Chef Rubber RUBBAIRE PRO Instructions for use

Instruction & Maintenance

1/2HP COMPRESSOR

RUBBAIRE PRO

Thank you and congratulations on your purchase of the

Chef Rubber RubbAire air compressor.

This is a quality-built, highly efficient compressor, which, if properly used and

maintained, will perform to your full satisfaction for many years to come.

Chef Rubber RubbAire air compressors are virtually soundless and are totally automatic.

Each unit includes a tank pressure gauge, line pressure gauge, line pressure regulator,

moisture trap/filter, safety valve, air-intake filter and a handle for balanced carrying.

Please follow the instructions carefully to guarantee trouble-free operation.

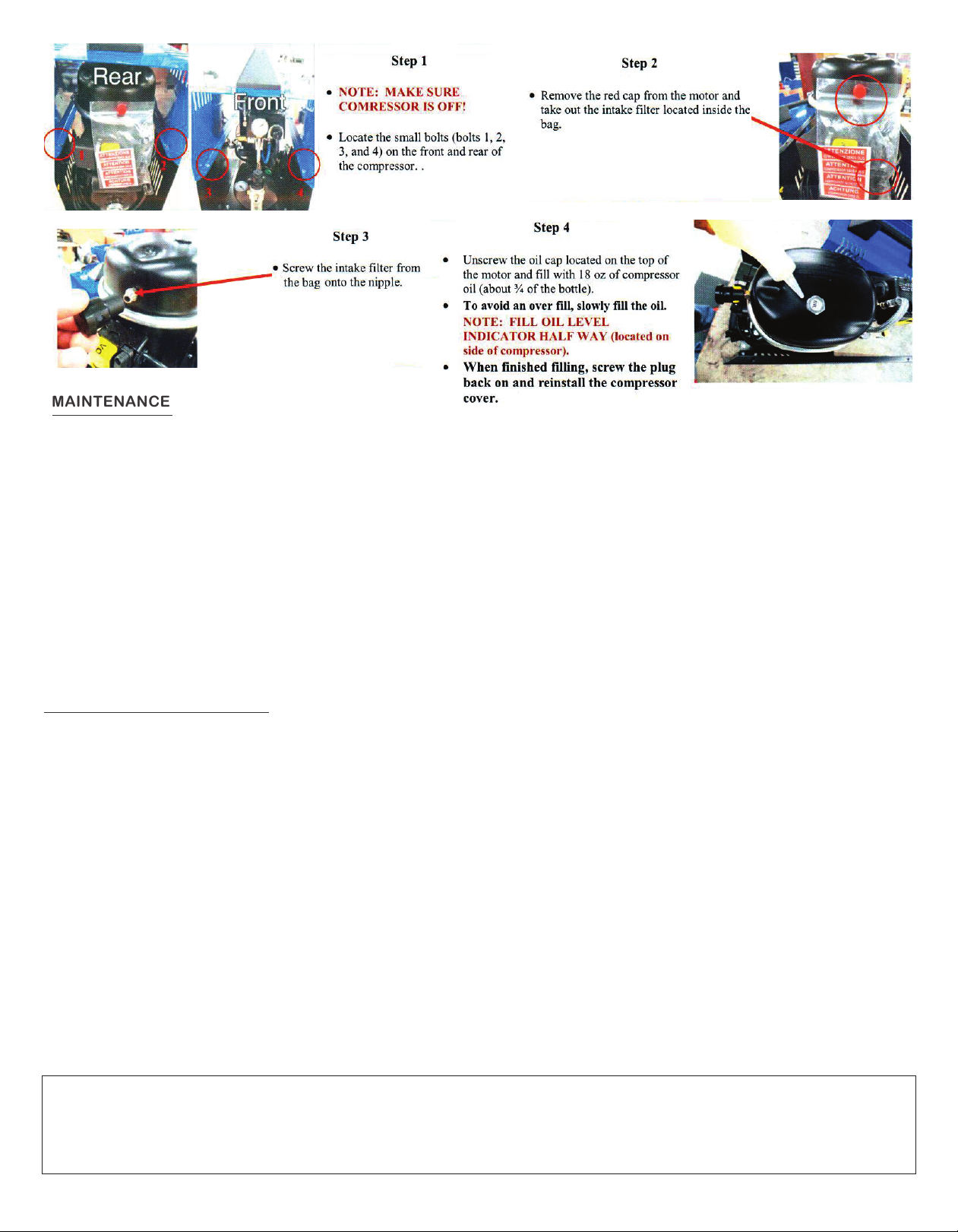

PRE-OPERATING INSTRUCTIONS

Remove your RubbAire compressor from the

packaging. Read all of the literature enclosed

and inspect the unit for possible shipping

damages. Then remove the white shipping plug

from the hole in the top section of the pump. The

Air-Intake Filter and the oil bottle spout are in a

plastic bag hanging from the braided metal air

hose coming out of the side of the pump.

Attach the spout to the oil bottle. Pour the oil

into the open hole. Stop when the oil level

reaches the middle of the oil sight glass,

which is located on the side of the pump.

Then place the Air-Intake filter into the

open hole (See illustration). Connect

desired air hose and selected tooling to the

threaded port on the Filter Regulator marked “OUT”.

See reverse for more instructions.

MAINTENANCE

AIR INTAKE FILTER: The air intake filter must be kept clean to permit easy airflow into the compressor. Filters that have become dirty, oily, or clogged can be cleaned

thoroughly in a detergent soap and water solution or replaced. Cleaning or replacing the Air Intake Filter, under normal operating conditions is necessary every 3 to 6

months. Never operate the compressor without an Air Intake Filter in place.

MOISTURE TRAP: If used properly, the moisture trap (which is built into the Filter/Regulator) will trap moisture and dirt particles before releasing air into the line. Periodic

checks for moisture and traces of oil should be done on a routine basis by looking through the clear bowl attached to the underside of the Filter/Regulator. When moisture

and/or oil traces are detected, they can be removed by pressing up the valve core, which is located at the bottom of the bowl. The air pressure will blow the moisture and

oil trace out through the valve core. Should it become necessary to remove the clear bowl for cleaning.

CAUTION should be taken that there is no air pressure in the bowl at the time it is unscrewed.

OIL LEVEL: Periodically check the oil level at the oil sight glass. Should the level drop towards the lower edge of the glass, add the necessary quantity to bring the level

up to the middle of the oil sight glass. (See illustration in Pre-Operating Instructions). It is strongly recommended to change the oil after every 150 hours of operation or

when the oil is discolored. To change the oil, remove the air intake filter and tilt the unit until all oil has drained.

PRESSURE TANK: The air tank should be checked for water daily. Unplug the unit and release all air in the storage tank by opening the drain plug on the lower side of

the pressure tank. Tilt the unit towards the plug to allow water to drain. The air hose and other accessories should also be drained on a regular basis.

NOTICE: The oil supplied with your compressor is a highly researched synthetic grade oil. Do not mix or substitute the oil in your compressor with other available brands.

Use of oil not specified by the manufacturer will result in compressor breakdown and void the limited warranty.

COMPRESSOR SAFETY TIPS

• Carefully inspect the hoses, fittings and overall appearance before each use.

• Always operate the compressor on a level surface.

• Periodically check the oil level at the oil sight glass.

• Use only properly grounded outlet that will accept 3 pronged plugs. Do no operate the compressor with a damaged cord.

• Keep the compressor free of dust, dirt, and paint. This will prolong Air Intake operation and prevent clogging for Safety

Relief Valve.

• Use only recommended air handling tools and attachments that are acceptable for pressures rated for this company.

• Adjust the pressure regulator according to your compressor with other available brands. Any attempt to use oil differenty

from that specified by the manufacturer will result in compressor breakdown and void the Limited Warranty.

• Do no direct the air stream at your body.

• To reduce the risk of ELECTRIC SHOCK, do no expose the unit to rain or water while in use.

• Never attempt to service the compressor while it is plugged into an electrical outlet.

• Avoid direct contact with surface while operating – high temperatures may be present.

• Use only factory authorized parts.

• Always store your compressor in a clean and dry environment when not in use. Make sure all air pressure has been

released from the system.

WARNING:

ANY ATTEMPT TO SERVICE YOUR COMPRESSOR BY REMOVING THE COMPRESSOR SHELL OR TERMINAL BOX COVER,

TAMPERING WITH THE PRESSURE SWITCH SETTING AND/OR GROUNDING PLUG WILL VOID THE LIMITED WARRANTY, AND MAY

MAKE THE COMPRESSOR UNSAFE TO USE.

OPERATING INSTRUCTIONS

1. Make sure the Air-Intake Filter has been installed (See Pre-Operating Instructions).

2. Make sure that the automatic ON/OFF Pressure Switch is in the OFF position (turned fully counter-clockwise).

3. Plug the cord into 110 Volt Grounded outlets. Unit should be grounded because in the event of an electrical short, grounding reduces the risk of electric

shock. The plug must be plugged into an outlet that is properly installed and grounded in accordance with all local codes and ordinances. If it is

necessary to use an extension cord, DO NOT USE common household cords. Use a HEAVY-DUTY extension cord. Not using a HEAVY-DUTY extension

cord will cause loss of power to the compressor, and possibly damage the electrical components. NOTICE: TAMPERING WITH THE POWER CORD

OR GROUNDING TERMINAL WILL VOID WARRANTY

4. Turn the automatic ON/OFF Pressure Switch to the “ON” position by turning the knob clockwise until it stops. This pressure switch has been set to

automatically start and stop at the correct PSI levels. Leave it in the “ON” position until you need to turn off your compressor. To do this, simply

turn the knob down counter clockwise. If the electrical power is interrupted while the compressor is in operation and it fails to restart after the

power comes back on, turn the knob to the “OFF” position. This will release any pressure in the line and enable the compressor to restart.

5. After the compressor has run for a complete cycle and shuts off, the Pressure Regulator can then be adjusted to your desired setting. Simply lift the knob

until it unlocks, and then turn it clockwise to increase the pressure, or counter clockwise to reduce it. Watch the pressure gauge close to the regulator to

measure the pressure needed. NOTICE: A standard feature on your compressor is the Safety Relief Valve. The Valve opens automatically if the

tank pressure goes beyond a safe level. DO NOT ATTEMPT TO ADJUST OR REMOVE THIS DEVICE.

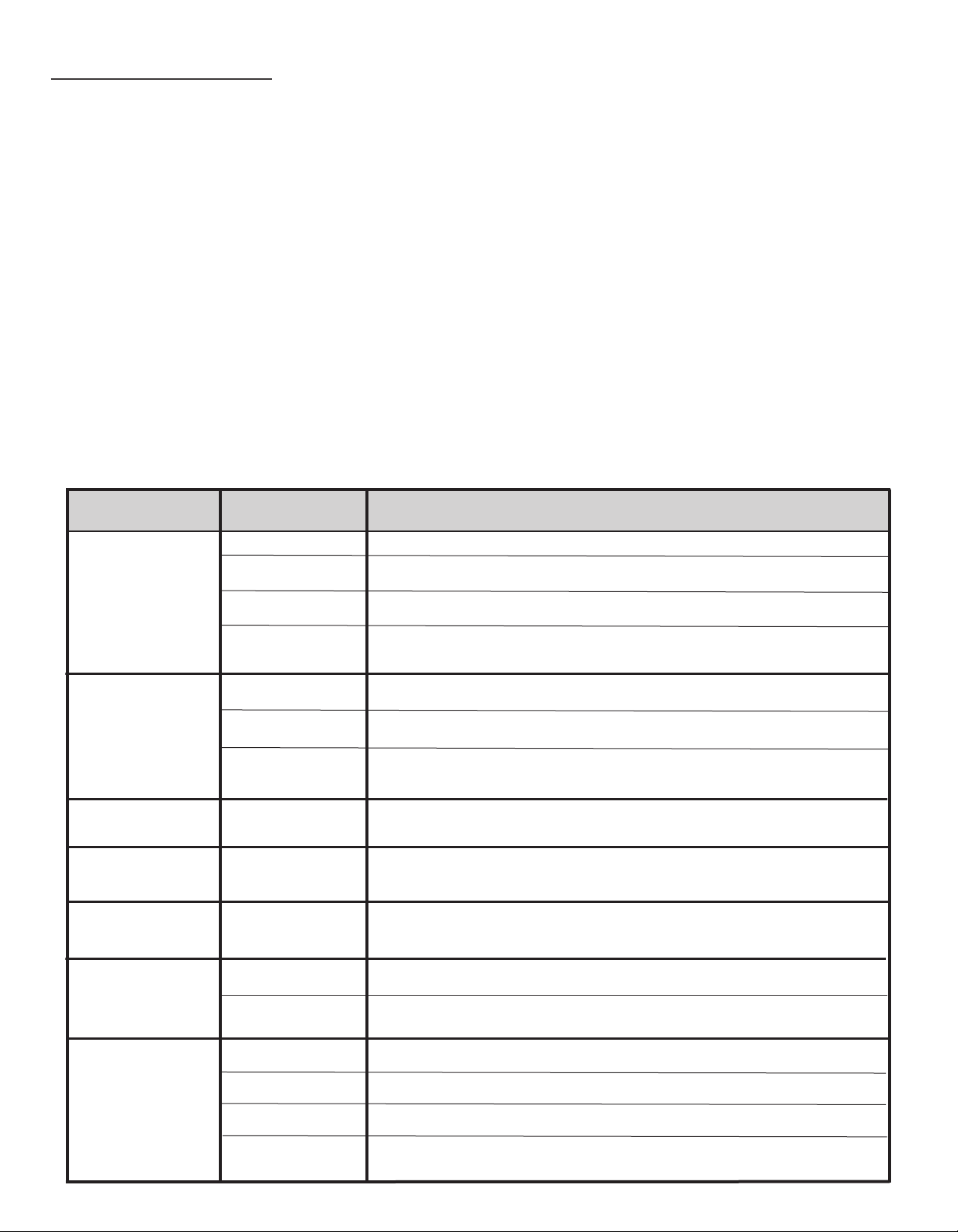

TROUBLE CAUSE REMEDY

Compressor will

not run

Compressor runs

but will not

supply air

Rattling noise

during operation

Milky oil in

compressor

Air-Tank not holding

pressure when

compressor is not running

No air pressure

shown on regulator

gauge

Compressor

operates very hot

No Power

Bad cord connection for

incorrect extension cord

Holding tank is fully

pressurized

Thermal overload

protection has tripped

Check outlet voltage, fuse and circuit breakers

Check cord connection for visible damage- if using an extension cord, make sure it is UL

approved, and it’s heavy duty and grounded

Use your equipment to lower pressure in tank

Wait 15 minutes and try starting again – if this was the cause, make sure compressor is in well

ventilated area: check installation leaks; set the regulator’s pressure minimum required for

your equipment

Air pressure regulator

not set properly

Air-Intake Filter clogged

or not installed

Extensive leak

Reset Air-Regulator to pressure required by your equipment

Clean Air-Intake Filter or replace

Install Air-Intake Filter on suction tube or hole (see machine set-up); check all fittings, connections

and equipment, close your pressure regulator all the way (counterclockwise) – if pressure in tank

builds up, leak is in your installation

Compressor motor

touching shell

Operate on level surface – check oil level and adjust if it’s necessary

Oil has been contaminated

with moisture or other

foreign matter

Change oil – Oil needs to be changed every 150 hours

Faulty check valve Disconnect pressure hose at pump and check for leaking back into pump – Clean or replace the check

valve – Spray all connections and manifold with soap solution and reseal or replace leaking parts

No equipment connected

to compressor

Regulator has not been

adjusted

Connect equipment

Lift knob and turn clockwise until gauge shows required pressure – Gauge should be set at minimum

level required by your equipment

Oil level is incorrect

Non-Ventilated Area

Undersized model

Leaks in installation

Fill unit with oil unit MID level. Make sure compressor is well ventilated area.

Duty cycle of compressor should not exceed 50% - if pump is on for 1 minute it should stay off 1 minute

Make sure no leaks are present. The setting on the pressure regulator must be at your equipment

minimum level.

Ventilate working area

TROUBLE SHOOTING GUIDE

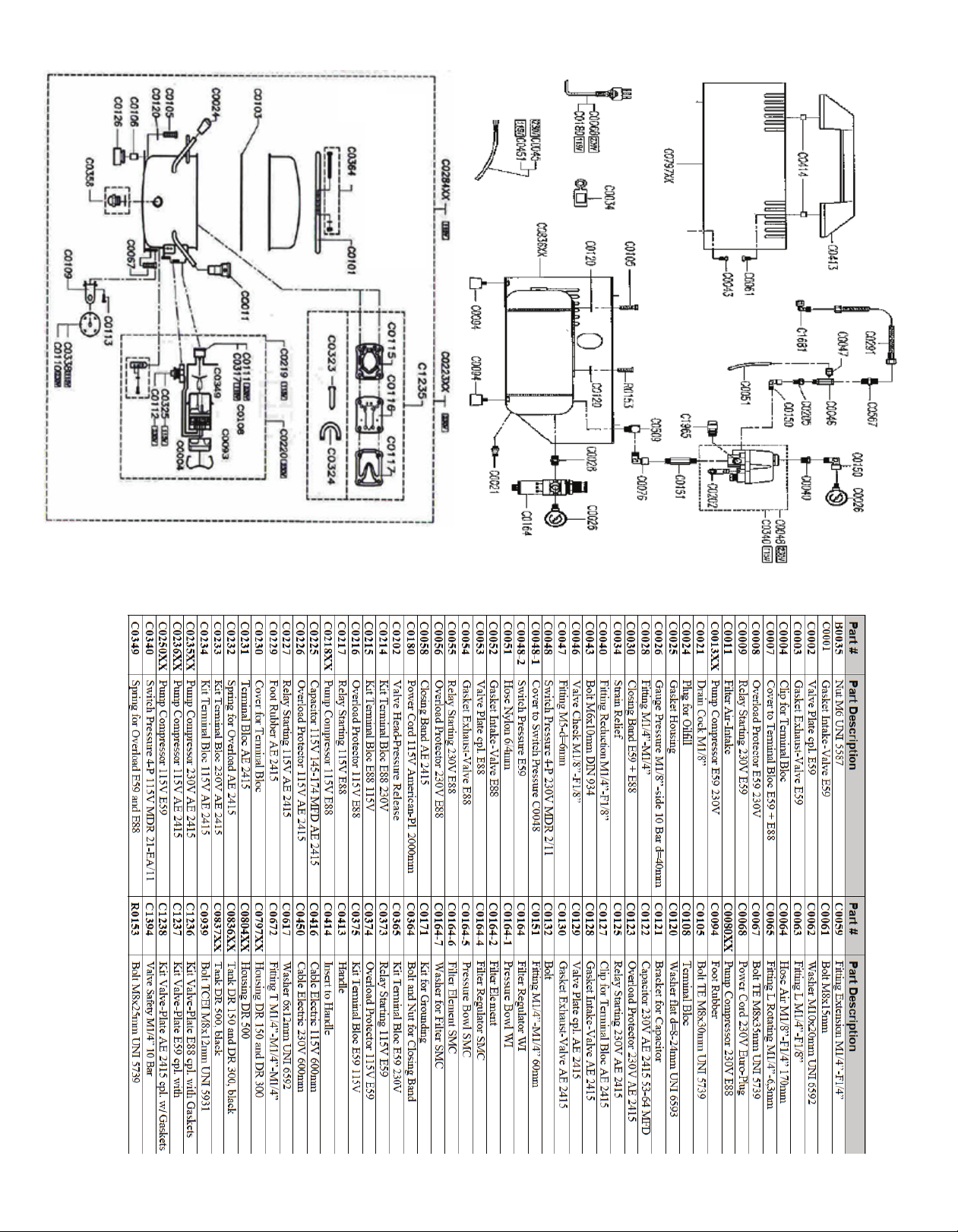

RUBBAIRE PARTS LIST

RUBBAIRE EXPLODED VIEW

MOTOR EXPLODED VIEW

www.chefrubber.com

(830) 685-3156

Popular Compressor manuals by other brands

AERZEN

AERZEN VML Series Installation, assembly and operating instructions

Scheppach

Scheppach GK250o Original instruction manual

Gude

Gude 50066 Instructions for use

Schulz

Schulz MSI 5,2 ML quick start guide

AquaScape

AquaScape Pro Air 20 Instructions & maintenance

Coltri Compressors

Coltri Compressors ERGO MCH-16/EM Use and maintenance manual

COLTRI

COLTRI MCH-5-10-14 EVO CNG Use and maintenance manual

ALDI

ALDI WorkZone WZK 183 user manual

Schneider Airsystems

Schneider Airsystems PEM 500-15-50 B Original operating manual

WilTec

WilTec AF18A instruction manual

John Bunn

John Bunn Neb-u-Tyke Bella the Butterfly JB0112-071 user manual

GEA

GEA HG22e Series Assembly instructions