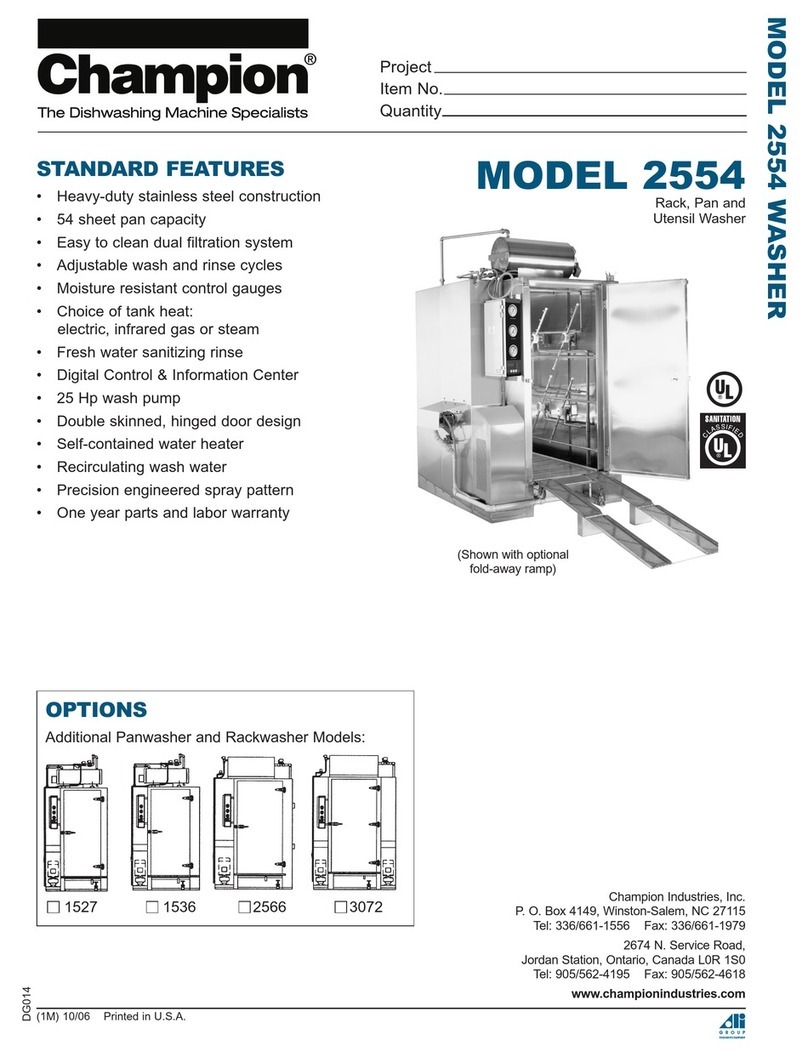

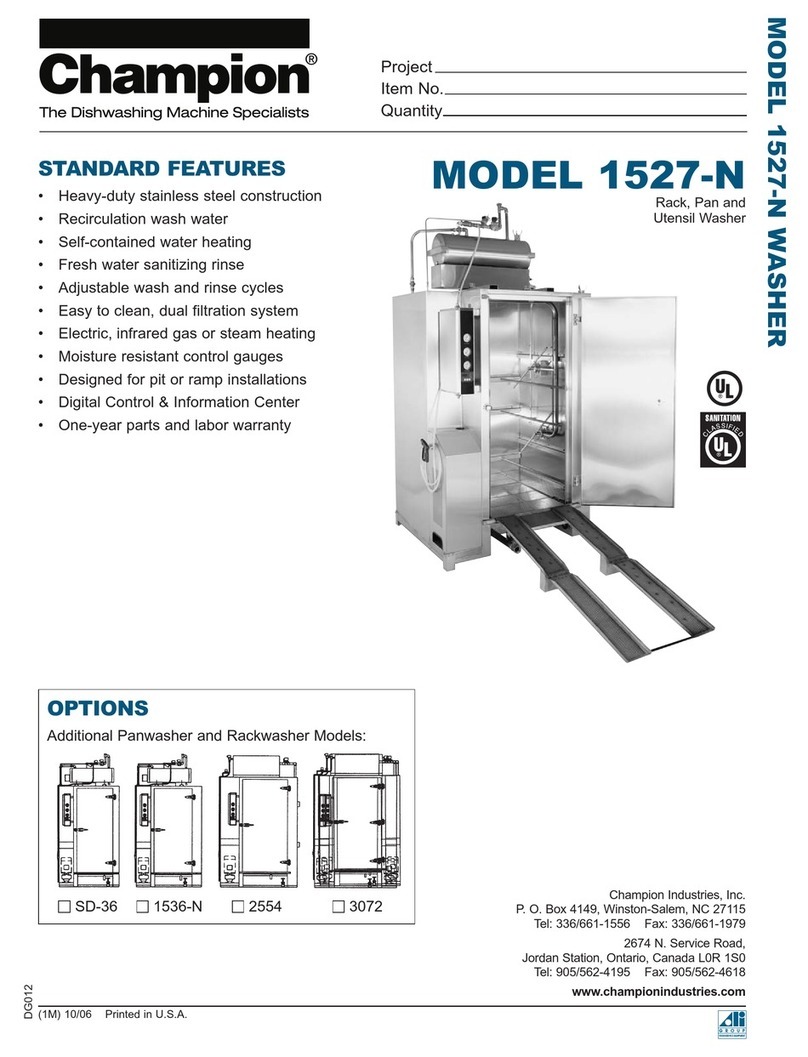

Volume crated: 130 cu. ft.

Shipping weight crated: 600 lbs.

Dimensions shown in inches

Warning: Plumbing and electrical connections

should be made by qualified personnel who will

observe all the applicable plumbing, sanitary, safety

codes and the National Electrical Code.

Note: Water Hammer Arrestor(meetingASSE-1010

standard or equivalent)tobesupplied

(byothers)incommonwatersupplylineatservice

connection.

Plumbing Notes: Because of the variation

in house-supplied steam and water pressures, steam

andwaterpressureregulatingvalves(PRVs)maybe

needed.(WaterPRVisstandardonmachineswith

booster.)ThePRVscaneitherbepurchasedfrom

Champion or obtained locally.

Venting Notes: Fabricatedductsize:

3-7/8”x15-7/8”(Outsidedimensions)

Machine only

Minimum Maximum

Supply Ckt. Overcurrent

Elec. Rated Conductor Protective

Specs. Amps Ampacity Device

208/60/1 94 125 125

240/60/1 83 110 110

208/60/3 53 70 70

240/60/3 47 60 60

480/60/3 23 30 30

575/60/3 18 25 25

TABLE A MACHINE CONNECTION

Machine and steam built-in booster

Minimum Maximum

Supply Ckt. Overcurrent

Elec. Rated Conductor Protective

Specs. Amps Ampacity Device

208/60/1 16 20 20

240/60/1 15 20 20

208/60/3 8 15 15

240/60/3 8 15 15

480/60/3 4 15 15

575/60/3 3 15 15

TABLE B BOOSTER CONNECTION

70°F/39°CRise–48kW

Electricbuilt-inbooster(boosteronly)

Minimum Maximum

Supply Ckt. Overcurrent

Elec. Rated Conductor Protective

Specs. Amps Ampacity Device

208/60/3 133 175 175

240/60/3 115 150 150

480/60/3 58 80 80

575/60/3 48 60 60

40°F/22°CRise–27kW

Electricbuilt-inbooster(boosteronly)

Minimum Maximum

Supply Ckt. Overcurrent

Elec. Rated Conductor Protective

Specs. Amps Ampacity Device

208/60/3 75 100 100

240/60/3 65 80 80

480/60/3 32 40 40

575/60/3 27 35 35

Due to an ongoing value analysis program at Champion, specifications contained in this catalog are subject to change without notice.

ChampionIndustries,Inc.,P.O.Box4149,Winston-Salem,NC27115•800/532-8591•Fax:336/661-1979•www.championindustries.com

2674N.ServiceRoad,JordanStation,Ontario,CanadaL0R1S0•800/263-5798•Fax:905/562-4618

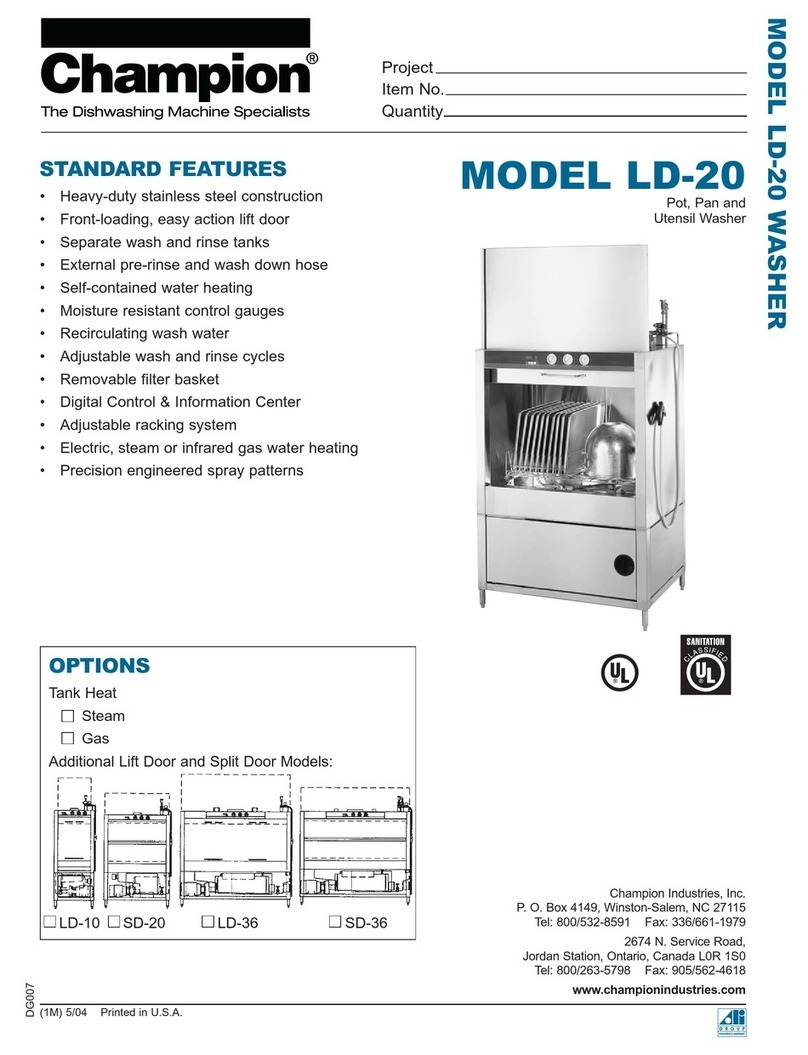

Utilities

1Electrical

A Machineconnection(seeTableA)

B Boosterconnection(seeTableB)

2Hot Water

3/4”NPT180°F/82°Cmin.hotwater

connection.(Machinewithoutbooster.)

3/4”NPT140°F/60°Cmin.hotwater

connection.(40°F/22°Crisebooster)

3/4”NPT120°F/49°Cmin.hotwater

connection.(60°F/34°Crisebooster)

3/4”NPT110°F/49°Cmin.hotwater

connection.(70°F/39°Crisebooster)

Flowpressure20-22psi.

3Drain

1-1/2”NPTmachineconnection.

Maximumflow15gpm.

4 Steam

A 3/4”NPTmachineconnection.

Flowpressure15-30PSI.(Steamcoil)

B 3/4”NPTmachineconnection.

Flowpressure15-30PSI.

(Steaminjector)

5Condensate (nobackpressure)

1/2”NPTmachinereturntoboiler

6Vents

A Loadend:200CFM@1/4”S.P.

B Unloadend:400CFM@1/4”S.P.

(Withblower-dryerincreaseroom

ventilationby600CFM.)

44” Single Tank

High-Temperature

Rack Conveyor Dishwashing Machine

MODEL 44

SPECIFICATIONS

Capacity

Racksperhr.(NSFrated) 208

Washtank(USgal.) 21

Conveyorspeed(ft/min.) 5.8

Motor Horsepower

Drive 1/6

Wash2

Water Consumption

USGal.perhr.

(max.use) 234

USGal.perrack 1.12

Heating

TankHeat,electric(kW) 15

Tankheat,steam(lbs/hr.requiredat

15PSIflowpressure) 75

Electricbooster(built-in)

(Available40°Friseonly) 27

Electricbooster(external)

(kWsuppliedfor70°Frise) 48

Steambooster(lbs./hr.

requiredfor40°Frise) 120

Steambooster(lbs./hr.

requiredfor70°Frise) 205

Venting

Loadend(minimumCFM) 200

Unloadend(minimumCFM) 400

Standard 20” x 20”

rack complement

Peg 2

Flat 1