100440 - 3000 LB. WINCH KITASSEMBLY

8

Parts Included

Assembly Parts

Mounting Channel (A).................................................1

M10 ×25 Hexagon head bolts (B) ..............................2

M10 Lock Nut (C)........................................................2

Aluminum Hawse (D)..................................................1

M8 ×35 Hexagon head bolts (E) ................................2

Flat Washer Ø8 (F)......................................................2

Lock Washer Ø8 (G)....................................................2

Lock Nut M8 (H) .........................................................2

ASSEMBLY

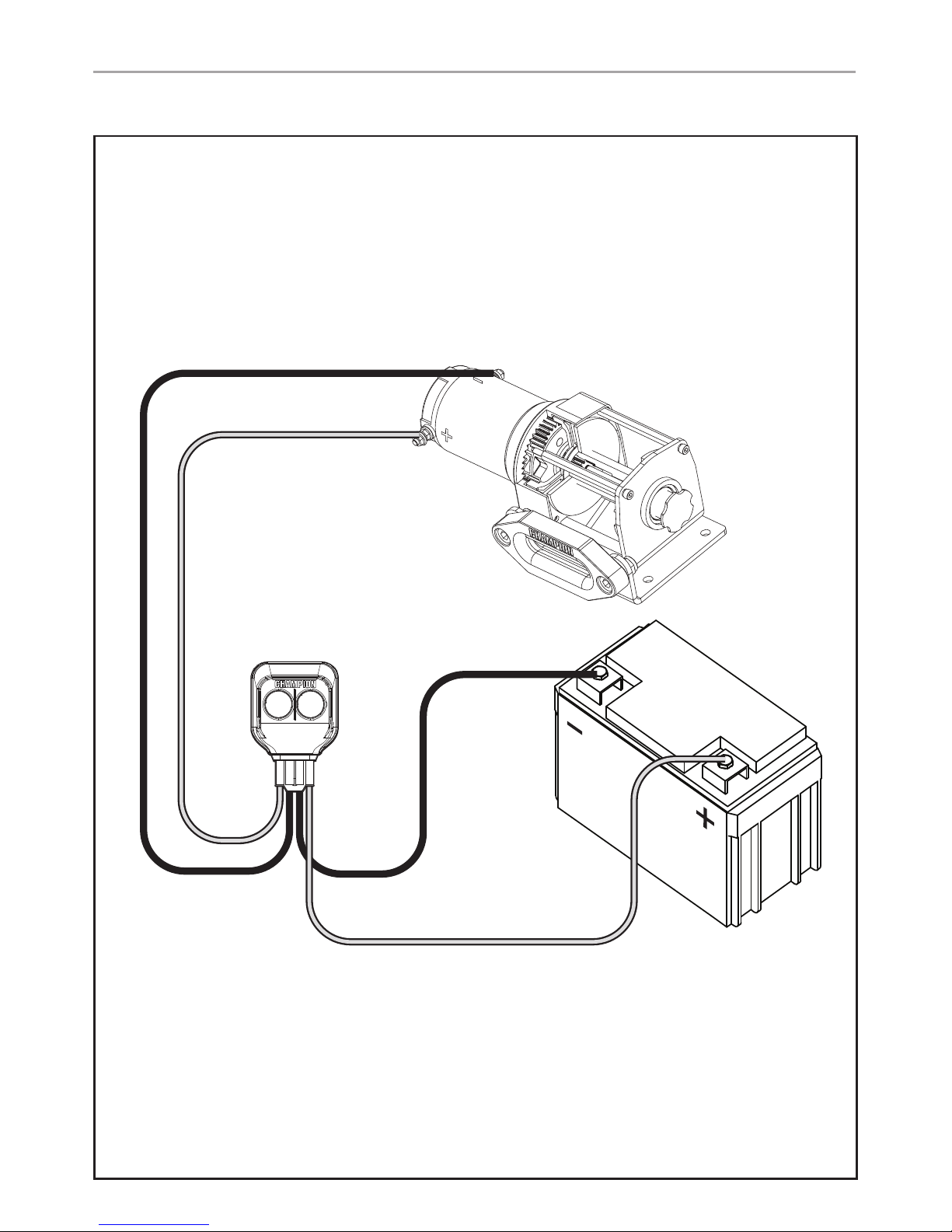

Your CPE 3000 lb. (1,361 kg) winch is designed with a

bolt pattern that is standard in this class of winch. Many

winch mounting kits are available that utilize this bolt

pattern for the most popular UTV’s and ATV’s. If you

cannot find a kit locally, contact CPE and we will provide

you with the name of a dealer near you.

!CAUTION

Mounting bolts must be SAE grade 5 or better and

torque to 34 ft. lb.

!CAUTION

If utilizing a mounting plate, ensure that the three

major sections (motor, drum, and gear housing) are

properly aligned. Proper alignment of the winch will

allow for even distribution of the full rated load.

"NOTICE

The type of vehicle to which the winch and mounting

channel will be applied, will dictate the type of

mounting kit that should be used (Speed MountTM

hitch adapter, standard mounting channel, or

specialty mounting kit).

Assembling the Winch

1. Insert two hexagon head bolts (B) through the

aluminum hawse (D) and through the mounting

channel (A). Secure with the lock nuts (C)

provided.

B

C

A

D

2. Turn the winch upside down. Place the mounting

channel (A) on the winch, making sure the winch is

centered in the middle of it.

3. Thread the M8 ×35 hexagon head bolts (E)

through the mounting channel (A). Secure with flat

washers (F), lock washers (G), and lock nuts (H)

Tighten the bolts. DO NOT over tighten.

AE

F

G

H

4. Turn winch right side up. Disengage the clutch by

moving the cam ring to the “Out” position. Release

the rope and pull through the aluminum hawse.

5. Attach the clevis hook to the rope with the short

pin and cotter pin, and then the hand strap to the

clevis hook.