CF MOTO CF150T-6A User manual

WWW.CFMOTO.COM

CF150T-6A

CF125T-22A Service Manual

All manuals and user guides at all-guides.com

all-guides.com

$OOULJKWUHVHUYHG

&+81)(1*+2/',1**5283&2/7'

WWW.CFMOTO.COM

All manuals and user guides at all-guides.com

7KLVPDQXDOFRQWDLQVDQLQWURGXFWRU\

GHVFULSWLRQRISURFHGXUHVIRULQVSHFWLRQ

PDLQWHQDQFHRYHUKDXOGLVDVVHPEO\

DVVHPEO\UHPRYDODQGLQVWDOODWLRQRI

FRPSRQHQWVDQGSDUWVWURXEOHVKRRWLQJDQG

VHUYLFHGDWDWRJHWKHUZLWKLOOXVWUDWLRQVRI

*ORU\0RGHO&)7$DQG&)7$

&KDSWHUJHQHUDOVHUYLFH

LQIRUPDWLRQWRROVYHKLFOHVWUXFWXUHDQG

WHFKQLFDOGDWD

&KDSWHUPDLQSRLQWRILQVSHFWLRQ

DGMXVWDQGPDLQWDLQUHSDLU

&KDSWHUGLVDVVHPEO\RISDUWVDQG

FRPSRQHQWVLQVWDOODWLRQRYHUKDXODQG

WURXEOHVKRRWLQJ

&KXQIHQJ+ROGLQJ*URXS+DQJ]KRX

0RWRUF\FOHV0DQXIDFWRU\LQJ&R/WG

7HFKQLFLDQ'HSW

0DU

!"# $

%" % &

%# '

(

)# *

% % +

% + %

,

-

%. /

. 0

(# % #

1 2 3

% %4 3

5 2 4

#

( 2

# $

%## &

# '

)

% *

!##

6 -

% 2# ,# /

."# 0

All manuals and user guides at all-guides.com

% ."

) %

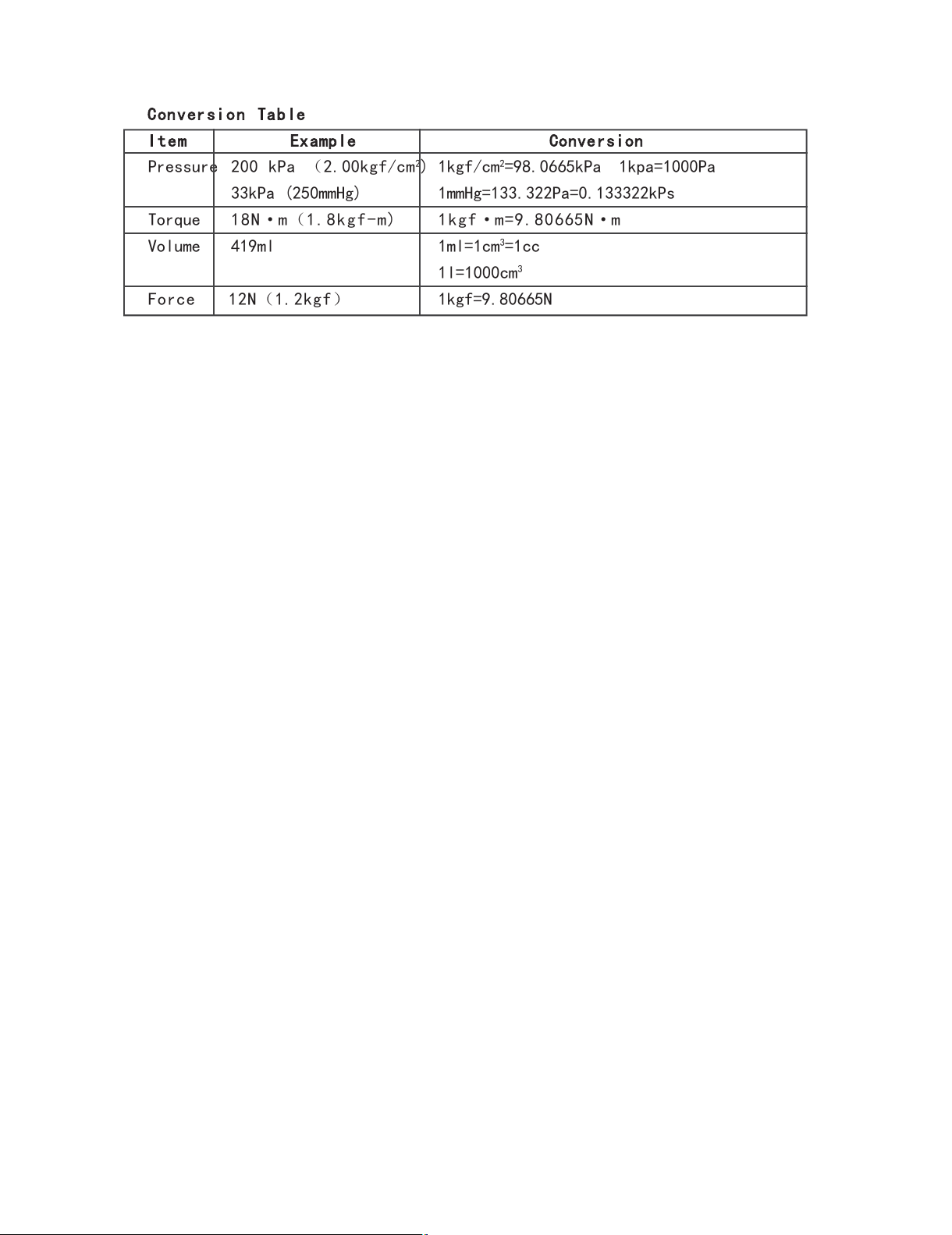

3UHVVXUH N3DNJIFP NJIFP N3DNSD 3D

N3DPP+J PP+J 3D N3V

7RUTXH 1PNJIP NJIP 1P

9ROXPH PO PO FP FF

O FP

)RUFH1NJINJI 1

All manuals and user guides at all-guides.com

0DLQWHQDQFH

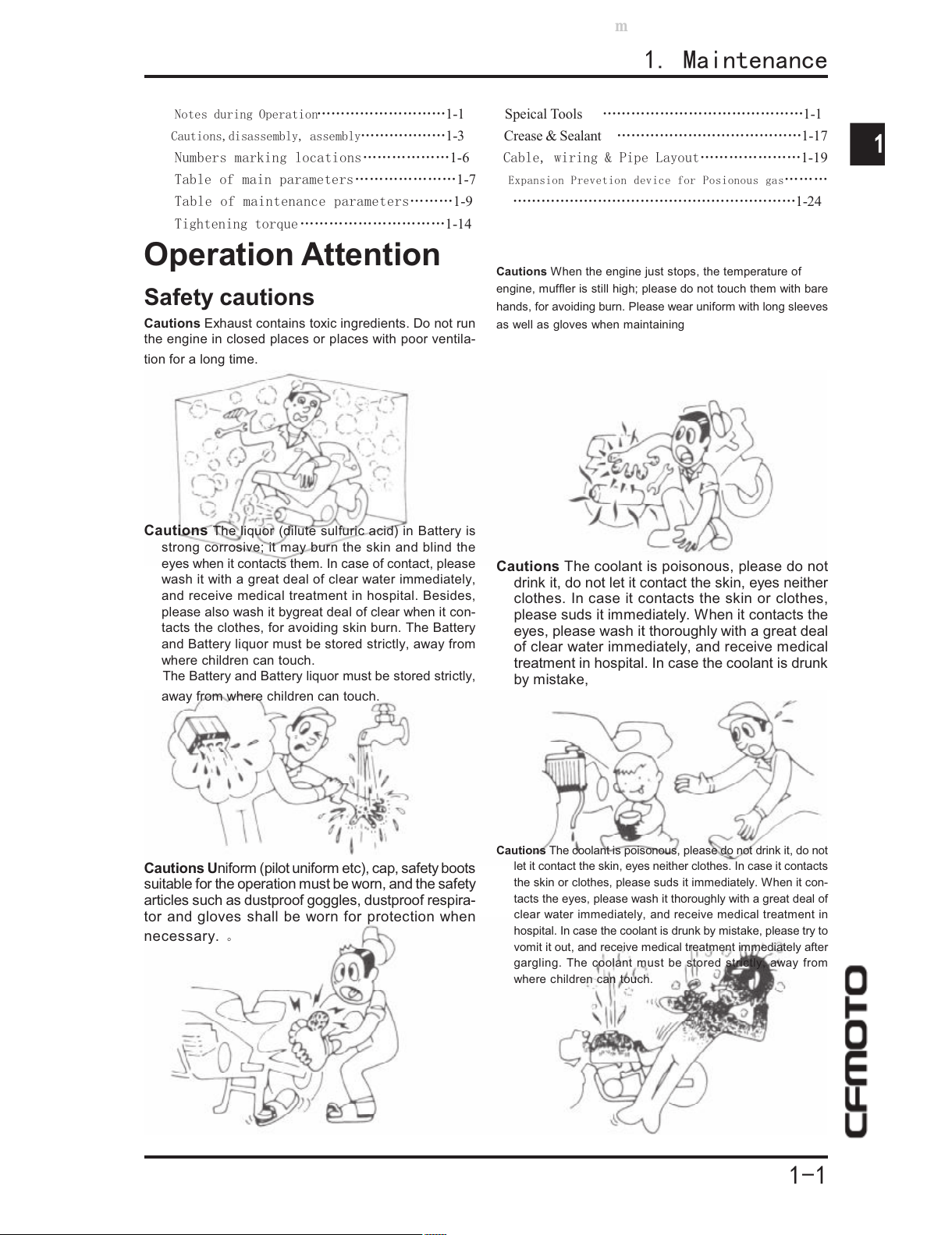

Operation Attention

Safety cautions

Cautions Exhaust contains toxic ingredients. Do not run

the engine in closed places or places with poor ventila-

tion for a long time.

Cautions The liquor (dilute sulfuric acid) in Battery is

strong corrosive; it may burn the skin and blind the

eyes when it contacts them. In case of contact, please

wash it with a great deal of clear water immediately,

and receive medical treatment in hospital. Besides,

please also wash it bygreat deal of clear when it con-

tacts the clothes, for avoiding skin burn. The Battery

and Battery liquor must be stored strictly, away from

where children can touch.

The Battery and Battery liquor must be stored strictly,

away from where children can touch.

Cautions Uniform (pilot uniform etc), cap, safety boots

suitable for the operation must be worn, and the safety

articles such as dustproof goggles, dustproof respira-

tor and gloves shall be worn for protection when

necessary.

Cautions The coolant is poisonous, please do not

drink it, do not let it contact the skin, eyes neither

clothes. In case it contacts the skin or clothes,

please suds it immediately. When it contacts the

eyes, please wash it thoroughly with a great deal

of clear water immediately, and receive medical

treatment in hospital. In case the coolant is drunk

by mistake,

Cautions The coolant is poisonous, please do not drink it, do not

let it contact the skin, eyes neither clothes. In case it contacts

the skin or clothes, please suds it immediately. When it con-

tacts the eyes, please wash it thoroughly with a great deal of

clear water immediately, and receive medical treatment in

hospital. In case the coolant is drunk by mistake, please try to

vomit it out, and receive medical treatment immediately after

gargling. The coolant must be stored strictly, away from

where children can touch.

1RWHVGXULQJ2SHUDWLRQ1-1 Speical Tools1-1

&DXWLRQVGLVDVVHPEO\DVVHPEO\1-3 Crease & Sealant 1-17

1XPEHUVPDUNLQJORFDWLRQV1-6 &DEOHZLULQJ3LSH/D\RXW1-19

7DEOHRIPDLQSDUDPHWHUV1-7 ([SDQVLRQ3UHYHWLRQGHYLFHIRU3RVLRQRXVJDV

7DEOHRIPDLQWHQDQFHSDUDPHWHUV1-9 1-24

7LJKWHQLQJWRUTXH1-14

Cautions When the engine just stops, the temperature of

engine, muffler is still high; please do not touch them with bare

hands, for avoiding burn. Please wear uniform with long sleeves

as well as gloves when maintaining.

All manuals and user guides at all-guides.com

&)0272

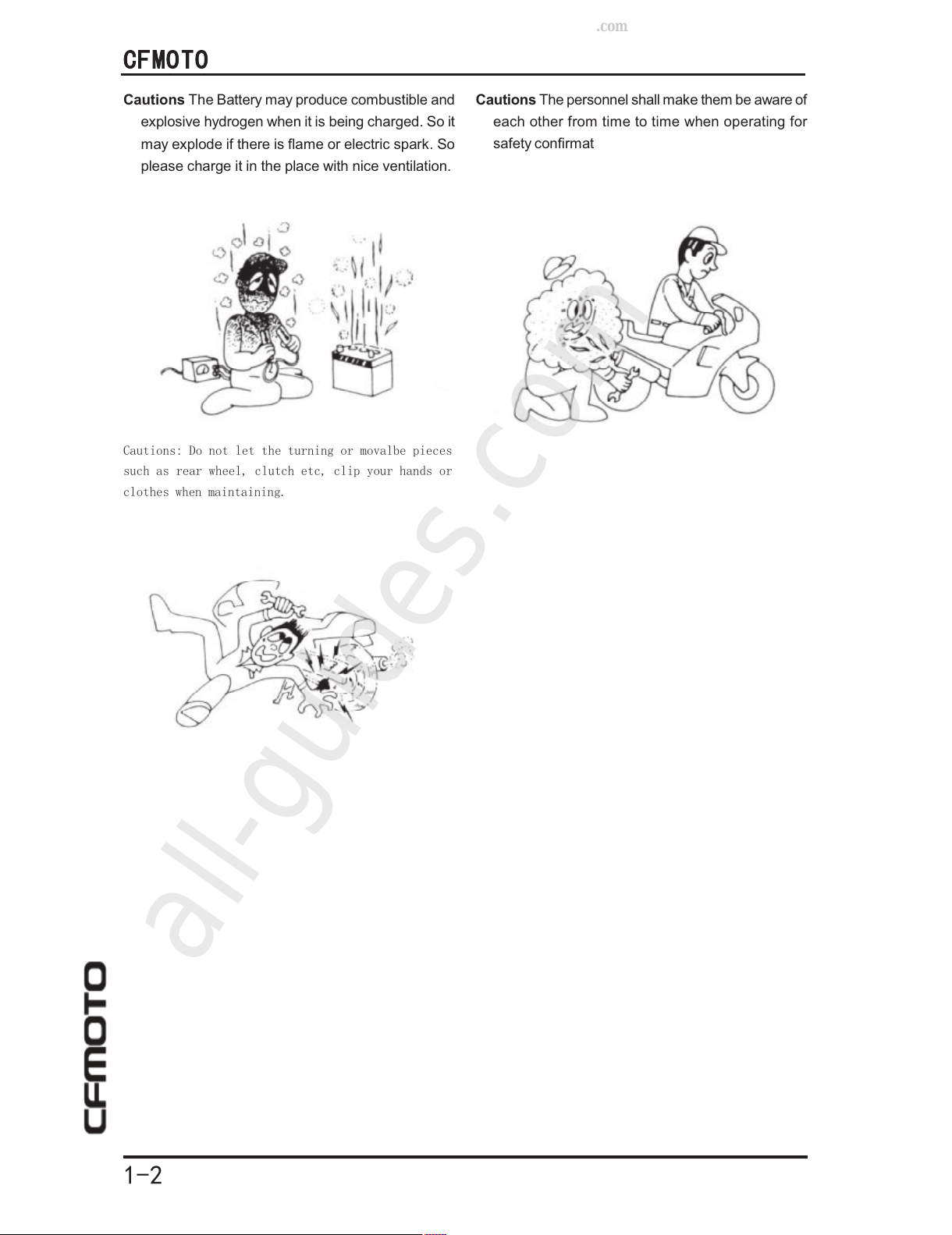

Cautions The Battery may produce combustible and

explosive hydrogen when it is being charged. So it

may explode if there is flame or electric spark. So

please charge it in the place with nice ventilation.

&DXWLRQV'RQRWOHWWKHWXUQLQJRUPRYDOEHSLHFHV

VXFKDVUHDUZKHHOFOXWFKHWFFOLS\RXUKDQGVRU

FORWKHVZKHQPDLQWDLQLQJ

Cautions The personnel shall make them be aware of

each other from time to time when operating for

safety confirmation.

All manuals and user guides at all-guides.com

all-guides.com

0DLQWHQDQFH

Disassembly&installation

Must use CFMOTO genuine parts or recom-

mended parts for components,lubrication or

grease.

The parts of each system shall be arranged and stored

separately, so that the parts can be assembled to the

original places.

The parts shall be washed and the cleanser shall

be blown away by compressed air prior to deter-

mination when they are disassembled and

inspected. The working surface shall be lubricated

before assembly.

Insert and arrange the bolts one by one and make

sure the insertion volume of each bolt is equal

before inserting them, when the bolt length is

unidentified.

Please clean the dirt, dusts on the vehicle before

maintenance.

The gasket, O-ring, piston pin retainer and split

pin must be renewed after disassembly.

The elastic retainer will deform if it is opened too

wide upon disassembly, then it will easily fall off

when assembled again. Please do not use the elas-

tic retainer that is already loose and without

elasticity.

Inspect the necessary sites upon disassembly,

measure the relevant data, so that the original

status can be resumed after assembly.

The fasteners such as bolts, nuts and screws shall

be pre-fastened, and then be fastened on the di-

agonal according to regulated fastening torque in

the principle of from big to small, from inside to

outside.

All manuals and user guides at all-guides.com

&)0272

The rubber parts shall be checked whether they are

aged upon disassembly, renew them in advance

when necessary. Besides, try not to make volatile

oil, grease etc attach on the rubber parts, for they are

not resistant to corrosion of gasoline or kerosene.

3URSHUVSHFLDOWRROVPXVWEHDSSOLHGWRWKH

RSHUDWLRQVZKLFKUHTXLUHVSHFLDOWRROV

7KHLQVLGHRURXWVLGHWUDFNRIEDOOEHDULQJVKDOOEHWXUQHGPDQXDOO\IRU

FRQILUPLQJWKHIOH[LELOLW\DQGVPRRWKQHVVRIWXUQLQJ

The parts that are loose axially or radially shall be renewed. The parts that are

unsmooth shall be washed with oil, and the parts that are not repaired after washing shall

be renewed (the dual-side dustproof type cannot be washed)

Press it into the machine or axis, and the bearing shall be renewed if the pressed part is

not tight enough.

Do not let the bearing race turn back when blowing the ball

bearing by compressed air after washing. If the bearing race

turns back, its high back turning speed will be beyond the limit

that may result in damage of bearing. The bearing shall be

lubricated with engine oil or grease before assembly.

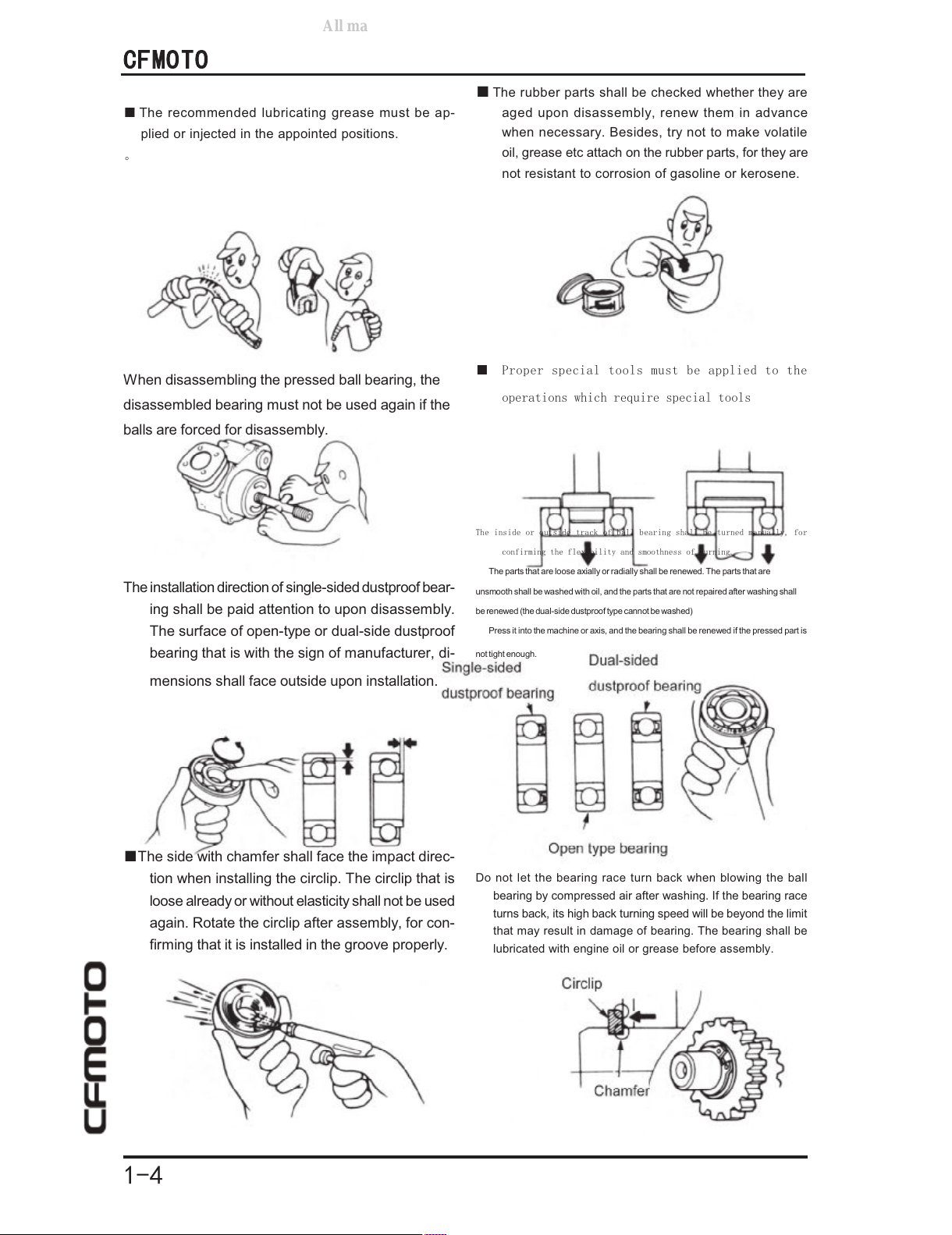

The recommended lubricating grease must be ap-

plied or injected in the appointed positions.

When disassembling the pressed ball bearing, the

disassembled bearing must not be used again if the

balls are forced for disassembly.

The installation direction of single-sided dustproof bear-

ing shall be paid attention to upon disassembly.

The surface of open-type or dual-side dustproof

bearing that is with the sign of manufacturer, di-

mensions shall face outside upon installation.

The side with chamfer shall face the impact direc-

tion when installing the circlip. The circlip that is

loose already or without elasticity shall not be used

again. Rotate the circlip after assembly, for con-

firming that it is installed in the groove properly.

All manuals and user guides at all-guides.com

0DLQWHQDQFH

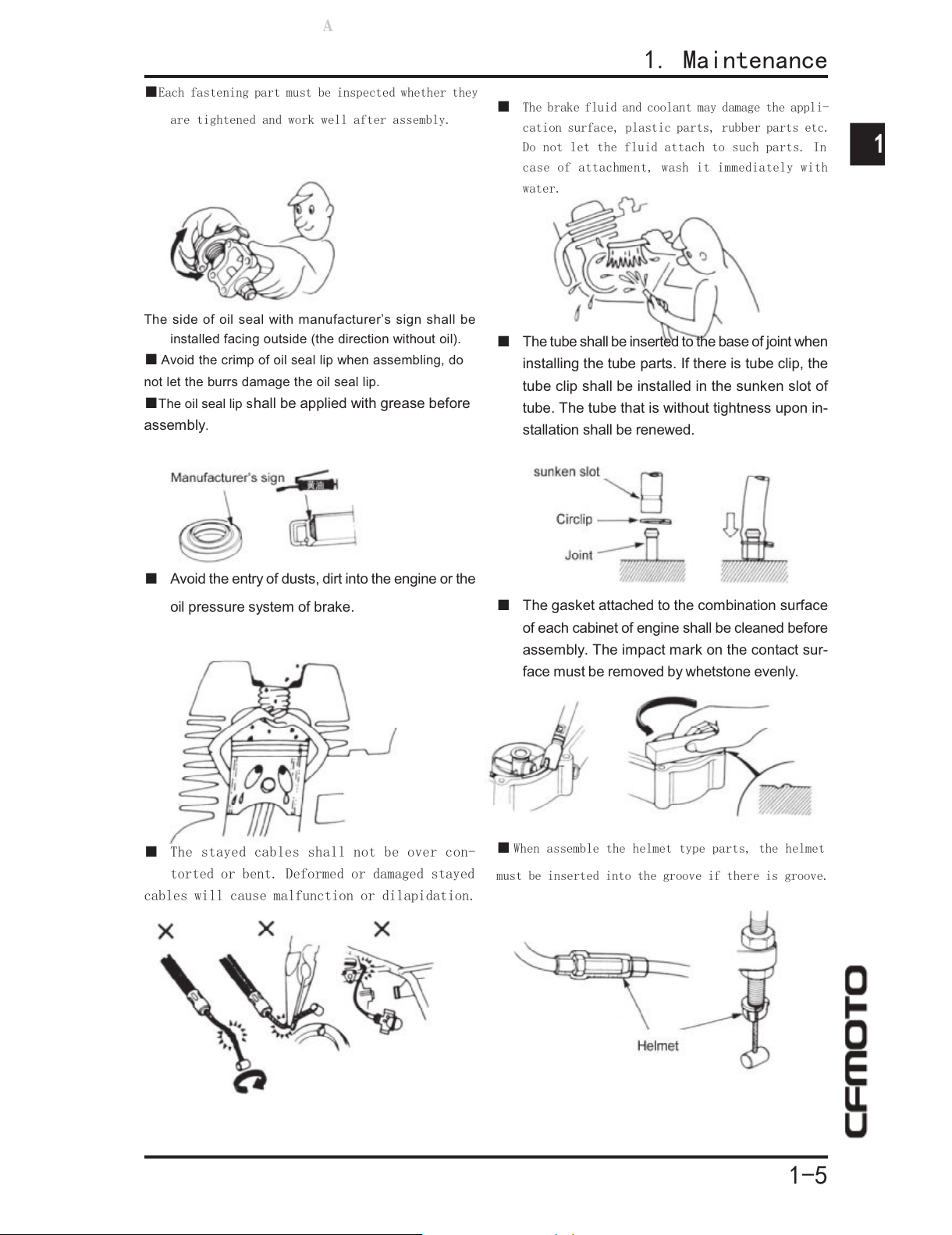

(DFKIDVWHQLQJSDUWPXVWEHLQVSHFWHGZKHWKHUWKH\

DUHWLJKWHQHGDQGZRUNZHOODIWHUDVVHPEO\

The side of oil seal with manufacturer’s sign shall be

installed facing outside (the direction without oil).

Avoid the crimp of oil seal lip when assembling, do

not let the burrs damage the oil seal lip.

The oil seal lip shall be applied with grease before

assembly.

Avoid the entry of dusts, dirt into the engine or the

oil pressure system of brake.

7KHVWD\HGFDEOHVVKDOOQRWEHRYHUFRQ

WRUWHGRUEHQW'HIRUPHGRUGDPDJHGVWD\HG

FDEOHVZLOOFDXVHPDOIXQFWLRQRUGLODSLGDWLRQ

7KHEUDNHIOXLGDQGFRRODQWPD\GDPDJHWKHDSSOL

FDWLRQVXUIDFHSODVWLFSDUWVUXEEHUSDUWVHWF

'RQRWOHWWKHIOXLGDWWDFKWRVXFKSDUWV,Q

FDVHRIDWWDFKPHQWZDVKLWLPPHGLDWHO\ZLWK

ZDWHU

The tube shall be inserted to the base of joint when

installing the tube parts. If there is tube clip, the

tube clip shall be installed in the sunken slot of

tube. The tube that is without tightness upon in-

stallation shall be renewed.

The gasket attached to the combination surface

of each cabinet of engine shall be cleaned before

assembly. The impact mark on the contact sur-

face must be removed by whetstone evenly

:KHQDVVHPEOHWKHKHOPHWW\SHSDUWVWKHKHOPHW

PXVWEHLQVHUWHGLQWRWKHJURRYHLIWKHUHLVJURRYH

All manuals and user guides at all-guides.com

&)0272

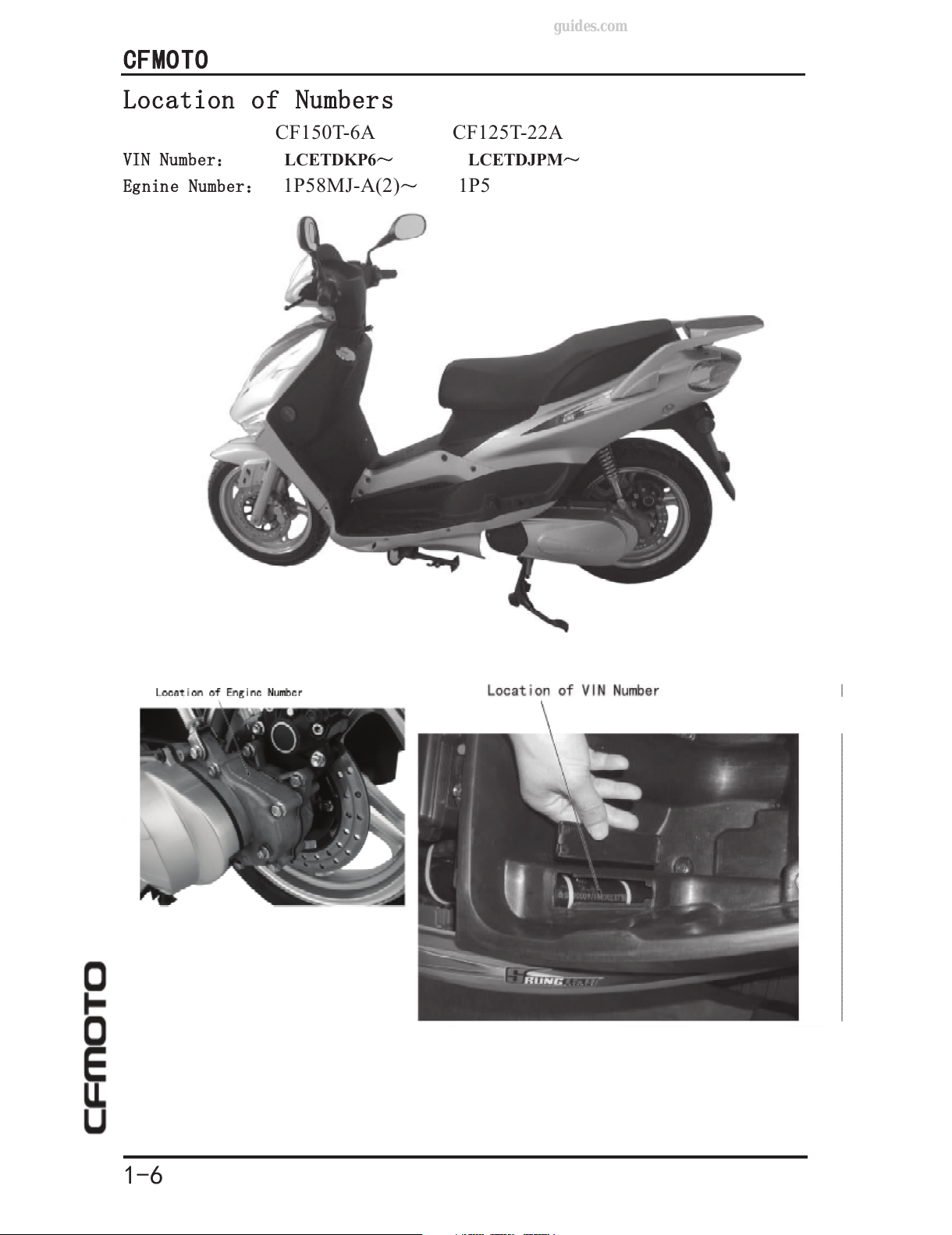

CF150T-6A CF125T-22A

LCETDKP6

LCETDJPM

1P58MJ-A(2)

1P52MI-B(2)

All manuals and user guides at all-guides.com

0DLQWHQDQFH

Item Parameter

N

ame and model CF150T-6A / CF125T-22A

Len

g

th 1950mm

Width 71 5mm

Height 1195mm

Wheelbase 1320mm

Engine model 1P58MJ-A(2) /1P52MI-B(2)

Total displacemen

t

152.7ml /124.6ml

Fuel type Above 93#

Gross weight 138kg

N

umber of passenger 2 Persons(Incl: Driver)

Rated load 150kg

Tyre specification Front-wheel 100/80-14 M/C 48L

Rear wheel 120/80-14 M/C 58L

Minimum

g

round Ga

p

130mm

Minimum turnin

g

diameter 4500mm

Engine

Startup mode Electronic Starting

Engine model 4-Stroke Gasoline Engine

Cylinder quantity and

distribution

Single-cylinder, horizontal

Model of combustion

chamber

Hemisphere

Valve drive model OHC Chain Drive

BoreStroke 5857.8mm 52.457.8mm

Compression ratio 111 10.31

Max. power 9.0kW/8500r/min 6.5kW/8500r/min

Max. torque 10.8N m/7250r/

min 8.0Nm/7000r/min

Air

distribution

Phase

Inl

et

va

lv

e

opening 0(1mm)BTDC

closing 30(1mm)ABDC

Ou

tle

t

va

lv

e

opening 35(1mm)BTDC

closing 0(1mm)TDC

Lubricating method Pressure, splashing type

Type of lubricating oil pump Rotor type

T

yp

e of lubricatin

g

oil filter Full flow filtration screen

Cooling mode Forcing water cooling

All manuals and user guides at all-guides.com

all-guides.com

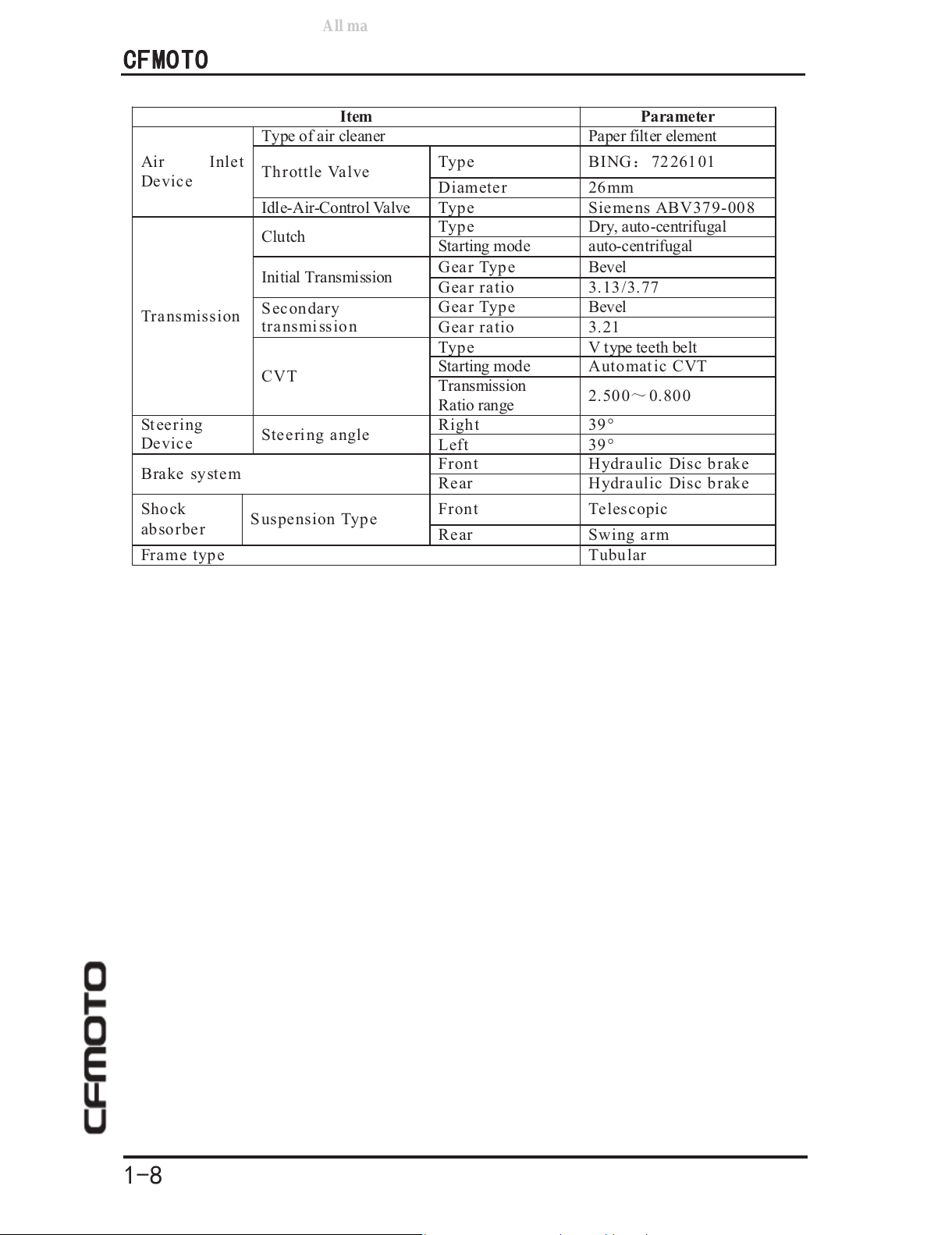

&)0272

Item Parameter

Air Inlet

Device

T

yp

eofaircleaner Pa

p

er filter element

Throttle Valve Type BING7226101

Diameter 26mm

Idle-Air-Control Valve T

yp

e Siemens ABV379-008

Transmission

Clutch Typ e Dry, auto-centrifugal

Starting mod

e

aut

o

-centrifugal

Initial Transmission Gear Type Bevel

Gear ratio 3.13/3.77

Secondary

transmission

Gea r Type Bevel

Gear ratio 3.21

CVT

T

yp

eVt

yp

e teeth bel

t

Starting mod

e

Automat ic CVT

Transmission

Ratio range 2.5000.800

Steering

Device Steering angle Ri

g

ht 39°

Left 39°

Brake system Front Hydraulic Disc brake

Rear Hydraulic Disc brake

Shock

absorber Suspension Type Front Telescopic

Rear Swing arm

Frame type Tubular

All manuals and user guides at all-guides.com

0DLQWHQDQFH

7DEOHRI0DLQWHQDQFH

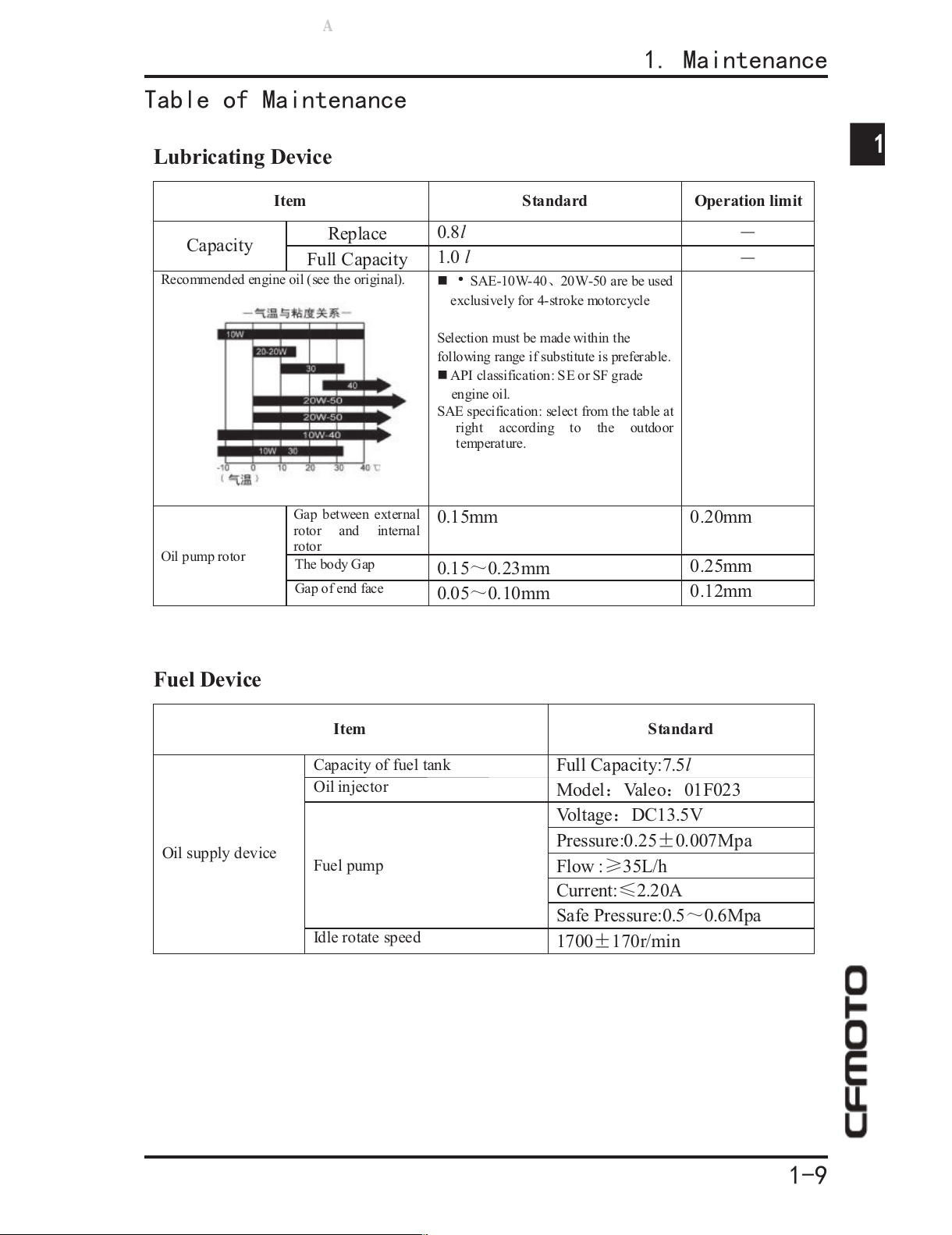

Lubricating Device

Item Standard Operation limit

Capacity Replace 0.8l

Full Capacity 1.0

l

Recommended engine oil (see the original). SAE-10W-4020W-50 are be used

exclusively for 4-stroke motorcycle

Selection must be made within the

following range if substitute is preferable.

API classification: SE or SF grade

engine oil.

SAE specification: select from the table at

right according to the outdoor

temperature.

Oil pump rotor

Gap

b

etween external

rotor and internal

rotor

0.15mm 0.20m

m

The body Gap 0.150.23mm 0.25m

m

Gap of end face 0.050.10mm 0.12m

m

Fuel Device

Item Standard

Oil supply device

Capacity of fuel tank Full Capacity:7.5

l

Oil injector ModelVa l e o01F023

Fuel pump

Vol t ag e DC13.5V

Pressure:0.250.007Mpa

Flow :35L/h

Current:2.20A

Safe Pressure:0.50.6Mpa

Idle rotate spee

d

1700170r/min

All manuals and user guides at all-guides.com

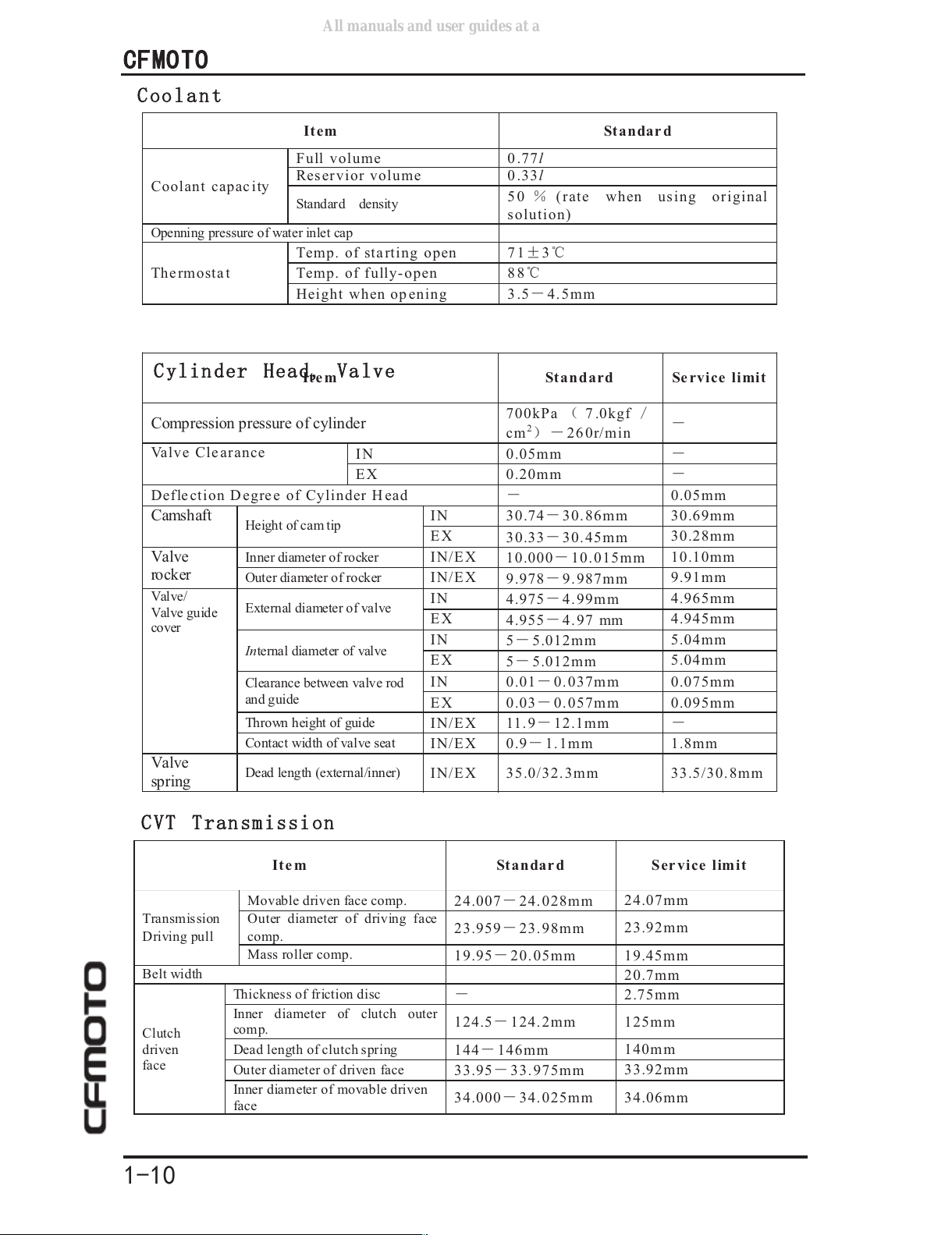

&)0272

Item Standard

Coolant capacity

Full volume 0.77l

Reservior volume 0.33l

Standard density 50 (rate when using original

solution)

Openning pressure of water inlet cap

The rmostat

Temp. of starting open 713

Temp. of fully-open 88

Height when opening 3.54.5mm

Item Standard Service limit

Compression pressure of cylinder 700kPa 7.0kgf

cm2260r/min

Valve Clearance IN 0.05mm

EX 0.20mm

Deflection Degree of Cylinder Head 0.05mm

Camshaft Height of cam tip IN 30.7430.86mm 30.69mm

EX 30.3330.45mm 30.28mm

Valve

rocker

Innerdiameterofrocker IN/EX 10.00010.015mm 10.10mm

Outer diameter of rocker IN/EX 9.9789.987mm 9.91mm

Valve/

Valve guide

cover

External diameter of valve IN 4.9754.99mm 4.965mm

EX 4.9554.97 mm 4.945mm

Internal diameter of valve IN 55.012mm 5.04mm

EX 55.012mm 5.04mm

Clearance between valve rod

and guide

IN 0.010.037mm 0.075mm

EX 0.030.057mm 0.095mm

Thrown height of guide IN/EX 11.912.1mm

Contact width of valve seat IN/EX 0.91.1mm 1.8mm

Valve

spring Dead length (external/inner) IN/EX 35.0/32.3mm 33.5/30.8mm

Item Standard Service limit

Transmission

Driving pull

Movable driven face comp. 24.00724.028mm 24.07mm

Outerdiameterofdrivingface

comp. 23.95923.98mm 23.92mm

Mass roller comp. 19.9520.05mm 19.45mm

Belt width 20.7mm

Clutch

driven

face

Thickness of friction disc 2.75mm

Inner diameter of clutch outer

com p. 124.5124.2mm 125mm

Dead length of clutch spring 144146mm 140mm

Outer diameter of driven face 33.9533.975mm 33.92mm

Inner diameter of movable driven

face 34.00034.025mm 34.06mm

All manuals and user guides at all-guides.com

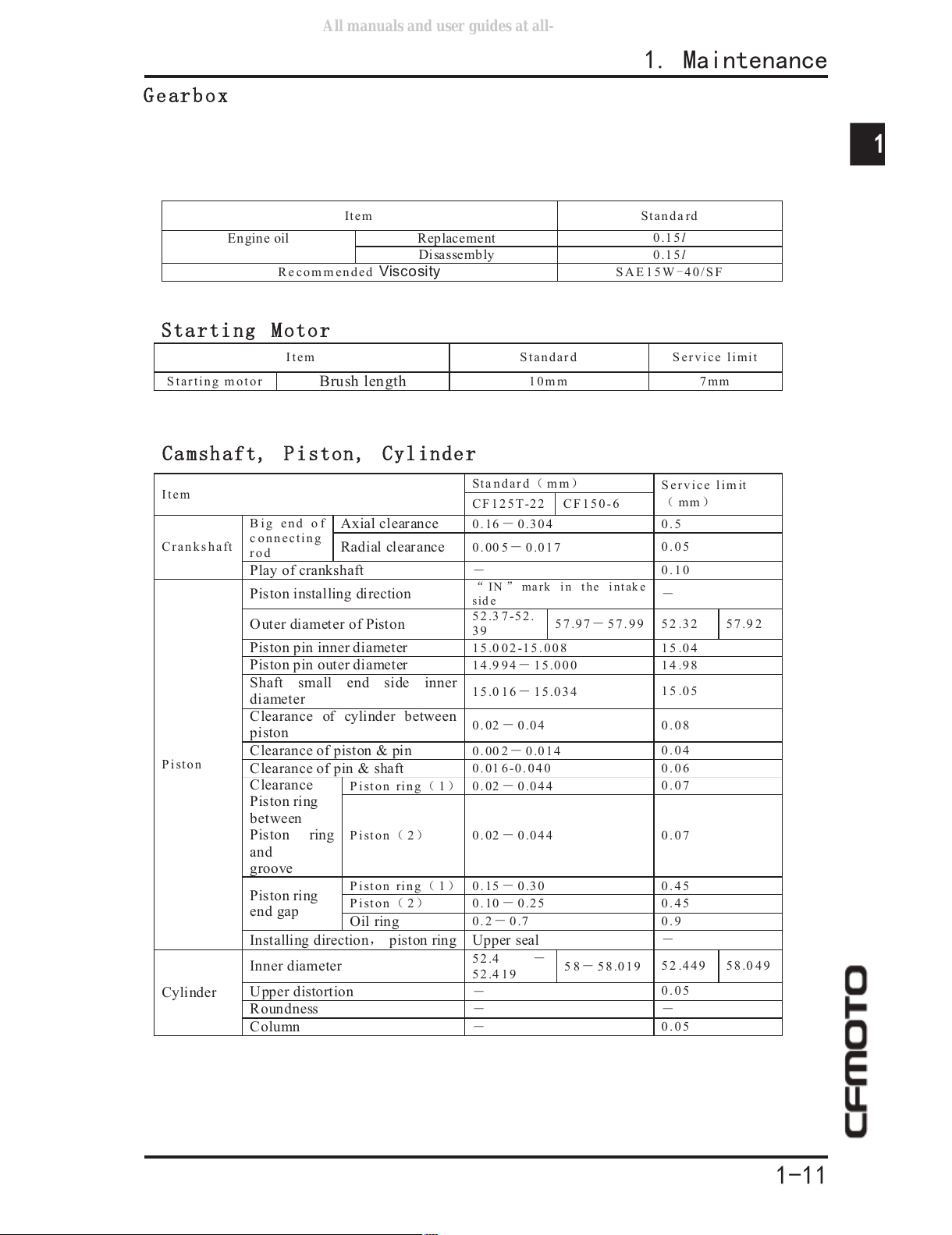

0DLQWHQDQFH

!

"

Item Standard

Engine oil Re

p

lacement 0.15l

Disassembly 0.15l

Recommended Viscosity SAE15W40/SF

Item Standard Service limit

Starting motor Brush length 10mm 7mm

Item StandardmmService limit

mm

CF125T-22 CF150-6

Crankshaft

Big end of

connecting

rod

Axial clearance 0.160.304 0.5

Radial clearance 0.0050.017 0.05

Play of crankshaft 0.10

Piston

Piston installing direction IN mark in the intake

side

Outer diameter of Piston 52.37-52.

39 57.9757.99 52.32 57.92

Piston pin inner diameter 15.002-15.008 15.04

Piston pin outer diameter 14.99415.000 14.98

Shaft small end side inner

diameter 15.01615.034 15.05

Clearance of cylinder

b

etween

piston 0.020.04 0.08

Clearance of piston & pin 0.0020.014 0.04

Clearance of pin & shaft 0.016-0.040 0.06

Clearance

Piston ring

between

Piston ring

and

g

roove

Piston ring10.020.044 0.07

Piston20.020.044 0.07

Piston ring

end gap

Piston ring10.150.30 0.45

Piston20.100.25 0.45

Oil ring 0.20.7 0.9

Installing directionpiston ring Upper seal

Cylinder

Inner diameter 52.4

52.419 5858.019 52.449 58.049

Upper distortion 0.05

Roundness

Column 0.05

All manuals and user guides at all-guides.com

&)0272

# $"

% $"

&' !

Item Standard Service

Limit

Fro nt w heel

Bending, front wheel shaft 0.2mm

Play of wheel

rim

Vertical 0.8mm 2.0mm

Horizontal 0.8mm 2.0mm

Tire

Groove 1.6mm

Air

pressure

225kPa 2.25kgf

cm2

Item Standard Service

Limit

Rear wheel

Play of wheel

rim

Vertical 0.8mm 2.0mm

Horizontal 0.8mm 2.0mm

Tire

Groove 1.6mm

Air

p

ressure 225kPa2.25kgfcm2

Item Standard

Service

Limit

Fr o nt b ra ke Brake handle free travel 1020mm

Brake disc thickness 4mm 3mm

Rear brake Brake handle free travel 1020mm

Brake disc thickness 4mm 3mm

All manuals and user guides at all-guides.com

all-guides.com

0DLQWHQDQFH

& " (

" (" !)" '*+

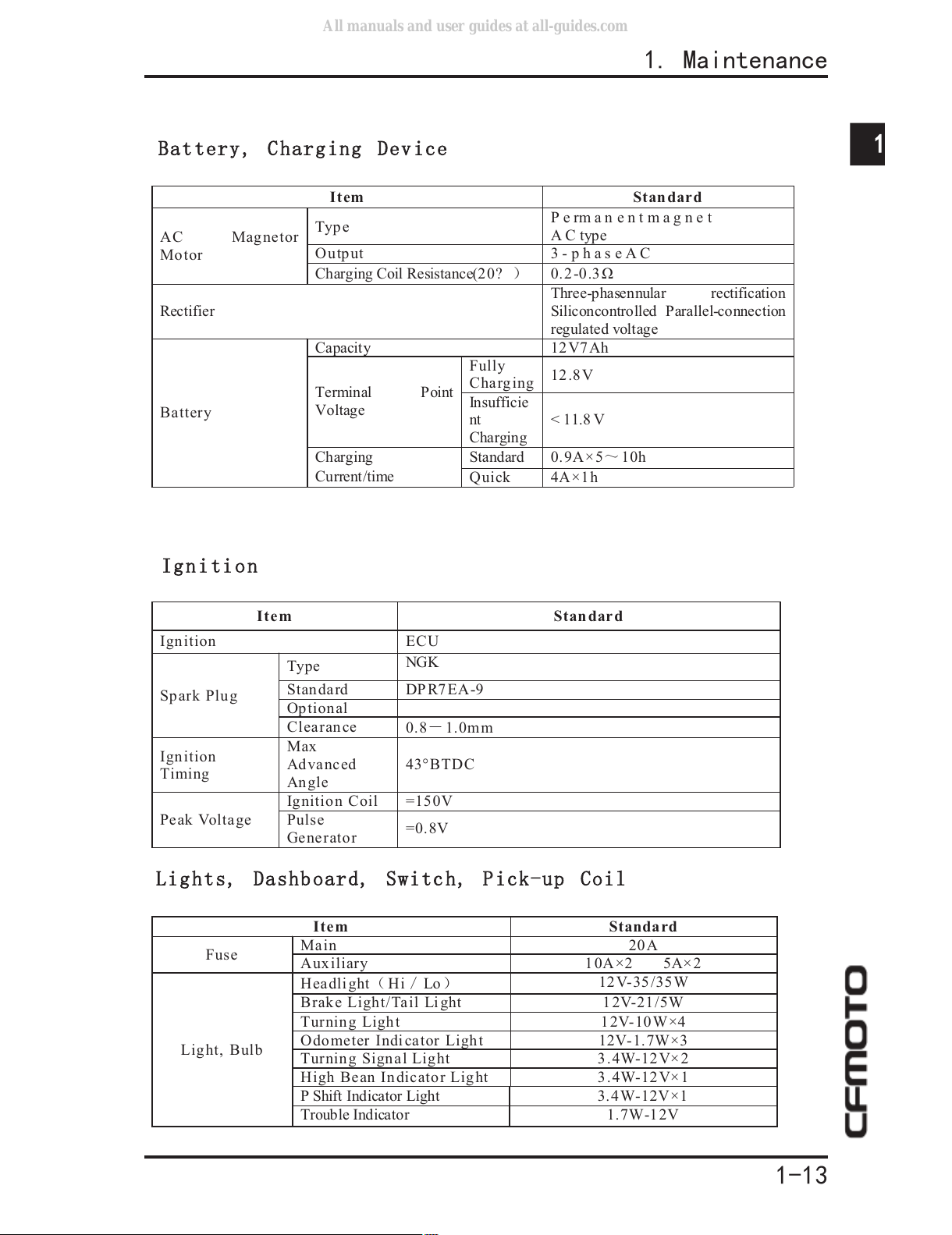

Item Standard

AC Magnetor

Motor

Type P e rm a n e n t m a g n e t

ACt

ype

Output 3 -

p

h a s e A C

Charging Coil Resistance(2 0? 0.2-0.3Ω

Rectifier

Three

-

p

hasennular rectification

Siliconcontrolled Parallel-connection

regulated voltage

Battery

Ca

p

acit

y

12V7Ah

Terminal Point

Voltage

Fully

Charging 12.8V

Insuffici

e

nt

Charging

<11.8V

Charging

Current/time

Standard 0.9A×510h

Quick 4A×1h

Item Standard

Ignition ECU

Spark Plug

Type NGK

Stan da rd DP R7 EA-9

O

p

tional

Clearance 0.81.0mm

Ignition

Timing

Max

Advanced

Angle

43°BTDC

Peak Voltage

Ignition Coil =150V

Pulse

Gene rator =0.8V

Item Standard

Fuse Main 20A

Auxiliary 10A×25A×2

Light, Bulb

HeadlightHiLo 12V-35/35W

Brake Light/Tail Light 12V-21/5W

Turning Light 12V-10W×4

Odometer Indicator Li

g

ht 12V-1.7W×3

Turning Signal Light 3.4W-12V×2

High Bean Indicator Light 3.4W-12V×1

P Shift Indicator Light 3. 4 W- 12V ×1

Trouble Indicator 1.7W-12V

All manuals and user guides at all-guides.com

&)0272

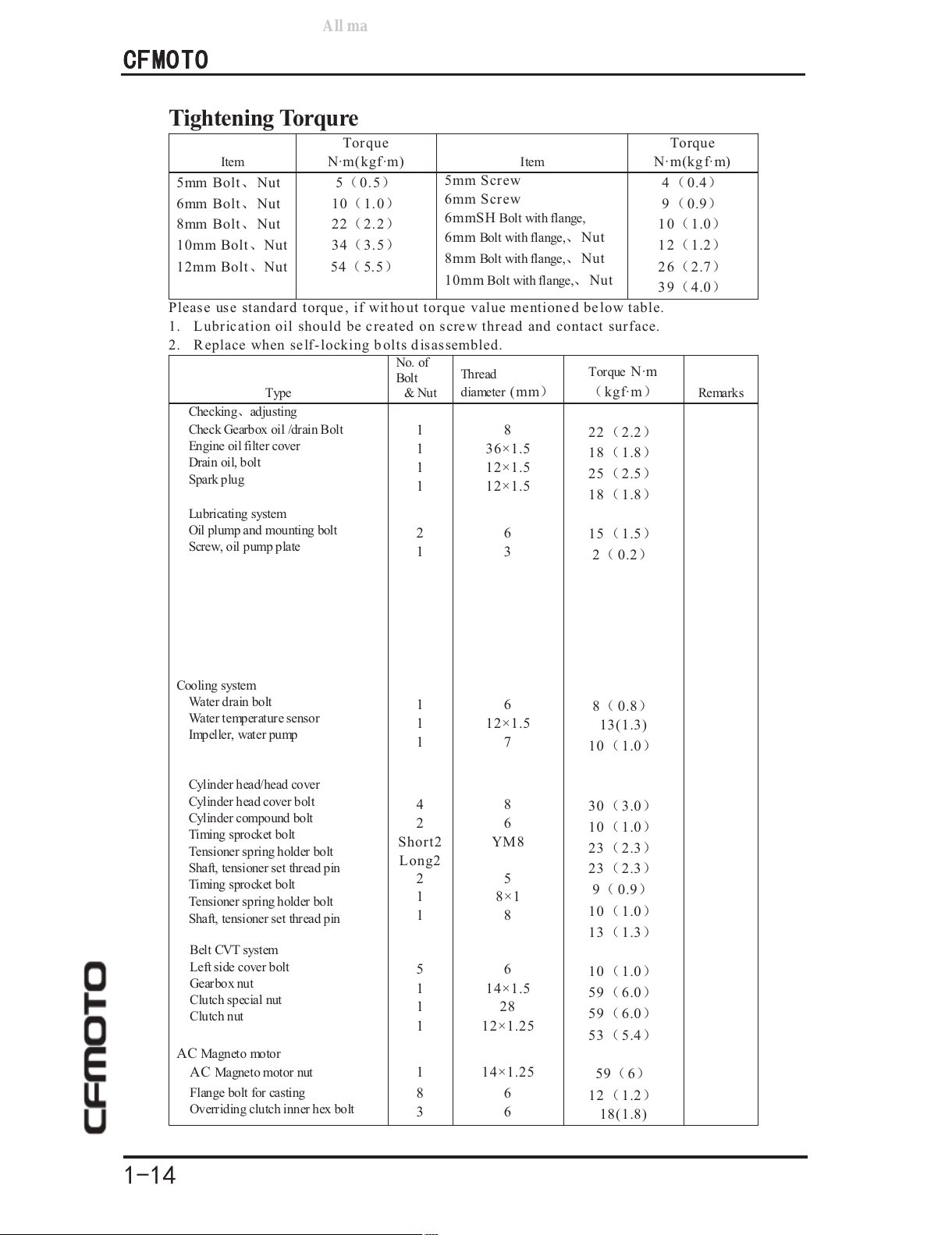

Tightening Torqure

Item

Torque

N·m(kgf·m) Item

Torque

N·m(kgf·m)

5mm BoltNut

6mm BoltNut

8mm BoltNut

10mm BoltNut

12mm BoltNut

50.5

101.0

222.2

343.5

545.5

5mm Screw

6mm Screw

6mmSH Bolt with flange,

6mm Bolt with flange,Nut

8mm Bolt with flange,Nut

10mm Bolt with flange,Nut

40.4

90.9

101.0

121.2

262.7

394.0

Please use standard torque, if without torque value mentioned below table.

1. Lubrication oil should be created on screw thread and contact surface.

2. Replace when self-locking bolts disassembled.

Type

N

o. of

Bolt

&Nut

Thread

diameter (mm

Torque N·m

kgf·mRemark s

Checkingadjusting

Check Gearbox oil /drain Bolt

Engine oil filter cover

Drain oil, bolt

Spark plug

1

1

1

1

8

36×1.5

12×1.5

12×1.5

222.2

181.8

252.5

181.8

Lubricating system

Oil plump and mounting bolt

Screw, oil pump plate

2

1

6

3

151.5

20.2

Cooling system

Water drain bolt

Water temperaturesensor

Impeller, water pump

1

1

1

6

12×1.5

7

80.8

13(1.3)

101.0

Cylinder head/head cover

Cylinder head cover bolt

Cylinder compound bolt

Timing sprocket bolt

Tensioner spring holder bolt

Shaft, tensioner set thr ead pin

Timing sprocket bolt

Tensioner spring holder bolt

Shaft, tensioner set thr ead pin

4

2

Short2

Long2

2

1

1

8

6

YM8

5

8×1

8

303.0

101.0

232.3

232.3

90.9

101.0

131.3

Belt CVT system

Left side cover bolt

Gearbox nut

Clutch special nut

Clutch nut

5

1

1

1

6

14×1.5

28

12×1.25

101.0

596.0

596.0

535.4

AC Magneto mo tor

AC Magneto motor nut 1 14×1.25 596

Flange bolt for casting

Overriding clutch inner hex bolt

8

3

6

6

121.2

18(1.8)

All manuals and user guides at all-guides.com

0DLQWHQDQFH

#

Typ e

No. of

Bolt &

Nut

Thread

diameter

mm

Tightening torque

Nmkgfm

Remar

ks

Engine disassembly

Engine suspension mounting bolt

Engine suspension shaft nut

2

1

10

10

555.6

555.6

Front wheel, Front suspension,

Steering System

Handlebar lock nut

Steering handle mounting nut

Front wheel axle nut

Shock absor ber mounting bolt

(upper)

1

1

1

4

25

10

12

8

687.0

555.6

808.1

404.1

Rear wheel ,Rear suspension

Rear wheel axle nut

Shock absorber mounting

bolt(upper)

Shock absorber mounting

bolt(lower)

Rear fork mounting bol

t

1

2

2

2

16

10

8

10

14014.3

555.6

303.1

555.6

Brake system

Front brake disc mounting bol

t

56 121.2

Rear brake disc mounting screw 38 262.7

Front brake caliper mounting bolt 28 303.1

Rear brake caliper mounting bolt 28 303.1

Muffler

Mounting nut (Front elbow)

Mounting bolt(Muffler barrel)

Oxygen Se ns or

2

3

1

8

10

18

262.7

555.6

606

Other

Screw ( Taillight/brake light comp.) 24.21.80.1.8

All manuals and user guides at all-guides.com

&)0272

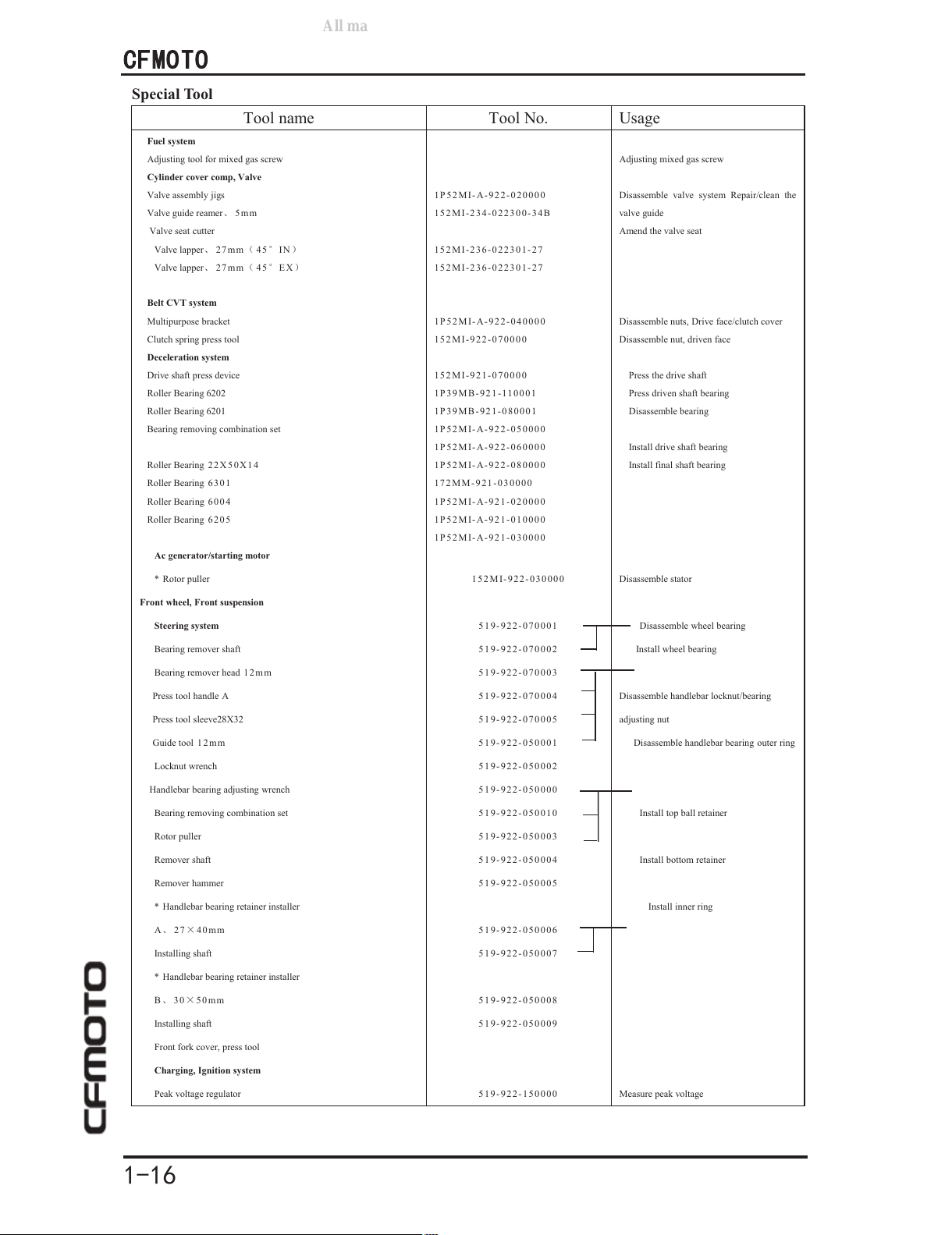

Special Tool

Tool name Tool No. Usage

Fuel system

Adjusting tool for mixed gas screw Adjusting mixed gas screw

Cylinder cover comp, Valve

Valve assembly jigs

Valve guide reamer5mm

Valve seat cutter

Valve lapper27mm45IN

Valve lapper27mm45EX

1P52MI-A-922-020000

152MI-234-022300-34B

152MI-236-022301-27

152MI-236-022301-27

Disassemble valve system Repair/clean the

valve guide

Amend the valve seat

Belt CVT system

Multipurpose bracket

Clutch spring press tool

1P52MI-A-922-040000

152MI-922-070000

Disassemble nuts, Drive face/clutch cover

Disassemble nut, driven face

Deceleration system

Drive shaft press device

Roller Bearing 6202

Roller Bearing 6201

Bearing removing combination set

Roller Bearing 2 2X50X14

Roller Bearing 6 3 0 1

Roller Bearing 6 0 0 4

Roller Bearing 6 2 0 5

152MI-921-070000

1P39MB-921-110001

1P39MB-921-080001

1P52MI-A-922-050000

1P52MI-A-922-060000

1P52MI-A-922-080000

172MM-921-030000

1P52MI-A-921-020000

1P52MI-A-921-010000

1P52MI-A-921-030000

Press the drive shaft

Press driven shaft bearing

Disassemble bearing

Install drive shaft bearing

Install final shaft bearing

Ac generator/starting motor

* Rotor puller 152MI-922-030000 Disassemble stator

Front wheel, Front suspension

Steering system

Bearing remover shaft

Bearing remover head 1 2mm

Press tool handle A

Press tool sleeve28X32

Guide tool 1 2 mm

Locknut wrench

Handlebar bearing adjusting wrench

Bearing removing combination set

Rotor puller

Remover shaft

Remover hammer

* Handlebar bearing retainer installer

A2740mm

Installing shaft

* Handlebar bearing retainer installer

B3050mm

Installing shaft

Front fork cover, press tool

519-922-070001

519-922-070002

519-922-070003

519-922-070004

519-922-070005

519-922-050001

519-922-050002

519-922-050000

519-922-050010

519-922-050003

519-922-050004

519-922-050005

519-922-050006

519-922-050007

519-922-050008

519-922-050009

Disassemble wheel bearing

Install wheel bearing

Disassemble handlebar locknut/bearing

adjusting nut

Disassemble handlebar bearing outer ring

Install top ball retainer

Install bottom retainer

Install inner ring

Charging, Ignition system

Peak voltage regulator 5 1 9 - 9 2 2 - 150000 Measure peak voltage

All manuals and user guides at all-guides.com

This manual suits for next models

1

Table of contents

Other CF MOTO Scooter manuals