Check-line LS-9-12000 User manual

– 1 –

Table of Contents

1.0 Introduction............................................................................................................... 2

1.1 Package Contents

2.0 Safety Instructions..................................................................................................... 2

3.0 Overview ................................................................................................................... 3

4.0 Assembly and Connection ........................................................................................ 4

4.1 Typical Connection Examples

5.0 Operation .................................................................................................................. 6

6.0 Flash Tube Replacement ........................................................................................... 7

7.0 Specications ............................................................................................................ 8

8.0 Warranty........................................................................................................ back cover

– 8 –

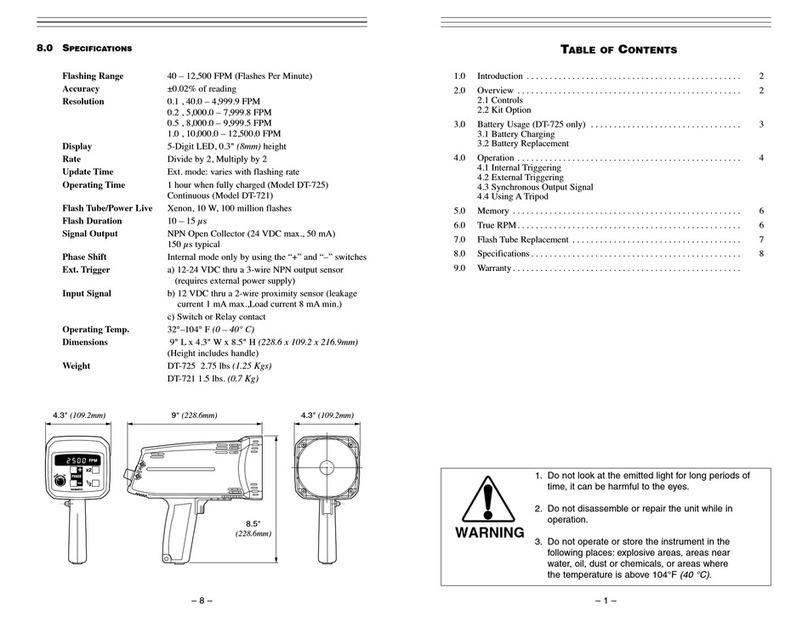

7.0 Specifications

GENERAL PARAMETERS

Frequency range 0 to12,500 FPM (ashes per minute)

Power supply 24 VDC (+/-20%) / 40 W

DIN 41524 5-pin standard connector

Universal power supply unit available

External trigger input 3 to 30 V/max. 5 mA

Isolated optocoupler

DIN 41524 5-pin standard connector

Uout = Uin, max. 200 mA

Switchable trigger input

Trigger output For parallel connection

FLASH PARAMETERS

Flash duration <10 μs

Light intensity/sharpness adjustable, on rotary knob

Light intensity single ash approx. 20 megalux/12"/30cm

Light intensity 2,500 Lux/12"/30cm

Illumination area 12 x 20"(30 x 50 cm)

Flash colour approx. 6000 to 6500 K

Flash energy 2,000 mJ (@ ≤ 900 FPM)

HOUSING

Material Aluminium

Dimensions 9.1 x 5.1 x 4.4" (230 x 130 x 112mm)

Weight 3.09 lbs. (1,400g)

AMBIENT CONDITIONS

Ambient temperature 32° to104°F (0° to 40°C)

Storage temperature –13° to 158°F (–25° to 70°C)

Humidity max. 95% non-condensing

CERTIFICATIONS

CE certication

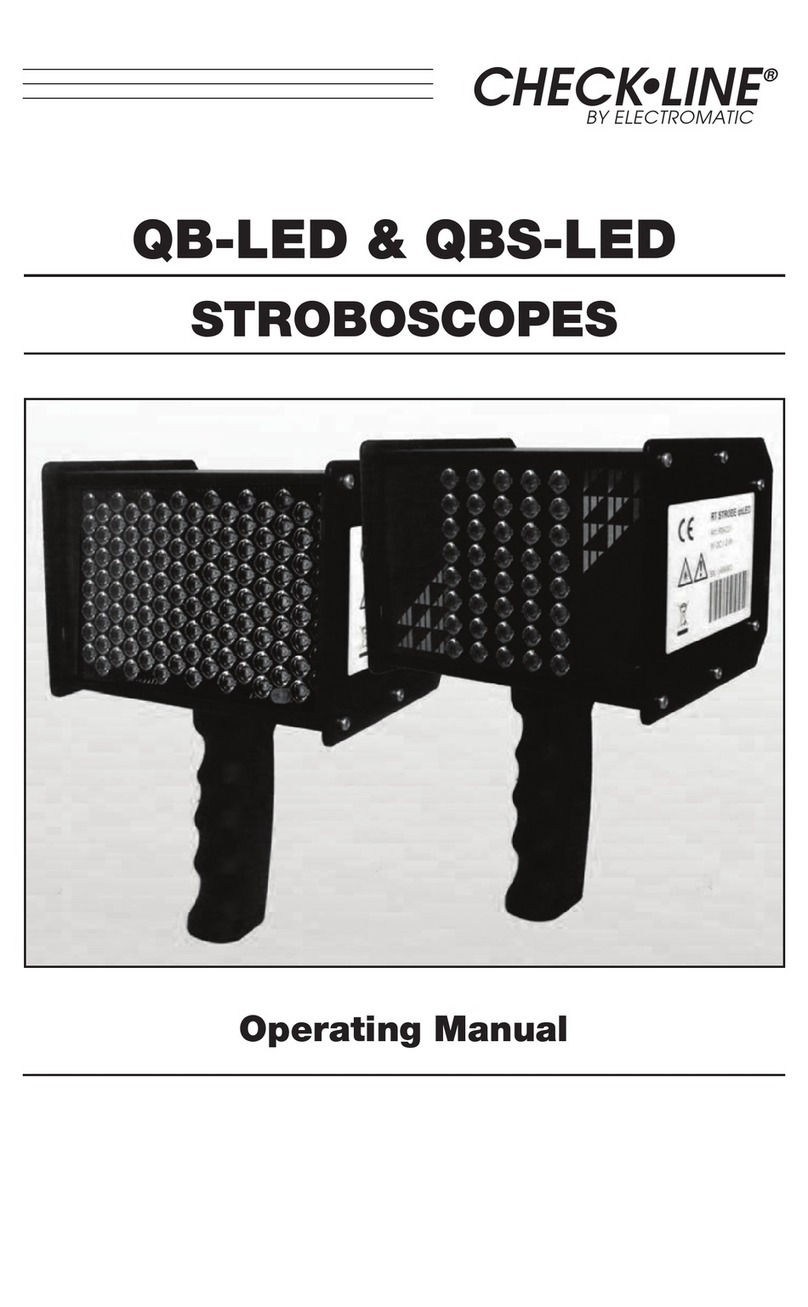

1.0 Introduction

Congratulations on your purchase of a Checkline® LS-9-12000 Linear Stroboscope.

It uses the principle of stroboscopic lighting to create an illusion of stopped motion,

allowing detailed inspection of objects moving at high speeds.

NOTE: When using a stroboscope, it is important to remember that while objects may

appear to become motionless, they are, in fact, still moving. Exercise proper care to

prevent injury.

Please read this instruction manual thoroughly before operating your stroboscope. If you

have any questions not answered by this manual, call your local supplier, or visit our

web chat interface at www.checkline.com for full product support.

1.1 Package Contents

LS-9-12000 Stroboscope is shipped fully assembled in a metal enclosure. Your package

should contain the following items:

• Stationary stroboscope

• Flash tube, factory installed

• Operating instruction

• Connector (1) for trigger input and supply

After unpacking, please examine your stroboscope for signs of mishandling during

shipping. If damage has occurred, contact Electromatic before attempting to plug in the

instrument. Notify your shipping carrier immediately for damage claim instructions.

2.0 Safety

LS-9-12000 stroboscopes operate at dangerously high voltages. Disconnect

the unit from the power supply and wait two minutes for the capacitor to

discharge before replacing the ash tube. Any service beyond ash tube

replacement is not recommended.

• Do not look directly at the emitted light; it can damage your eyes. It

may also trigger seizures in people with photosensitive epilepsy.

• Flash tubes are lled with high-pressure gas. When handling the

ash tube always always wear safety glasses and protective gloves.

• Do not allow inammable liquids and water enter the stroboscope.

• When operating the stroboscope with the front screen facing

upwards, the screen can heat up.

• The stroboscope must not be used in explosion hazard areas.

– 2 – – 7 –

6.0 Flash Tube Replacement

1. Switch off the LS-9-12000 and remove the power supply plug.

Wait two minutes for the capacitor to discharge before continuing.

2. Loosen the six (6) T10-TORX screws on the side of the unit with the

yellow label.

NOTE: Do not open the

screws on the other side of the

unit. They are not T10-TORX

type.

3. Slide front glass out laterally.

4. Using a clean cloth, carefully

remove the old ashbulb.

5. Pick up new ashbulb with a

clean cloth (free of dust and

grease) and insert into the two

retaining clips. Orient the tube

so that the trigger wire can

be easily attached to the

terminal clamp screw.

Ensure that the ashtube is

correctly positioned inthe socket.

IMPORTANT: When the ashtube is

correctly positioned, the extra length

of wire will be closest to the RIGHT

retaining clip and near the terminal

clamp screw.

6. Re-insert the front screen and replace the screws.

NOTE: Never operate the stroboscope without a front screen or with a

defective front screen.

High Voltage!

Use only the manufacturer’s original ashtubes.

Never touch the ashtube to your bare skin.

Only use the device with an undamaged front lens tted.

– 3 –

3.0 Overview

Glass Lens Trigger

Wire

Clamp

Open this end

only for

ashtube

replacement

Reector

Flash Tube

Metal Enclosure

On Back (see below): Sockets for trigger input and supply voltage, ON/OFF switch,

LED power indicator

On Bottom: 3 threaded holes for equipment

mounting, tripod connection

– 6 –

5.0 Operation

1. Position the stationarystroboscope

and connect the trigger input signal

and supply voltage to the sockets as

outlined in Section 4.0.

2. Switch the stroboscope on. The red

LED will light, indicating that the

unit is ready for use.

3. As soon as the trigger signal is

applied, the strobe will start to ash

with the trigger frequency.

4. If the ashing frequency coincides with the movement frequency, a stationary

image will appear.

NOTE: A stationary image will not only appear with an identical ashing

frequency, but also with multiples and fractions of the ashing frequency.

5. Switching between sockets 1 and 2:

Use the rocker switch located between the two sockets to choose into which

of the two sockets a trigger signal is to be fed.

Please make sure that an input signal is actually present at the

socket selected.

6. Setting the brightness:

Use the rotary knob marked with SHARP/BRIGHT and the

symbols to adjust the brightness to your needs.

Turn to the left, towards (SHARP): Brightness is reduced.

Turn to right, towards (BRIGHT): Brightness is increased.

Input #2 Power

Trigger Output

(SLAVE)

Brightness/Sharpness

Adjustment Knob

Input #1

External Trigger

Input

Select Switch

Controls

– 4 –

4.0 Assembly and Connection

Point the stroboscope at the object to be observed.

On the bottom of the stroboscope are 3 threaded

holes, which allow you to afx it to the equipment

to be observed or a stand (available as an option):

• Center = 1 x 1/4” threaded hole

• Right and left, with a total distance of

60mm = 2 x M5 threaded holes

The stationary stroboscope has two identical

assigned sockets (located on the back of the unit) for the combined input of trigger

signal and supply voltage. The assignment of plug contacts is shown in Figure 1.

CAUTION: Please make the

connections in accordance with the

wiring diagram (Fig. 1). The trigger

input is potential-free. The potential-

free input is suitable for PNP and

NPN signals. A matching plug for

these input sockets is included with

the stroboscope.

RECOMMENDATION: Use

shielded cable to connect the trigger

signal.

CAUTION: Do not trigger the

stroboscope with signals above

12,500 FPM.

4.1 Typical connection examples

Please take connection examples

from Figures 2 to 5. Note that you

will need optional accessories for

some of the examples (stationary

stroboscope, AC Adapter, sensor,

etc.)

Figure 2 Trigger signal from

optional stroboscope

control unit, supply

voltage from optional

AC Adapter.

+24V

ID-Pin

GND

In1 In2 Out

DIN 41 524

(EN 60130-9)

1

2

3

5

4

1

2

3

5

4

stationary stroboscope

Plug A

Plug B

AC Adapter

In1 or In2 or Out

In1 or In2

StrobeControl

Figure 1

Figure 2

– 5 –

FIG. 3 Trigger signal and supply

voltage from external

equipment.

FIG. 4 Trigger signal from external

equipment, supply voltage

from optional AC Adapter.

FIG. 5 Trigger signal from

optional sensor, supply

voltage for strobe and

sensor from optional

AC Adapter.

The voltage is either supplied by the

strobe power supply unit (available

as an option) or the equipment being

observed.

NOTE: When using the LS-9-12000 stroboscope without a stroboscope control unit,

the stroboscope ashes with the trigger signal of the connected equipment. This signal

cannot be inuenced without a stroboscope control unit.

stationary stroboscope

Plug AMachine

In1 or In2

Figure 3

stationary stroboscope

Plug B

Plug AAC Adapter

Machine

In1 or In2 or Out

In1 or In2

Figure 4

stationary stroboscope

Plug B

Plug AAC Adapter

Sensor

In1 or In2

In1 or In2 or Out

Figure 5

Adapter.

8.0 Warranty

ELECTROMATIC Equipment Co., Inc. (ELECTROMATIC) warrants to the original

purchaser that this product is of merchantable quality and conrms in kind and quality

with the descriptions and specications thereof. Product failure or malfunction arising

out of any defect in workmanship or material in the product existing at the time of

delivery thereof which manifests itself within one year from the sale of such product,

shall be remedied by repair or replacement of such product, at ELECTROMATIC’s

option, except where unauthorized repair, disassembly, tampering, abuse or

misapplication has taken place, as determined by ELECTROMATIC. All returns

for warranty or non-warranty repairs and/or replacement must be authorized by

ELECTROMATIC, in advance, with all repacking and shipping expenses to the address

below to be borne by the purchaser.

THE FOREGOING WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO, THE

WARRANTY OF MERCHANTABILITY AND FITNESS FOR ANY PARTICULAR

PURPOSE OR APPLICATION. ELECTROMATIC SHALL NOT BE RESPONSIBLE

NOR LIABLE FOR ANY CONSEQUENTIAL DAMAGE, OF ANY KIND OR

NATURE, RESULTING FROM THE USE OF SUPPLIED EQUIPMENT, WHETHER

SUCH DAMAGE OCCURS OR IS DISCOVERED BEFORE, UPON OR AFTER

REPLACEMENT OR REPAIR, AND WHETHER OR NOT SUCH DAMAGE IS

CAUSED BY MANUFACTURER’S OR SUPPLIER’S NEGLIGENCE WITHIN ONE

YEAR FROM INVOICE DATE.

Some State jurisdictions or States do not allow the exclusion or limitation of incidental

or consequential damages, so the above limitation may not apply to you. The duration

of any implied warranty, including, without limitation, tness for any particular

purpose and merchantability with respect to this product, is limited to the duration of

the foregoing warranty. Some states do not allow limitations on how long an implied

warranty lasts but, not withstanding, this warranty, in the absence of such limitations,

shall extend for one year from the date of invoice.

ELECTROMATIC Equipment Co., Inc.

600 Oakland Ave. Cedarhurst, NY 11516—USA

Tel: 1-800-645-4330/ Tel: 516-295-4300/ Fax: 516-295-4399

Every precaution has been taken in the preparation of this manual. Electromatic Equipment Co.,

Inc., assumes no responsibility for errors or omissions. Neither is any liability assumed for damages

resulting from the use of information contained herein. Any brand or product names mentioned

herein are used for identication purposes only, and are trademarks or registered trademarks of

their respective holders.

CHECK•LINE®

BY ELECTROMATIC

Stationary Stroboscope

Model LS-9-12000

Operating Manual

Distributed by: ABQ Industrial LP USA

Tel: +1 (281) 516-9292 / (888) 275-5772 eFax: +1 (866) 234-0451

Web: https://www.abqindustrial.net E-mail: [email protected]

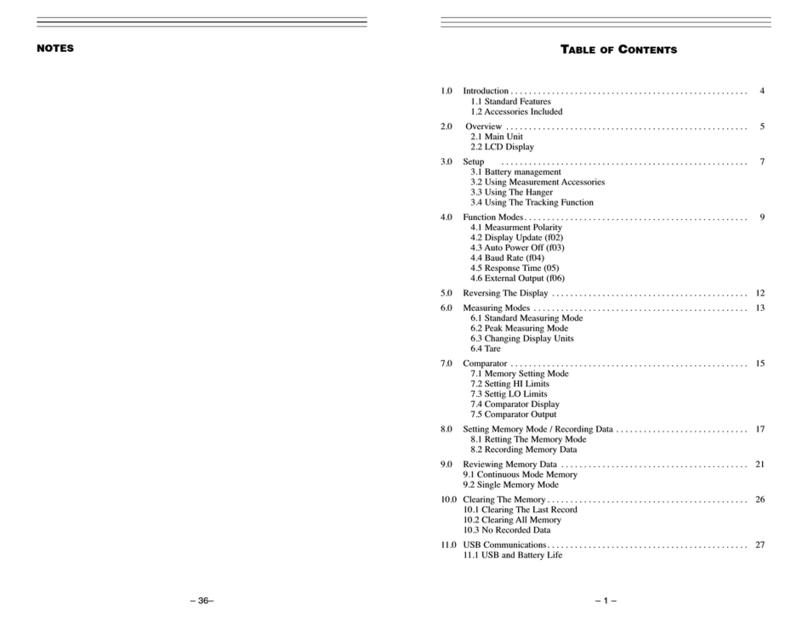

Table of contents

Other Check-line Test Equipment manuals

Check-line

Check-line DT-725 User manual

Check-line

Check-line CP-425-KIT User manual

Check-line

Check-line FGV-XY User manual

Check-line

Check-line DT-311D User manual

Check-line

Check-line QB-LED User manual

Check-line

Check-line TSV-1000 User manual

Check-line

Check-line TI-25P User manual

Check-line

Check-line DS-2000LED User manual

Check-line

Check-line TTC Series User manual

Check-line

Check-line PK2 User manual