Check-line DS-2000LED User manual

–1–

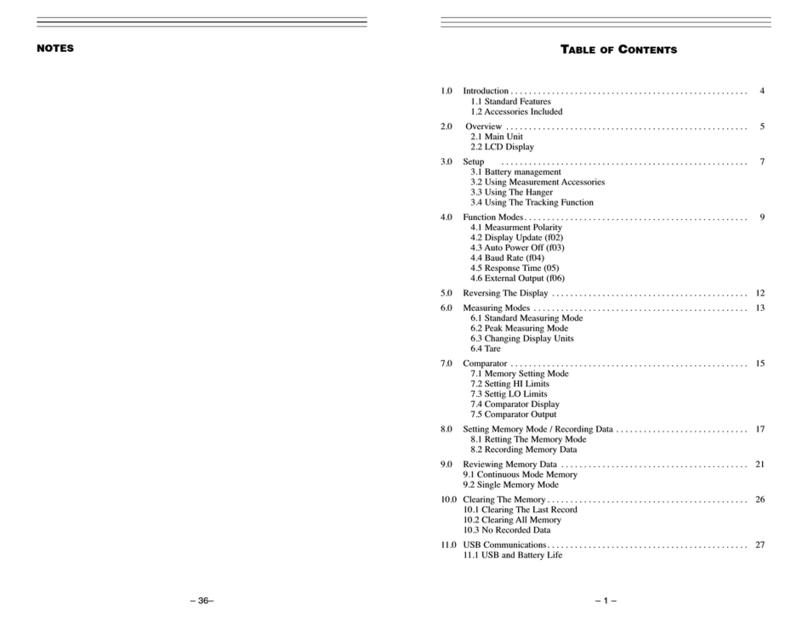

TABLE OF CONTENTS

01.0 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 02

02.0 Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 02

03.0 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 03

3.1 Display

3.2 Mode Keys

04.0 Installing/Changing the batteries . . . . . . . . . . . . . . . . . . . . . 05

05.0 Operation (LS-2000LED) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 06

5.1 Special Functions

06.0 Additional Operating Instruction (OT Models Only) . . . . . . 08

07.0 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

08.0 Slowing Down Motion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

09.0 Harmonics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

10.0 Determining An Object’s True RPM . . . . . . . . . . . . . . . . . . . 13

11.0 Multi-Key Combination Features . . . . . . . . . . . . . . . . . . . . . 17

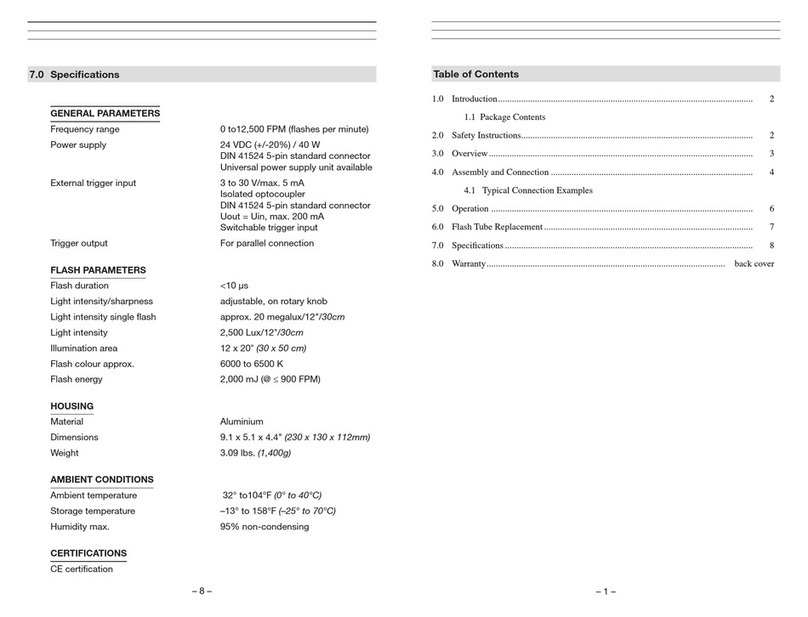

12.0 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

13.0 Factory Default Parameter Settings . . . . . . . . . . . . . . . . . . . 19

14.0 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

–20–

14.0 WARRANTY

The manufacturer warrants to the original purchaser that this product

is of merchantable quality and confirms in kind and quality with the

descriptions and specifications thereof. Productfailure or malfunction

arising out of any defect in workmanship or material in the product

existing at the time of delivery thereof which manifests itself within one

year from the sale of such product, shall be remedied by repair or

replacement of such product, at the manufacturer’s option, except where

unauthorized repair, disassembly, tampering, abuse or misapplication

has taken place, as determined by the manufacturer. All returns for

warranty or non-warranty repairs and/or replacement must be

authorized by the manufacturer, in advance, with all repacking and

shipping expenses to the address below to be borne by the purchaser.

THE FOREGOING WARRANTY IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING BUT NOT

LIMITED TO, THE WARRANTY OF MERCHANTABILITY AND

FITNESS FOR ANY PARTICULAR PURPOSE OR APPLICATION.

ELECTROMATIC SHALL NOT BE RESPONSIBLE NOR LIABLE

FOR ANY CONSEQUENTIAL DAMAGE, OF ANY KIND OR NATURE,

RESULTING FROM THE USE OF SUPPLIED EQUIPMENT,

WHETHER SUCH DAMAGE OCCURS ORIS DISCOVERED BEFORE,

UPON OR AFTER REPLACEMENT OR REPAIR, AND WHETHER

OR NOT SUCH DAMAGE IS CAUSED BY MANUFACTURER’S OR

SUPPLIER’S NEGLIGENCE WITHIN ONE YEAR FROM INVOICE

DATE.

Some State jurisdictions or States do not allow the exclusion or

limitation of incidental or consequential damages, so the above

limitation may not apply to you. The duration of any implied warranty,

including, without limitation, fitness for any particular purpose and

merchantability with respect to this product, is limited to the duration

of the foregoing warranty. Some states do not allow limitations on how

long an implied warranty lasts but, not withstanding, this warranty, in

the absence of such limitations, shall extend for one year from the date

of invoice.

Every precaution has been taken in the preparation of this manual. The manufacturer,

assumes no responsibility for errors or omissions. Neither is any liability assumed for

damages resulting from the use of information contained herein. Any brand or product

names mentioned herein are used for identification purposes only, and are trademarks

or registered trademarks of their respective holders.

See page 10 for important safety precautions.

–2 –

1.0 INTRODUCTION

Congratulations on your purchase of a DS-2000LED or DS-2000LED-OT

portable stroboscope. The strobe is used to make objects which are

moving at high speeds to appear to move in slow motion or become

motionless. When this occurs, you can safely and easily analyze their

motion, check for proper registration, determine sources of unwanted

vibration, etc.

Typical applications include:

■High speed assembly lines, conveyor systems, bottling operations, etc.

■Printing presses and cloth looms

■Motors, fans, pumps and turbines

■Calibration and inspection equipment

■Monitoring laboratory & research applications

Models Available

■DS-2000LED: operates from Internal Rechargeable Battery or

AC-Power.

■DS-2000LED-OT: same as above but includes external trigger output.

2.0 CONTENTS

■Stroboscope

■ Operating manual

■Calibration certificate

■ Batteries

■Case

■OT Model Only: Cable with plug for trigger signal

2.1 Optional Accessories

■Tripod adapter

■ Tripod

■Calibration certificate

■Belt pouch

–19–

13.0 FACTORY DEFAULT PARAMETERS

The standard parameters on the LED Strobe are:

■ TRIGGER INT (Internal)

■FPM 1000

■Hz 16.6

■PULSE µm 333

■PULSE deg 2.0°

■DELAY ms 0.0

■ PHASE deg. 0°

■DIVIDER 1

■OPTION 0

–3–

3.0 OVERVIEW

1

2

43

5

6

7

8

9

10

11

14

12

13

3.1 Display

1PULS µs Flash duration (in microseconds)

2 PULS deg Flash duration (in degrees).

3DELAY ms Delay time (in milliseconds) between the

internal trigger signal and the flash.

–18–

12.0 SPECIFICATONS

GENERAL DATA

Protection class IP65

Frequency range 30 – 300.000 FPM

Display LCD, multiple lines

Accuracy 0,02% (+/- 1 digit)

Resolution ± 0,1 (30 ... 999 FPM)

Certified CE

FLASH PARAMETER

Flash duration Adjustable

Light emission 3000 Lux @ 6000 FPM / 20cm (7,9 inch)

Flash color ca. 6.500 K / Approx. 6.500 K

POWER SUPPLY

Power supply 3 x AA size disposable batteries or

3 x NiMH rechargeable batteries

Continuous use time NiMH: approx. 11 h @ 6.000 FPM

Disposable: approx. 6 h @ 6.000 FPM

HOUSING

Material Aluminium / ABS Heavy duty design

Dimensions 191 x 82 x 60 mm / 7,5 x 3,2 x 2,4 inch

Weight Approx. 400g (including batteries)

AMBIENT CONDITIONS

Temperature Range 0° ... 45° C / 32° ... 113° F

Humidity Protection code IP65

Additional information for Stroboscope Pocket LED with trigger input and output

TRIGGER INPUT

Principle Optocoupler, voltage-free

Low level < 1 V

Level 3 … 32 V, NPN + PNP

TRIGGER OUTPUT

Principle Short-circuit and overvoltage proof transistor

output to the optocoupler control, non-isolated

Level max. NPR, max32V

Pulse length Adjustable

Maximum current 50mA

Reverse voltage protection Yes

– 4 –

04PHASE deg Delay time between the internal trigger signal

and the flash (in degrees relative to the

frequency).

05DIV Pulse divider, maximum value 255

06OPT Trigger signal edge selection

0 = positive edge

1= negative edge

07Display For units, see numbers 8-10.

08FPM Flashes per minute.

091/min Rotations per minute

10 Hz Frequency of motion per second.

11 RANGE External trigger signal is causing the flash

frequency to be too high

12 EXT External trigger signal selected

13 INT Device is generating flash frequency.

14 LOBAT Battery running low

NOTE: A parameter which has been set to differ frm the default setting

flashes during operation.

3.2 Mode Keys

On/Off Press and hold down the button for approx.

3 seconds

Mode Button Each time the Mode Button is pressed, the

gauge switches to the next setting in the

numerical order (1–10, see pages 3 & 4).

NOTE: Some modes only effect the functioning of the device when

external triggering is employed.

Increases the currently set value.

Speeds up when this button is held down.

Halves the currently set value.

Speeds up when this button is held down.

Doubles the currently set value.

Speeds up when this button is held down.

Lowers the currently set value.

Speeds up when this button is held down

–17–

Helpful Hints

■The most commonly used formulas are indicated by an asterisk.

■The values for “X,” “Y” and “Z” are taken in descending order. For

example, the value for “X” is greater than the value for “Y.”

■The values are for successive singular harmonic images. Do not use

multiple images.

■If two points are recorded, equation (1) Y gives only approximate

results. Equations (2) with (4) and (3) with (5) are more precise, but

error can be introduced due to the rounding.

■If three points are found, Equation (6) is the most commonly-used

formula.

■For completeness, equations (9) through (21) offer mathematical

derivations and condensed versions of Equation (6). Also included

are the formulas for calculating Sx, Sy and Sz.

11.0 MULTI-KEY COMBINATION FEATURES

M

+

*

–

\Key Description of Functions

M

+Pressing both buttons simultaneously resets

the gauge to its default settings.

–

+Pressing both buttons simultaneously

activates and deactivates the Button Lock.

M

+Pressing both buttons simultaneously

switches between internal and external

trigger signals.

–5–

4.0 INSTALLING/CHANGING THE BATTERIES

1. If strobe is ON, switch the power OFF by pressing and holding the

button (see pages 3 and 4) for 3 seconds.

2. Unscrew the 2 screws at back of the strobe and remove the battery

compartment cover.

3. Insert 3 new, fully charged AAA batteries into the battery

compartment, following the polarity marked on the case.

4. Replace the battery cover and screws.

Do not overtighten.

NOTE: Disposable or rechargeable (NiMH) batteries may be used.

–16–

Step 2: As the flash rate is lowered, three singular harmonic images

are found.(The first image at 9,600 RPM is rejected because it

is a double image). Point "X" is 7,200, point "Y" is 4,800 and

Point "Z" is 3,600.

Step 3: To calculate the true RPM, enter these values into one of

the equations shown below. For this example, we will use

equation (6).

RPM = 2AB(A+B)/(A-B)2

= 2x2,400x1,200x(2,400+1,200)/

(2,400-1,200)2

=14,400

Where A = (X-Y)

= 7,200 - 4,800

= 2,400

And B = (Y-Z)

= 4,800 – 3,600

= 1,200

Therefore, the true speed of the object is 14,400 RPM. To help further

illustrate this point, the figure below shows the harmonic relationship of

the four images found in this example:

If TWO points, “X” and “Y” are

recorded:

(1) *RPM = XY/(X-Y)

(2) *RPM =Sx(Sx+1)(X-Y)

(3) RPM =S (S -1)(X-Y)

(4) *Sx= Y/(X-Y), rounded

(5) Sy= X/(X-Y), rounded

If THREE points, “X,” “Y” and “Z”

are recorded:

(6) *RPM = 2AB(A+B)/(A-B)2

(7) *A= (X-Y)

(8) *B (Y-Z)

Variations of THREE point formulas:

(9) *RPM = 2PS/D2

(10) P = Product, (A*B)

(11) S = Sum, (A+B)

(12) D = Difference, (A-B)

(13) *Sx= 2(Y-Z)/(X+Z-2Y)

(14) Sy = (X-Z)/(X+Z-2Y)

(15) Sz= 2(X-Y)/(X+Z-2Y)

(16) *Sx= 2B/(A-B)

(17) Sy= (A+B)/(A-B)

(18) Sz= 2A/(A-B)

(19) Sx= 2B/D

(20) Sy= S/D

(21) Sz= 2A/D

Depending on the accuracy desired, either two or three harmonic points

can be found. These points are used in one of the following equations:

Formulas for calculating “Out of Range” RPMs.

Harmonic

FPM/RPM

1/4 1/3 1/2 2/3 5/6 1/1

3,600 4,800 7,200 9,600 12,000 14,400

– 6 –

5.0 OPERATION

1. Make sure that the strobe has 3 charged batteries in the battery

compartment; and they they are aligned in the corrected polarity.

2. Aim the strobe at a moving object, then press and hold the ON/OFF

Button for approximately 3 seconds.There will be a slight delay

before the strobe begins flashing. The strobe will flash at the most

recently set frequency in flashes per minute, which appears on the

display.

NOTE: If the Low Battery icon begins to flash (item 15, page 4),

replace the batteries (see section 4).

3. Press the Mode Button to cycle through the different settings.

Stop when the desired setting is highlighted on the display..

Display fields Influencing the set signal. Refer to figure on page 3.

01 PULS µs Flash duration (in microseconds).

02 PULS deg Flash duration (in degrees).

03DELAY ms Delay time (in milliseconds) between the internal

trigger signal and the fl ash.

04PHASE deg Delay time between the internal trigger signal

and the flash (in degrees,relative to the

frequency).

Units deisplayed. Refer to figure on page 3.

08 FPM Flashes per minute.

10 Hz Frequency of motion per second.

Operating information

13 INT Device is generating flash frequency.

14 LOBAT Battery is running low.

NOTE: A parameter which has been set to differ from the default setting

flashes during operation.

NOTE: Pressing the and buttons simultaneously resets the

strobe to its default settings.

NOTE: Some modes only effect device functioning when external

triggering is employed.

NOTE: Static images are not only created at a precisely corresponding

flash frequency, but also at multiples and fractions of this

frequency.

–15–

The harmonic images at 6,000 and 4,000 RPM are not singular, but dou-

ble and quadruple. A singular image does appear at 3,000 and again at

1,500 RPM. 1,500 is one half of 3,000. Therefore, the rate is 3,000 RPM.

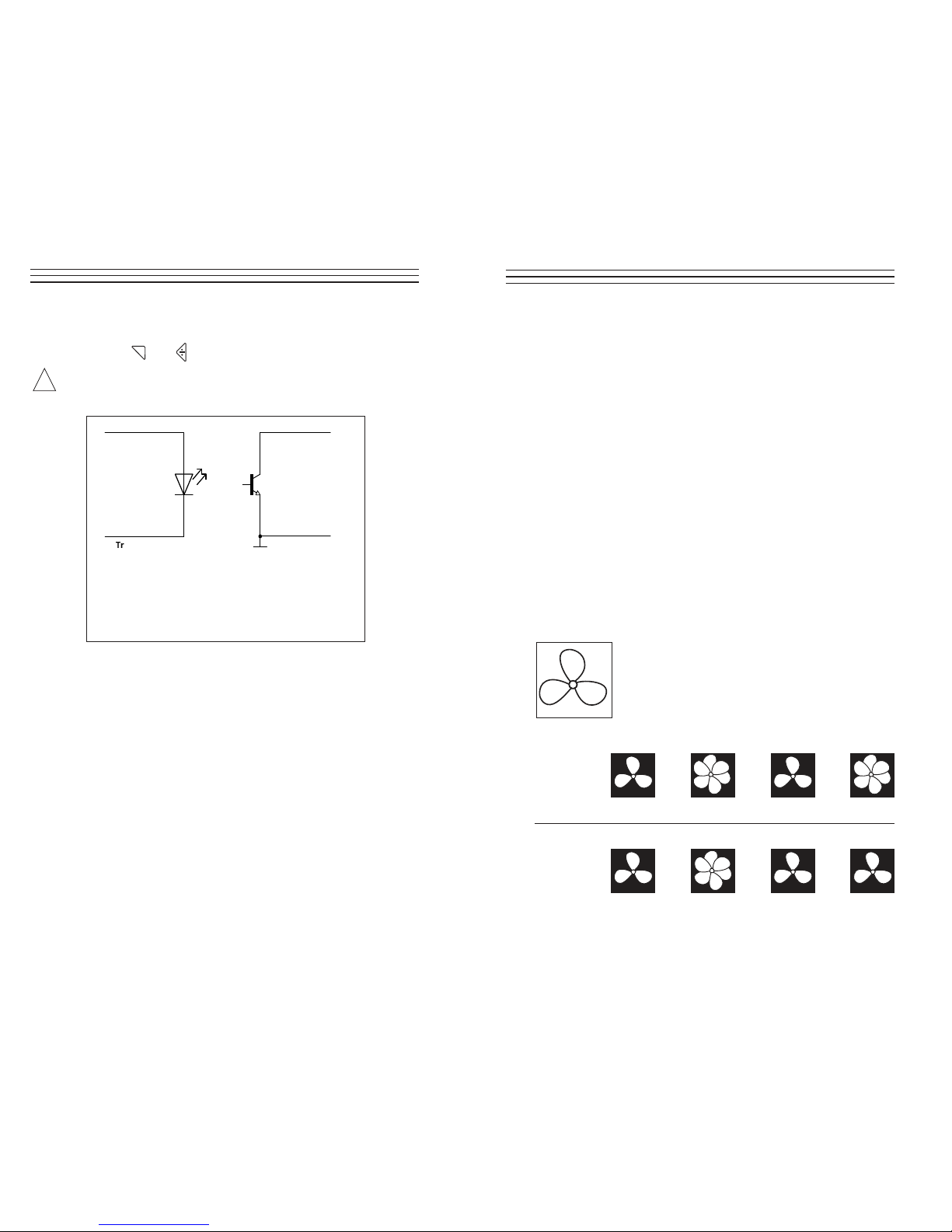

Example 3: (Out of Range)

This final example shows how speeds faster than 12,000 RPM (the upper

limit of the Pocket-Strobe) can be calculated.

This is the object which is rotating. Its speed is known

only to be greater than 12,000 RPM. Because it has a

uniform shape, an orientation mark is added.

To determine its speed, three steps are required:

1. Starting from the maximum speed of the strobe, slowly reduce the

flash rate. Look for singular frozen harmonic images.

2. Find at least two images. (For greater accuracy, find three). Label

these rates as“X,” “Y’ (and possibly “Z”).

3. Plug these values into a suitable equation (see page 19) and calculate

the object’s RPM.

Step 1: As the speed is reduced, the following images appear:

Image No.: 1 2 3 4

Flash Rate: 6,000 4,000 3,000 1,500

Image No: 1 2 3 4

Flash Rate: 9,600 7,200 4,800 3,600

Point “X” Point “Y” Point “Z”

M

M

–7–

4. If the flash frequency corresponds to the motion frequency, a static

image will be created. If the image does not appear static (motion-

less), adjust the flash frequency using the Adjustment Buttons as

indicated below

Increases the currently set value.

Speeds up when this button is held down.

Halves the currently set value.

Speeds up when this button is held down.

Doubles the currently set value.

Speeds up when this button is held down.

Lowers the currently set value.

Speeds up when this button is held down.

CAUTION: Although the object may appear to be motionless, it is

still moving and should NEVER be touched.

5 The following functions are activated by simultaneously pressing

the buttons shown below:

+ = Reset to default settings

+ = Activate/Deactivate Button Lock.

Prevents current settings from being changed accidentally

5.1 Using Special Functions

PULS µs/PULS deg:

Flash duration. This function enables you to set the fl ash duration.

Using this function, you can influence the brightness and focus of

the object of observation. This adjustment can either bemade in

absolute form (microseconds) or in relative form (degrees).

DELAY ms

Adjustment of delay time between the internal trigger signal and

the flash (in milliseconds). Thisfunction enables you to set a fixed

delay time between the internal trigger signal and the flash.

Example: The position of observation can be adjusted extremely

precisely without altering the flash frequency. You can shift the

observation position within a motion cycle.

PHASE deg

Phase shift adjustment between the internal trigger signal and the

flash (in degrees, relative to the frequency). This function enables

you to set a fixed angle between the internal trigger signal and the

flash.

Example: The position of observation can be adjusted extremely

precisely without altering the flash frequency. You can shift the

observation position within a motion cycle.

CAUTION

!

–14–

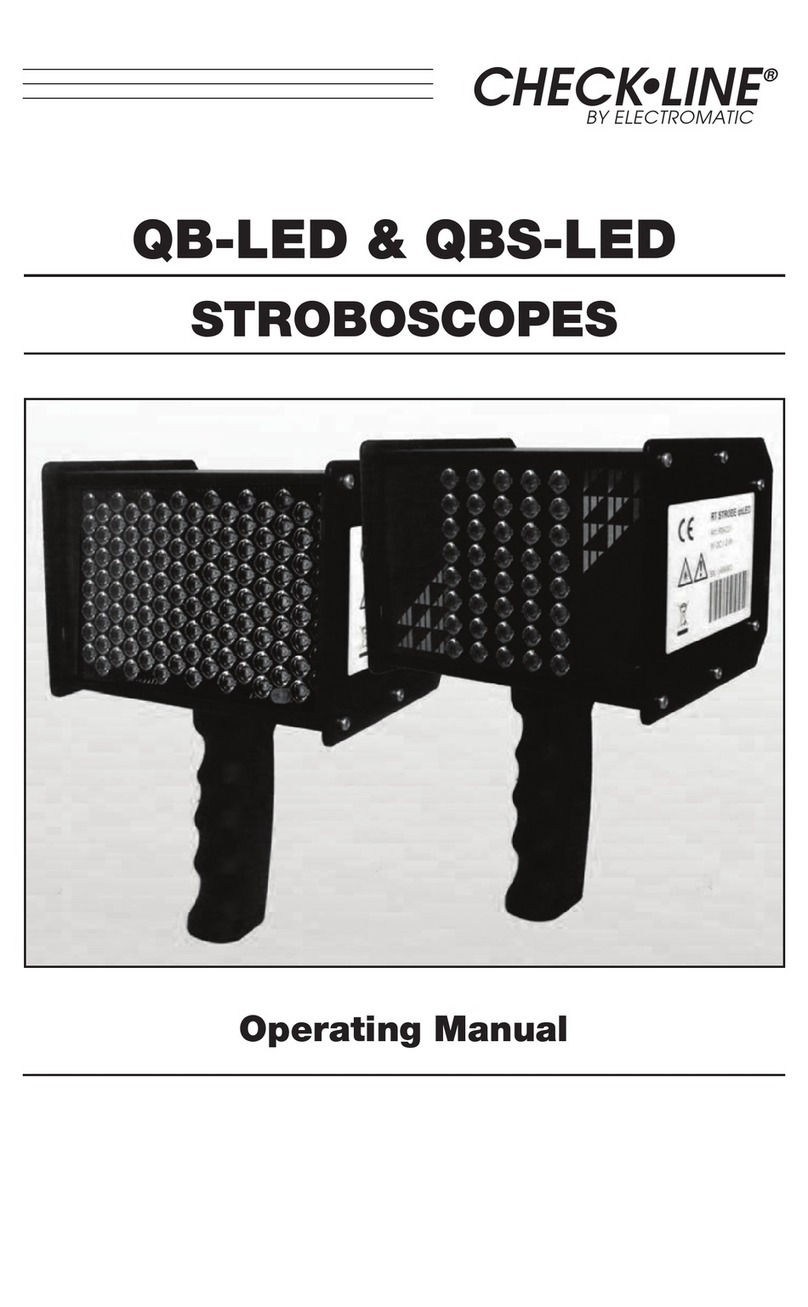

What is the actual rate of the fan? Images 1, 3, 5, 7, and 8 are all

“frozen,” so the rate could be taken as 3,300. 1,100, 825, 660 or 550.

Which is correct?

In order to determine the fan’s actual speed, a mark is

added to one of the blades and the test is run again.

Image No.: 1 2 3 4

Flash Rate: 3.300 1,650 1,100 916.6

Image No.: 5 6 7 8

Flash Rate: 825 733.3 660 550

Using the orientation mark, it is now clear that the images appearing at

3,300, 825 and 660 RPM are multiple-image harmonics. In each of these

cases, three identification marks appear. On the other hand, a singular

image appears at 1,100 and again at 550.

Here, only one mark appears. Recall that “a singular image always

appears at exactly one half of the object’s true RPM.” 550 is one half

of 1,100. Therefore, the rate of the fan must be 1,100 RPM.

Example 2: (Within Range No Mark Needed)

This example illustrates how the actual speed of an object can be deter-

mined without the use of an orientation mark—provided that the object

has a suitable shape.

Assume that the speed of this cam is known only to be

less than 7,000 RPM. Because it has a unique shape, it

does not need an identifying mark. As the flash rate is

lowered from 7,000, the following harmonic images

appear.

M

+

*

–

–

–

– 8 –

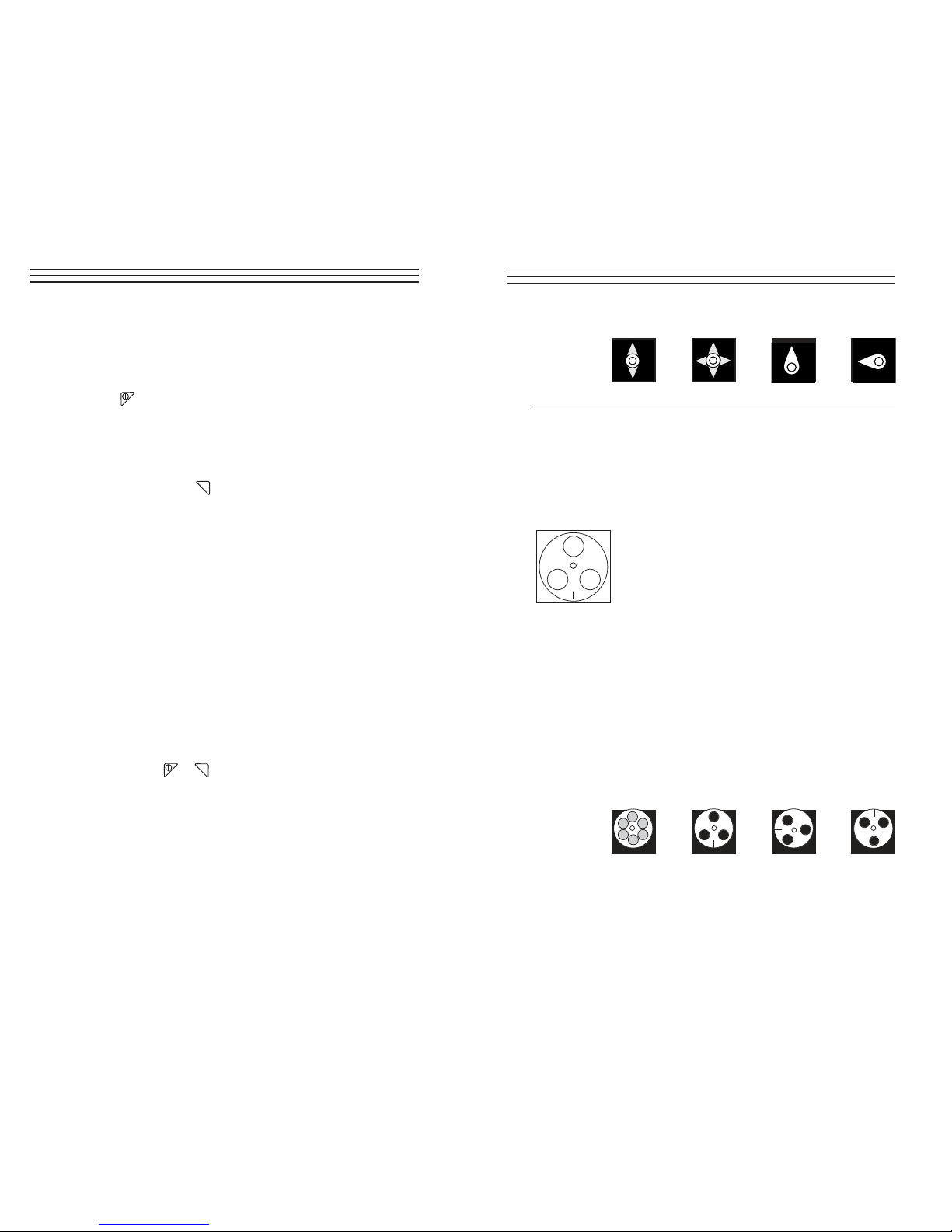

6.0 ADDITIONAL OPERATING INSTRUCTIONS (OT MODEL ONLY)

1. Press the and buttons simultaneously to switch between

internal and external trigger signal.

CAUTION: Do not use signals over 300,000 FPM Hz to trigger the device.

Display fields (see pages 3 and 4)

Influencing the input signal before the flash is generated

3 DELAY ms Adjustment of delay time (in milliseconds) between

the internal trigger signaland the fl ash.

4 PHASE deg Phase shift adjustment between the internal trigger

signal and the flash (in degrees, relative to the

frequency).

5DIV Pulse divider, maximum value 255.

6OPT Trigger signal edge selection

0 = positive edge

1 = negative edge

T

rigger input

3 … 32V

BROWN

BLUE

Trigger output

max. 50mA

WHITE

BLACK

CAUTION

!

The trigger input is potential-free and is suitable for PNP

and NPN signals. A cable with plug, correspnding to

these iput jacks, is provided with the device.

Trigger Connection Assignment - Trigger Jack

–13–

10.0 DETERMINING AN OBJECT’S TRUE RPM

The strobe can be used as a digital tachometer to determine the true

RPM and/or the reciprocation rate of an object. This is done by visually

“freezing” the object’s movement and then reading the LCD display. As

with all stroboscopes, it is important to verify that this frozen image is

not a harmonic of the object’s actual rate.

Helpful Hints

■Knowing the approximate rate of the object in advance gives you a

useful starting point.

■If the object has a uniform shape, like a multi-blade fan or motor

shaft, you must give it an identifying mark (using paint or reflective

tape or equivalent) in order to differentiate its orientation.

■A singular image always appears at exactly one half of the object’s

true RPM.

■Mathematical harmonic techniques can be used to determine an

object’s true RPM if it is greater than the upper limit of the

stroboscope.See Example 3 on page 15.

Example 1 (Within Range):

This example shows why identifying marks are

important.

Suppose you want to determine the true RPM of this

fan. The only thing you know is that its speed is less

than 3,500 RPM. If you slowly decrease the flash rate

starting from 3,500 FPM, the following “frozen” images

appear:

Image No.: 1 2 3 4

Flash Rate: 3.300 1,650 1,100 916.6

Image No.: 5 6 7 8

Flash Rate: 825 733.3 660 550

M

–9–

Unit displayed

91/min Rotations per minute.

10 Hz Frequency of motion per second.

NOTE: When an external trigger signal is used, the units 1/min (rather

than FPM) or Hz are displayed.

Operating information

11 RANGE External trigger signal is causing the flash frequency to

be too high.

12 EXT External trigger signal selected.

13 INT Device is generating flash frequency.

NOTE: A parameter which has been set to differ from the default

setting flashes during operation.

6.1 Using Special Functions (OT model)

DELAY ms

Adjustment of delay time between the internal trigger signal and

the flash (in milliseconds). This function enables you to set a fixed

delay time between the input signal and the output signal.

Example: The external trigger signal is generated before the

required observation point (= flash position of the stroboscope). In

this case the connected stroboscope would regularly fl ash too soon.

With the DELAY ms function, you can set the value by which the

output signal should be delayed.

PHASE deg

Phase shift adjustment between the internal trigger signal and the

flash (in degrees, relative to the frequency). This function enables

you to set a fixed angle between the internal trigger signal and the

flash.

Example: The external trigger signal is generated before the

required observation point (=f lash position of the stroboscope). In

this case the connected stroboscope would regularly fl ash too soon.

With the PHASE deg function, you can adjust the delay so that the

fl ash position of the stroboscope is altered by a set angle. This

setting is independent of the current speed ofrotation, which means

that the stroboscope will flash at the required position even during

the start-up process or when the speed of rotation is fluctuating.

–12–

9.0 HARMONICS

If you continuously increase the flash rate while strobing an object, it

may appear to freeze, slow down, speed up, go forward, freeze again, go

backwards, form multiple images, etc. These images appear at mathe-

matically determined multiples or harmonics of the object’s actual speed.

Example: Assume you wish to slow the motion of the fan used in the

last example, but you want it to be brighter.

Technique: Starting from 1,000 FPM, slowly increase the flash rate.

At 1,500 FPM the image will appear to freeze again.

Continue to increase the rate. The image will appear to

freeze again at 3,000 FPM. At this rate, the fan appears to be

very bright.

Helpful Hint:

■Harmonic images appear at both whole number multiples as well as

fractional intervals of the object’s actual rate. For example, a fan

rotating at 1,000 RPM will appear to be frozen at the whole number

multiples of 2,000 (2x), 3,000 (3x), 4,000 (4x) etc., as well as at the

fractional rates of 500 (1/2x),750 (3/4x), 833 (5/6x) and 1,500 (1 1/2x),

etc.

■Some of the harmonic images are “singular” in appearance while

others are “multiple.” This becomes important if you want to

determine the objects actual rate as discussed in section 10.0.

–10–

DIV (pulse divider)

This function is only active when an external trigger signal is

employed. With the pulse divideryou can set a value x, by which the

external trigger signal is then divided.

Example: An external trigger (e.g. rotation sensor) scanning a gear

wheel issues a signal forevery tooth scanned. At a DIV value of 10,

only every tenth input pulse is transmitted to the connected

stroboscope as a trigger signal.

OPT

Trigger signal edge selection. 0 = positive edge, 1 = negative edge.

With this option, the polarityof the trigger signal can be defined.

7.0 SAFETY PRECAUTIONS

Stroboscopes give the illusion of stopped motion.

Do not touch the machine or object being observed.

The use of stroboscopes may induce an epileptic seizure

in those persons predisposed to this type of attack.

Do not use this product in an explosive environment.

Do not use this product in wet or condensating

environments.

Do not allow liquids or metallic objects to enter into the

ventilation holes.

Wear adequate eye protection when using this product.

Failure to do so could result in serious injury.

The DS-2000LED / DS-2000LED-OT are designed for

battery operation only.Do not operate the instrument

while it is recharging. Failure to follow these

instructions willdamage the unit and void its warranty.

DANGER HIGH VOLTAGE!

To reduce risk of an electronic shock, do not open the

stroboscope. There are no user-serviceable parts inside.

–11–

8.0 SLOWING DOWN MOTION

As discussed, the primary use of the strobe is to slow down or “freeze”

the apparent motion of moving objects. This allows you to analyze their

run-time performances safely and easily.

To make an object appear to move in slow motion, you need to strobe it

at a rate slightly above or slightly below its actual speed or any

harmonic of its speed as discussed below.

Helpful Hints:

The speed at which the object appears to move can be determined by

subtracting the flash rate from the object’s actual rate.

Example: If an object is rotating at 1,000 RPM and you strobe it at a

rate of 1,005 flashes per minute (FPM), the object will appear

to be moving at a rate of 5 RPM.

Speed = Actual Rate minus Flash Rate

= 1,000 –1,005 = 5

= 5 RPM

The direction (clockwise vs. counterclockwise or forward vs. backward)

at which the object appears to move is determined by the flash rate,

the object’s actual direction of movement and the orientation of the

stroboscopic beam to the object.

Example: Assume you wish to visibly slow down the movement of a fan

which is rotating clockwise at 1,000 RPM.

Case 1: If you stand in front of it and strobe it at a rate of 1,005

flashes per minute (FPM), the object will appear to be moving

at a rateof 5 RPM in a counterclockwise direction.

Case 2: If you stand in front of it and strobe it at a rate of 995 FPM,

it will appear to move at a rate of 5 RPM in a clockwise

direction.

Case 3: If you stand behind it and strobe it at a rate of 1,005 FPM,

it will appear to move in a clockwise direction at a rate of 5

RPM.

Case 4: If you stand behind it and strobe it at a rate of 995 FPM, it

will appear to move in a counterclockwise direction at a rate

of 5 RPM

NOTE: Typically, stroboscopes are brightest (and can illuminate an

object the best) when the flash rate is between 2,000 and 6,000

FPM. Often, you can still make an object appear to be frozen or

moving in slow motion within this range because of the effect

of harmonics. This principle is explained section 9.0.

CAUTION

!

Pocket

STROBOSCOPE

CHECK

•LINE®

BY ELECTROMATIC

Models DS-2000LED / DS-2000LED-OT

OPERATING MANUAL

Distributed by: ABQ Industrial LP USA

Tel: +1 (281) 516-9292 / (888) 275-5772 eFax: +1 (866) 234-0451

Web: https://www.abqindustrial.net E-mail: [email protected]

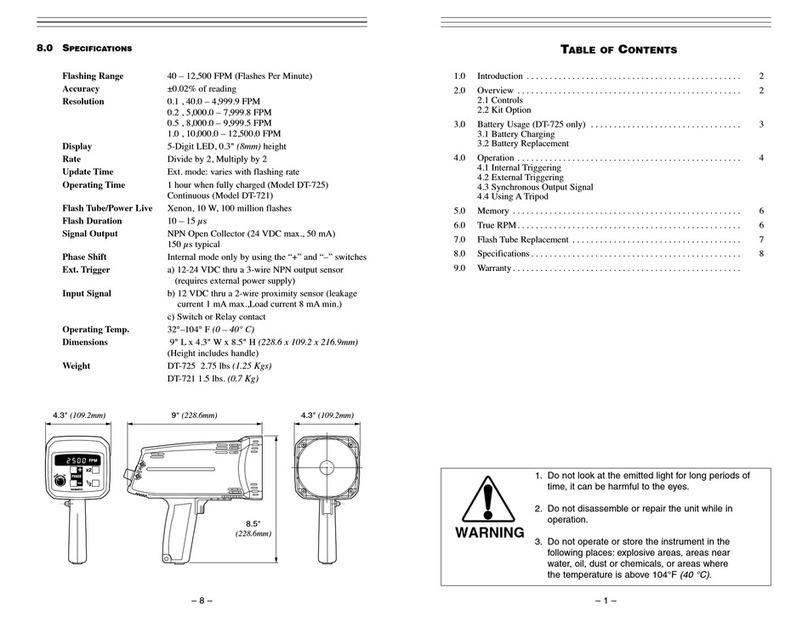

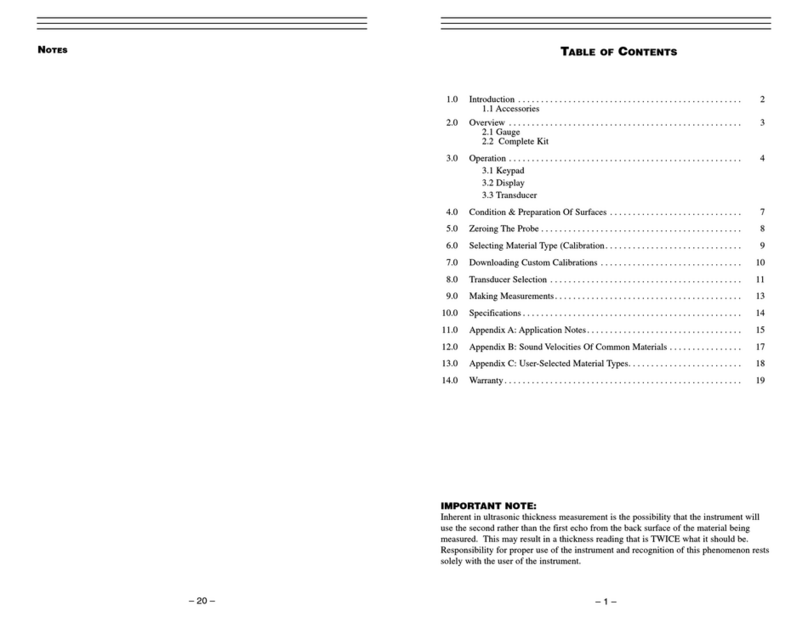

This manual suits for next models

1

Table of contents

Other Check-line Test Equipment manuals

Check-line

Check-line QB-LED User manual

Check-line

Check-line LS-9-12000 User manual

Check-line

Check-line DT-311D User manual

Check-line

Check-line CP-425-KIT User manual

Check-line

Check-line NS-600 User manual

Check-line

Check-line FGV-XY User manual

Check-line

Check-line MiniTest 7200 FH Manual

Check-line

Check-line DT-725 User manual

Check-line

Check-line TI-25S User manual

Check-line

Check-line TSV-1000 User manual