CG AIR IC-TMSV-120/60 Manual

INSTALLATION & OPERATING INSTRUCTIONS FOR ELECTRONIC CONTROLS

IC-TMSV-120/60, IC-TMSV-120/60-L & IC-TMSV-240/60

IC-TMSPV-120/60, IC-TMSPV-120/60-L & IC-TMSPV-240/60

IMPORTANT: KEEP FOR WARRANTY

____________________________________________________________________________________________________________________________________________

Bathtub manufacturer Purchase date

____________________________________________________________________________________________________________________________________________

Dealer name Phone

____________________________________________________________________________________________________________________________________________

Electronic control model and serial number

____________________________________________________________________________________________________________________________________________

Blower model and serial number Pump model and serial number

TMSV > VARIABLE & P/VARIABLE

ENGLISH

2013-01-04

Thank you for your confidence in CG AIR SYSTÈMES INC. We can assure you that CG AIR SYSTÈMES INC. uses the best materials and applies the most

strict quality control measures to ensure that each and every unit meets the highest standards of quality. Furthermore, all CG AIR SYSTÈMES INC. com-

ponents comply with the requirements of the Canadian Standards Association (CSA) and Underwriters Laboratories (UL).

FUNCTIONS

The system will stop automatically after 20 minutes.

PUMP MODE:

Optional water level detectors:

Strategically installed in the bathtub, these will prevent your pump from

starting without the minimum water required.

BLOWER MODE:

Advanced function: An automatic drying cycle will start 20 minutes after

the blower is turned off.

Optional water level detectors: These activate a drying cycle 20 minutes

after the bathtub is emptied even if the system was not used.

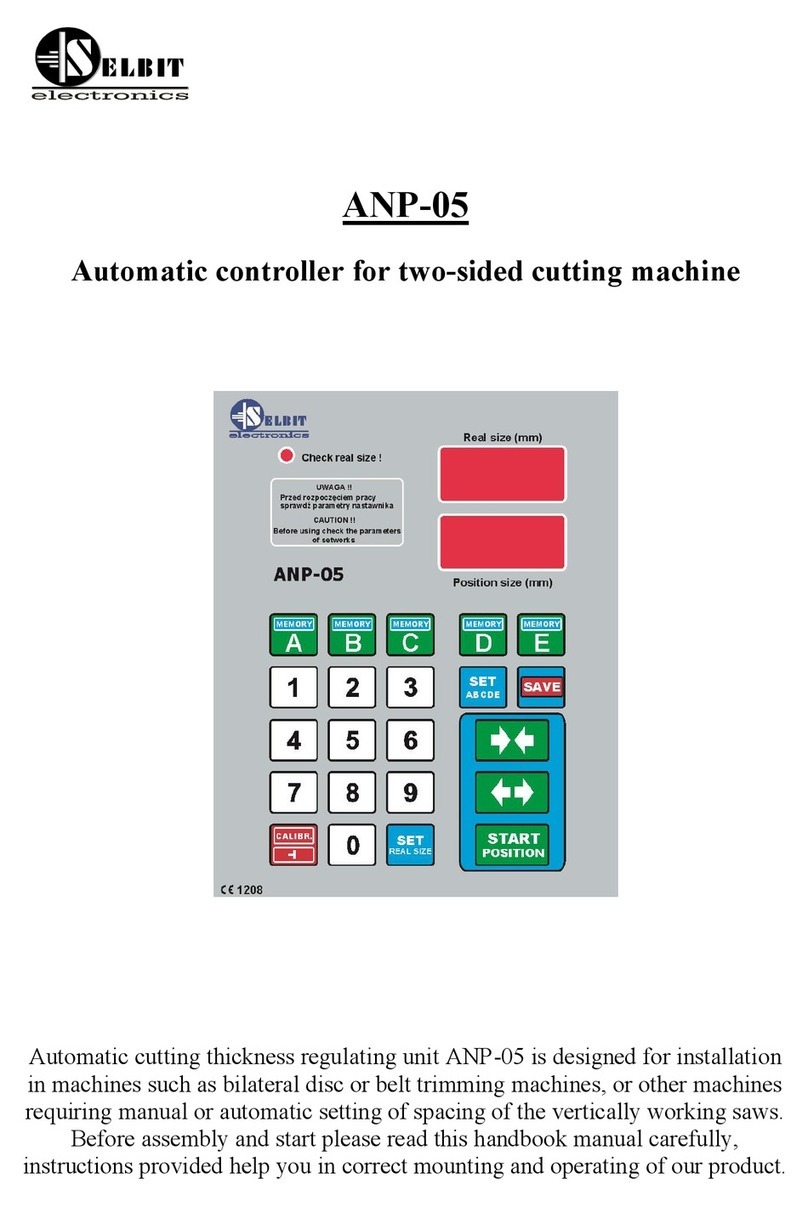

FUNCTIONS: SINGLE SYSTEM (1 KEYPAD TO ACTIVATE 1 TMS CONTROL)

TMS KEYPAD - VARIABLE SPEED TMS KEYPAD - VARIABLE SPEED WITH AUXILIARY OUTPUT

}Press once to start the blower or the pump.

}Press a second time to stop

the blower or the pump.

}Press and hold 3 sec., speed will gradually vary

between maximum and minimum.

}Press and hold 6 sec., speed will go directly

to minimum and then straight back to maximum.

}Press and hold this key to increase or decrease

the blower or the pump speed until desired level.

}Press this key to start or stop the auxiliary equipment.

They always start at maximum speed.

TMS KEYPAD - 1 SPEED TMS KEYPAD - 1 SPEED WITH AUXILIARY OUTPUT

}Press this key to start

the blower or the pump

}Press this key to stop

the blower or the pump

}Press this key to start or stop

the auxiliary equipment.

}Press this key to start

the blower or the pump.

}Press this key to stop

the blower or the pump.

Here is an example of a keypad

which activates two TMS controls:

1 VARIABLE

SPEED CONTROL

+

1 SPEED CONTROL WITH

AUXILIARY OUTPUT

Depending on which control

is used to operate the system,

button icons may differ.

}Press this key to start or stop

the blower or the pump.

}Press and hold this key to increase

or decrease the blower or

the pump speed until desired level.

}1st press; speed will vary gradually

from maximum to minimum.

}2nd press; speed will go directly to minimum

and then straight back to maximum.

}3rd press; returns to maximum speed.

FUNCTIONS: DOUBLE SYSTEM (1 KEYPAD TO ACTIVATE 2 TMS CONTROLS)

CAUTION

1. Read these instructions and rules carefully. Failure to follow them could

cause a unit malfunction. Warning! A malfunction could cause serious

bodily injuries, and/or property damages.

2. Check your local electrical safety and plumbing codes. The installation

must comply with these guidelines.

3. No modifications, additions or deletions should be made to the elec-

tronic control without factory approval.

4. This electronic control should not be located near a heat source

except for pumps, blowers or other electronic controls.

5. Wiring should be permanent. Do not use an extension cord. Have the

electrical part of the installation done by, or approved by, a qualified

electrician.

6. Always shut off the electrical power to the breaker panel before servicing.

7. Ensure that a Class A ground fault circuit interrupter (G.F.C.I.) is installed

as part of the wiring.

INSTALLATION

1. For an electronic control not provided with NEMA plugs, connect the

factory pre-installed 14/3 type SJ cable to a junction box (not provided

by the manufacturer). Depending on your model, run a separate 120V,

60Hz, 15A max or 240V, 60Hz, 15A max G.F.C.I. (Class A protected)

electric circuit from the main fuse box to the junction box. Use a 14

gage cable with 3 conductors (2 wires plus ground) in connections up

to 100 feet (30,4m) from the main fuse box. Refer to your local electrical

code if the distance between the installation site of the bathtub unit

and the main fuse box is more than 100 feet (30,4m).

2. IMPORTANT: Locate the side to be placed on top as indicated on the

control box (UP/HAUT). Fix the electronic control box firmly with two

screws.

3. Connect the keypad to the control box cable (indicated by the word

“KEYPAD” on the control box).

4. Connect the power output cable to the blower or pump. Use a junc-

tion box if your electronic control and/or blower or pump are not pro-

vided with molded plugs.

5. Connect the terminal lug on the heatsink to the ground with an

uninsulated wire of 8 gage minimum.

6. Verify connection and functioning of all components of the system

before finalizing the installation.

7. The auxiliary output option makes it possible to connect a piece of

equipment of 120Volts / 0,5Amp maximum. (Only available with

120V/60Hz control)

8. For optional water level detectors, see section WATER LEVEL DETECTORS.

OPTIONAL: WATER LEVEL DETECTORS

WALL OUTLET OR

JUNCTION BOX DEPENDING

ON INSTALLATION

OPTIONAL WITH

120V/60HZ CONTROL

AUXILIARY

EQUIPMENT

120 VOLTS

0,5AMP

MAXIMUM

MAIN BREAKER

PANEL

120V-240V/60Hz

3/14 AWG

14/2 AWG

ATTENTION, THIS GROUND

CONNECTION TO THE HEAT

SINK IS REQUIRED WHEN

GROUND LOG IS PRESENT

ELECTRONIC CONTROL

KEYPAD

CONNECTORS

IMPORTANT:

15A/120V GROUND FAULT CIRCUIT INTERRUPTER CLASS "A".

OPTIONAL: WATER LEVEL DETECTORS

WALL OUTLET OR

JUNCTION BOX DEPENDING

ON INSTALLATION

OPTIONAL WITH

240V/60HZ CONTROL

AUXILIARY

EQUIPMENT

240 VOLTS

0,5AMP

MAXIMUM

MAIN BREAKER

PANEL

120V-240V/60Hz

3/14 AWG

14/2 AWG

ELECTRONIC CONTROL

KEYPAD

CONNECTORS

ATTENTION, THIS GROUND

CONNECTION TO THE HEAT

SINK IS REQUIRED WHEN

GROUND LOG IS PRESENT

IMPORTANT:

15A/240V DOUBLE POLE BREAKER WITH GROUND

FAULT CIRCUIT INTERRUPTER CLASS "A".

INSTALLATION: SINGLE SYSTEM (1 KEYPAD TO ACTIVATE 1 TMS CONTROL)

INSTALLATION FOR UL AND CSA CERTIFICATIONS - 120 VOLTS

INSTALLATION FOR UL AND CSA CERTIFICATIONDS- 240 VOLTS

IMPORTANT:

15A/240V DOUBLE POLE BREAKER WITH GROUND

FAULT CIRCUIT INTERRUPTER CLASS "A".

MAIN BREAKER

PANEL

120V-240V/60Hz

OPTIONAL: WATER LEVEL DETECTORS

OPTIONAL: WATER LEVEL DETECTORS

OPTIONAL WITH

120V/60HZ CONTROL

AUXILIARY

EQUIPMENT

120 VOLTS

0,5AMP

MAXIMUM

120 VOLTS

0,5AMP

MAXIMUM

14/2 AWG

3/14 AWG

3/14 AWG

WALL OUTLET OR

JUNCTION BOX

DEPENDING

ON INSTALLATION

WALL OUTLET OR

JUNCTION BOX

DEPENDING

ON INSTALLATION

OPTIONAL WITH

120V/60HZ CONTROL

AUXILIARY

EQUIPMENT

ELECTRONIC CONTROL

#1

ELECTRONIC CONTROL

#2

CONTROL

#1

CONTROL

#2

KEYPAD

CONNECTORS

ATTENTION, THIS GROUND

CONNECTION TO THE HEAT

SINK IS REQUIRED WHEN

GROUND LOG IS PRESENT

ATTENTION, THIS GROUND

CONNECTION TO THE HEAT

SINK IS REQUIRED WHEN

GROUND LOG IS PRESENT

14/3 AWG

JUNCTION BOX

ALL WIRES INSIDE THE BOX

NEED TO BE 6" LONG.

USE COPPER CONDUCTORS

ONLY.

GROUND

RED

BLACK

WHITE

IMPORTANT:

15A/240V DOUBLE POLE BREAKER WITH GROUND

FAULT CIRCUIT INTERRUPTER CLASS "A".

MAIN BREAKER

PANEL

120V-240V/60Hz

OPTIONAL: WATER LEVEL DETECTORS

OPTIONAL: WATER LEVEL DETECTORS

OPTIONAL WITH

120V/60HZ CONTROL

AUXILIARY

EQUIPMENT

120 VOLTS

0,5AMP

MAXIMUM

120 VOLTS

0,5AMP

MAXIMUM

3/14 AWG

3/14 AWG

OPTIONAL WITH

120V/60HZ CONTROL

AUXILIARY

EQUIPMENT

ELECTRONIC CONTROL

#1

ELECTRONIC CONTROL

#2

CONTROL

#1

CONTROL

#2

KEYPAD

CONNECTORS

ATTENTION, THIS GROUND

CONNECTION TO THE HEAT

SINK IS REQUIRED WHEN

GROUND LOG IS PRESENT

ATTENTION, THIS GROUND

CONNECTION TO THE HEAT

SINK IS REQUIRED WHEN

GROUND LOG IS PRESENT

OPTIONAL: WATER LEVEL DETECTORS

OPTIONAL WITH

240V/60HZ CONTROL

AUXILIARY

EQUIPMENT

240 VOLTS

0,5AMP

MAXIMUM

14/2 AWG

3/14 AWG

IMPORTANT:

15A/240V DOUBLE POLE BREAKER WITH GROUND

FAULT CIRCUIT INTERRUPTER CLASS "A".

MAIN BREAKER

PANEL

120V-240V/60Hz

GROUND

BLACK

WHITE

JUNCTION BOX

ALL WIRES INSIDE THE BOX

NEED TO BE 6" LONG.

USE COPPER CONDUCTORS ONLY.

ELECTRONIC CONTROL

#2

CONTROL

#1

CONTROL

#2

KEYPAD

CONNECTORS

OPTIONAL: WATER LEVEL DETECTORS

OPTIONAL WITH

240V/60HZ CONTROL

AUXILIARY

EQUIPMENT

240 VOLTS

0,5AMP

MAXIMUM

3/14 AWG

ELECTRONIC CONTROL

#1

ATTENTION, THIS GROUND

CONNECTION TO THE HEAT

SINK IS REQUIRED WHEN

GROUND LOG IS PRESENT

ATTENTION, THIS GROUND

CONNECTION TO THE HEAT

SINK IS REQUIRED WHEN

GROUND LOG IS PRESENT

INSTALLATION: DOUBLE SYSTEM (1 KEYPAD TO ACTIVATE 2 TMS CONTROLS)

INSTALLATION FOR UL CERTIFICATION - 120 VOLTS INSTALLATION FOR UL OR CSA CERTIFICATIONS - 120 VOLTS

INSTALLATION FOR UL OR CSA CERTIFICATIONS - 240 VOLTS

WARRANTY

All electronic controls are warranted to be free of defects in manufactur-

ing, material and workmanship for a period of one year from the date of

purchase by the owner/end-user.

Limitations

This warranty does not apply to the bathtub and/or spa but solely to the

components manufactured by CG AIR SYSTÈMES INC.

This warranty shall not apply to the following incorrect operating proce-

dures, breakage or damages caused by fault, abuse, misuse, careless-

ness, misapplication, alteration, modification, improper maintenance of

the unit, as well as an act of God, fire, chemical or natural corrosion or

any other casualty.

The owner of the product covered by the present warranty is entirely

responsible for the proper installation of the product in accordance with

the installation manual provided. CG AIR SYSTÈMES INC. neither installs

nor supervises nor contracts for the installation and consequently cannot

be held responsible for the installation.

CG AIR SYSTÈMES INC. is not responsible for any damages or claims result-

ing from defects that could have been discovered, repaired or avoided

by inspection and testing prior to installation.

CG AIR SYSTÈMES INC. makes no express warranty, no warranty for mer-

chantability, no warranty of fitness for particular purposes, neither any other

warranty implied or statutory for its products other than specified above.

In no event shall CG AIR SYSTÈMES INC.’s liability exceed the purchase

price of the defective part.

If any such product proves to be defective within the warranty period,

CG AIR SYSTÈMES INC. reserves the right to repair or replace the defec-

tive product with one of equal value.

Commercial limitations

In addition to the above conditions and limitations, if the product is to be

used as a display, the warranty period begins when the product has

been placed on display. Under no circumstances will CG AIR SYSTÈMES

INC. be responsible for any profit loss due to a malfunction of the unit. This

warranty gives the owner/end-user specific legal rights and the

owner/end-user may have other rights which vary from one

state/province to another.

CG AIR SYSTÈMES INC. reserves the right to discontinue and/or change

models, colors and specifications in design together with replacement

parts without notice and without incurring any obligations.

TROUBLESHOOTING

Always switch off power before servicing.

The electronic control fails to operate:

1. Verify electric power supply. Reset circuit or replace fuse if necessary.

2. Verify all electrical connections (including keypad connection).

3. Verify that the Ground Fault Circuit Interrupter (G.F.C.I.) has not

tripped.

4. If the system has been functioning for quite some time, it is possible that

the thermal protection has shut off the motor. It is programmed to

switch off the system and to wait for at least 30 minutes before using it

again. Verify that air is flowing through all jets. If not, cover the jets with

warm water, then switch system ON and OFF several times. The air out-

lets should be cleared. If this is not sufficient, carefully knock on the jet

heads with the handle of a screw driver or a similar plastic tool while

the blower is running.

5. If you have added a keypad extension, make sure that it has been cer-

tified by the manufacturer of the electronic control. It could be the

cause of your problem.

The blower or pump never stops:

1. Verify that the blower is well connected to the control box.

2. Verify the keypad connection.

3. Verify that there is no water reaching the electrical components under

your bathtub.

The pump starts but stops after about 1 second:

1. Verify the keypad connection.

2. The water level sensor does not detect water in the bathtub. Water

must reach at least 2 inches (5cm) above the highest jet, add water

and restart. If there is sufficient water, the water level detectors may

not be installed properly.

3. Contact your dealer for further troubleshooting.

For further details visit our web site at: www.cgair.com

PRINTED AND

MANUFACTURED

IN CANADA

ELECTRONIC

CONTROL #1

AIR

ELECTRONIC

CONTROL #2

WHIRLPOOL

OUTPUT INTPUT

UP/HAUT

W/D KEYPAD OUTPUT INTPUT

UP/HAUT

W/D KEYPAD

BLOWER & PUMP SYSTEM

3

1

4

2

CONTROL

#1

CONTROL

#2

KEYPAD

CONNECTORS

BLOWER SYSTEM PUMP SYSTEM

BLOWER PUMP

12

1

2

WATER LEVEL DETECTORS

SINGLE SYSTEM (1 KEYPAD TO ACTIVATE 1 TMS CONTROL)

DOUBLE SYSTEM (1 KEYPAD TO ACTIVATE 2 TMS CONTROLS)

This manual suits for next models

5

Popular Controllers manuals by other brands

Phocos

Phocos ECO-N user manual

MidNite Solar

MidNite Solar Brat quick start guide

ZPA Pecky, a.s.

ZPA Pecky, a.s. MODACT MOKPED 100 Ex Installation and operating instructions

DNF Controls

DNF Controls ST600-KIPRO user manual

Life

Life RG1 24DL Installation, use and maintenance

Davey

Davey RainBank KRBS1 installation instructions