CG Emotron DSV15 User manual

Emotron DSV15/35 AC drive

0.25 … 2.2 kW

Mounting and switch on instruction

This page intentionally left blank!

3

Contents

Contents

1General information 4

1.1 Read first, then start 4

1.2 Notations and conventions 4

1.2.1 Product code 4

2Safety instructions 5

2.1 Basic safety measures 5

2.2 Residual hazards 6

2.3 Application as directed 6

3Product description 7

4Mounting 8

4.1 Important notes 8

4.2 Mechanical installation 9

4.3 Electrical installation 12

4.3.1 1-phase mains connection 230/240 V 12

4.3.1.1 Fusing and terminal data 13

4.3.2 3-phase mains connection 400 V 16

4.3.2.1 Fusing and terminal data 17

4.3.3 Connection to the IT system 18

4.3.4 CANopen 19

4.3.5 Modbus 20

4.3.6 PROFIBUS 21

4.3.7 EtherCAT 22

4.3.8 EtherNet/IP 23

4.3.9 PROFINET 24

4.3.10 Connection of the safety module 25

4.3.10.1 Important notes 25

4.3.10.2 Connection plan 26

4.3.10.3 Terminal data 26

5Commissioning 27

5.1 Important notes 27

5.2 Before initial switch-on 27

5.3 Initial switch-on / functional test with terminal control 28

6Technical data 30

6.1 Standards and operating conditions 30

6.2 1-phase mains connection 230/240 V 32

6.2.1 Rated data 32

6.3 3-phase mains connection 400 V 33

6.3.1 Rated data 33

4

1 General information

Read first, then start

1General information

1.1 Read first, then start

Read this documentation thoroughly before carrying out the installation andcommissioning.

▶Please observe the safety instructions!

1.2 Notations and conventions

1.2.1 Product code, examples:

DSV15-23-1P7-20

DSV35-40-1P3-20

DSV

15

23

1P7

20

Series

1-phase

230V

Rated current 1.7A

IP20

DSV

35

40

1P3

20

Series

3-phase

400V

Rated current 1.3A

IP20

Information

and tools with regard to the Emotron products can be found on the Internet:

http://www.emotron.com

à

File-archive

WARNING!

5

Safety instructions 2

Basic safety measures

2Safety instructions

2.1 Basic safety measures

Disregarding the following basic safety measures may lead to severe personal injury and damage to material

assets!

The product

• must only be used as directed.

• must never be commissioned if they display signs of damage.

• must never be technically modified.

• must never be commissioned if they are not fully mounted.

• must never be operated without required covers.

Connect/disconnect all pluggable terminals only in deenergised condition.

Only remove the product from the installation in the deenergisedstate.

Insulation resistance tests between 24V control potential and PE: According to EN 61800−5−1, the maximum

test voltage must not exceed 110 VDC.

Observe all specifications of the corresponding documentation supplied. This is the precondition for safe

and trouble-free operation and for obtaining the product features specified.

The procedural notes and circuit details described in this document are only proposals. It is up to the user to

check whether they can be adapted to the particular applications. CG D&A does not take any responsibility

for the suitability of the procedures and circuit proposals described.

The product must only be used by qualified personnel. IEC 60364 or CENELEC HD 384 define the skills of

these persons:

• They are familiar with installing, mounting, commissioning, and operating the product.

• They have the corresponding qualifications for their work.

• They know and can apply all regulations for the prevention of accidents, directives, and lawsapplicable

at the place of use.

Observe the specific notes in the other chapters!

6

2 Safety instructions

Residual hazards

2.2 Residual hazards

The user must take the residual hazards mentioned into consideration in the risk assessment for his/her

machine/system.

If the above is disregarded, this can lead to severe injuries to persons and damage to material assets!

Product

Observe the warning labels on the product!

Icon

Description

Electrostatic sensitive devices:

Before working on the inverter, the staff must ensure to be free of electrostatic charge!

Dangerous electrical voltage

Before working on the inverter, check whether all power connections are dead! After mains OFF, power con-

nections X100 and X105 carry a dangerous electrical voltage for the time specified on the inverter!

High leakage current:

Carry out fixed installation and PE connection in compliance with EN 61800−5−1 or EN 60204−1 !

Hot surface:

Use personal protective equipment or wait until devices have cooleddown!

Motor

If there is a short circuit of two power transistors, a residual movement of up to 180°/number of pole pairs

can occur at the motor! (For 4-pole motor: residual movement max. 180°/2 =90°).

This residual movement must be taken into consideration by the user for his/her risk assessment.

2.3 Application as directed

• The product must only be operated under the operating conditions prescribed in this documentation.

• The product meets the protection requirements of 2014/35/EU: Low-Voltage Directive.

• The product is not a machine in terms of 2006/42/EC: Machinery Directive.

• Commissioning or starting the operation as directed of a machine with the product is not permitted until

it has been ensured that the machine meets the regulations of the EC Directive 2006/42/EC: Machinery

Directive; observe EN 60204−1.

• Commissioning or starting the operation as directed is only allowed when there is compliance with the

EMC Directive 2014/30/EU.

• The harmonised standard EN 61800−5−1 is used for the inverters.

• The product is not a household appliance, but is only designed as component for commercial orprofes-

sional use in terms of EN 61000−3−2.

• In accordance with EN 61800−3, the product can be used in drive systems that have to comply with the

categories given in the technical data.

In residential areas, the product may cause EMC interferences. The operator is responsible for taking

interference suppression measures.

7

Product description 3

3Product description

8

4

Mounting

Important notes

4Mounting

4.1 Important notes

Dangerous electrical voltage

Possible consequence: death or severe injuries

▶All works on the inverter must only be carried out in the deenergised state.

▶After switching off the mains voltage, wait for at least 3 minutes before you start working.

DANGER!

9

Mounting

Mechanical

installation

4

4.2 Mechanical installation

Dimensions 0,25 kW ... 0,37 kW

All dimensions in mm

10

4

Mounting

Mechanical installation

Dimensions 0,55 kW ... 0,75 kW

All dimensions in mm

11

Mounting

Mechanical

installation

4

Dimensions 1,1 kW ... 2,2 kW

All dimensions in mm

12

4

Mounting

Standard

I/O

100

mA

F1

Q1

L

L

L1

L2

3

N

PE

3/N/PE

AC

400

V

L1

L2

3

N

PE

3/N/PE

AC

208

V

...

240

V

L1

L2

N

PE

2/N/PE

AC

208

V

...

240

V

1/N/PE

A

C

170

V

...

264

V

45

Hz

...

65

Hz

F1

…

F2

Q1

2/PE

A

C

170

V

...

264

V

45

Hz

...

65

Hz

F1

…

F3

Q1

2/PE

A

C

170

V

...

264

V

45

Hz

...

65

Hz

+

+

CANopen

Modbus

PROFIBUS

EtherCAT

PROFINET

EtherNet/IP

+

AC 240 V

3 A

Application I/O

+24

V

+10

V

ϑ

ϑ

DC

24

V

SELV/PELV

(+19.2

…

+28.8

V)

DI3

DI4

+

M

3~

S1

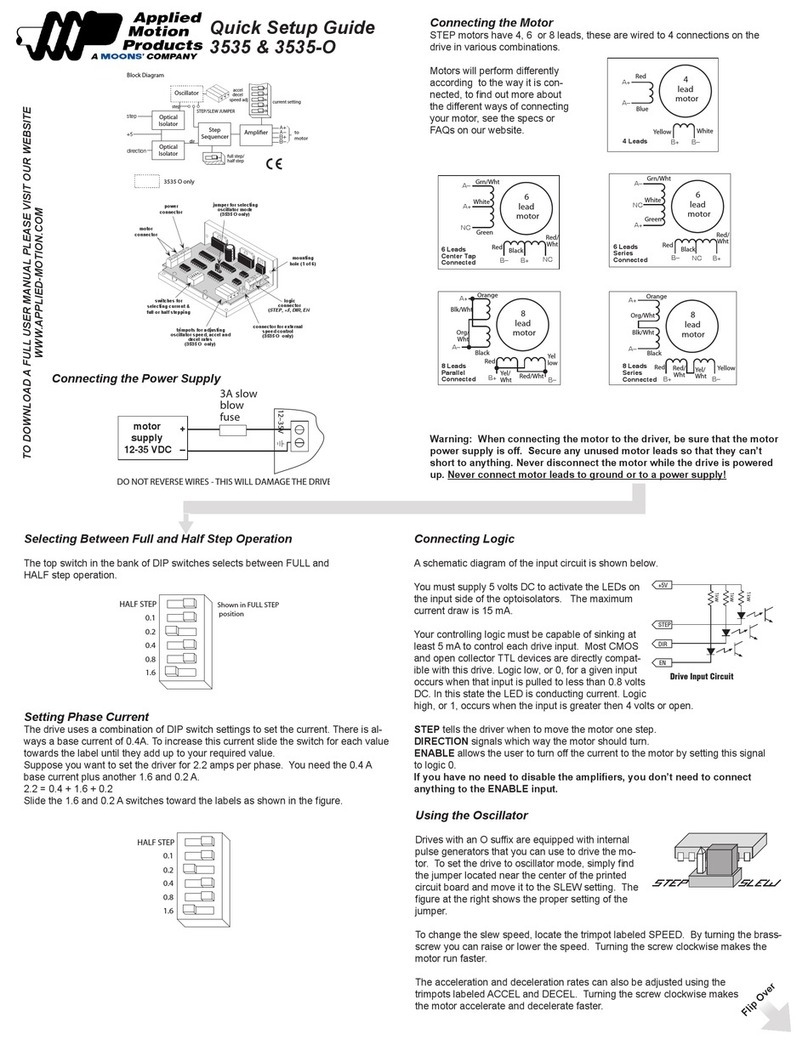

Electrical installation

1-phase mains connection 230/240 V

4.3 Electrical installation

4.3.1 1-phase mains connection 230/240 V

The wiring diagram is valid for Emotron DSV15-35 inverters.

COM

NC

NO

Fig. 1: Wiring example

S1 Run/Stop

Fx Fuses

Q1 Mains contactor

--- Dashed line = options

X105

U

V

W

Rb1

Rb2

X100

L1

L2/N

X109

T1

T2

X9

X1

SIA

GS

SIB

Safety

STO

X100

L1

L2/N

X216

CH

CL

CG

X3

24E

24E

GND

GND

DO1

AI1

DI1

AI2

DI2

10V

DI3

GND

DI4

AO1

DI5

24V

DI6

24V

DI7

AO2

DI1

DO2

GND

GND

X216

TA

TB

COM

4.4k

4.4k

0

...

10

V

X226

1k

...

10k

10

mA

4.4k

X100

L1

L2/N

4.4k

X246

IN

OUT

X247

4.4k

4.4k

IN

OUT

X256

4.4k

X257

X266

X267

13

Mounting

4

Electrical installation

1-phase mains connection 230/240 V

4.3.1.1 Fusing and terminal data

Inverter

DSV15231P7

DSV15232P4

DSV15233P2

DSV15234P2

DSV15236P0

DSV15237P0

DSV15239P6

Cable installation in

compliance with

EN 60204-1

Laying system

B2

Operation

without mains choke

Fuse

Characteristic

gG/gL or gRL

Max. rated current

A

10

10

16

16

25

25

25

Circuit breaker

Characteristic

B

Max. rated current

A

10

10

16

16

25

25

25

Operation

with mains choke

Fuse

Characteristic

gG/gL or gRL

Max. rated current

A

10

10

16

16

25

25

25

Circuit breaker

Characteristic

B

Max. rated current

A

10

10

16

16

25

25

25

Earth-leakage circuit

breaker

≥ 30 mA, type A or B

Mains connection

Connection

X100

Connection type

Screw terminal

Min. cable cross-section

mm²

1

Max. cable cross-section

mm²

2.5

6

Stripping length

mm

8

Tightening torque

Nm

0.5

0.7

Required tool

0.5 x 3.0

0.6 x 3.5

Motor connection

Connection

X105

Connection type

Screw terminal

Min. cable cross-section

mm²

1

Max. cable cross-section

mm²

2.5

Stripping length

mm

8

Tightening torque

Nm

0.5

Required tool

0.5 x 3.0

PE connection

Connection

PE

Connection type

PE screw

Min. cable cross-section

mm²

1

Max. cable cross-section

mm²

6

Stripping length

mm

10

Tightening torque

Nm

1.2

Required tool

0.8 x 5.5

14

4

Mounting

Electrical

installation

3-phase mains

connection

400 V

Standard

I/O

100

mA

L

L1

L2

3

N

PE

3/N/PE

AC

400

V

F1

…

F3

Q1

3/PE

A

C

340

V

...

528

V

45

Hz

...

65

Hz

CANopen

Modbus

PROFIBUS

EtherCAT

PROFINET

EtherNet/IP

+

AC 240 V

3 A

Application I/O

+24

V

+10

V

ϑ

ϑ

DC

24

V

SELV/PELV

(+19.2

…

+28.8

V)

DI3

DI4

+

M

3~

S1

4.3.2 3-phase mains connection 400 V

The wiring diagram is valid for Emotron DSV 35 inverters.

COM

NC

NO

Fig. 3: Wiring example

S1 Run/Stop

Fx Fuses

Q1 Mains contactor

--- Dashed line = options

X105

U

V

W

Rb1

Rb2

X100

L1

L2

L3

+UG

-UG

X109

T1

T2

X9

X1

SIA

GS

SIB

Safety

STO

X216

CH

CL

CG

X3

24E

24E

GND

GND

DO1

AI1

DI1

AI2

DI2

10V

DI3

GND

DI4

AO1

DI5

24V

DI6

24V

DI7

AO2

DI1

DO2

GND

GND

X216

TA

TB

COM

4.4k

4.4k

0

...

10

V

X226

1k

...

10k

10

mA

4.4k

4.4k

X246

IN

OUT

X247

4.4k

4.4k

IN

OUT

X256

4.4k

X257

X266

X267

15

Mounting

Electrical

installation

3-phase mains

connection

400 V

4

4.3.2.1 Fusing and terminal data

Inverter

DSV35401P3 DSV35401P8 DSV35402P4 DSV35403P2 DSV35403P9 DSV35407P3

Cable installation in

compliance with

EN 60204-1

Laying system

B2

Operation

without mains choke

Fuse

Characteristic

gG/gL or gRL

Max. rated current

A

10

10

10

16

16

16

Circuit breaker

Characteristic

B

Max. rated current

A

10

10

10

16

16

16

Operation

with mains choke

Fuse

Characteristic

gG/gL or gRL

Max. rated current

A

10

10

10

16

16

16

Circuit breaker

Characteristic

B

Max. rated current

A

10

10

10

16

16

16

Earth-leakage circuit

breaker

≥ 30 mA, type B

Mains connection

Connection

X100

Connection type

Screw terminal

Min. cable cross-section

mm²

1

Max. cable cross-section

mm²

2.5

Stripping length

mm

8

Tightening torque

Nm

0.5

Required tool

0.5 x 3.0

Motor connection

Connection

X105

Connection type

Screw terminal

Min. cable cross-section

mm²

1

Max. cable cross-section

mm²

2.5

Stripping length

mm

8

Tightening torque

Nm

0.5

Required tool

0.5 x 3.0

PE connection

Connection

PE

Connection type

PE screw

Min. cable cross-section

mm²

1

Max. cable cross-section

mm²

6

Stripping length

mm

10

Tightening torque

Nm

1.2

Required tool

0.8 x 5.5

16

4

Mounting

Electrical

installation

Connection

to the IT system

4.3.3 Connection to the IT system

Internal components have earth/ground potential if the IT screws are not removed.

Consequence: the monitoring functions of the IT system respond.

▶Before connection to an IT system be absolutely sure to remove the IT screws.

DSV15231P7, DSV15232P4

DSV15233P2, DSV15234P2, DSV15236P0, DSV15237P0, DSV15239P6

NOTICE!

TX10

(≥ 0.55 kW)

TX10

TX10

(≥ 0.55 kW)

17

Mounting

Electrical

installation

CANopen

4

4.3.4 CANopen

Typical topologies

Terminal description

CANopen

Connection

X216

Connection type

Spring terminal

Min. cable cross-section

mm²

0.5

Max. cable cross-section

mm²

2.5

Stripping length

mm

10

Tightening torque

Nm

-

Required tool

0.4 x 2.5

Basic network settings

Use the DIP switch to set the node address and baud rate and to activate the integrated bus terminating

resistor.

Bus termination

Baud rate

CAN node address

R

d

c

b

a

64

32

16

8

4

2

1

OFF

OFF

ON

OFF

ON

20 kbps

OFF

OFF

OFF

OFF

OFF

OFF

OFF

Inactive

OFF

OFF

ON

ON

50 kbps

Value fromparameter

ON

OFF

OFF

ON

OFF

125 kbps

Node address - example:

Active

OFF

OFF

OFF

ON

250 kbps

OFF

OFF

ON

OFF

ON

ON

ON

OFF

OFF

OFF

OFF

Value fromparameter

(500 kbps)

Node address = 16 + 4 + 2 + 1 = 23

OFF

ON

OFF

OFF

1 Mbps

All other combinations

Value fromparameter

(500 kbps)

Printed in bold = CG setting

The network must be terminated with a 120 Ω resistor at the physically

first

and last node.

Set the "R" switch to ON at these nodes.

CH CL CG CH CL CH CH CL CG

Line

A1

A2

A3

An

120 120 120 120

R R

X216 X216 CG

R

X216 CL CG

R

X216

a

O

N

R

d

c

b

1

2

4

8

16

32

64

CAN Address

Baud

18

4

Mounting

Electrical

installation

Modbus

4.3.5 Modbus

Typical topologies

Terminal description

Modbus

Connection

X216

Connection type

Spring terminal

Min. cable cross-section

mm²

0.5

Max. cable cross-section

mm²

2.5

Stripping length

mm

10

Tightening torque

Nm

-

Required tool

0.4 x 2.5

Basic network settings

Use the DIP switch to set the node address and baud rate and to activate the integrated bus terminating

resistor.

R c b a 128 64 32 16 8 4 2 1

Mode Address

Bus termina-

tion

Baud rate

Parity

Modbus node address

R

c

b

a

128

64

32

16

8

4

2

1

OFF

n.c.

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

Inactive

Automatic detection

Automatic detection

Value fromparameter

ON

ON

ON

Node address - example:

Active

Value fromparameter

Value fromparameter

OFF

OFF

OFF

ON

OFF

ON

ON

ON

Node address = 16 + 4 + 2 + 1 = 23

Node address > 247: value from parameter

Printed in bold = CG setting

The network must be terminated with a 120 Ω resistor at the physically

first

and last node.

Set the "R" switch to ON at these nodes.

TA

TB COM

TA TA TA

TB

COM

Line

A1

A2

A3

An

120 120 120 120

X216

X216 TB COM

X216 TB COM

X216

O

N

19

Mounting

Electrical

installation

PROFIBUS

4

R

4.3.6 PROFIBUS

Typical topologies

M Master X1 Repeater

Sxx Slaves R Activated bus terminating resistor

Sub D socket 9-pin - X226

View

Pin

Assignment

Description

5 1

5 1

9 6

9 6

1

Shield

Additional shield connection

2

n.c.

3

RxD/TxD-P

Data line-B (received data/transmitted data+)

4

RTS

Request To Send (received data/transmitted data, no differential

signal)

5

M5V2

Reference potential (bus terminating resistor-)

6

P5V2

5 V DC / 30 mA (bus terminating resistor +, OLM, OLP)

7

n.c.

8

RxD/TxD-N

Data line-A (received data/transmitted data-)

9

n.c.

Basic network settings

Use the DIP switch to set the station address.

The baud rate is detected automatically.

Printed in bold = CG setting

The network must be terminated with a resistor at the physically

first

and last node.

Activate

the bus

terminating

resistor at these nodes in the bus

connection

plug.

64 32 16 8 4 2 1

O

N

PROFIBUS Address

PROFIBUS

station

address

64

32

16

8

4

2

1

OFF

OFF

OFF

OFF

OFF

OFF

OFF

Value from parameter

Station

address - example:

OFF

OFF

ON

OFF

ON

ON

ON

Station

address = 16 + 4 + 2 + 1 = 23

Do not set

station

address = 126 and

station

address = 127. These

station

addresses are invalid.

R X1 R

Line with repeater

M

R

S11

S12

S1n

S21

R

S2n

1

2

20

4

Mounting

Electrical

installation

EtherCAT

R

4.3.7 EtherCAT

Typical topologies

M Master

SD Slave Device

Bus-related information

Name

EtherCAT

Communication medium

Ethernet 100 Mbps, full duplex

Use

Connection of the inverter to an

EtherCAT network

Connection system

RJ45

Status display

2 LEDs

Connection designation

In: X246

Out: X247

Basic network settings

The rotary encoder switch allows you to set an EtherCAT identifier.

x 16 x 1

Setting

Identifier

0x00

Value fromparameter

0x01 ... 0xFF

Switch position

Line

M

IN OUT IN OUT

SD1

SD2

IN

SDn

This manual suits for next models

7

Table of contents

Other CG DC Drive manuals