©2011 The Chamberlain Group, Inc.

01-36190D All Rights Reserved

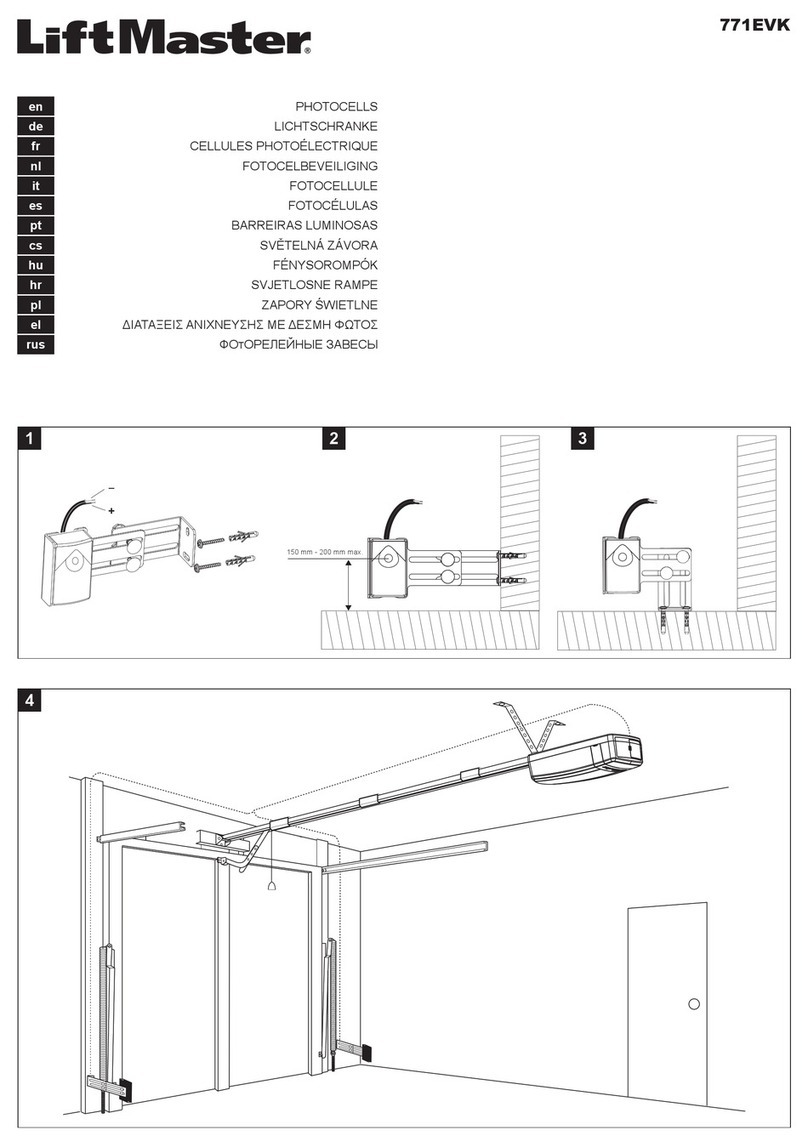

WIRING

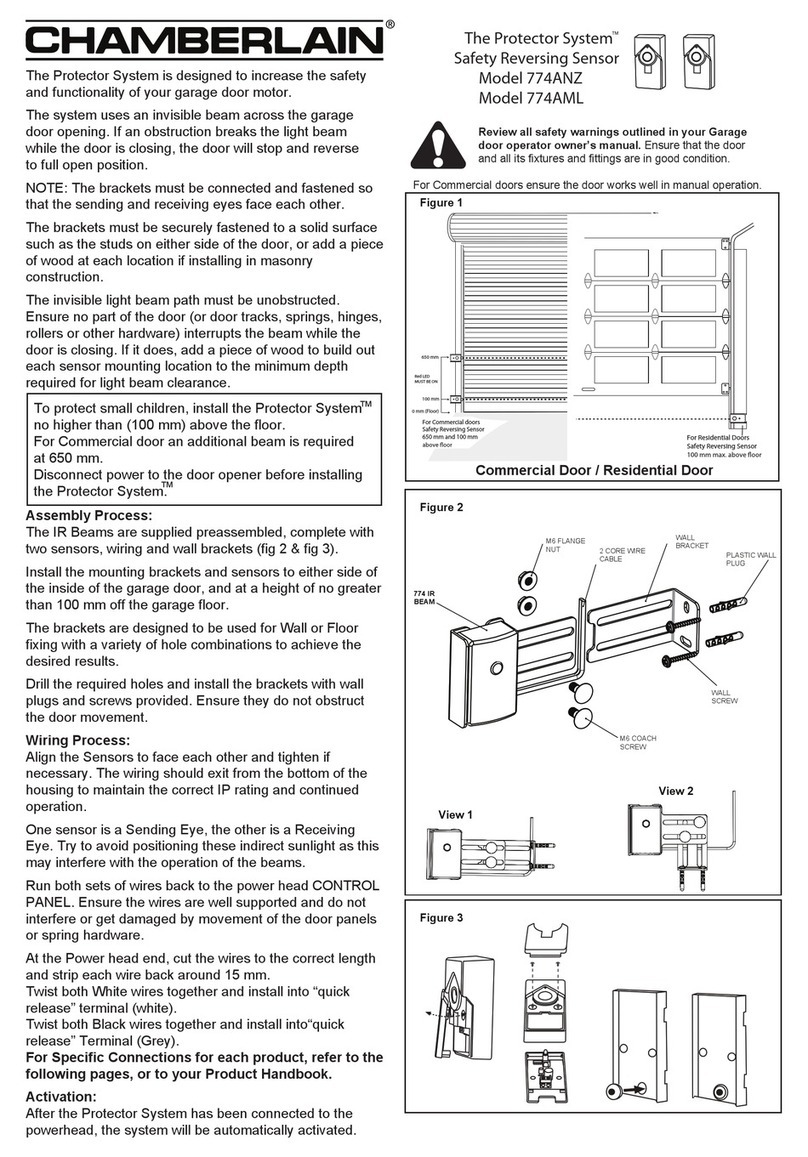

1Plug the loop detector into the desired slot (Shadow, Interrupt, or Exit) on the

expansion board of the operator. NOTE: If only LOOPDETLM loop detectors are

used, manual frequency adjustments are not required and crosstalk is

eliminated. If a LOOPDETLM is used in combination with other alternate loop

detectors, then manual frequency adjustments may be required.

Insert the twisted wires from the loop into the corresponding terminal (Shadow,

Interrupt, or Exit) on the expansion board of the operator. Polarity does not

matter.

2

1Turn the dial to TEST. The loop detector will send a signal to the main board

simulating a vehicle over the loop.

Exit: If the gate is closed, it will open or if the gate is already open it will

remain open.

Shadow: Active ONLY when the gate is in the open position. If the gate is

open, it will remain open.

Interrupt: If the gate is closing, it will open.

Turn the dial back to the desired sensitivity setting.

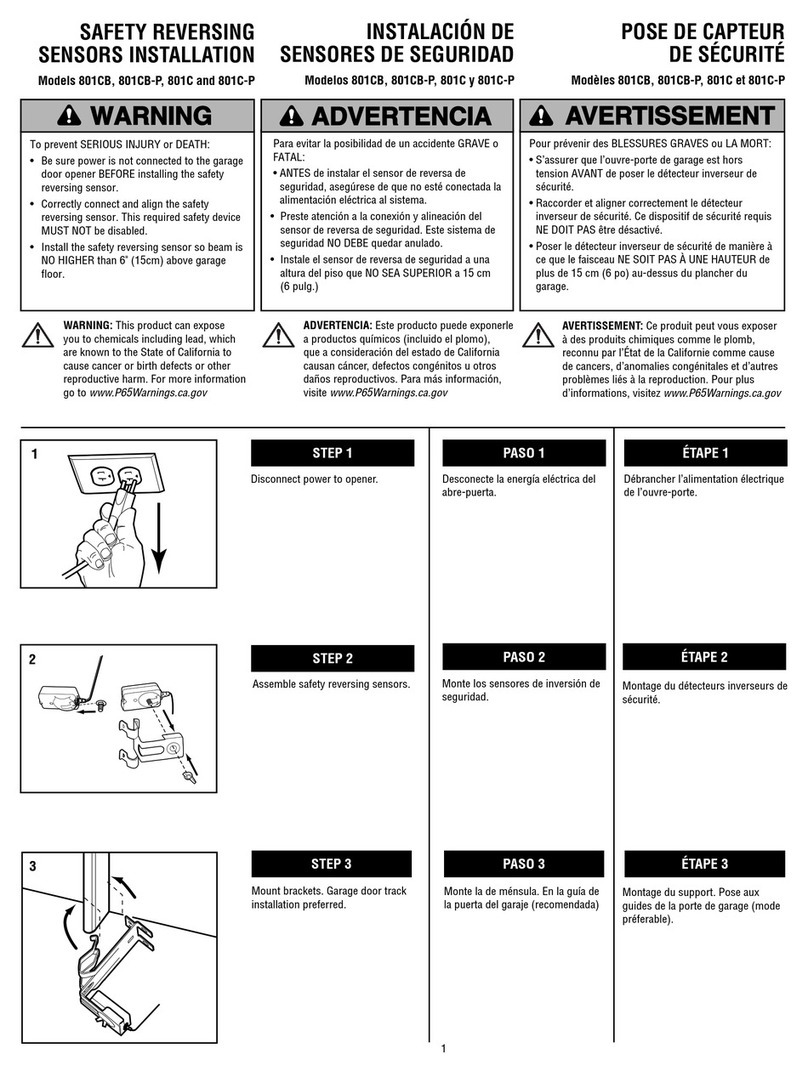

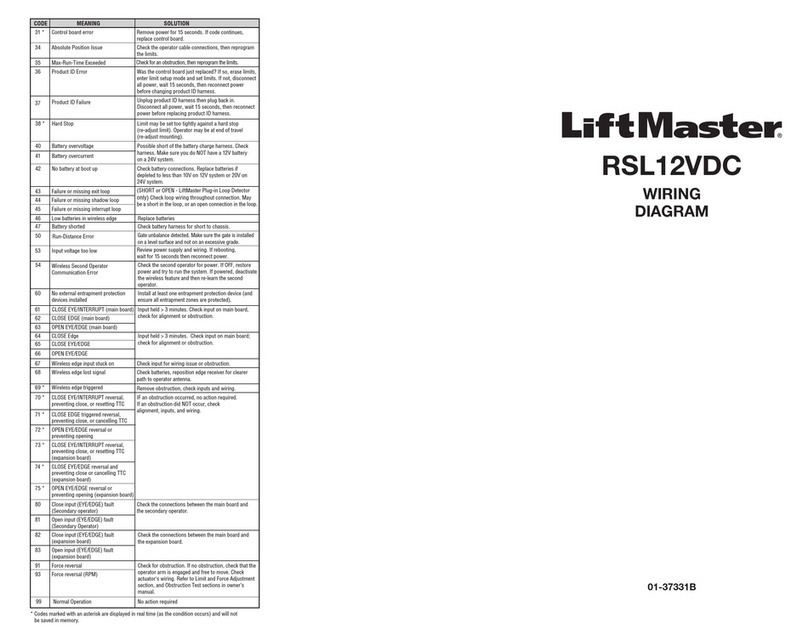

BLUE LED WHITE LED EXPLANATION

1 Blink (every 10

seconds)

OFF Normal Operation

2 Blinks Rapid Blinks (active fault)

or OFF

Open Loop (see TROUBLESHOOTING)

3 Blinks Rapid Blinks (active fault)

or OFF

Shorted Loop (see TROUBLESHOOTING)

4 Blinks Rapid Blinks (active fault) Failed Authentication (see

TROUBLESHOOTING)

OFF 2 Blinks Successful Reset

OFF Slow Blinks Loop detector is in TEST or PROG mode

Solid Solid Active Loop

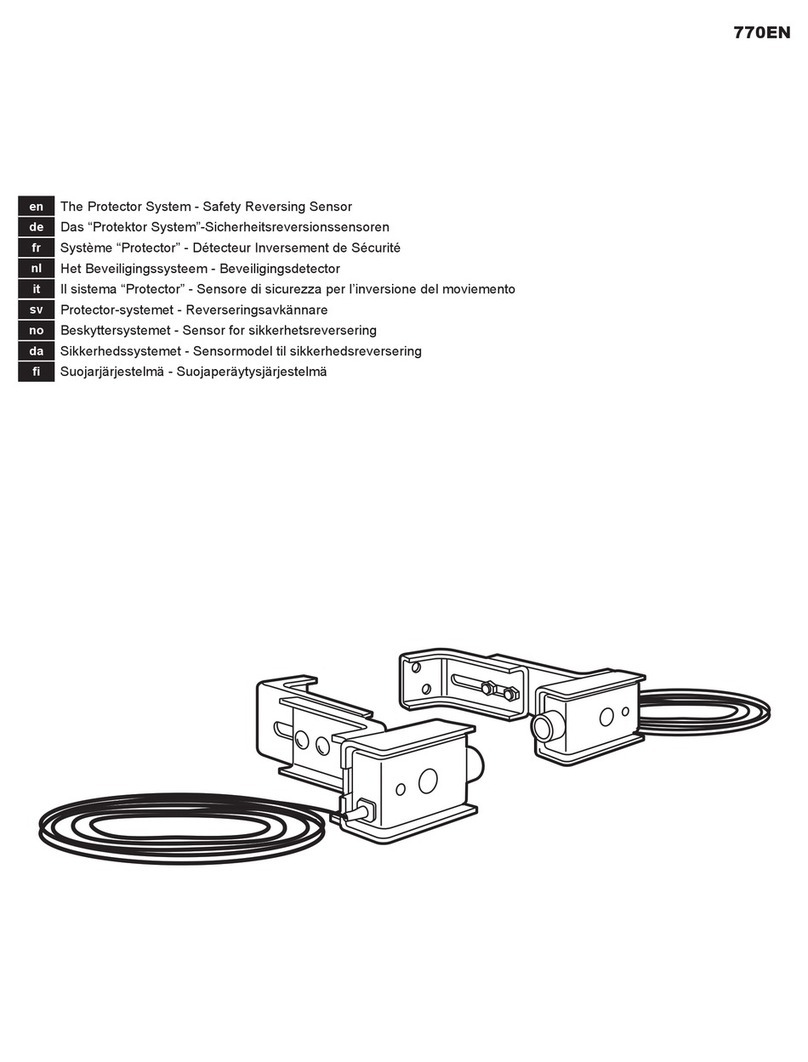

Blue LED

(located under dial) Dial

Boost Switch

Frequency Button

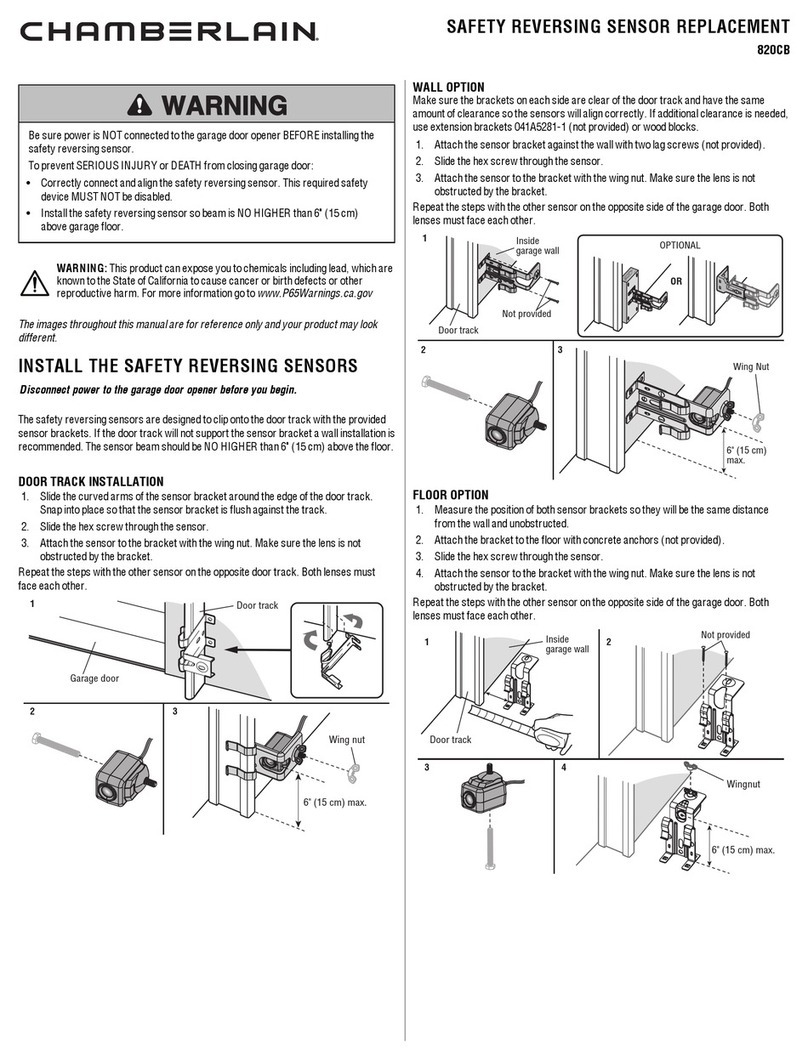

OPERATION

FREQUENCY

To change the frequency of the loop detector:

Turn the dial to PROG.

Press the frequency button to cycle through the 4 frequency settings.

NOTE: The blue LED will blink to indicate the current frequency setting.

To reset frequency to factory default, hold the frequency button for 5 seconds.

1

2

BOOST SWITCH

The boost switch will increase the sensitivity of the loop detector to detect high profile

vehicles (such as semi trucks).

WARRANTY

DIAL SETTINGS EXPLANATION

TEST Mode Used to test the loop detector

1-8 Determines the sensitivity setting for the loop detector:

1 is the lowest sensitivity (large vehicle) setting and 8 is the

highest sensitivity (small vehicle). Default setting is 4.

PROG Mode Used to change the frequency of the loop detector

TROUBLESHOOTING

ONE YEAR LIMITED WARRANTY

The Chamberlain Group, Inc. warrants to the first retail purchaser of this product that

is free from defect in materials and/or workmanship for a period of 1 year from the

date of purchase.

www.liftmaster.com

2

White LEDs

(located under dial)

Shadow Slot Interrupt Slot Exit Slot

Exit Loop

Interrupt Loop

Shadow Loop EXPANSION BOARD

THIS DEVICE COMPLIES WITH PART 15 OF THE FCC RULES. OPERATION IS SUBJECT TO THE FOLLOWING TWO

CONDITIONS: (1) THIS DEVICE MAY NOT CAUSE HARMFUL INTERFERENCE, AND (2) THIS DEVICE MUST ACCEPT ANY

INTERFERENCE RECEIVED, INCLUDING INTERFERENCE THAT MAY CAUSE UNDESIRED OPERATION.

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

Open or Shorted Loop (2 and 3 Blink errors):

Test the loop detector (refer to TEST THE LOOP DETECTOR section). If the loop

detector passes the test, this indicates the loop detector is working properly and there

is an issue with the loop wiring.

Failed Authentication (4 Blink error):

• Check the wire connecting the expansion board to the main board or

• Unplug the loop detector then plug it back into the same slot (clears all faults and

keeps the current frequency settings, authenticates) or

• Unplug the loop detector. Then unplug the J15 plug on the operator’s control

board and plug it back in after 2-3 seconds. This allows the loop detector to be

plugged into a different slot (clears all faults and keeps the current frequency

settings, authenticates).

To clear a fault:

• Press the reset button on the operator (clears all faults) or

• Unplug the loop detector then plug it back into the same slot.

The loop is making false detections:

• There is crosstalk between the LOOPDETLM and the alternate loop detector or

• Change the frequency or lower the sensitivity setting of the loop detector.

The loop will not activate when a vehicle passes over it:

• Turn the boost switch ON or increase the sensitivity of the loop detector or

• If the blue and white LEDs are solid, indicating an Active Loop, and the operator

does not activate, there could be a fault. Once the loop is inactive, check the LED

codes for a fault (refer to LED table above).

TEST THE LOOP DETECTOR