8

D

GB

F

E

96188-09.2013-DGbFEI

3|Areas of application

ATTENTION! Compressor operation is possible within the operating limits

shown in the diagrams. Please note the signicance

of the shaded areas. Thresholds should not be selected as design

or continuous operation points.

- Max. permissible discharge end temperature 140 °C

-Max.permissibleswitchingfrequency8x/h.

- A minimum running time of 3 min. steady-state condition

(continuous operation) must be achieved.

For operation with additional cooling:

- Use only oils that are highly thermally stable.

- Avoid continuous operation near the limits.

Foroperationwithfrequencyconverter:

- The maximum current and power consumption must not be

exceeded. Inthecaseofoperationabovethemainsfrequency,

the application limit can therefore be limited.

When operating in the vacuum range, there is a danger of air

enteringonthesuctionside.Thiscancausechemicalreactions,

a pressure rise in the condenser and an elevated compressed-gas

temperature. Prevent the ingress of air at all costs!

Thecompressorsarelledatthefactorywiththefollowingoiltype:

-forR134a,R404A/R507,R407C FUCHSRenisoTritonSE55

-forR22 FUCHSRenisoSP46

Compressorswithesteroilcharge(FUCHSRenisoTritonSE55)aremarkedwithanXinthetype

designation(e.g.HGX22e/190-4).

3.1 Refrigerants

• HFKW/HFC: R134a,R404A/R507,R407C

• (H)FCKW/(H)CFC: R22

3.2 Oil charge

3.3 Limits of application

INFO! Forrefilling,werecommendtheaboveoiltypes.

Alternatives: seelubricantstable,Chapter7.5.

The oil level must be in the

visible part of the sight

glass; damage to the com-

pressor is possible if over-

filled or underfilled!

max.oillevel

min.oillevel

ATTENTION!

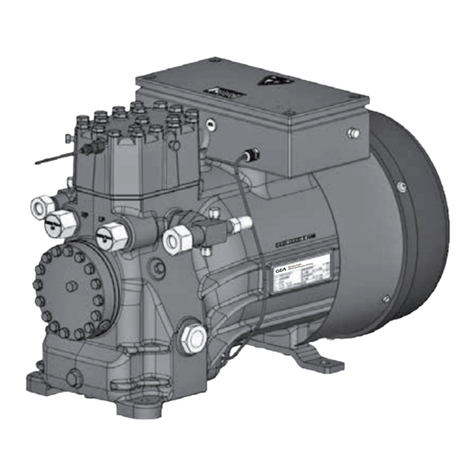

Fig.4