Charles CP212-EP User manual

LT-CP212EP

1st Printing, March 30, 2017

©Copyright 2017 Charles Industries, Ltd. All Rights reserved. Printed in the United States of America.

Availability of features and technical specifications herein are subject to change without notice.

Charles is a registered trademark of Charles Industries.

Page 1 of 4

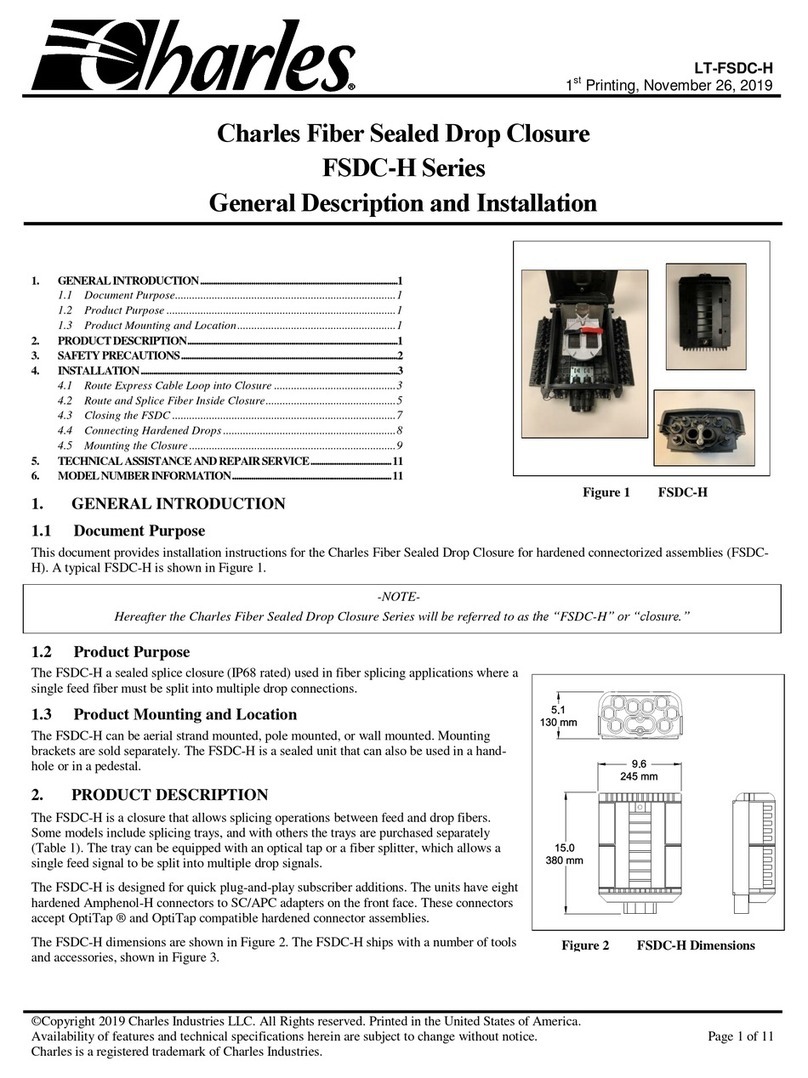

Expanded Base Installation Guide for Charles CP212-EP Pedlock®

Secondary Distribution Pedestal

Figure 1 Expanded Split Base

Secondary Distribution Pedestal

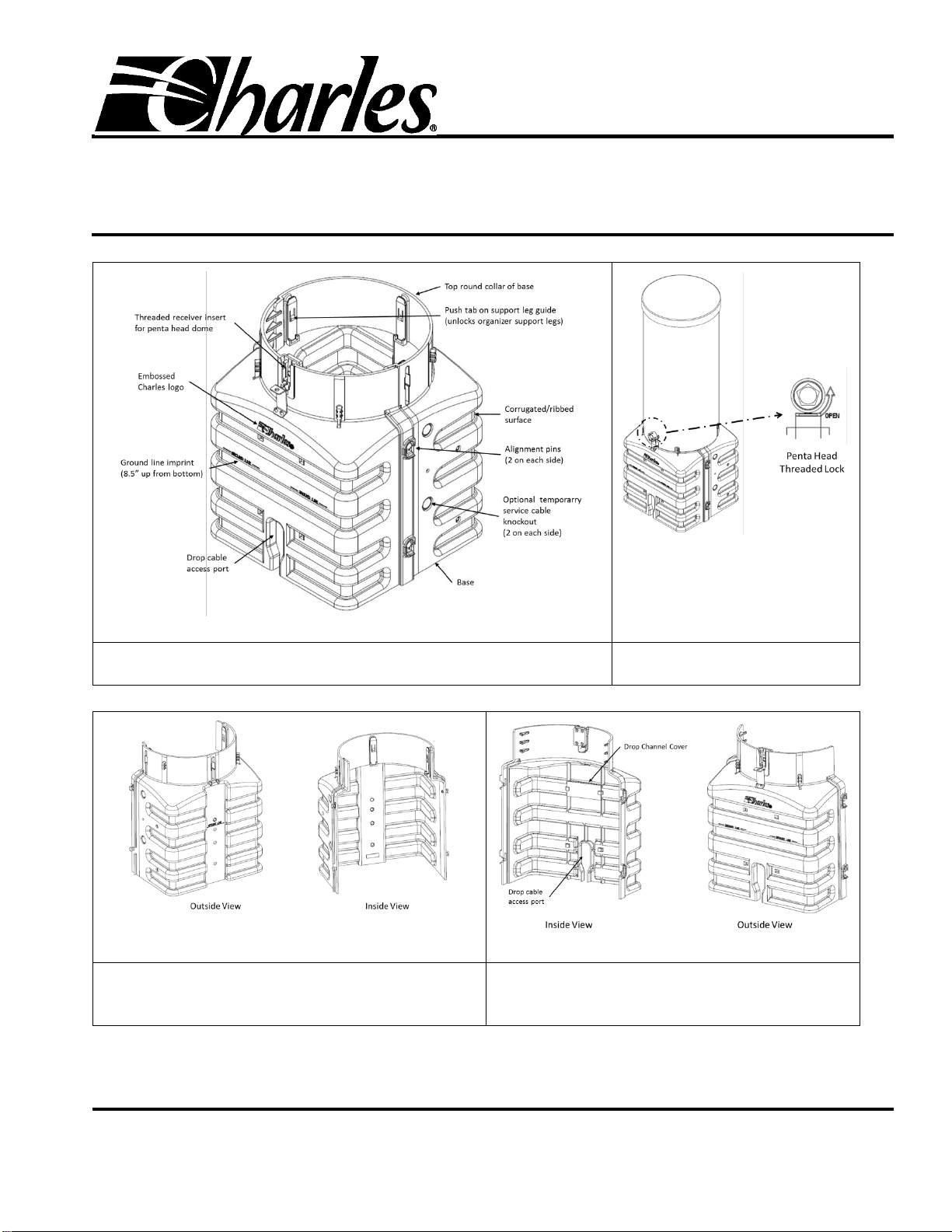

Figure 2 Penta Head Lock

Secondary Distribution Pedestal

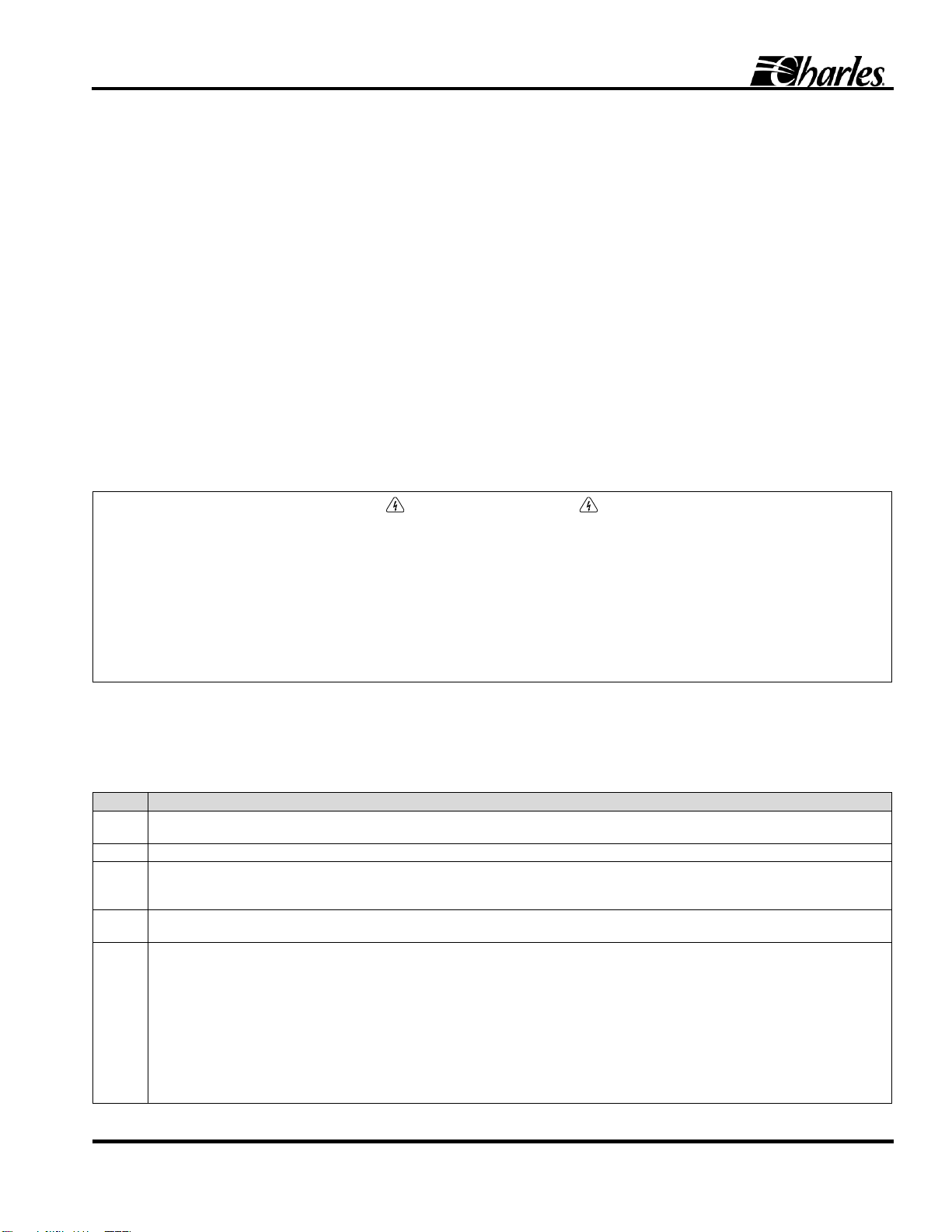

Figure 3 Rear Half

Expanded Split Square Base

Secondary Distribution Pedestal

Figure 4 Front Half

Expanded Split Square Base

Secondary Distribution Pedestal

LT-CP212EP

Page 2 of 4

1GENERAL INTRODUCTION

1.1 Document Purpose

This document provides general installation instructions for the CP212-EP series pedestals (and variants) designed for above-grade secondary

power distribution networks. Please follow company-specific installation practices.

1.2 Document Status

Whenever this document is updated, the reason will be stated in this paragraph.

Print 1 –First release of document.

1.3 Product Purpose

The Charles Pedlock® pedestal is an above-grade device that provides environmental protection for buried cables. Charles’ free-breathing

pedestal offers superior OSP protection against flood, fire, dirt, weather, salt-fog, insects, and impact. The pedestal’s expanded capacity, split

base can be opened to install around less flexible cables, inner-duct, or conduit-fed cable bundles in new construction, around existing cable or

conduit in pedestal replacement or rehabilitation applications. The square design and ribbed walls provide extra stability.

1.4 Product Mounting and Location

The pedestal base is installed (per local practice) in a trench or hole in the ground, up to the Ground Line (GL) indicator (see Figure 1). When

the base is installed, the pedestal is easily secured with the overlapping outer dome. The outer dome is secured to the base with an interlocking

dome tab and threaded penta-head lock, which can be secured to the pedestal base using the integrated hasp bracket along with a user-supplied

locking device.

-GROUNDING WARNINGS

Always follow local codes and company practices for performing proper cable and site bonding and grounding. Perform all bonding

and grounding prior to fiber, electrical, and communications connections.

-CABLE WARNINGS-

Be careful not to damage any buried cables or service wires while digging either to expose cables or to prepare a hole or trench, or

while driving stakes.

-BODILY HARM WARNINGS-

Cable components may be very sharp. Extreme caution should be taken to prevent personal injury. Protective work gloves are

recommended when handling electrical cable.

2INSTALLING THE PEDESTAL BASE

Follow the steps in Table 1 to install a Charles expanded pedestal base in a trench. Follow company practice regarding bonding/grounding

procedures.

Table 1 Installing an Expanded Pedestal Base

Step

Instruction

1

Prepare trench. Be careful not to damage any buried cables or wires while digging. Dig and prepare the cable trench, per local

company practices.

2

Establish an earth ground. Verify an earth ground is accessible and available at or near the pedestal base installation site.

3

Place cables, conduit, or inner-duct into trench. Place or lay cable/conduit in the trench per local practice. In the final position,

conduit height should be 1.5 inches below the bottom of the base collar, but no higher than the bottom of the collar.

Note: The most accurate cut can be made after the base has been set to its proper depth.

4

Unpack and inspect equipment. Unpack and inspect the pedestal. Remove the pedestal from the shrink wrap/skid and inspect for

damage. If the equipment has been damaged in transit, immediately report the extent of the damage to the distributor or carrier.

5

Obtain tools, materials and equipment. Assemble the following tools and equipment to perform the pedestal base installation.

Penta-head wrench

Level

Clean, dry, pea gravel (approved 3/8”-5/8” diameter only)

Tape measure

Hammer/mallet

Safety glasses

Work gloves

Cable grounding materials and equipment

Soil tamping tool(s)

LT-CP212EP

Page 3 of 4

Step

Instruction

6

Remove dome from base. Using a penta-head wrench, turn counter-clockwise until the spring-loaded penta bolt floats freely.

Grasp the dome and slightly twist the entire dome counter-clockwise to unlatch the dome's rear lock feature. Then lift the dome off

the pedestal.

7

Open the base (optional). With the dome removed, the two halves of the base can be separated by lifting up the front half of the

base (Charles Logo) out of its alignment pins and away from the rear half.

8

Remove knockouts (if required). Generally, the stake, if used, is attached at the rear of the base, which has the knockouts already

removed for use with the Charles Universal Mounting Stakes (UMSxx-STD). For different mounting positions, the knockouts may

need to be removed.

To remove any knockout, pierce the material around the recessed portion with a utility knife, working the blade into several locations

around the knockout. After the blade has been pushed through the material at these locations, remove the knockout. CAUTION: Do

not use a hammer or punch to remove.

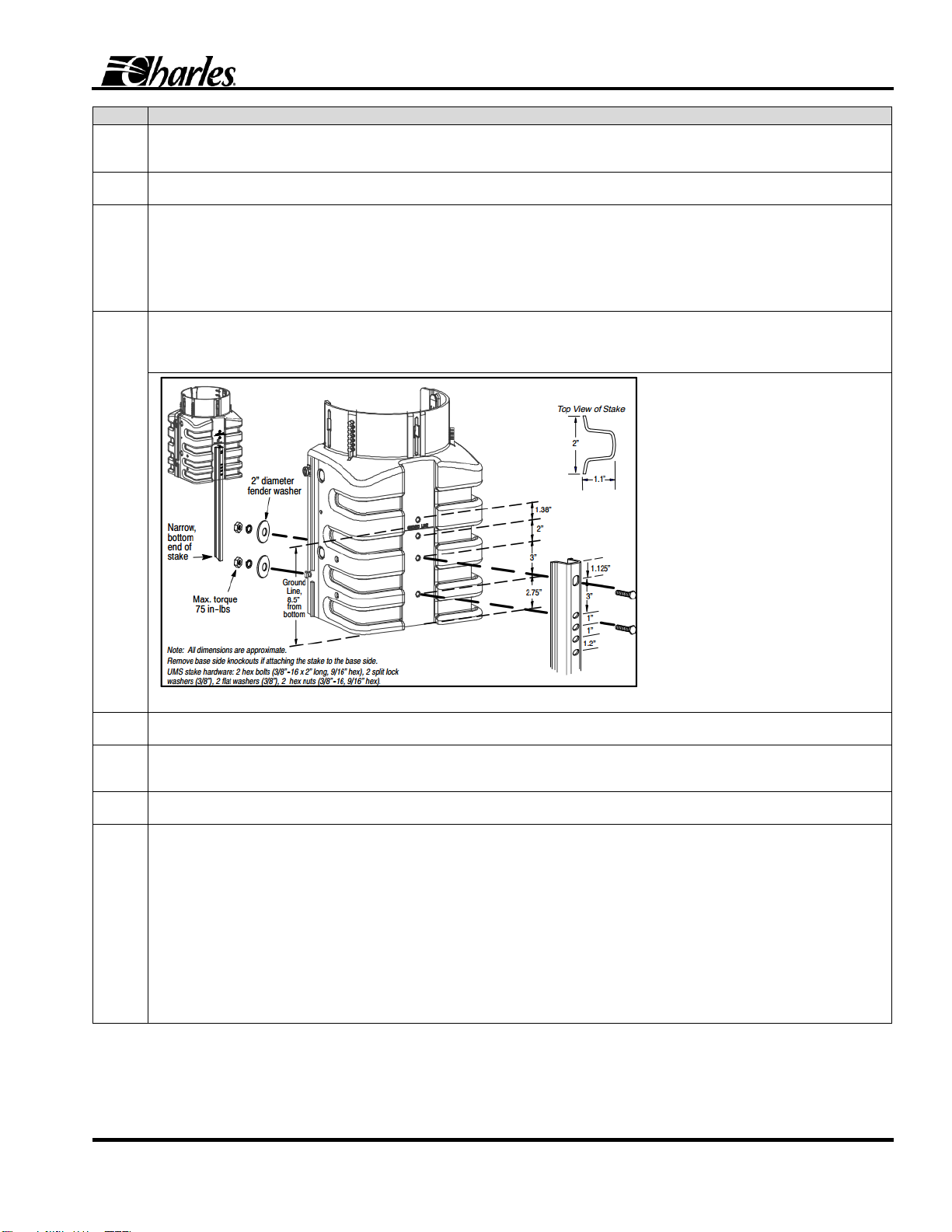

9

Install mounting stake. Install the mounting stake as shown in Figure 5. Attach the stake to the base by aligning the mounting bolts

to the desired knockouts. Next, press the stake to the outside of the base and insert the bolts into the base holes from the outside.

Place a 2” diameter washer and lock washer onto each bolt. Tighten bolt to a maximum of 75 in- lbs. Use only the supplied

galvanized hardware.

Figure 5 Mounting the UMS Stake on the Base

10

Assemble the base. If the cable tails can fit through the base collar, the two halves can be assembled prior to positioning the base.

Lift the front half over and onto the four alignment pins.

11

Determine base installation location. Position the base in the approximate desired position in the trench. The front or drop side of

the base (Charles logo) generally faces the street. Using either the back half of the base or the entire assembly, position the feed

cables/conduit toward the rear of the base.

12

Place/prepare earth ground. Always follow local codes and company practice when preparing earth ground and when grounding

cables/equipment. Per local company practice, prepare an earth ground for the pedestal at or near the base.

13

Position and level base in trench and begin backfill. Position the base and level per company practice.

Note: Maintain a level base as backfill is being added and tamped. Once the cables/conduit has been positioned, the base can be

placed in the trench with the optional attached stake (see Figure 5 and Step 9).

As the trench is backfilled, periodically tamp the soil, always pushing the soil toward the base. This practice will help remove air from

the backfill soil, making settling less likely to occur (see Figure 6). The base is designed to maintain its orientation after installation;

therefore, it is important to verify that the base is level during the entire installation procedure.

Note: Should it be necessary to straighten a pedestal at any future time (such as in the event of uneven ground settling),

never attempt to straighten an installed pedestal by manipulating, pushing, or pulling on the attached dome, as pedestal

damage may result. To re-plumb and straighten a pedestal after initial installation, first remove the soil from around the

base, then re-adjust the base until a proper level is achieved.

LT-CP212EP

Page 4 of 4

Step

Instruction

14

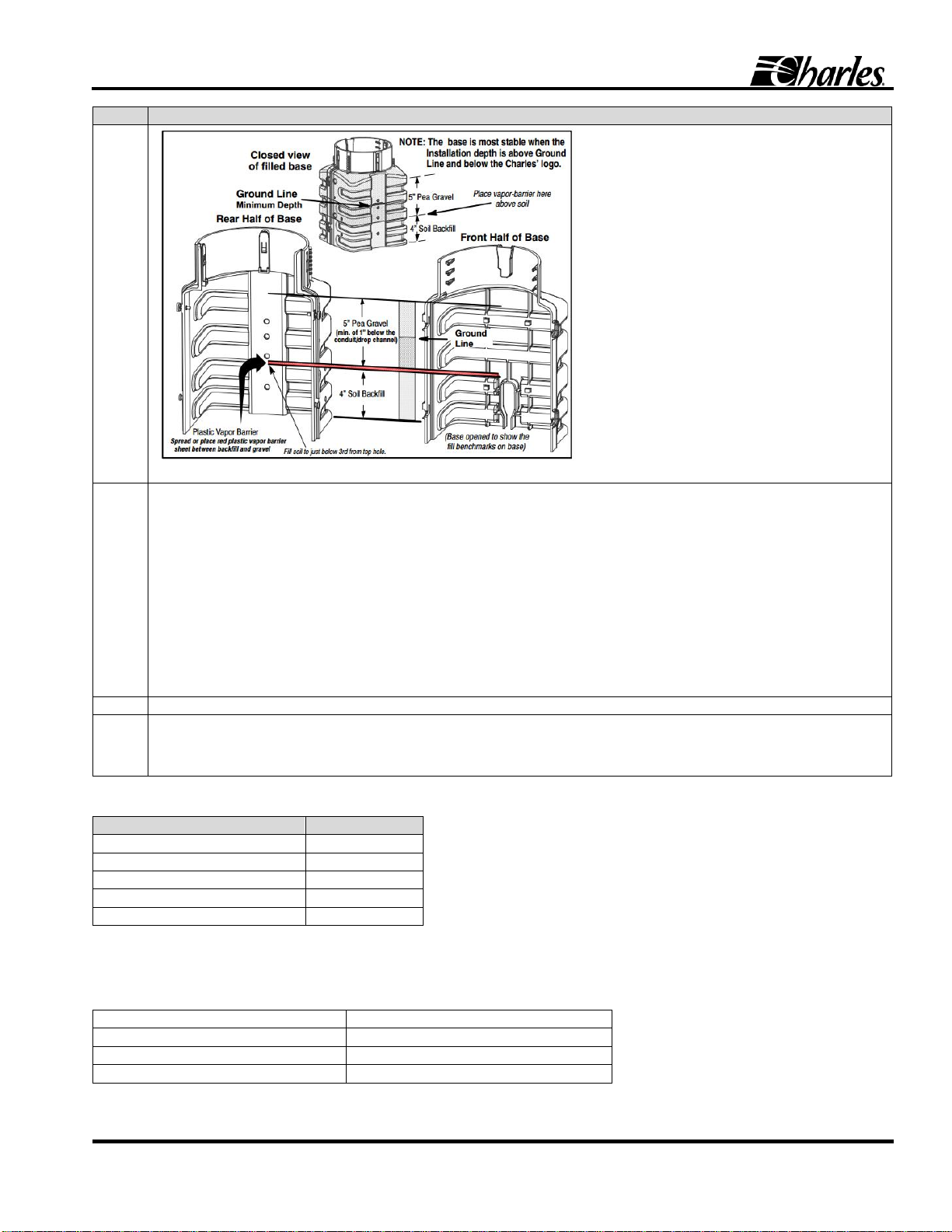

Figure 6 Backfill Levels Inside the Base

15

Install backfill soil, moisture barrier and pea gravel. Referring to Figure 6, alternately backfill the base, inside and outside,

tamping the soil as it is added. The soil on the inside of the base should cover the second rib from the bottom. On the outside, the

backfill should be even with or above the ’Ground Line’ but below the dome. Installing the base one rib higher than the ground line

makes the base more stable.

Caution: Never mound backfill soil on the outside of the base to make it appear that the base has been installed to the

recommended depth.

When the backfill on the inside of the base has been added to the proper height, the red moisture barrier is installed. The moisture

barrier sheet should be fitted around cables/conduits, slitting the sheet when necessary. Plug all open conduits prior to pouring in

any pea gravel (clean, dry, pea gravel, 3/8”-5/8” diameter only). Referring to Figure 6, pour 5 to 6 inches of pea gravel into the base.

The gravel should be no higher than the uppermost rib.

Note: If the conduit has been trimmed to the height described in Step 3, the gravel will be 1-1.5 inches below the top of the duct.

16

End of base installation - determine next procedure. Perform required wiring connections as required.

17

Install dome. Note: The dome can only be fully installed when there is no cable in the way. Lift the dome over any cables, aligning

the dome lock with the base receiver. Twist the dome clockwise to engage the dome to the base’s rear inter-locking tab. Using the

penta-head tool, push and turn the spring loaded lock bolt until tight (do not over-tighten). Attach secondary hasp lock between

dome locking cup and base hasp.

Table 2 Pedestal Base Physical Specifications

Feature

12” pedestal

Height, base only, incl. collar

18.5 in.

Height, base bottom to ground line

8.5 in.

Height, dome top to ground line

35 in.

Depth, base (front to back)

15.1 in.

Width, base (side to side)

16.1 in.

NOTE: All dimensions are approximate.

3CUSTOMER TECHNICAL SERVICE

If technical assistance or customer service is required, contact Charles Industries by calling or using one of the following options:

847-806-8500 (Tech. Service local)

847-806-6300 (Customer Service)

800-607-8500 (Tech. Service toll-free)

847-806-6653 (Customer Service FAX)

847-806-8556 (Tech. Service FAX)

mktserv@charlesindustries.com (email)

techserv@charlesindustries.com (email)

www.charlesindustries.com (website)

Table of contents

Other Charles Industrial Equipment manuals