6

ENGLISH RT10005

safety rules

Training

1. Read the Operator’s Manual completely before

attempting to use this chipper-shredder.

2. Do not allow anyone to operate your chipper-

shredder who has not read the Operator’s Manual

or has not been instructed on the safe use of the

chipper-shredder.

3. Never allow children or untrained adults to operate

this machine.

4. Many accidents occur when more than one (1)

person operates the chipper-shredder. If a helper is

assisting, never actuate controls until helper is clear

of the area.

5. Never allow anyone to ride on the machine.

6. Never transport cargo on the chipper-shredder.

7. Projectiles can exit the chipper-shredder at high

velocities. Therefore, the following instructions

should be heeded at all times.

a. Never operate the unit on hardened ground, such

as asphalt or concrete.

b. Never operate the unit close to any buildings or

walls.

c. Do not allow children, pets, bystanders, and

assistants to be within 75 ft. (22.9 m) of the

unit during operation.

d. Do not lean directly over any chute, entry or exit,

during operation.

8. Keep the operator zone and adjacent area clear for

safe, secure footing.

9. If your chipper-shredder is equipped with an

internal-combustion engine and intended for use

near any unimproved forest, brush, or grass covered

land, the engine exhaust should be equipped with

a spark arrestor. Make sure you comply with local,

state, and federal codes. Take appropriate fire-

fighting equipment with you.

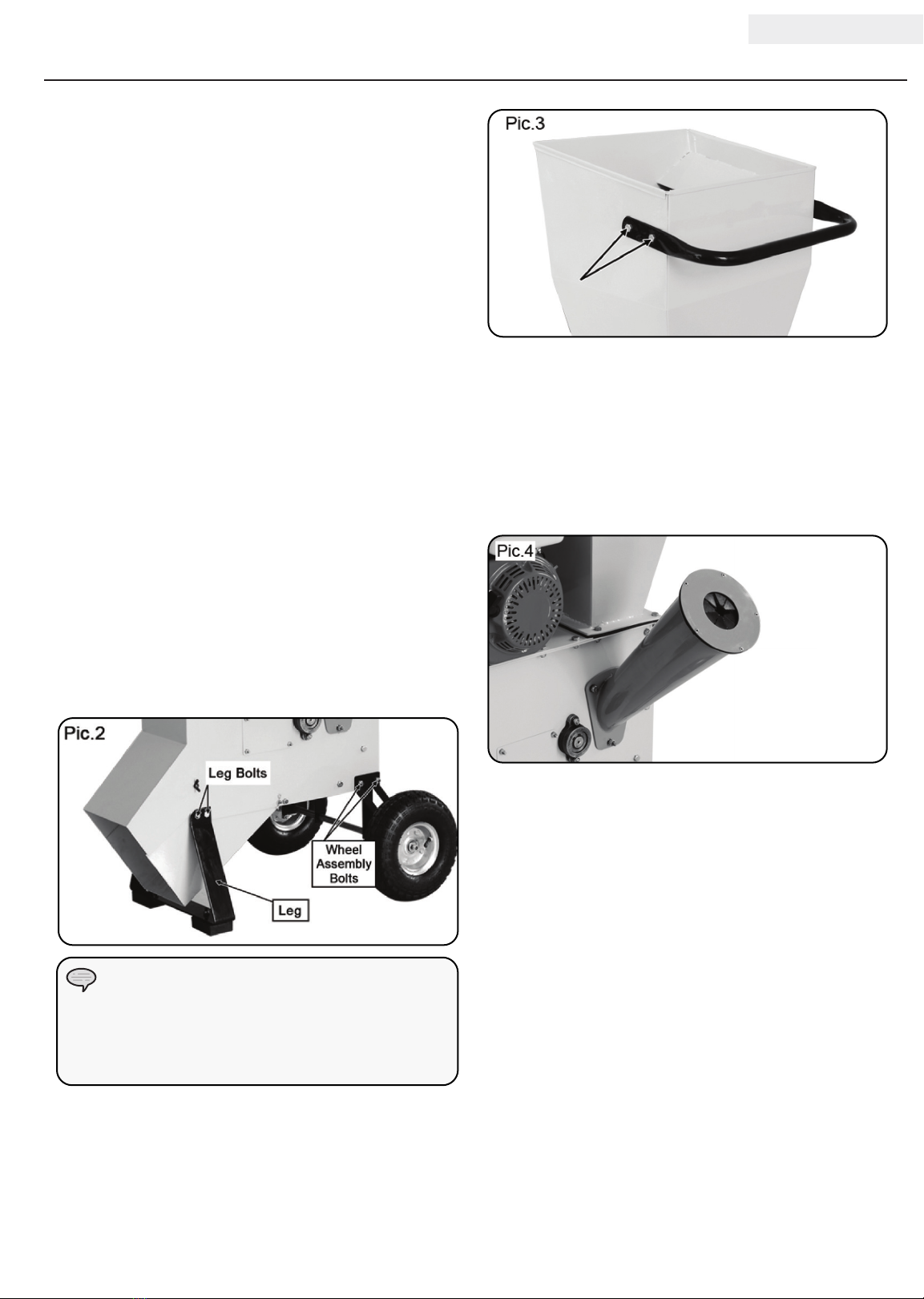

10. Chipper-shredders should be used only for chipping

branches 2 in. (5.1 cm) or less in diameters or

shredding vegetation with small diameter branches.

Do not use for other purposes.

11. Always make sure the spark plug wire is

disconnected from the engine when not in use, and

before cleaning or maintenance.

Preparation

1. Be thoroughly familiar with all controls and with

proper use of the equipment.

2. Make sure the spark plug wire is disconnected until

operation.

3. Safety Gear:

a. Always wear safety shoes or heavy boots when

operating the machine.

b. Always wear safety glasses or goggles when

operating the machine.

c. Never wear jewelry or loose-fitting clothing that

might become entangled in moving or rotating

parts of the machine.

d. Always wear hearing protection.

e. Tie back long hair or anything that will dangle

and may get entangled.

4. Inspection:

a. Make sure the spark plug wire has been fully

removed and the unit is grounded.

b. Make sure the chutes, chambers, and intakes/

exits are all clean and free of any debris.

c. Make sure the work area is clean and has no

obstacles or distractions.

d. Make sure all connections and parts are secure

and undamaged.

e. Make sure collection bag is fully connected and

secure.

f. Make sure material to be chipped is less than

2 in. (5 cm) in diameter. Branches to be chipped

can be pruned down.

g. Make sure material to be chipped or shredded is

not damp or wet.

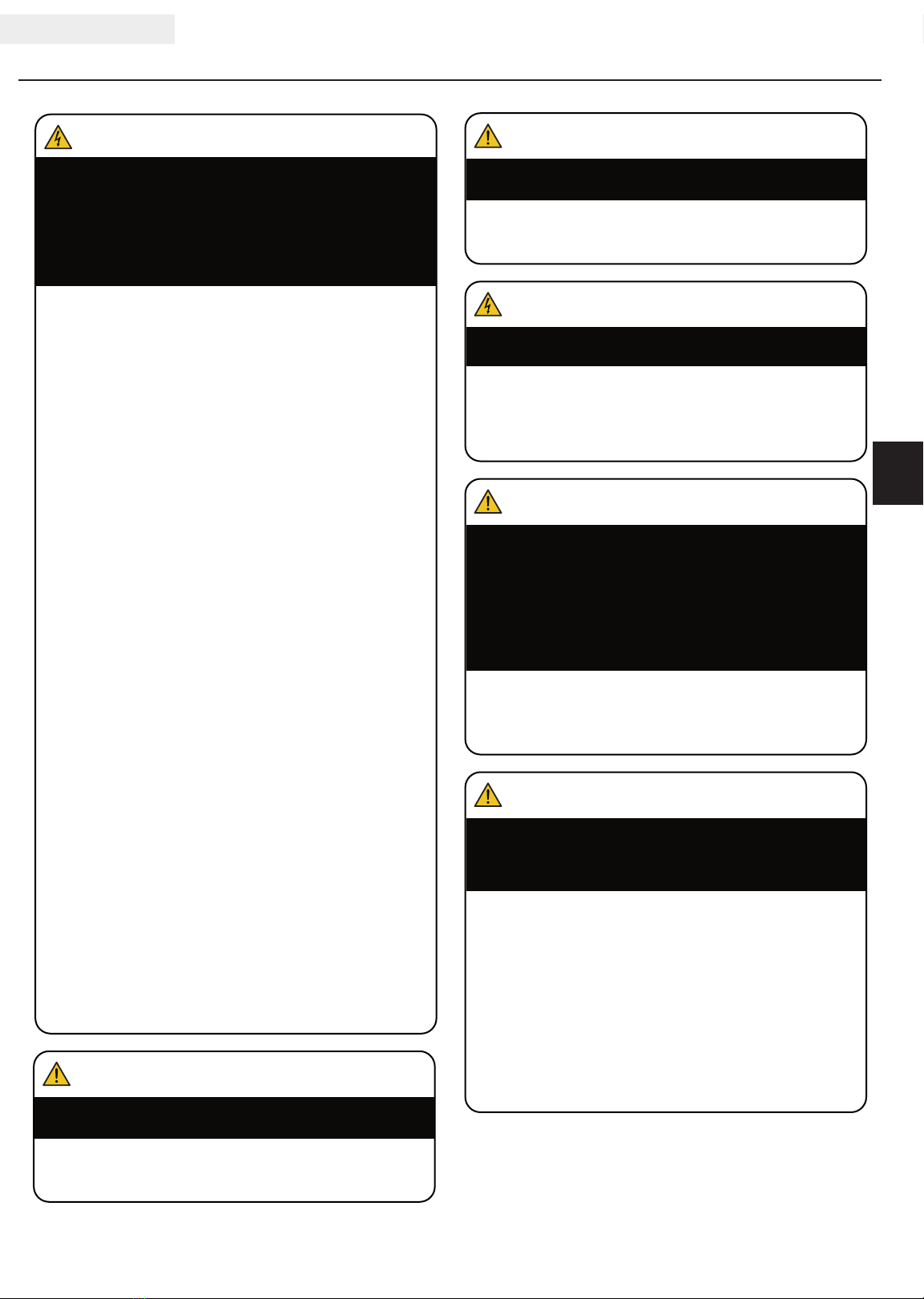

5. Check to make sure the chipper-shredder is on a

level surface that is not asphalt, concrete or harden

ground. Block the wheels and ensure support leg

is secure to prevent unintended movement of the

chipper-shredder during operation.

a. Always operate the chipper shredder from the

manufacturer’s indicated operator zone.

6. Fuel:

a. Use an approved fuel container.

b. Never add fuel to a running or hot engine.

c. Fill fuel tank outdoors with extreme care. Never

fill fuel tank indoors.

d. Replace gasoline cap securely and clean up any

spilled fuel.