnect the power of the instrument.

The instrument is now shut down.

Instrument Power Cut

During normal operation, the instrument can only be shut down by operating the front panel power

switch. Do not directly operate the back panel power switch or disconnect the power connection

with the instrument; otherwise, the instrument cannot enter the normal shutdown state, which will

damage the instrument or cause loss of the current instrument status / measurement data. Please

always shut down the instrument in the right way.

2.1.3.3 Cutting off the Power

Under abnormal circumstances, in order to avoid personal injury, emergency power cut of the signal

generator is necessary. At this point, you just need to unplug the power cord (from the AC socket or from

the power socket on the back panel of the instrument). Therefore, sufficient operating space should be

reserved when operating the instrument to allow you to directly cut off the power when necessary.

2.1.4 Correct Use of Connectors

Connectors are often used in various tests of the signal generator. Please pay attention to the

following precautions when using connectors:

2.1.4.1 Checking Connectors

Anti-static wristbands should be worn when checking connectors. A magnifier is recommended to

check the following:

1) Whether the electroplated surface is worn, and whether there are deep scratches.

2) Whether the thread is deformed.

3) Whether there are metal particles on the thread of the connector and the joint surface.

4) Whether the inner conductor is bent or broken.

5) Whether the bolt sleeve of the connector rotates badly.

Caution

Be Careful

!

2 Getting Prepared

2.1 Preparations before Operation

8

Avoid Damaging Instrument Ports through Connector Checking

Any damaged connector may damage the good connector connected to it even when during the first

measurement connection. In order to protect the various interfaces of the signal generator itself, it is

necessary to check the connectors before operating the connector.

2.1.4.2 Connection Method

Connectors should be checked and cleaned before measurement connection to ensure them to be

clean and free of damages. Anti-static wristbands should be worn during the connection. The correct

connection method and steps are as follows:

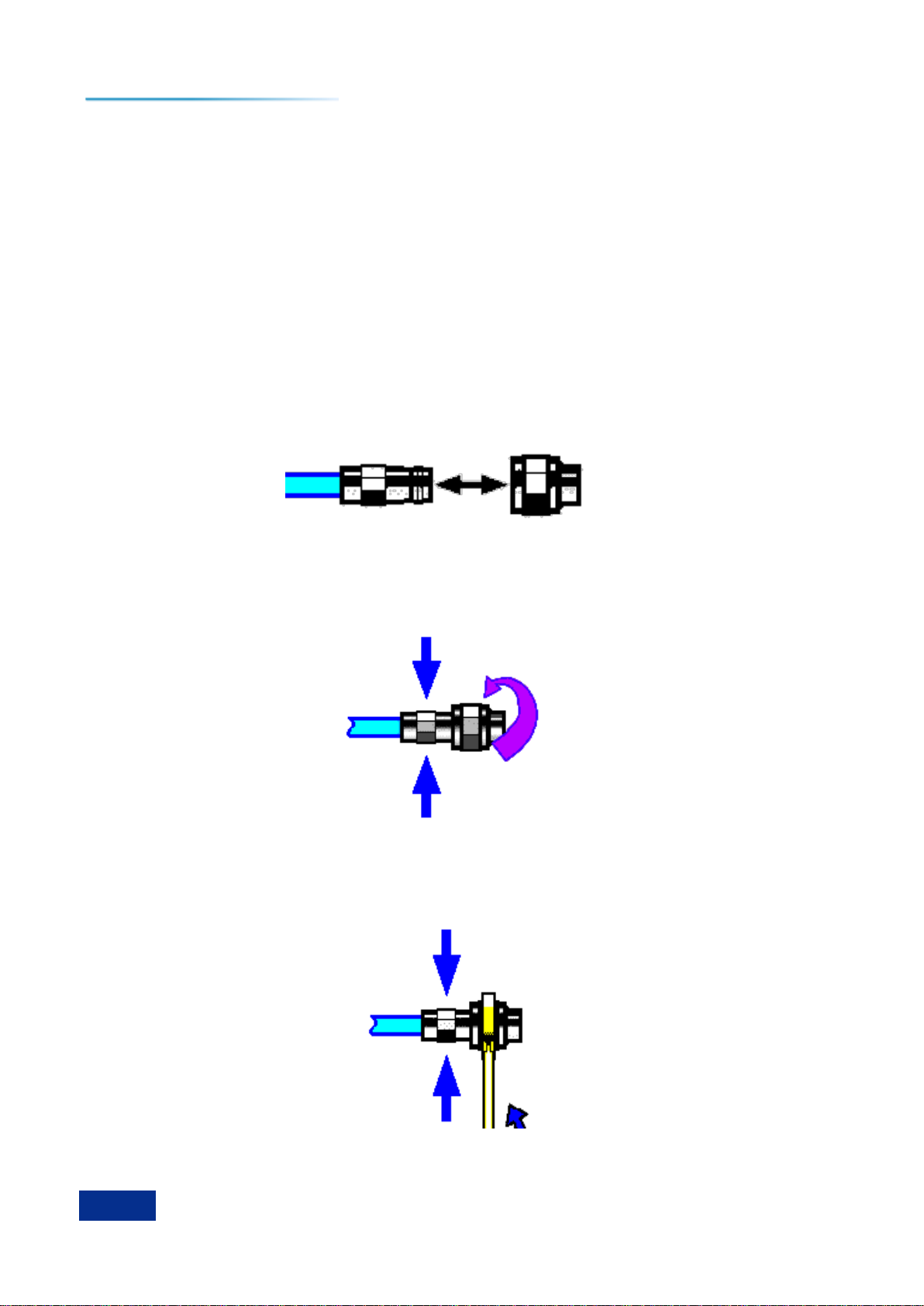

Step 1. As shown in Figure 2.4, align the axes of the two devices to be connected to ensure that the

pins of the male connector slide into the female connector concentrically.

Figure 2.4 The axes of the interconnected devices are along a straight line.

Step 2. As shown in Figure 2.5, move the two connectors horizontally together so that they can be

smoothly engaged. Rotate the connector bolt sleeves (not the connectors themselves) until tightened.

There should be no relative rotation between the connectors during the connection.

Figure 2.5 Connection method

Step 3. As shown in Figure 2.6, the connection is completed with a torque wrench. Attention should

be paid to prevent the torque wrench from exceeding the initial bending point. An auxiliary wrench can

be used to prevent the connectors from rotating.

Figure 2.6 Competing the connection with a torque wrench

Keep still

Rotate the

screw sleeve

Keep still

2 Getting Prepared

2.1 Preparations before Operation

9

2.1.4.3 Disconnection Method

Step 1. Support the connectors to prevent any connector from being twisted, shaken or bent.

Step 2. An open-end wrench can be used to prevent the connectors from rotating.

Step 3. Loosen the bolt sleeves of the connectors with another wrench.

Step 4. Complete the disconnection by rotating the connector sleeves by hand.

Step 5. Pull the two connectors apart horizontally.

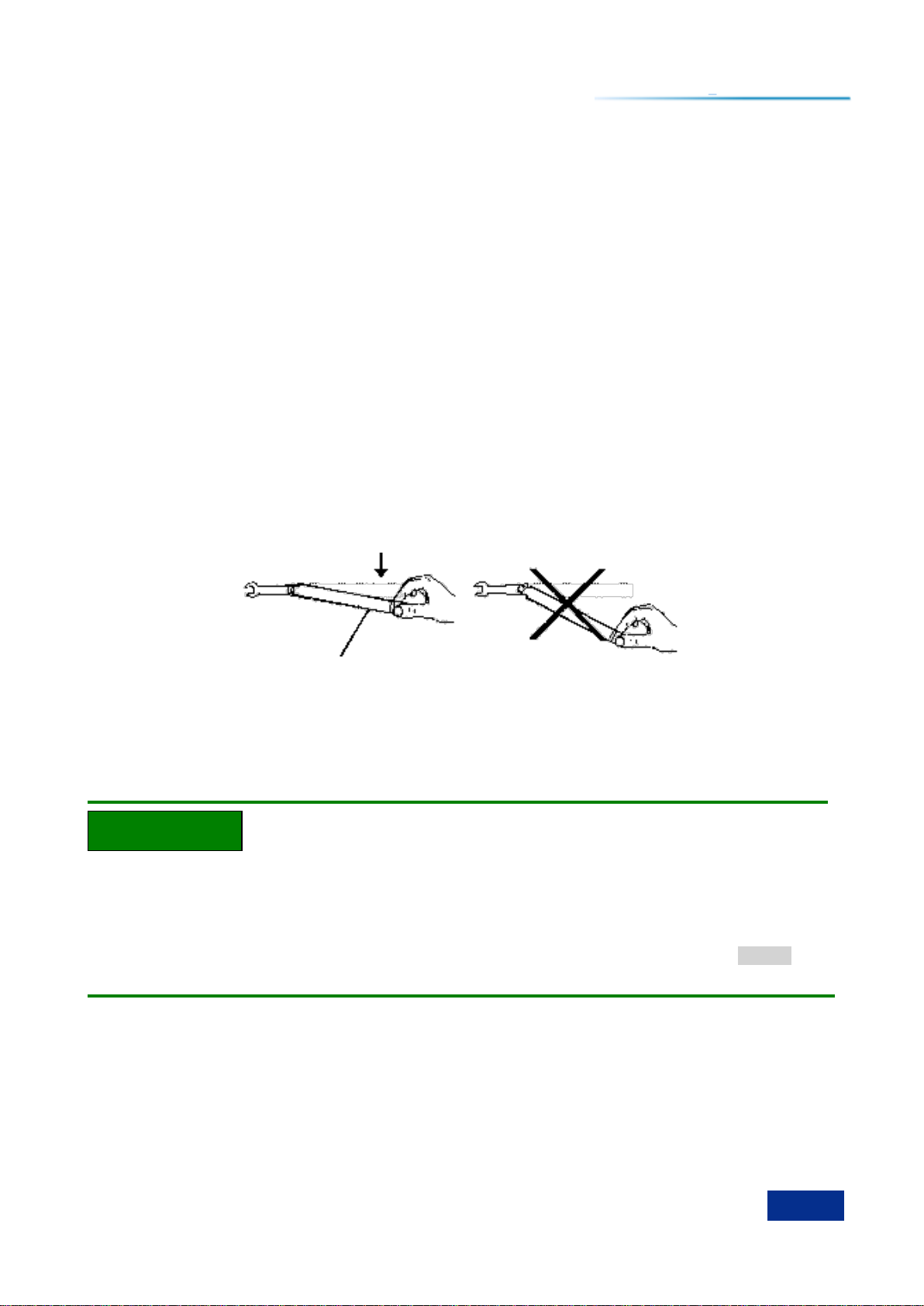

2.1.4.4 Use of Torque Wrenches

The use of a torque wrench is shown in Figure 2.7. The following points should be paid attention to

when using a torque wrench:

Make sure that the torque of the torque wrench is set correctly before use.

Make sure that the angle between the torque wrench and another wrench (used to support

connectors or cables) is within 90° before applying force.

Gently grasp the end of the torque wrench handle and apply a force in the direction

perpendicular to the handle until the breakout torque of the wrench is reached..

Figure 2.7 Use of a torque wrench

2.1.5 User Check

After the first power-on of 1465 series signal generator, it is necessary to check whether the

instrument works normally to ensure subsequent measurement.

Hard Keys on the Front Panel and Soft Keys in the Manu

The front panel keys are described as follows: [Frequency], where frequency is the name of the

hard key;

If a key corresponds to multiple states, the option of the selected value whose color changes and

the background is darkened indicates that the state is valid. For example: [Sweep Time Manual Auto]

indicates that the manual option of sweep time is valid.

2.1.5.1 Self-test

Connect the 1465 series signal generator to the power supply. Observe whether the power indicator

above the power switch in the lower left corner of the front panel is yellow, which indicates that the

standby power supply is working normally. Touch the front panel power switch and observe whether the

front panel power indicator turns green and the backlight of the display is on. The display start-up

process needs about 30 seconds, and then the boot status interface is displayed.

After 10 minutes of preheating, set the signal generator as follows:

Torque direction

Stop applying force when the

handle is to be bent

Tip

2 Getting Prepared

2.1 Preparations before Operation

10

Step 1. Press the [System] key on the front panel key or tap the [System] function area on the

touchscreen to enter the system menu.

Step 2. Select [self-test] in the self-test options.

Step 3. In the pop-up self-test configuration window, select the self-test project, select [Start Test],

and observe the test results: If successful, "all pass" will be displayed, indicating that the instrument

works normally; if failed, "Self-test failure, XX items failed" will be displayed, indicating that the

instrument is not working properly. In such case, please contact our Service Consultation Center

according to the contact information provided in the inside front cover or "4.3 Repair", and we will repair

or replace it as soon as possible according to the actual situation.

2.1.5.2 Function Verification

Turn on the 1465 series signal generator and preheat it for at least 30 minutes. The RF output

terminal is applied with matching load. Set the instrument as follows:

Step 1. Press the [Power] key on the front panel or tap the [Power] function area on the touch

screen to enter the power menu, and set the power at 0 dBm in the pop-up dialog box for power

parameter settings.

Step 2. Press the [Frequency] key on the front panel or tap the [Frequency] function area on the

touch screen to enter the power menu, and set the continuous wave at 100 MHz in the pop-up dialog box

for frequency parameter settings.

Step 3. Press the [FR On / Off] key on the front panel or tap the [FR] function area on the touch

screen to turn on RF output of the signal generator.

Step 4. Set the frequency of the signal generator up at the interval of 100 MHz with the arrow keys

on the front panel until the maximum frequency is reached. Pay attention to the alarm indication area of

the front panel display. If there is no alarm, it indicates that the instrument is working normally; If there is

any alarm information, it indicates that the instrument is not working properly. In this case, please contact

our Service Consultation Center according to the contact information provided in the inside front cover or

"4.3 Repair", and we will repair or replace it as soon as possible according to the actual situation.

2.1.6 Online Help

The 1465 series signal generator offers online help feature. Press the yellow [Help] key on the left

side of the front panel to call the online help file "Help".

2 Getting Prepared

2.1 Preparations before Operation

11

Figure 2.8 Opening 1465 online help file

2 Getting Prepared

2.2 Operating System Configuration

12

2.2 Operating System Configuration

The 1465 series signal generator is equipped with Windows 7 operating system, which has been

configured according to the functions and requirements of the instrument. The host software of the

instrument is based on Windows 7 operating system, which has been installed before shipment of the

instrument. To ensure normal operation of the instrument software, certain rules must be obeyed when

using the operating system.

Windows 7 Configuration ……………………………………………………………………………12

Windows 7 System Security and Maintenance ……………………………………………………14

Third-party Software Affects Instrument Performance

The 1465 series signal generator adopts the open Windows environment. Installing other third-party

software may affect the performance of the signal generator. Please use only software that has been

tested by the manufacturer and is compatible with the host software.

2.2.1 Windows 7 Configuration

The operating system of 1465 series signal generator has been configured to the best state before

shipment of the instrument. Any change of the operating system settings may cause decline in the

measurement performance of the instrument. Normally, you need not make any changes to settings of

the Windows operating system.

BIOS Settings are not Modifiable

Users should not modify the settings in BIOS; otherwise, the instrument may be subject to

exceptions in startup and operation.

Changing System Configuration Causes Problems

In case of problem in the use of the instrument or system crashes due to change in the system

configuration, the system recovery tool of the instrument can be used to recover the operating system

and the application software. You can also contact our Service Consulting Center by dialing our service

number provided in this manual, and we will solve your problems as soon as possible.

However, in order to facilitate users in measurement reports and system integration, the following

items can be changed by users as required.

Configuring GPIB ……………………………………………………………………………………12

Configuring LAN ………………………………………………………………………………………13

2.2.1.1 Configure GPIB

Users may need to modify the GPIB address when using the signal generator to build the system.

Caution

Caution

Caution

2 Getting Prepared

2.2 Operating System Configuration

13

The default GPIB address of the local machine is 19.

The GPIB address can be change as follows:

Press the [System] key on the front panel or tap the [System] function area on the touch screen and

select [GPIB Interface] to enter the interface shown in Figure 2.9, where you can change the address in

the GPIB address bar with numeric keys on the front panel or by tapping on the touch screen.

Figure 2.9 GPIB port settings

2.2.1.2 Configuration LAN

a) Change host name

The host name (computer name) of 1465 series signal generator has been preset as "41-PC" before

leaving the factory. In order to avoid the repeated names in the network, for such cases as multiple 1465

signal generators are connected in the same network, users may change the host names as required.

The specific steps to change the host name are as follows: (or you can refer to Help Document of

Microsoft Windows 7.)

Step 1. Press the [System] key or tap the [System] function are and select "LAN Interface" to enter

the network property settings page as shown in Figure 2.10, which displays the "Host Name" in the

current LAN.

Step 2. Edit and type in the new host name, and close the current dialog box.

2 Getting Prepared

2.2 Operating System Configuration

14

Figure 2.10 Lan port configuration

b) Configure IP address, subnet mask, and default gateway

The IP address and gateway are so preset as to automatically obtain IP address before shipment of

the instrument. IP address, subnet mask, and gateway can be changed manually. In the window shown

in Figure 3.10, you can change the IP address, subnet mask and default gateway. For detailed

operations, please refer to the steps in "a) Changing host name" or refer to the Help Document of

Microsoft Windows 7.

c) Change system firewall settings

The firewall is used to prevent unauthorized users from remotely operating the instrument.

Therefore, we suggest that you enable the firewall protection. The firewall protection for all port

connections of the system related to remote operations has been enabled before shipment of the 1465

series signal generator.

The Administrator has the only permission to change firewall settings.

2.2.2 Windows 7 System Security and Maintenance

2.2.2.1 Antivirus Software

Installation of antivirus software may have some negative effects on the performance of the

instrument. To avoid virus infection, users are strongly recommended not to use the instrument as a

normal computer for browsing web pages or transferring files.

Before using any USB mobile storage devices, it is firstly required to carry out anti-virus processing

on such mobile devices based on a computer installed with the latest antivirus software to prevent the

devices from become virus carriers.

Once the signal generator system platform is infected with virus, it will have a negative impact on its

operation and use. In such cases, system recovery operation is recommended. Refer to the relevant

content in "2.2.2.2 System Maintenance" of this section for details on system recovery operation.

2.2.2.2 System Maintenance

1) Windows 7 Backup

Users are recommended to make system backups regularly. The data and system of the instrument

can be backed up completely with the "System Recovery Tool" of this instrument. For detailed operation,

please refer to "System Backup and Recovery".

It is recommended that in order to make backups of the instrument before it can be used for

Other manuals for 1465 Series

2

This manual suits for next models

14

Table of contents