Champ AirDog A6HSDE640 User manual

PATENT

www.AirDogDiesel.com/patents

INSTALLATION MANUAL

For DETROIT SERIES 60 ENGINES

Model Years 2003-2009

Part No. A6HSDE640

Providing “Test Cell Performance” in “Real World Conditions” Since 1993

Proudly Made in the USA

www.airdogdiesel.com

1-573-635-0555 or

1-877-463-4373

High Pressure Fuel Air Separator

with Positive Fuel Air Separation System

PLEASE READ

THESE INSTRUCTIONS

THOROUGHLY

BEFORE BEGINNING

INSTALLATION

Revised 10/14/2022

2

Amazingly Simple Installation

Mounts on frame and connects between the

engine transfer (fuel) pump and engine. Air/

vapor return line connects to engine fuel

return line.

Amazingly Simple Operation

Operates in conjunction with the fuel flow

and pressure created by the engine’s transfer

pump. Separates and removes entrained air

plus vapor from fuel pump cavitation before

the fuel enters the engine.

The AirDog®Champ is proudly

made in the USA and features

a 4 year limited warranty.

sImproves Fuel Mileage

sLengthens Injector Life

sSmoother Idle

sImproves Throttle Response

sMaximizes Torque

sReduces Emissions

Proudly made in the USA

877-GO-DIESEL (877-463-4373)

airdogdiesel.com

With PureFlow Technologies AirDog®Champ

system installed, your diesel engine can

perform as designed, even under the most

extreme conditions.

3

PureFlow®Technologies, Inc.

AirDog®Champ Detroit Series 60®2003-09

TABLE OF CONTENTS

Section 1………….........…….…...………............…..…………..….Table of Contents

Section 2………………….................….…….…...…Installation and Safety Guidelines

Section 3……………………..........………………………………………..…Parts List

Section 4…………………..................................………...........….....System Overview

Installation Procedures

Section 5………………………............………………...Mounting the AirDog® Champ

Fuel Lines, Fittings, & Fuel Line Upgrade

Section 6A……..…...………....................Fuel Line from Transfer Pump to Secondary

Filter Head and/or AirDog®Champ

Section 6B….….….......…..................Fuel Line from AirDog®Champ to Engine Head

Section 6C…..…….....…….....………………............………Air/Vapor Return to Tank

Maintenance

Section 7...….….....…..............…..……................................................…Filter Service

Optional Kits Available

Section 1 Table of Contents

PN FLK-CHP Champ Fuel Line Kit

This kit contains all components most commonly

needed when installing the Champ frame mount

air separation system using #8 ttings and Eaton

Weatherhead supply lines. This kit uses #6 air and

vapor return lines and includes 8′ of 1/2″ general

purpose high pressure hose to be cut into 2 pieces

for the fuel supply running from the pump or

secondary lter head/housing, if equipped with

one, into the Champ and for the supply running

out of the Champ to the head or fuel rail. 7’ of

low pressure line is also included for the air and

vapor return line.

PN UPG-DEFS Detroit Upgrade Kit

Detroit Series 60 engine utilizes “FOR SEAL”

ttings with steel lines on the high pressure side

of the transfer pump. These ttings have small

passageways and are restrictive to the fuel ow

to the engine. To maximize the eciency of

the engine, it is necessary to replace the restric-

tive fuel ttings and lines with larger and less

restrictive lines and ttings. These ttings and

#8 DOT approved fuel lines are supplied with

the AirDog® Detroit Series 60 Fuel System

Upgrade Kit.

4

PureFlow®Technologies, Inc.

AirDog®Champ Detroit Series 60®2003-09

Section 2 Installation & Safety Guidelines

INSTALLATION GUIDELINES

The installation of your AirDog®Champ can be made relatively easy by following the

steps outlined in this manual, and:

1. Inventory the package components. Notify PureFlow Technologies

immediately of any missing or damaged parts.

2. Read the installation manual completely. Understand how the system

operates and the installation recommendations before beginning.

3. Proper location of the AirDog®Champ on the vehicle is essential. Consider

hazards presented to the equipment by road debris and the elements.

4. Follow the installation recommendations and guidelines contained

herein, but please note that individual installations may vary.

SAFETY GUIDELINES

CAUTION:Chock the vehicle’s tires to prevent rolling.

CAUTION:Wear safety glasses when operating power tools, such as drills and

grinders, or when using a punch or chisel.

CAUTION:Do not drill into or weld the top of the frame rail or within 1-½” of the

frame rail ange on the side of the frame rail.

CAUTION:Route the fuel lines and electrical harnesses, keeping them away from hot

exhaust components and/or moving parts. Properly secure the fuel lines and electrical

harnesses to prevent chang.

If you are uncertain of any installation procedure, please call

PureFlow®Technologies, Inc. at 573-635-0555 for technical assistance.

NOTE: The pictures used in this manual are for example only and may not depict

the exact components as found on your truck.

5

PureFlow®Technologies, Inc.

AirDog®Champ Detroit Series 60®2003-09

Installation Parts List

Section 3 Parts List

1 #6M JIC x 3/8 F NPTF Straight Connector 4A-1-04-06-06-S

1 3/8 M SAE x 3/8 M SAE x 3/8 M NPTF Tee 4A-4-08-06-06-B

1 #6 x #6 F Union Swivel 4A-1-22-06-06-B

1

#6F SAEX x #6F SAEX Union Swivel (Back of Head)

4A-2-01-08-06-SZ-XLG

1 #8M JIC x 1/4 M NPTF Straight Connector - Ported 4A-1-02-08-04-S-P

1

#8M JIC x 16mm M w/O-Ring Straight Connector - Ported

4A-1-01-08-16-S-P

960-06-0640-FK Detroit 03-09 Fitting Kit

(Transfer

Pump)

2 #8M JIC x 1/2 M ORB Straight Connector 4A-1-02-08-08-S

1 #6M JIC x 3/8 M ORB Straight Connector 4A-1-01-06-06-S

960-06-0560 Basic Champ Fitting Kit

CHPFK-640-PB Installation Kit

908-00-0304 Frame Mount Kit

2 Mounting Bracket 002-3C-0003

002-3C-0004

1 901-08-0100 Hardware Kit Includes:

4 ea 3/8-16 x 1-1/4 HHCS 1J-1-C20SZ

4 ea 3/8-16 Hex Nut 1S-1-CSZ

4 ea 3/8 Split Lock Washer 1R-6-CSZ

4 ea 1/4-20 x 2 SHCS 1L-A32C

4 ea 1/4 Split Lock Washer 1R-6-AC

4 ea 1/4-20 Hex Nut 1S-1-AC

QTY Description Part Number Image

1 Installation Manual 206-6-0640

1 AirDog® Champ High Pressure Air Separator A6HS-WIP

1 AirDog® Fuel Filter FF200-MG-6

SBK-1000 Sandwich Bracket Kit

1 901-08-0100-SB Hardware Kit Includes:

4 ea 3/8-16 x 1 FHSCS 1M-C16SZ

3 ea 3/8-16 x 3-1/2 HHCS 1J-1-C56SZ

3 each 3/8-16 x 4-1/2 HHCS 1J-1-C72SZ

7 ea 3/8-16 Hex Nut 1S-1-CSZ

7 ea 3/8 Split Lock Washer 1R-6-CSZ

1 Sandwich Mounting Bracket Kit for AirDog®& Champ

Includes: 1 Front Bracket (002-3C-0010-SBF), 1 Back Bracket 908-00-8888

(002-3C-0011-SBB), & 1 Universal Bracket (002-3C-0006PCB)

OPTIONAL

See page 3 for additional fuel line kit available.

6

PureFlow®Technologies, Inc.

AirDog®Champ Detroit Series 60®2003-09

Section 4 System Overview

SYSTEM OVERVIEW

Welcome to the AirDog®Champ

High Pressure Fuel Air Separation System for Class 8 Trucks

The AirDog®Champ with ADVANCED FUEL AIR SEPARATION is a premium fuel air

separator for the Detroit Series 60 engines.

The AirDog®Champ is installed between the engine transfer pump

or secondary fuel lter and the engine fuel rail, to remove virtually

all entrained air and vapor from the fuel ow to

the engine. Additionally, the engine rail pressure

must be set correctly to completely ll the injector

barrel. Please consult your DDEC manual for your

engine for correct (rail) fuel pressure settings.

TYPICAL INSTALLATION LAYOUT

Fuel to Engine

Air/Vapor Return Line

connects to engine return line

Engine Fuel Pump

Engine

Fuel

Return to Tank

AirDog®Champ

For engines without a secondary

lter, connect the transfer pump

directly to the AirDog®Champ

7

PureFlow®Technologies, Inc.

AirDog®Champ Detroit Series 60®2003-09

Section 5 Mounting the AirDog®Champ

Mounting the Champ to the Frame without Drilling

Determine which holes in

bracket 1 that you are going

to need by holding it up to the

frame of your vehicle.

Use mounting hardware to

mount bracket 1 to bracket

2. The position of bracket

2 can be adjusted vertically

and horizontally to suit your

particular needs.

Using product mounting

hardware, mount product to

brackets.

Install 2 of the frame bracket

bolts on top of bracket 1 &

bracket 3. Slide over frame and

install bottom bolt.

Note: 3.5” and 4.5” bolts are

included. Use the length best

suited to your vehicle’s frame

width.

Tighten bolts as needed.

Install lter.

Bracket 1

Bracket 2

Bracket 3

Mounting Hardware

Bracket Bolts

OPTIONAL KIT AVAILABLE (PN: SBK-1000)

8

PureFlow®Technologies, Inc.

AirDog®Champ Detroit Series 60®2003-09

Section 5 Mounting the AirDog®Champ

Mounting the Champ to the Frame by Drilling

Selecting the best location to mount the AirDog®Champ.

Installing the AirDog®Champ at the proper location on the vehicle is most important. When deciding

where to locate the AirDog®, the following points should be considered:

• Best relationship to the secondary fuel lter and back of engine head.

• Protection from the elements and road debris.

•Accessibility for service.

Figures 2 and 3 depict the AirDog®Champ mounted on the frame. There are many variations in the

arrangements of the components on the various trucks. With a little ingenuity, the AirDog®Champ

can be easily installed on any Class 8 truck.

Figure 2

Figure 3

5-1. Hold the AirDog® Champ, with the brackets and lter attached, next to the frame at the selected

mounting location. Check for clearance. If mounted between the frame and steer tire, turn the

steering wheel fully to the left and right to check for tire clearance.

Figure 4

Figure 5

5-2. Mark and center punch the hole locations. Drill a 3/8” hole at each of the 4 locations and attach

the AirDog®Champ brackets.

WARNING! DO NOT DRILL INTO OR DAMAGE ANY WIRING, AIR

LINES, OR OTHER COMPONENTS LOCATED BEHIND

THE FRAME RAIL.

9

PureFlow®Technologies, Inc.

AirDog®Champ Detroit Series 60®2003-09

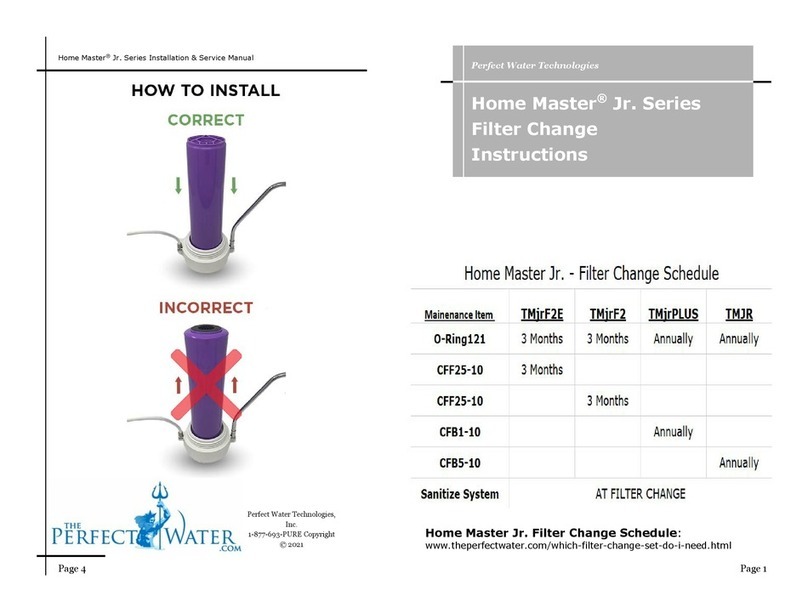

Section 6 Fuel Line Overview

FUEL LINE OVERVIEW

AirDog®Series 60 Fuel Line Upgrade

The Detroit Diesel Series 60 engine (model years 2003-2009) utilizes “FOR SEAL” or face

o-ring ttings on the high pressure side of the transfer pump. These ttings have small pas-

sageways and are restrictive to the fuel ow to the engine. To maximize the eciency of the

2003-2009 Detriot Series 60 engine, it is necessary to replace the “OE” restrictive fuel ttings

and lines with the larger and less restrictive AirDog® Champ ttings. Special AirDog®Champ

ttings for this purpose are supplied with the installation kit. #8 fuel lines are available from

your local parts house.

VS

0.240” ID

0.375” ID

0.260” ID

“OE” 14mm Face O-Ring

Fitting with Restricted Passageway

AirDog®Ported Fitting #8 JIC x

14mm with Large Passageway

Figure 6

Figure 7

Fuel Supply Line: The fuel supply line from the transfer pump to the AirDog®Champ and to

the engine should be size 8.

Air/Vapor Return Line: The AirDog®Champ return line should be connected to the engine’s

return line, low pressure side. A size 6 line for the air/vapor return line is adequate.

10

PureFlow®Technologies, Inc.

AirDog®Champ Detroit Series 60®2003-09

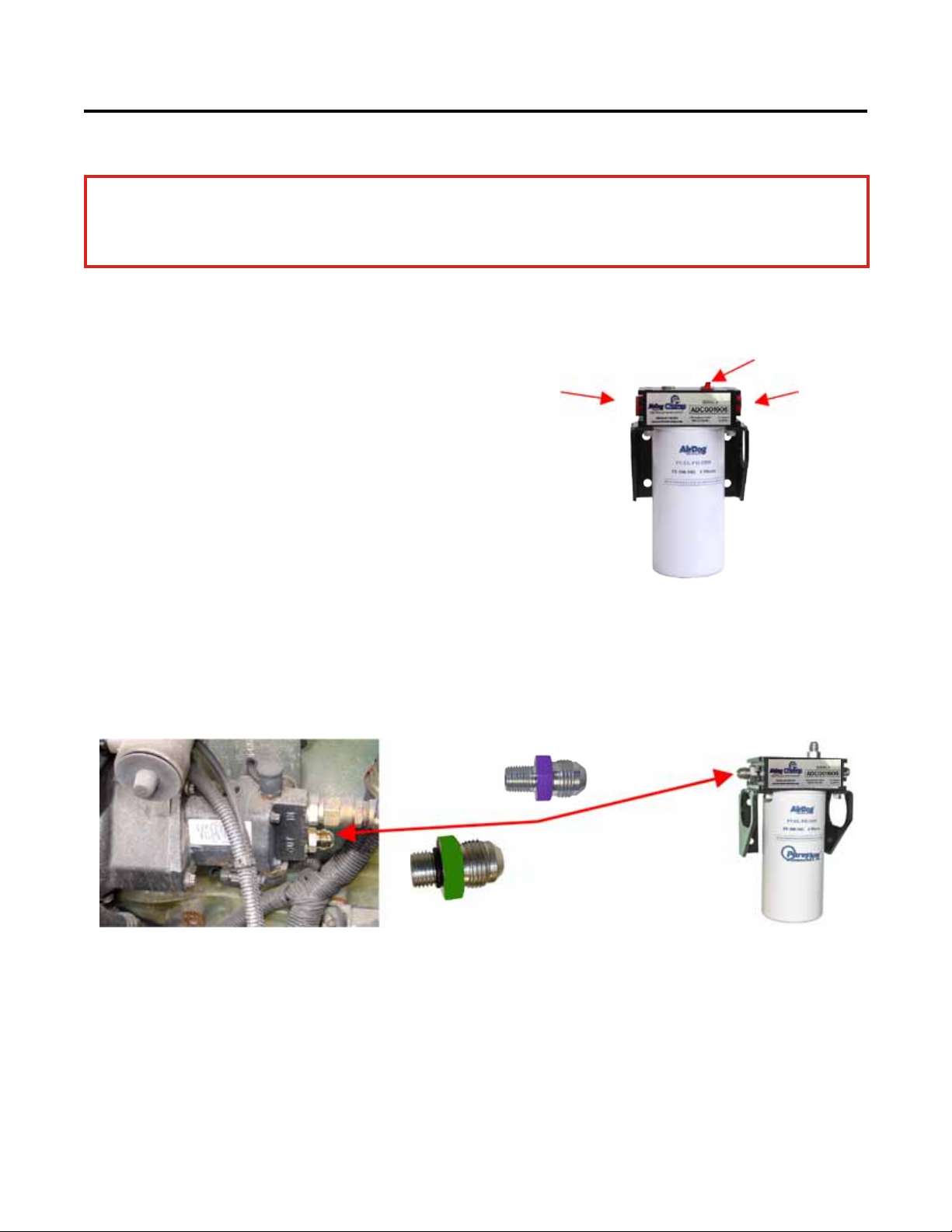

Section 6 Fuel Lines & Fittings

Section 6A: Fuel Lines, Fittings, & Fuel Line Upgrade

6A-1. Install ttings in the AirDog® Champ as follows:

A#8 M JIC x 1/2” M ORB (PN 4A-1-02-08-08-S) “FUEL IN”

B#6 M JIC x 3/8” M ORB (PN 4A-1-01-06-06-S)“AIR RETURN”

C#8 M JIC x 1/2” M ORB (PN 4A-1-02-08-08-S) “FUEL OUT”

6A-2. Remove the original steel fuel line and tting from the transfer

pump and install a ported

16mm M x #8 M JIC

tting (PN 4A-1-01-08-16-S-P) OR a 1/4” M NPT x #8 M

JIC tting (PN 4A-1-02-08-04-S-P) into the transfer pump “Out” port.

6A-3. Measure, cut, and assemble a #8 fuel line to connect the engine transfer pump to the Champ

“FUEL IN” tting.

Figure 9

Figure 10

1/4” NPT

16mm

FUEL LINE NOT INCLUDED - SEE PAGE 3 FOR AVAILABLE FUEL LINE KIT

- USING THIS OPTIONAL COST EFFECTIVE KIT WILL MAKE

INSTALLATION EASIER AND MORE EFFICIENT.

AC

B

Figure 8

11

PureFlow®Technologies, Inc.

AirDog®Champ Detroit Series 60®2003-09

Section 6 Fuel Lines & Fittings

Section 6B: Fuel Line From Engine Head to AirDog®Champ

6B-1. Remove the fuel supply line and inlet tting from the back of the engine head.

6B-2. Install the new extended

3/8” M NPT x #8 M JIC extra long 90° elbow

(PN 4A-2-01-08-06-SZ-XLG)

in the inlet port at the back of the engine head.

Figure 11

Figure 12

6B-3. Measure, cut, and assemble a #8 fuel line to connect

the AirDog®Champ outlet port to the new #8 JIC fuel

inlet supply tting just installed in the back of the engine

head.

Section 6C: Air/Vapor Return to Tank

6C-1. Remove the ENGINE fuel return

line from the check valve at the back of

the engine head.

6C-2. Assemble the AirDog®Champ

return tee (PN 4A-1-04-06-06-S, PN 4A-4-08-

06-06-B, & PN 4A-1-22-06-06-B) and install

it on the outlet side of the Detroit check

valve. Reconnect the original engine

return line to the return tee.

6C-3. Measure, cut, and assemble a #6

air/vapor return line and connect the

Champ air/vapor return port to the return

tee just installed.

Figure 13

Figure 14

Figure 15 Figure 16 Figure 17

Figure 18 Figure 19

NOTE: Secure all fuel lines to

prevent damage from abrasion.

12

PureFlow®Technologies, Inc.

AirDog®Champ Detroit Series 60®2003-09

Section 7 Filter Service

AirDog® Champ

Fuel Filter

6 Micron Micro-Glass

Built in check valve

Prevents fuel from

draining from the engine

head during lter changes

Servicing the AirDog®Champ Fuel Filter

The AirDog® fuel lters have a typical lifespan of 25,000+ miles, and up to 40,000 miles, as they

are made with a high-quality and high-capacity Micro-Glass media, as opposed to a paper element,

and lter life is aected by many variables. In any case, we do not recommend exceeding 40,000

miles of service with a fuel lter. It is recommended that you keep a replacement AirDog® fuel lter

on hand, ready for replacement. When replacing the fuel lter, be sure to clean the under side of

the Champ base. Rub clean diesel fuel or oil on lter seal before installing to ensure a proper seal.

Follow the instructions on the lter for proper tightening procedures.

NOTE: Due to the fact that fuel lters are often OVER TIGHTENED and dicult to

remove, it is suggested to carry a second lter wrench to use as a backup wrench when

changing the fuel lter.

Dispose of waste fuel and used lters properly to protect our environment.

13

PureFlow®Technologies, Inc.

AirDog®Champ Detroit Series 60®2003-09

NOTES

14

PureFlow®Technologies, Inc.

AirDog®Champ Detroit Series 60®2003-09

NOTES

15

PureFlow®Technologies, Inc.

AirDog®Champ Detroit Series 60®2003-09

NOTES

16

PureFlow®Technologies, Inc.

AirDog®Champ I Detroit Series 60®2003-09

Bulletin No. 206-6-0640

Revised Oct 14, 2022

Copyright©2016

CD Patents, LLC

All Rights Reserved

Table of contents