CGS HELIOS QD TI User manual

206 FLETCHER RD ᛫ARTESIA, NM 88210 CGS SUPPRESSORS LLC, A DIVISION OF CGS GROUP LLC

HELIOS QD TI SUPPRESSOR MANUAL (C)

Before using this product, please take a moment to read and understand this manual. If you have any questions, please feel free to

call us at any time!

PRODUCT FEATURES

•Variable Function, CGS silencers are the only silencers

in the world capable of being a standard function type

silencer or a flow bypass type silencer simply by

swapping the front cap with a 7/8”wrench.

•DMLS (3D Printed) additive manufactured construction

provides a stronger and more durable product.

•Modularity at both ends makes it the most versatile

and capable silencer available.

•Shallow taper joints are used at each threaded junction

to maintain concentricity and provide superior

retention.

•Comes with many feature-rich accessories with

additional parts available for separate purchase

depending on user needs.

•Proprietary coating prevents copper/carbon/lead/etc

build up within the silencer, but the silencer can still be

serviced if and when necessary.

PRODUCT SPECIFICATIONS

•Caliber –5.56mm, but up to 7.62mm Capable.

•Length –7.2” in Direct Thread Config.

•Diameter –1.5” at Rear, 1.75” at Front.

•Weight –11.6oz in 1/2X28 Direct Thread Config, 11oz

with QD Adapter Ring.

•10” minimum barrel length (5.56 and similar such as

5.45x39).

MATERIAL SPECIFICATIONS

•Helios QD Ti Core –Grade 5 Titanium

•Kit Accessories –Grade 5 Titanium

•Finishes –S-Line (HBN) internal, black DLC external

206 FLETCHER RD ᛫ARTESIA, NM 88210 CGS SUPPRESSORS LLC, A DIVISION OF CGS GROUP LLC

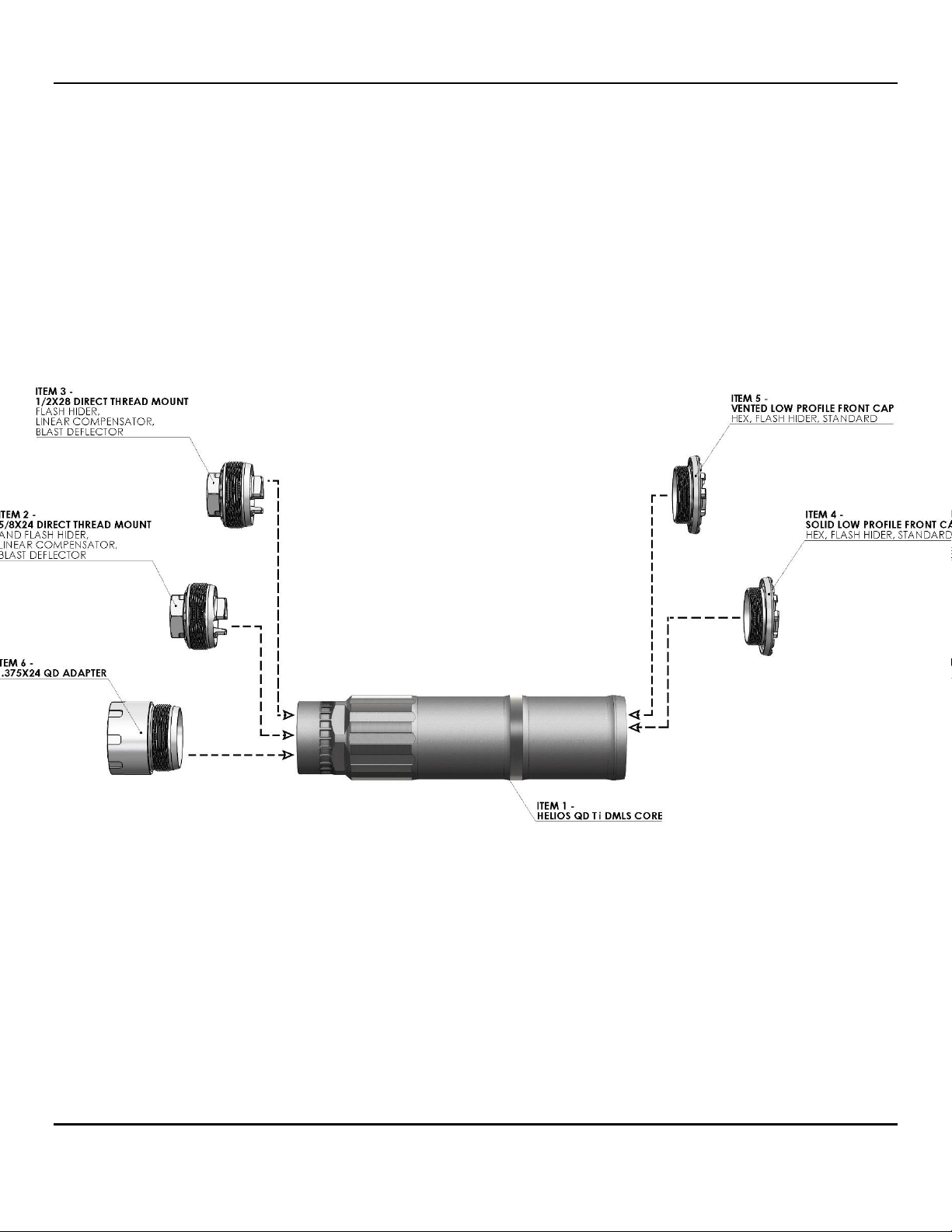

HELIOS QD TI (COM) SUPPRESSOR PARTS DIAGRAM

206 FLETCHER RD ᛫ARTESIA, NM 88210 CGS SUPPRESSORS LLC, A DIVISION OF CGS GROUP LLC

GENERAL OVERVIEW

The Helios QD Ti is based on the Helios QD, which is a shorter variant of CGS Hyperion Technology utilizing 1.375x24

pattern QD mount compatibility. The Helios QD, which this titanium variant is based on, was made for left handed shooters

to reduce/eliminate toxic gas in the face depending on the host firearm and was originally made for a 10.4” select fire 5.56

carbine and similar hosts such as the MK18 as well as for the M249, MK46, and variants. In some cases, the Helios QD Ti

is quieter than some other companies' fullsize rifle silencers even though the Helios QD Ti is only 6.58" added length in its

default direct thread state. As most people will never need a heavy duty silencer for extreme hard use with short barrel

rifles, machine guns, and belt feds, the Helios QD Ti will fit the bill for the vast majority of peoples realistic, practical uses.

The Helios QD Ti is built as a lightweight, and the first of its type dual function, 5.56mm silencer that just happens to have

a bore large enough to pass a 7.62mm projectile. It's a lightweight 5.56 silencer first and foremost, but with the balancing

act to get it where we wanted for sound at the ear and muzzle, we settled on a bore diameter that just happens to fit

7.62mm projectiles. Using the larger bore on a 5.56mm silencer helps achieve better sound at the ear on some 5.56mm

and similar semi auto hosts. The .355-.375” bore diameter tapering larger going forward also helps with unstable 5.56mm

and similar, basically eliminating the potential for strikes. The rear socket is modular, so you can use it as a direct thread

silencer or you can use it with any 1.375x24 pattern QD mount. All CGS rifle silencers at the time of this writing are

classified as precision rifle silencers due to their symmetrical design. CGS rifle silencers have very minimal POI shift, if

even present, and is often at the 6 o’clock area. Repeatability is excellent due to symmetrical design and concentricity

throughout the suppressor.

The CGS Helios QD Ti is limited to barrels of 10” or longer with 5.56 and similar such as 5.45. Currently everything

else just has to properly stabilize the projectile, such as using a 1:5 twist rate on 5.5” 300 Blackout subsonic. The Helios

QD Ti has a temperature limit of ~850 deg F, and once reaching this temperature band it should be allowed to cool

down. This is because, regardless of who makes a titanium silencer, titanium has inherent material properties which make

it more reactive and more rapidly susceptible to particle erosion past this temperature limit. ~850 deg F is around three full

auto magazines out of a 10.5”5.56 host firearm. Most people will never come close to reaching this temperature which is

why the Helios QD Ti is beyond suitable for most people. Stuff such as carbine classes and normal shooting is never going

to be an issue with this silencer. And in the future other accessories will be available which will further enhance the

capabilities of the Helios QD Ti.

The CGS Helios QD Ti comes with:

1) Helios QD Ti Core

2) 5/8 x 24 TPI Direct Thread Mount

3) 1/2 x 28 TPI Direct Thread Mount

4) Solid Low Profile Front Cap, Hex, Flash Hider, Standard

5) Vented Low Profile Front Cap, Hex, Flash Hider, Standard

6) QD Adapter Mount for 1.375 x 24 TPI pattern QDs from various companies

7) Hook Wrench for QD adapter (various other companies hook wrench products may be used if they fit)

8) SKB Hard Case for all components

The additive manufacturing process we use makes our rifle silencers far stronger than other comparative rifle silencers for

a few reasons. Our manufacturing process creates parts with even higher strength and hardness than billet or forgings or

castings or MIM, and does so with increased material density. There are no welds so there are no welds to fail and no

welds to warp which cause concentricity problems along the length of the silencer. This eliminates welding issues such as

welds breaking and their byproducts such as warping, entirely. The monolithic core structure and lack of welds make CGS

rifle silencers very strong and eliminates failures, concentricity problems, and QC issues from welds. Even if the weld looks

perfectly silver on the exterior you can easily have something that looks fine on the outside, but the weld won’t penetrate

properly for a number of reasons such as electrical problems within the machine itself, operator error, contamination, etc,

so the weld will be very weak and it won’t be caught until the weld failure occurs in the end users hands as their using it.

That applies to all materials, not just titanium.

The Hyperion VCD (Variable Core Diameter) design itself makes the silencer stronger than any other comparative silencer

by better controlling heat and pressure to prevent hot spots from forming. The first chamber is immediately vented and gas

is allowed to flow around the first core and is then reintroduced to the main flow further downstream. This also helps

reduce thermal signature as well as IR glow under nightvision. Simplicity in design eliminates unnecessary complexity

within the silencer. CGS titanium silencers also have a proprietary heat treatment applied which further increases strength

and hardness of the silencer core. All CGS rifle silencers are internally coated with hexagonal boron nitride (HBN, S-Line)

which decreases friction, increases surface hardness, and prevents fouling from sticking in the first place which eliminates

the need to clean because fouling can't easily stick to internal geometry, though they still could be cleaned if ever required.

It is a myth that rifle silencers “self-clean”regardless of who makes the silencer (NOTE A). The internal coating also

limits/eliminates titanium white sparking depending on cartridge and barrel length. Titanium white sparking is a separate

206 FLETCHER RD ᛫ARTESIA, NM 88210 CGS SUPPRESSORS LLC, A DIVISION OF CGS GROUP LLC

thing from flash and can't be controlled with a flash hider or flash hider front cap. The HBN coating is applied using DCD

(Dynamic Compound Deposition) which ensures every internal surface of the silencer is coated properly. The exterior is

coated with black DLC applied using PVD (Physical Vapor Deposition).

They're also the only dual function silencers available that can be converted simply by changing out the front cap with a

7/8" wrench. This allows you to have a traditional type silencer and a flow bypass type silencer all in one simple package.

With future front cap releases it'll also be adjustable across the entire spectrum of sound, flash, and gas reduction just by

swapping out the front cap. These future caps will help alleviate the peripheral flash that plagues the single function flow

bypass silencers currently available. No longer do you have to live with just one permanent setting on a silencer. Both front

caps and rear caps are retained with shallow taper joints which helps with concentricity and cap retention as it has more

grip than a square shoulder. Thanks to the additive manufacturing process his also makes it future proof so regardless of

when new front or rear caps are manufactured they'll always be concentric to the silencer bore.

CGS rifle silencers are also some of the very few that don't sacrifice subsonic performance to achieve supersonic

performance, it excels at both without compromise. Usually rifle silencers will either be good at supersonic and mediocre at

subsonic, or good at subsonic and mediocre at supersonic.

Since 99% of strikes occur on the front cap, since we don't use any welds in our silencers which eliminates concentricity

problems, and since our DMLS additive manufacturing process creates a superior product in every meaningful way there's

nothing that's going to need repairing other than on extremely rare occasion the front cap, and even then, front cap repairs

are exceedingly rare. In over four years at the date of this writing, no DMLS rifle silencer cores have been returned for

repair from military, government, or commercial customers or consultants because the root of the primary problems from

which strikes stem are eliminated. Core strike potential is a complete non-issue.

The exterior of the core features a 1.5" hex for a crescent wrench and the rear caps and front caps have a 7/8" hex for

crescent or open end wrenches or sockets and are substantial enough to use with most wrenches. The direct thread

mounts are made of Grade 5 titanium. These have a wide 7/8" sunken hex on the rear so most common size sockets will

fit. It also has a 3/4" hex on the opposite side so in the very unlikely event the direct thread mount somehow comes loose

from the silencer core, especially when mounted under a rail, the direct thread mount can be easily removed from the

barrel separately using a socket or a wrench. In the future we will offer some rear caps with the SIG 25 deg taper for better

compatibility with their products and for those that like to use that feature on their direct thread configs.

A separate QD Adapter for 1.375 x 24 TPI pattern QD mounts can be purchased which will allow the Helios QD to adapt to

any company's QD mount that is compatible with that system. The CGS QD Adapter still interfaces with the shallow taper

on the Helios QD Ti core. Since all the 1.375x24 pattern QDs from other companies sit on a normal 90 degree shoulder

there are no worries about anything coming loose. Obviously when you install a 1.375x24 pattern QD you lose the benefit

of the better concentricity that the QD Adapter taper joint provides for, but no big deal there as that already applies to every

silencer available that has that compatibility. The hook wrench will be included with the QD Adapter which can interface

with the notches on the exterior of the QD adapter for those people that don't already have a hook wrench that can do that

job. The QD adapter is long by default to be compatible with everything currently made by default. When installing a QD

mount to the CGS QD Adapter, install the QD mount to the CGS QD Adapter first, and then installed the CGS QD Adapter

to the Helios QD core.

OVERALL LENGTH (including Direct Thread Mount rear hex feature and Low Profile Front Cap front hex feature) –7.2"

ADDED LENGTH –(assuming .625”barrel threads) 6.58"

CORE ASSEMBLY WEIGHT (default 1/2x28 direct thread) - 11.6oz

DIAMETER - 1.75" (on main body) 1.5" (on rear body)

REAR CAP HEX –EXTERIOR 7/8”, INTERIOR 3/4”

FRONT CAP HEX - EXTERIOR 7/8”

NOTE A / CLEANING - All rifle silencers will build up fouling over time, regardless of what manufacturers choose to tell

consumers. It is an internet myth that rifle silencers don't need to be cleaned, there is an abundance of actual physical

evidence from many companies in the silencer industry that rifle silencers do accumulate fouling (copper/lead/carbon/etc)

and that they do need to be cleaned as that fouling can lead to significant weight gain, significant sound increase, flash

performance reduction, and in some cases accuracy reduction. It is best practice to weigh the silencer and record the base

weight prior to use. Then every 1-3000rds weigh it again and see how much build up it has inside. After an ounce or so

builds up then clean it according to the manufacturer's instructions. The S-Line internal coating used in all CGS rifle

silencers prevents most build up from occurring in the first place, which is something that nearly all other silencers do not

have. Cleaning of the Helios QD can be accomplished when needed by dunking the core in solvent for 24-48hrs and then

draining it. You can then shoot a mag through it (using the Vented front cap or no front cap installed) to remove whatever

fouling is loose. Repeat as needed. But chances are you will not get any meaningful build up over the course of tens of

thousands of rounds thanks to the internal S-Line coating.

206 FLETCHER RD ᛫ARTESIA, NM 88210 CGS SUPPRESSORS LLC, A DIVISION OF CGS GROUP LLC

ASSEMBLY

Prior to use, ensure all taper shoulders are clean,

threads are greased, and that components are

properly shouldered against their corresponding

surfaces and tightly secured to correct torque

values. Caps should be tightened to the Helios QD

Ti Core at 25-30ft/lb.

1. Remove the magazine from the firearm,

then visually and manually check and

clear the action and chamber of the

firearm. Make sure the host firearm is

unloaded at all times.

2. Thread the Direct Thread Rear Cap of

choice into the rear of the Helios Core

until hand tight. (Image 1-2)

3. Using a torque wrench on either the 1.5”

wrench flats of the Helios Core or the

7/8” socket on the Rear Cap, and while

holding the other part with another

wrench, tighten together until 25-30ft/lbs

is achieved. (Image 3)

4. Thread the Front Cap into the front of the

Helios QD Ti Core until hand tight (Images

4-5)

5. Using a torque wrench on either the 1.5”

wrench flats of the Helios Core or the

7/8” wrench flats on the Front Cap, and

while holding the other part with another

wrench, tighten together until 20-25ft/lbs

is achieved. (Images 6)

NOTE:

If the suppressor parts appear to be

misaligned when assembled, stop the

installation process and contact CGS. Use of

the suppressor if not properly assembled can

cause damage to the suppressor and firearm

and could cause injury to the shooter.

If you experience loosening of threaded

joints during shooting it is recommended to

degrease the threads and use a quality

thread locker such as Vibra-Tite 123 and

reasonably increase torque value.

206 FLETCHER RD ᛫ARTESIA, NM 88210 CGS SUPPRESSORS LLC, A DIVISION OF CGS GROUP LLC

INSTALLATION

1. Remove the magazine from the firearm,

then visually and manually check and

clear the action and chamber of the

firearm. Make sure the host firearm is

unloaded at all times.

2. Check the barrel threads to ensure they

are clean and free of debris. (Image 7)

3. Thread the assembled Helios QD Ti

clockwise onto the barrel threads, being

careful not to cross thread, until hand

tight and secure against the shoulder of

the barrel. Depending on the length of

the host firearm barrel threads, the Helios

QD Ti will shoulder on either the shoulder

behind the threads or the shoulder on the

muzzle. (Image 8-9)

4. For normal use, very hand tight will do.

For extended use, torque the Helios QD Ti

using the 3/4” wrench flats on the Rear

Cap to the barrel threads to 25-30ft/lbs

while using an armorers tool such as the

Geissele Reaction Rod to prevent

tweaking or damage to the host firearm

gas system or barrel assembly, then install

the Helios QD Ti Core to the Rear Cap.

5. Visually inspect that the suppressor is

mounted straight to the centerline of the

bore. Ensure that it is not tilted or canted

in any way, and that it is fully shouldered

and secure on the barrel. (Images 10-11)

NOTE:

If the suppressor appears to be misaligned,

stop the installation process and contact

CGS.

Use of the suppressor if not properly

mounted will cause damage to the

suppressor and firearm and could cause

injury to the shooter.

206 FLETCHER RD ᛫ARTESIA, NM 88210 CGS SUPPRESSORS LLC, A DIVISION OF CGS GROUP LLC

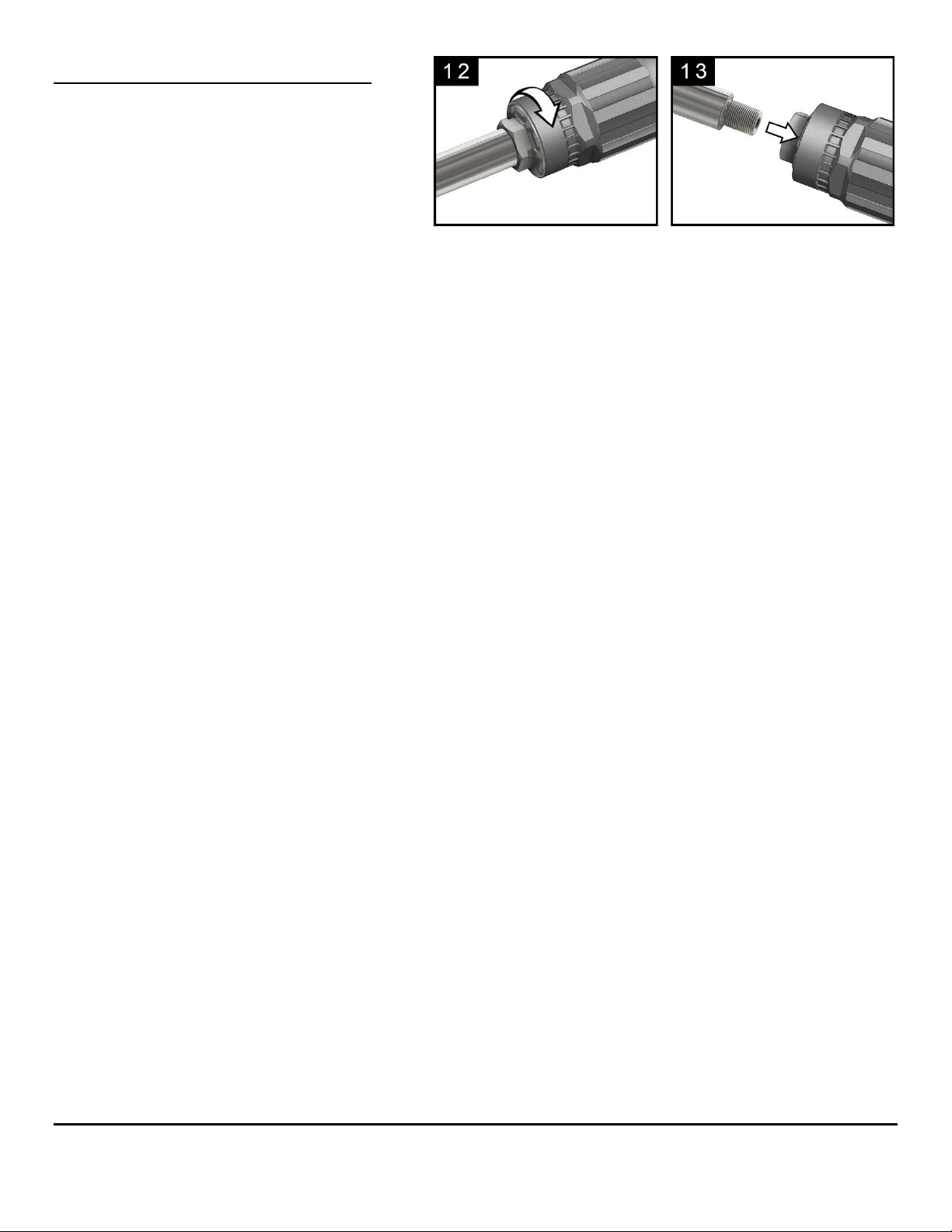

REMOVAL

CAUTION! Do not attempt to remove the

suppressor if it is hot.

1. Remove the magazine from the firearm,

then visually and manually check and

clear the action and chamber of the

firearm. Make sure the host firearm is

unloaded at all times.

2. Rotate the suppressor counterclockwise

until it has been removed from the

muzzle of the firearm. (Images 12-13)

206 FLETCHER RD ᛫ARTESIA, NM 88210 CGS SUPPRESSORS LLC, A DIVISION OF CGS GROUP LLC

DISASSEMBLY

1. With the suppressor removed from the

firearm and using a 7/8 wrench or socket,

unscrew the Front End Cap and remove it

from the suppressor while holding the

Helios QD Ti Core with a 1.5” wrench.

(Images 14-15)

2. With the suppressor removed from the

firearm and using a 7/8 wrench or socket,

unscrew the Rear End Cap and remove it

from the suppressor while holding the

Helios QD Ti Core with a 1.5” wrench.

(Images 16-17)

The suppressor is now completely

disassembled and ready for cleaning.

CLEANING NOTES:

1) Only clean if actually necessary,

when more than 1-2 ounces of

weight has been added to the base

recorded weight prior to use.

2) If cleaning becomes necessary, dunk

the Helios QD Ti Core in a titanium

safe solvent for 24-48 hours.

3) After the soak time has elapsed,

assemble the Helios QD Ti and

ensure all taper shoulders are clean,

threads are greased, and that

components are properly shouldered

against their corresponding surfaces

and tightly secured to correct torque

values.

4) Ensure the suppressor has drained

completely and fire ~10rds through it

with the front cap removed or with

the Full Vent Front Cap installed. This

will blow out any excess solvent.

Installed desired front cap after this

process is complete.

206 FLETCHER RD ᛫ARTESIA, NM 88210 CGS SUPPRESSORS LLC, A DIVISION OF CGS GROUP LLC

ASSEMBLY OF THE QD ADAPTER

Prior to use, ensure all taper shoulders are clean,

threads are greased, and that components are

properly shouldered against their corresponding

surfaces and tightly secured to correct torque

values. Caps should be tightened to the Helios

Core at 25-30ft/lb.

1. Remove the magazine from the firearm,

then visually and manually check and

clear the action and chamber of the

firearm. Make sure the host firearm is

unloaded at all times.

2. Thread the compatible 1.375x24 pattern

QD of choice into the rear of the CGS QD

Adapter until hand tight. (Image 18-19)

3. Using a torque wrench on the hex tool

feature of the chosen 1.375x24 pattern

QD, if it allows, and using the Hook

Wrench in the provided slots in the CGS

QD Adapter, tighten together until 25ft/lb

is achieved, or the torque value as stated

by the manufacturer of the compatible

QD device. (Image 20)

4. Thread the CGS QD Adapter assembly into

the rear of the CGS QD Adapter until hand

tight. (Image 21-22)

5. Using a torque wrench on the 1.5”

wrench flats of the Helios Core and while

using the Hook Wrench in the provided

slots in the CGS QD Adapter, tighten

together until ~30ft/lbs is achieved. You

want it to be very tight as with all

threaded joints. (Image 23)

NOTE:

If the suppressor parts appear to be

misaligned when assembled, stop the

installation process and contact CGS. Use of

the suppressor if not properly assembled can

cause damage to the suppressor and firearm

and could cause injury to the shooter.

The depicted generic mount on the left in

#18 is not included with the Helios QD Ti, it

just represents any 1.375x24 compatible QD

mount.

If you experience loosening of threaded joints during shooting it is

recommended to degrease the threads and use a quality thread locker

such as Vibra-Tite 123.

206 FLETCHER RD ᛫ARTESIA, NM 88210 CGS SUPPRESSORS LLC, A DIVISION OF CGS GROUP LLC

MAINTENANCE

1. It is recommended that the suppressor be weighed prior to use and recorded, and at intervals of 1000-3000 rounds depending on

the ammunition being used record the weight and round count. Once the Helios QD Ti is an extra ounce or two over the base

weight, it is a good time to clean the silencer. Only clean if actually necessary.

2. If cleaning becomes necessary, disassemble, and dunk the Helios Ti Core in a titanium safe solvent for 24-48 hours.

3. After the soak time has elapsed, assemble the Helios QD Ti and ensure all taper shoulders are clean, threads are greased, and that

components are properly shouldered against their corresponding surfaces and tightly secured to correct torque values.

4. Ensure the suppressor has drained completely and fire ~10rds through it with the front cap removed or with the Full Vent

Front Cap installed. This will blow out any excess solvent. Installed desired front cap after this process is complete.

5. Do not use a bore patch or jag to clean the suppressor.

6. After cleaning a light coating of grease should be applied the threads, and all taper shoulders should be cleaned.

WARNINGS AND DISCLAIMERS

•Always practice the basic rules of firearms safety when using the suppressor.

•Silencers may loosen during firing. It is important that you frequently verify that your suppressor is securely tightened during use.

It is recommended that you check for tightness every 30 rounds and use gloves or another barrier to ensure you are not burned.

•If you properly torque the silencer components together and use a wrench to torque the silencer to the barrel to the proper

torque value, there’s no chance of the silencer coming loose. Always torque the silencer to the barrel using a wrench when

possible.

•CGS is not responsible or liable for damages or injuries resulting from the improper use of this product; it is the user’s

responsibility to read and completely understand the instructions in this manual before using this product.

AMMUNITION RECOMMENDATIONS

•The Helios QD Ti was designed for semi auto and full auto firing of factory 5.56mm, 7.62mm, 6mm, 6.5mm, 6.8mm, 7.62x39, 300

AAC Blackout and similar ammunition. Contact CGS regarding other types of ammunition.

•We recommend the use of high quality factory loaded ammunition with this product for best sound performance, accuracy, and

reliability.

•Suppressors are designed to attenuate the muzzle blast of a firearm, but they do not alter or suppress the sonic crack caused by

supersonic projectiles as they break the sound barrier. Subsonic ammunition may be used.

BARREL LENGTH RESTRICTIONS

•The minimum barrel length allowed is 10.0” specifically for 5.56x45mm NATO and similar such as 5.45. Other cartridges currently

have no barrel length restrictions provided the projectile is properly stabilized. For any other questions on what is allowed, contact

CGS with specific information about your intended use (host, barrel length, cartridge, etc).

WARRANTY

Subject to restrictions, CGS warrants this suppressor to be free from any manufacturing defects for life. In the unlikely event

that you received a defective product, CGS will repair or replace the suppressor; it is at the discretion of CGS to determine if a

particular defect or condition is covered by this warranty.

If a repair is necessary, please contact CGS at [email protected] for a CGS representative to make arrangements for the

proper and legal return of the product. Please do not ship anything to CGS without first contacting CGS.

CGS Group, LLC

Customer Service

© 2019 CGS Group LLC. All rights reserved.

Table of contents