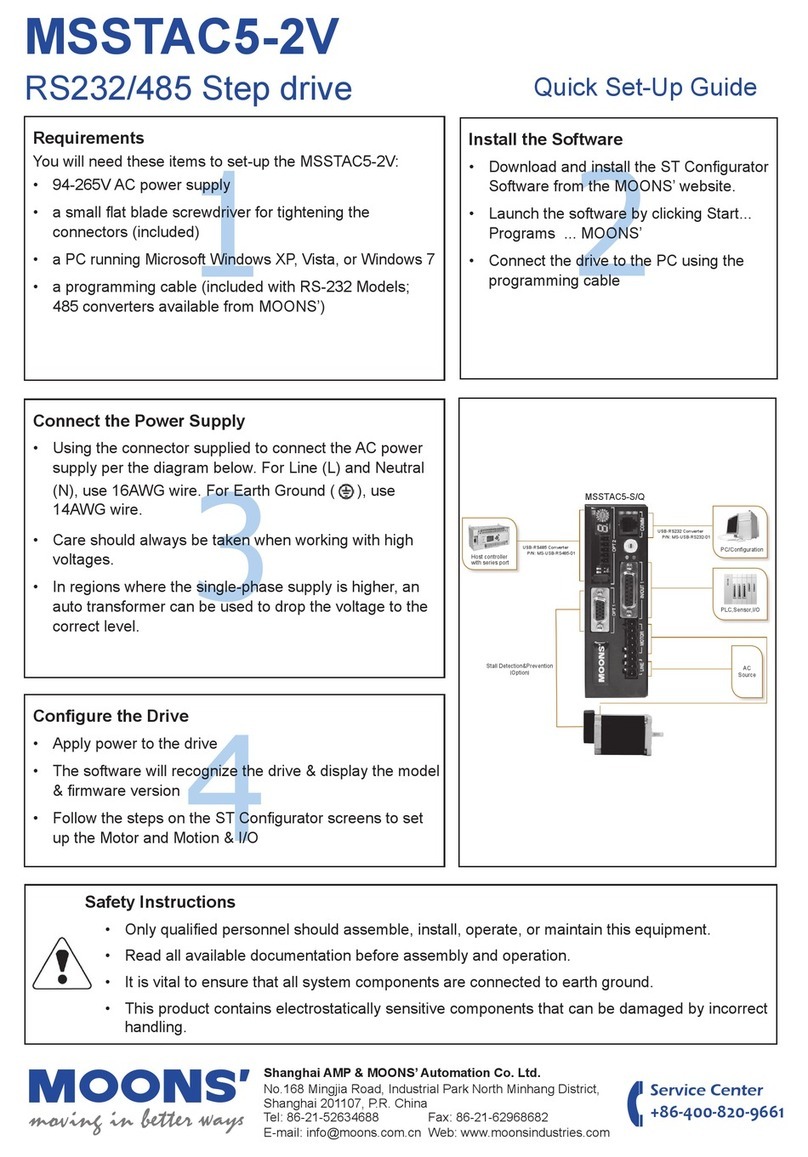

In some applications, step motors and drives are used with mechanical

switches only and there is no readily available source of +5 volts.

In these instances, the 12-35 VDC motor power supply can be used with ad-

ditional dropping resistors to power the opto LEDs. The recommended wiring

diagram is shown on page 11. Table I lists the appropriate resistor value to

use for a given power supply voltage. 1/4 watt or larger resistors should be

used.

Please do not to reverse the wiring, as damage to the LEDs will result

rendering the drives inoperable. Check your wiring carefully before

turning on the power supply!

Using Remote Speed Control Potentiometer

The latest revision of model 3535 O step motor drive includes an analog signal input

connector that can be used to control the oscillator speed externally. Normally, an on

board potentiometer controls the speed.

You will need:

• a 100kW or 200kW linear potentiometer. A multiturn type is recommended.

• a two pin female connector compatible with .025 inch square pins on .100”

centers. AMP type MTA-100 is one type that works well

• a shielded, two wire cable

To install the external pot:

• locate the connector on the 3535 O labelled ÒXSPD.Ó It can be found between the

signal connector and the three blue potentiometers.

• turn the screw on the blue SPEED potentiometer 15 turns counterclockwise. If you

don’t do this, the external potentiometer will not provide the correct speed range.

• prepare a cable with your pot on one end and the connector on the other end:

the potentiometer wiper connects to pin 2

the potentiometer CW terminal connects to pin 1

the third pot terminal connects to the wiper

the cable shield connects to the CW pot terminal

With this arrangement, speed will increase

as you turn the external pot clockwise.The

frequency range for the 200k ohm pot will be

600 to 5000 steps per second. The frequency

range for the 100k ohm pot will be900 to

5000 steps per second. The on board trim-

pots will still control acceleration and declera-

tion times. Turning the pots clockwise makes

the acceleration and deceleration faster (i.e.

reduces the time to or from speed).

Using Mechanical Switches with 3535-O Drive

The 3535-O was designed to be used with active logic and for that reason are optically

isolated. To activate the optoisolators a small, but not insignicant amount of current at

+5 volts DC is required.

cw

3535 O

Drive

external

pot

XSPD

connector

1

2

Motor

Power

Supply

12-35

VDC

+

–

R

R

Run/Stop switch

(closed=run)

Direction

switch

3535 O

drive

STEP +5 DIR

12-35VDC

Supply R Supply R Supply R

Voltage Ohms Voltage Ohms Voltage Ohms

12 1200 21 3000 30 4700

15 1800 24 3600 33 5100

18 2400 27 4200 35 5600

Table I: External Dropping Resistors

Choosing a Power Supply

To nd out how to choose a power supply refer to the tech notes on our website.

Mounting the Drive

To operate the drive continuously at maximum power you must properly mount it on

a heat sinking surface with a thermal constant of no more than 4°C/watt. Often, the

metal enclosure of your system will make an eective heat sink.

smooth flat surface

#4 screws

wide side mount narrow side mount

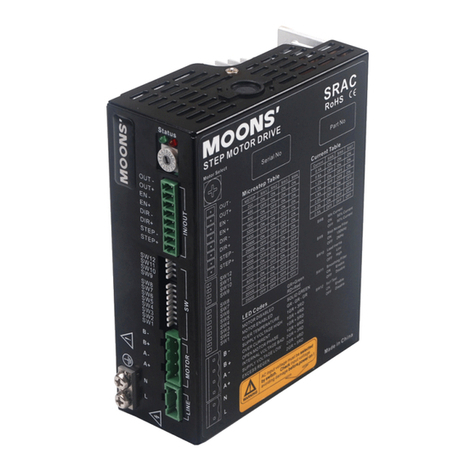

Technical Specications

Ampliers

Dual, bipolar H-bridge, pulse width modulated switching at 20kHz. 12-35 VDC

input. 0.4 - 3.5 amps/phase output current, switch selectable in 0.1 A incre-

ments. 122 watts maximum output power. Automatic idle current reduction,

reduces current to 50% of setting after one second

Oscillator (O sux)

400 to 5000 steps per second. Linear acceleration and deceleration, individu-

ally adjustable from 5 to 900 msec.

Inputs

Step, direction and enable, optically isolated, 5V logic. 5mA/signal, sink re-

quirement. Motor steps on rising edge of stepline. 10 µsec minimum low pulse.

50 µsec minimum set up time for direction signal. Step input doubles as run/

stop in oscillator mode. (0 = run, 1 = stop.)

Physical

Mounted on 1/4 inch thick black anodized aluminum heat transfer chassis.

1.5 x 3.0 x 4.0 inches overall. Power on LED.

Maximum chassis temperature: 70° C.

Connectors

European style screw terminal blocks. Motor: 4 position. Signal Input: 4 posi-

tion. DC Input: 2 position.

CE Mark.

Complies with EN55011A and EN50082-1(1992).

Applied Motion Products, Inc.

18645 Madrone Pkwy

Morgan Hill, CA 95037

T: 800-525-1609 | applied-motion.com

Doc 920-0013 Rev C - 8/4/2022