CHEFOOK PM 10 3V User guide

12

CHAP. 7 - MAINTENANCE

7.1 - GENERALITY

Before carrying out any maintenance operation it is necessary to:

Disconnect the power supply from the mains to completely isolate the machine from the

rest of the plant.

7.2 - POWER SUPPLY CABLE

Periodically check the wear of the cable and eventually call the “AFTER-SALES CENTRE” to

replace it.

7.3 - TOOLS

If the tools should not work the product correctly, call the “AFTER-SALES CENTRE”.

CHAP. 8 - DISMANTLING

8.1 - DECOMMISSIONING

If, for any reason it should be decided to place the machine out of order, ensure it cannot be

used by any other person: disconnect and cut the electrical connections.

8.2 - RAEE Waste of Electrical and Electronic Appliances

According to art.13 of Legislative Decree 25 July 2005, n.151 ”Implementation of

Directives 2002/95/EC, 2002/96/EC and 2003/108/EC, concerning the restriction on the

use of certain hazardous substances in electrical and electronic equipment, as well as

the disposal of waste”.

The symbol of the crossed out wheeled bin on the appliance or on its packaging indicates that,

at the end of its life-span, the product must be collected separately from other waste.

Once reached the end of its life-span, the differential collection of this appliance is arranged

and managed by the manufacturer. The user wanting to dispose of this appliance will therefore

have to contact the manufacturer and follow the system adopted by him to allow the separate

collection of the appliance that has reached the end of its life-span.

The adequate differential collection for the subsequent start of the appliance dismantled for

recycling, treatment and compatible environmental disposal, contributes to avoid possible

negative effects on the environment and on health, and favours the re-use and/or recycle of

the materials composing the machine.

The unlawful disposal of the product on behalf of the owner, involves the application of

administrative sanctions provided by the normative in force.

1

USE AND MAINTENANCE

INSTRUCTIONS MANUAL

Planetary mixers 10-20-30-40

Ed. 04/2021 - ver.002

2

PREMISE

This manual has been edited to supply the client with information on the machine and on the rules

connected to it, as well as the use and maintenance instructions for a better use of the mean,

keeping its efficiency intact in time.

This manual must be handed over to the persons in charge of using the machine and its periodic

maintenance.

INDEX OF CHAPTERS

CHAP. 1 - INFORMATION ON THE MACHINE page 3

1.1 - GENERAL PRECAUTIONS

1.2 - SAFETY DEVICES INSTALLED ON THE MACHINE

1.2.1 - mechanical safety devices

1.2.2 - electrical safety devices

1.3 - DESCRIPTION OF THE MACHINE

1.3.1 - general description

1.3.2 - constructive features

1.3.3 - machine composition

CHAP. 2 - TECHNICAL DATA page 6

2.1 - SIZE, WEIGHT, FEATURES ...

CHAP. 3 - RECEIVING THE MACHINE page 7

3.1 - SHIPPING THE MACHINE

3.2 - CHECKING THE PACKAGE UPON RECEIPT

3.3 - DISPOSAL OF PACKAGING

CHAP. 4 - INSTALLATION page 8

4.1 - PLACING THE MACHINE

4.2 - SINGLE PHASE ELECTRICAL CONNECTION

4.2.1 - THREE PHASE ELECTRICAL CONNECTION

4.2.2 - tools rotation direction

4.3 - ELECTRICAL LAYOUT

4.3.1 - Electrical system layout mod. 10-20-30

4.4 - FUNCTIONING CHECK

CHAP. 5 - USE OF MACHINE page 9

5.1 - CONTROLS

5.2 - LOADING THE PRODUCT

CHAP. 6 - ROUTINE CLEANING page 10

6.1 - GENERALITY

6.2 - PROCEDURE TO FOLLOW WHEN CLEANING MACHINE

6.2.1 - cleaning the tools and bowl

6.2.2 - general cleaning

CHAP. 7 - MAINTENANCE page 12

7.1 - GENERALITY

7.2 - POWER SUPPLY CABLE

7.3 - TOOLS

CHAP. 8 - DISMANTLING page 12

8.1 - DECOMMISSIONING

8.2 - RAEE Waste of Electrical and Electronic Appliances

11

CHAP. 6 - ROUTINE CLEANING

6.1 - GENERALITY

The machine must be cleaned at least once a day or, if necessary, more frequently.

All parts of the machine which come into direct or indirect contact with the product to be

worked, must be scrupulously cleaned.

The machine must not be cleaned with high pressure cleaners or water jets but with water

and neutral detergents. Tools, scrubbers and anything else which might superficially

damage the machine must not be used.

Before carrying out any cleaning operation it is necessary to:

a) Disconnect the mains to completely isolate the machine from the rest of the plant;

6.2 - PROCEDURE TO FOLLOW WHEN CLEANING THE MACHINE

6.2.1 - cleaning the tools and bowl

To clean the tools holder it is necessary to:

a) Remove the bowl from the machine body;

b) CAREFULLY dismantle the tool.

Once the components have been removed, clean them with warn water and a neutral

detergent.

The bowl and tool used must be washed with hot water and neutral detergents every time they

are to be left unused for more than two hours or at least once a day.

ATTENTION! Do not wash any Planetaria component in the dishwasher.

6.2.2 - general cleaning

NB.: Disconnect the power supply

The body of the machine can be cleaned with a neutral detergent and a damp cloth, frequently

rinsed with warm water.

When finished, accurately dry all parts.

FIG. n.10

10

5.2 - LOADING THE PRODUCT

The goods to be mixed must be loaded into the bowl exclusively with the motor still, paying

attention to the tool.

ATTENTION! Do not introduce solid products!

The procedure is the following:

1. Lower the lever (Fig.1 - ref.10) clockwise.

2. Insert the tool suitable for the work to be carried out;

3. Insert the bowl in the appropriate supports and fix it with the hooks present in the supports

(Fig.1 - ref.3).

4. (ATTENTION) place the product into the bowl paying attention to the inserted tool;

5. Lift the lever (Fig.1 - ref.10) anti-clockwise, in order to bring the bowl in working position;

6. Assume a correct position in order to avoid accidents (see FIG. n.9): the body must be

perpendicular to the work surface; the hands must not force the machine components or

obstruct the movements of the same.

In any case, do not lean on to the machine, avoiding assuming positions which

might entail direct contact with the machine.

ATTENTION!

Please use the planetary mixer for maximum 30 minutes ON

and then leave it 10 minutes OFF

7. Start the machine by pressing the “I” button.

8. To change speed, turn power off, select the desired speed then turn power on,

9. At the end of the work stop the machine by pressing stop button “0”;

10. Lower the lever (Fig.1 - ref.10) clockwise, the bowl lowers, therefore cautiously remove the

bowl.

FIG. n.9 - Correct position

3

CHAP. 1 - INFORMATION ON THE MACHINE

1.1 - GENERAL PRECAUTIONS

The machine must only be used by trained staff who must be perfectly aware of the safety

rules contained in this manual.

In case of personnel turnover, provide training in time.

Disconnect the machine from the mains before cleaning and maintaining.

When intervening for machine maintenance or cleaning (and therefore protections are

removed), carefully evaluate the residue risks.

During maintenance or cleaning, keep concentrated on the operations in progress.

Periodically check the state of the power supply cable; a worn cable or not intact,

represents a serious electrical danger.

Should the machine give reason to presume or show a malfunctioning, do not use it and do

not try to repair it; but call the “After-Sales Centre”.

Do not use the machine for frozen products, products with bones and, however, non-food

products.

Do not try to place your hands or other objects in the container whilst the machine is

working.

The manufacturer is lifted of every responsibility in the following cases:

the machine is tampered with by unauthorised personnel;

components are replaced with other non originals;

the instructions in this annual are not attentively followed;

the machine surfaces are treated with unsuitable products.

1.2 - SAFETY DEVICES INSTALLED ON THE MACHINE

1.2.1 - mechanical safety devices

With regard to mechanical safety, the machine described in this manual is in compliance with

Directive EEC 2006/42.

1.2.2 - electrical safety devices

With regard to mechanical safety, the machine described in this manual is in compliance with

Directive EEC 2006/95, 2004/108.

Therefore, the machine is provided with micro which causes the machine to stop in case the

protection grid on the bowl is removed (see FIG. n.1).

Despite the machine being equipped with the electrical and mechanical protections (both

during functioning and during cleaning and maintenance), RESIDUE RISKS do however exist,

which cannot be completely removed, recalled in this manual with ATTENTION.They refer to

the danger of bruising during cleaning of the machine and of accessories.

1.3 - DESCRIPTION OF THE MACHINE

1.3.1 - general description

Planetary mixer has been designed and realised by our company, with the precise aim to

homogenise, emulsify, whip-up food products like eggs, flour, cream and, however, not

particularly hard or consistent, and guarantee:

10

5.2 - LOADING THE PRODUCT

The goods to be mixed must be loaded into the bowl exclusively with the motor still, paying

attention to the tool.

ATTENTION! Do not introduce solid products!

The procedure is the following:

1. Lower the lever (Fig.1 - ref.10) clockwise.

2. Insert the tool suitable for the work to be carried out;

3. Insert the bowl in the appropriate supports and fix it with the hooks present in the supports

(Fig.1 - ref.3).

4. (ATTENTION) place the product into the bowl paying attention to the inserted tool;

5. Lift the lever (Fig.1 - ref.10) anti-clockwise, in order to bring the bowl in working position;

6. Assume a correct position in order to avoid accidents (see FIG. n.9): the body must be

perpendicular to the work surface; the hands must not force the machine components or

obstruct the movements of the same.

In any case, do not lean on to the machine, avoiding assuming positions which

might entail direct contact with the machine.

ATTENTION!

Please use the planetary mixer for maximum 30 minutes ON

and then leave it 10 minutes OFF

7. Start the machine by pressing the “I” button.

8. To change speed, turn power off, select the desired speed then turn power on,

9. At the end of the work stop the machine by pressing stop button “0”;

10. Lower the lever (Fig.1 - ref.10) clockwise, the bowl lowers, therefore cautiously remove the

bowl.

FIG. n.9 - Correct position

3

CHAP. 1 - INFORMATION ON THE MACHINE

1.1 - GENERAL PRECAUTIONS

The machine must only be used by trained staff who must be perfectly aware of the safety

rules contained in this manual.

In case of personnel turnover, provide training in time.

Disconnect the machine from the mains before cleaning and maintaining.

When intervening for machine maintenance or cleaning (and therefore protections are

removed), carefully evaluate the residue risks.

During maintenance or cleaning, keep concentrated on the operations in progress.

Periodically check the state of the power supply cable; a worn cable or not intact,

represents a serious electrical danger.

Should the machine give reason to presume or show a malfunctioning, do not use it and do

not try to repair it; but call the “After-Sales Centre”.

Do not use the machine for frozen products, products with bones and, however, non-food

products.

Do not try to place your hands or other objects in the container whilst the machine is

working.

The manufacturer is lifted of every responsibility in the following cases:

the machine is tampered with by unauthorised personnel;

components are replaced with other non originals;

the instructions in this annual are not attentively followed;

the machine surfaces are treated with unsuitable products.

1.2 - SAFETY DEVICES INSTALLED ON THE MACHINE

1.2.1 - mechanical safety devices

With regard to mechanical safety, the machine described in this manual is in compliance with

Directive EEC 2006/42.

1.2.2 - electrical safety devices

With regard to mechanical safety, the machine described in this manual is in compliance with

Directive EEC 2006/95, 2004/108.

Therefore, the machine is provided with micro which causes the machine to stop in case the

protection grid on the bowl is removed (see FIG. n.1).

Despite the machine being equipped with the electrical and mechanical protections (both

during functioning and during cleaning and maintenance), RESIDUE RISKS do however exist,

which cannot be completely removed, recalled in this manual with ATTENTION.They refer to

the danger of bruising during cleaning of the machine and of accessories.

1.3 - DESCRIPTION OF THE MACHINE

1.3.1 - general description

Planetary mixer has been designed and realised by our company, with the precise aim to

homogenise, emulsify, whip-up food products like eggs, flour, cream and, however, not

particularly hard or consistent, and guarantee:

4

- Maximum safety in use, cleaning and maintenance;

- Maximum hygiene thanks to the careful selection of the materials which come into contact

with food products, and with the elimination of the rough edges in the parts of the machine

which come into contact with the product, in order to obtain an easy and complete cleaning

as well as easy dismantling;

- Maximum yield;

- Robustness and stability of all its components;

- Maximum noiselessness;

- Easy handling.

1.3.2 - constructive features

Planetary mixer is made with the following materials:

- Painted aluminium and cast iron body;

- Easily removable stainless steel bowl;

- Stainless steel and aluminium tools;

- Chrome steel protection grid.

9

4.3 - ELECTRICAL LAYOUT

4.3.1 - Electrical system layout mod. 10-20-30

4.4 - FUNCTIONING CHECK (FIG. n.1)

Before testing the machine ensure that:

- The mixing bowl (FIG. n.1 - ref.8) is perfectly housed;

- The tool (FIG. n.1 - ref.5-6-7) is perfectly mounted;

- There are no accessories inside the bowl (FIG. n.1 - ref.8);

- The grid (FIG. n.1 - ref.2) is perfectly closed.

The procedure is the following:

1. action the Planetary mixer by pressing start button “I”, and subsequently stop button “0”;

2. Check if by opening the grid or lowering the bowl (FIG. n.1 - ref.2-8) the Planetary mixer

switches off.

POWER SUPPLY

230 V 50 Hz

CHAP. 5 - USE OF MACHINE

5.1 - CONTROLS

The controls are arranged on the body of the machine as highlighted in the following figure.

FIG. n.8 - Position of controls

1 - 0/I switch

2 - speed selector 1-2-3

Planetary mixer mod. 10 - 20

1 - push-button OFF/0

2 - push-button ON/I

3 - timer

Planetary mixer mod. 30 - 40

1

2 1 2

3

FIG. n.7

4

- Maximum safety in use, cleaning and maintenance;

- Maximum hygiene thanks to the careful selection of the materials which come into contact

with food products, and with the elimination of the rough edges in the parts of the machine

which come into contact with the product, in order to obtain an easy and complete cleaning

as well as easy dismantling;

- Maximum yield;

- Robustness and stability of all its components;

- Maximum noiselessness;

- Easy handling.

1.3.2 - constructive features

Planetary mixer is made with the following materials:

- Painted aluminium and cast iron body;

- Easily removable stainless steel bowl;

- Stainless steel and aluminium tools;

- Chrome steel protection grid.

9

4.3 - ELECTRICAL LAYOUT

4.3.1 - Electrical system layout mod. 10-20-30

4.4 - FUNCTIONING CHECK (FIG. n.1)

Before testing the machine ensure that:

- The mixing bowl (FIG. n.1 - ref.8) is perfectly housed;

- The tool (FIG. n.1 - ref.5-6-7) is perfectly mounted;

- There are no accessories inside the bowl (FIG. n.1 - ref.8);

- The grid (FIG. n.1 - ref.2) is perfectly closed.

The procedure is the following:

1. action the Planetary mixer by pressing start button “I”, and subsequently stop button “0”;

2. Check if by opening the grid or lowering the bowl (FIG. n.1 - ref.2-8) the Planetary mixer

switches off.

POWER SUPPLY

230 V 50 Hz

CHAP. 5 - USE OF MACHINE

5.1 - CONTROLS

The controls are arranged on the body of the machine as highlighted in the following figure.

FIG. n.8 - Position of controls

1 - 0/I switch

2 - speed selector 1-2-3

Planetary mixer mod. 10 - 20

1 - push-button OFF/0

2 - push-button ON/I

3 - timer

Planetary mixer mod. 30 - 40

1

2 1 2

3

FIG. n.7

8

FIG. n.4 - Technical-serial number plaque

CHAP. 4 - INSTALLATION

4.1 - PLACING THE MACHINE

The surface on which the machine will be located must allow for the support dimensions

indicated in the table (see Chap. 2), and, therefore, be sufficiently wide, correctly levelled, dry,

smooth, robust and stable.

Also, the machine must be installed in a room with 75% max humidity, not salty and a

temperature between +5°C and +35°C; however, in rooms which do not entail disorders of the

same.

4.2 - SINGLE PHASE ELECTRICAL CONNECTION

The machine is equipped with a power supply cable with 3x1.5 mm² section; 1.5m length and a

“SHUKO” plug.

Connect the machine 230 Volt 50 Hz, interposing a 10A, I = 0.03A magneto-thermal circuit

breaker. Ensure the earthing plant is perfectly functional.

Also check that the data reported on the technical-serial number plaque (FIG.n.4) corresponds

to the data reported on the delivery and accompanying documents.

4.2.1 - THREE PHASE ELECTRICAL CONNECTION

The machine is equipped with a feeding cable with a cross section area of 5x1,5mm², length

1.5m and a red 15A 3F + T CEI plug. Connect the machine to the 400 V. - 50Hz three-phase

supply mains, interposing a magnetothermic differential switch of 10 A, I=0.03A.

Also check that the data reported on the technical-serial number plaque (FIG.n.4) corresponds

to the data reported on the delivery and accompanying documents.

LEGEND

(A) = Product code and name

(B) = Power supply

(C) = Motor frequency

(D) = Amperage

(E) = Serial number

(F) = Barcode

(G) = Manifacturer

(H) = International Protection

(I) = Weight

(L) = Power

(M) = Origin

(A)

(B)

(C)

(D)

(E)

(H)

(I)

(L)

(F)

(G) (M)

Check the direction of the tools rotation with a

pulse of the “I” push-button (ON), immediately

followed by the “0” push-button OFF.

The direction of the tools rotation must be

clockwise when looking at the machine from the

front side (see arrow Fig. n°6). In the case that

the rotation direction is not exact, invert (Fig. n°

5) the position of two of the three phase wires

(black, gray or brown) in the plug.

4.2.2 - tools rotation direction

FIG. n.5

FIG. n.6

5

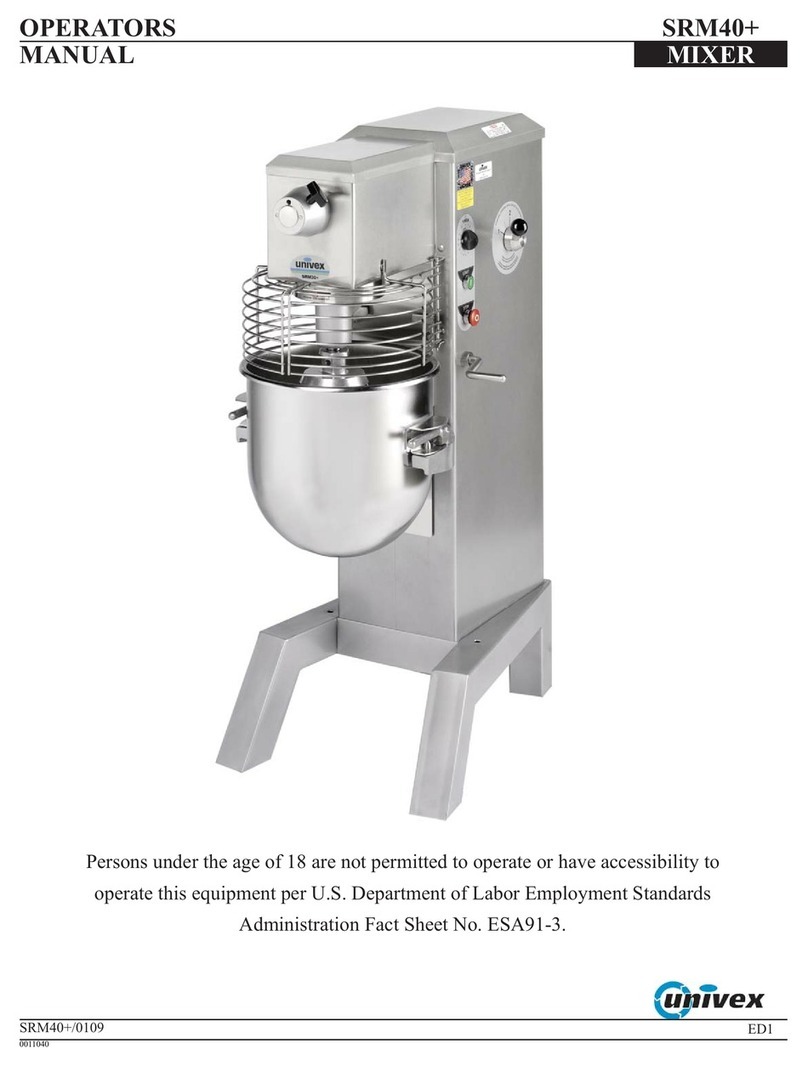

1.3.3 - machine composition

FIG. n.1 - General view of the machine

KEY:

1 Machine body 7 Spatula

2 Protection grid 8 Feed tray for add ingredients for mod. 30-40

3 Bowl fixing hook for. Mod. 20-30-40 9 Bowl support

4 Bowl 10 Power supply cable

5 Whisk 11 Bowl lift/lower lever

6 Hook 12 Controls

7

1

2

3

9

5

4 11

6

10

8

12

6

Model u.m. 10 lt.

AxB mm 360x345

CxDxE mm 440x500x630

Bowl capacity lt 10

Whisk revolutions r.p.m. 1 = 108

2 = 195

3 = 355

Motor Watt 450

Power supply 230V/50Hz

Net weight kg 40

20 lt.

420x440

515x560x770

20

1 = 97

2 = 220

3 = 316

1100

230V/50Hz

83

30 lt.

580x660

630x650x1160

30

1 = 93

2 = 167

3 = 285

1500

230V/50Hz

169

Noise level dB 70 70 70

40 lt.

670x784

707x698x1316

40

1 = 99

2 = 221

3 = 307

2200

400V/50Hz

223

70

ATTENTION: The electrical features for which the machine is prepared, are indicated on a

plaque applied on the back of the machine; before carrying out the electrical connection, see

4.2 electrical connection.

CHAP. 2 - TECHNICAL DATA

2.1 - SIZE, WEIGHT, FEATURES ...

FIG. n.2 - Overall dimensions

7

3.2 - CHECKING THE PACKAGE UPON RECEIPT

Upon receiving the package, if there are no external damages, open it to check that all the

material is contained within (see FIG. n.3). Whereas, if, upon receiving the package it shows

signs of mistreatments, impacts or falls, show the damage to the carrier and, within 3 days

from delivery date, shown on the documents, draft a precise report on the damages sustained

by the machine. Do not turn the package upside down!! When transporting, be sure that it

is firmly held from the 4 fundamental points (keeping it parallel to the ground).

3.3 - DISPOSAL OF PACKAGING

The packaging components (cardboard, plastic strap) are products assimilable with municipal

solid waste; for this reason, they can be easily disposed of.

In case the machine is installed in countries where particular rules exist, dispose of the

packaging in compliance with that provided by the rules in force.

FIG. n.3 - Packaging description

CHAP. 3 - RECEIVING THE MACHINE

3.1 - SHIPPING THE MACHINE (see FIG. n.3)

Planetary mixer leaves our warehouses accurately packed; the packaging is made of:

a) external wooden box;

b) the machine;

c) this manual;

d) CE declaration of conformity.

Mod. 20-30-40

Heavy package. Do not lift manually

unless with help of at least three

people

Move the package only by electrical

trolleys or manually, equipped with

lifting straps

c) d)

b)

a)

6

Model u.m. 10 lt.

AxB mm 360x345

CxDxE mm 440x500x630

Bowl capacity lt 10

Whisk revolutions r.p.m. 1 = 108

2 = 195

3 = 355

Motor Watt 450

Power supply 230V/50Hz

Net weight kg 40

20 lt.

420x440

515x560x770

20

1 = 97

2 = 220

3 = 316

1100

230V/50Hz

83

30 lt.

580x660

630x650x1160

30

1 = 93

2 = 167

3 = 285

1500

230V/50Hz

169

Noise level dB 70 70 70

40 lt.

670x784

707x698x1316

40

1 = 99

2 = 221

3 = 307

2200

400V/50Hz

223

70

ATTENTION: The electrical features for which the machine is prepared, are indicated on a

plaque applied on the back of the machine; before carrying out the electrical connection, see

4.2 electrical connection.

CHAP. 2 - TECHNICAL DATA

2.1 - SIZE, WEIGHT, FEATURES ...

FIG. n.2 - Overall dimensions

7

3.2 - CHECKING THE PACKAGE UPON RECEIPT

Upon receiving the package, if there are no external damages, open it to check that all the

material is contained within (see FIG. n.3). Whereas, if, upon receiving the package it shows

signs of mistreatments, impacts or falls, show the damage to the carrier and, within 3 days

from delivery date, shown on the documents, draft a precise report on the damages sustained

by the machine. Do not turn the package upside down!! When transporting, be sure that it

is firmly held from the 4 fundamental points (keeping it parallel to the ground).

3.3 - DISPOSAL OF PACKAGING

The packaging components (cardboard, plastic strap) are products assimilable with municipal

solid waste; for this reason, they can be easily disposed of.

In case the machine is installed in countries where particular rules exist, dispose of the

packaging in compliance with that provided by the rules in force.

FIG. n.3 - Packaging description

CHAP. 3 - RECEIVING THE MACHINE

3.1 - SHIPPING THE MACHINE (see FIG. n.3)

Planetary mixer leaves our warehouses accurately packed; the packaging is made of:

a) external wooden box;

b) the machine;

c) this manual;

d) CE declaration of conformity.

Mod. 20-30-40

Heavy package. Do not lift manually

unless with help of at least three

people

Move the package only by electrical

trolleys or manually, equipped with

lifting straps

c) d)

b)

a)

8

FIG. n.4 - Technical-serial number plaque

CHAP. 4 - INSTALLATION

4.1 - PLACING THE MACHINE

The surface on which the machine will be located must allow for the support dimensions

indicated in the table (see Chap. 2), and, therefore, be sufficiently wide, correctly levelled, dry,

smooth, robust and stable.

Also, the machine must be installed in a room with 75% max humidity, not salty and a

temperature between +5°C and +35°C; however, in rooms which do not entail disorders of the

same.

4.2 - SINGLE PHASE ELECTRICAL CONNECTION

The machine is equipped with a power supply cable with 3x1.5 mm² section; 1.5m length and a

“SHUKO” plug.

Connect the machine 230 Volt 50 Hz, interposing a 10A, I = 0.03A magneto-thermal circuit

breaker. Ensure the earthing plant is perfectly functional.

Also check that the data reported on the technical-serial number plaque (FIG.n.4) corresponds

to the data reported on the delivery and accompanying documents.

4.2.1 - THREE PHASE ELECTRICAL CONNECTION

The machine is equipped with a feeding cable with a cross section area of 5x1,5mm², length

1.5m and a red 15A 3F + T CEI plug. Connect the machine to the 400 V. - 50Hz three-phase

supply mains, interposing a magnetothermic differential switch of 10 A, I=0.03A.

Also check that the data reported on the technical-serial number plaque (FIG.n.4) corresponds

to the data reported on the delivery and accompanying documents.

LEGEND

(A) = Product code and name

(B) = Power supply

(C) = Motor frequency

(D) = Amperage

(E) = Serial number

(F) = Barcode

(G) = Manifacturer

(H) = International Protection

(I) = Weight

(L) = Power

(M) = Origin

(A)

(B)

(C)

(D)

(E)

(H)

(I)

(L)

(F)

(G) (M)

Check the direction of the tools rotation with a

pulse of the “I” push-button (ON), immediately

followed by the “0” push-button OFF.

The direction of the tools rotation must be

clockwise when looking at the machine from the

front side (see arrow Fig. n°6). In the case that

the rotation direction is not exact, invert (Fig. n°

5) the position of two of the three phase wires

(black, gray or brown) in the plug.

4.2.2 - tools rotation direction

FIG. n.5

FIG. n.6

5

1.3.3 - machine composition

FIG. n.1 - General view of the machine

KEY:

1 Machine body 7 Spatula

2 Protection grid 8 Feed tray for add ingredients for mod. 30-40

3 Bowl fixing hook for. Mod. 20-30-40 9 Bowl support

4 Bowl 10 Power supply cable

5 Whisk 11 Bowl lift/lower lever

6 Hook 12 Controls

7

1

2

3

9

5

4 11

6

10

8

12

4

- Maximum safety in use, cleaning and maintenance;

- Maximum hygiene thanks to the careful selection of the materials which come into contact

with food products, and with the elimination of the rough edges in the parts of the machine

which come into contact with the product, in order to obtain an easy and complete cleaning

as well as easy dismantling;

- Maximum yield;

- Robustness and stability of all its components;

- Maximum noiselessness;

- Easy handling.

1.3.2 - constructive features

Planetary mixer is made with the following materials:

- Painted aluminium and cast iron body;

- Easily removable stainless steel bowl;

- Stainless steel and aluminium tools;

- Chrome steel protection grid.

9

4.3 - ELECTRICAL LAYOUT

4.3.1 - Electrical system layout mod. 10-20-30

4.4 - FUNCTIONING CHECK (FIG. n.1)

Before testing the machine ensure that:

- The mixing bowl (FIG. n.1 - ref.8) is perfectly housed;

- The tool (FIG. n.1 - ref.5-6-7) is perfectly mounted;

- There are no accessories inside the bowl (FIG. n.1 - ref.8);

- The grid (FIG. n.1 - ref.2) is perfectly closed.

The procedure is the following:

1. action the Planetary mixer by pressing start button “I”, and subsequently stop button “0”;

2. Check if by opening the grid or lowering the bowl (FIG. n.1 - ref.2-8) the Planetary mixer

switches off.

POWER SUPPLY

230 V 50 Hz

CHAP. 5 - USE OF MACHINE

5.1 - CONTROLS

The controls are arranged on the body of the machine as highlighted in the following figure.

FIG. n.8 - Position of controls

1 - 0/I switch

2 - speed selector 1-2-3

Planetary mixer mod. 10 - 20

1 - push-button OFF/0

2 - push-button ON/I

3 - timer

Planetary mixer mod. 30 - 40

1

2 1 2

3

FIG. n.7

4

- Maximum safety in use, cleaning and maintenance;

- Maximum hygiene thanks to the careful selection of the materials which come into contact

with food products, and with the elimination of the rough edges in the parts of the machine

which come into contact with the product, in order to obtain an easy and complete cleaning

as well as easy dismantling;

- Maximum yield;

- Robustness and stability of all its components;

- Maximum noiselessness;

- Easy handling.

1.3.2 - constructive features

Planetary mixer is made with the following materials:

- Painted aluminium and cast iron body;

- Easily removable stainless steel bowl;

- Stainless steel and aluminium tools;

- Chrome steel protection grid.

9

4.3 - ELECTRICAL LAYOUT

4.3.1 - Electrical system layout mod. 10-20-30

4.4 - FUNCTIONING CHECK (FIG. n.1)

Before testing the machine ensure that:

- The mixing bowl (FIG. n.1 - ref.8) is perfectly housed;

- The tool (FIG. n.1 - ref.5-6-7) is perfectly mounted;

- There are no accessories inside the bowl (FIG. n.1 - ref.8);

- The grid (FIG. n.1 - ref.2) is perfectly closed.

The procedure is the following:

1. action the Planetary mixer by pressing start button “I”, and subsequently stop button “0”;

2. Check if by opening the grid or lowering the bowl (FIG. n.1 - ref.2-8) the Planetary mixer

switches off.

POWER SUPPLY

230 V 50 Hz

CHAP. 5 - USE OF MACHINE

5.1 - CONTROLS

The controls are arranged on the body of the machine as highlighted in the following figure.

FIG. n.8 - Position of controls

1 - 0/I switch

2 - speed selector 1-2-3

Planetary mixer mod. 10 - 20

1 - push-button OFF/0

2 - push-button ON/I

3 - timer

Planetary mixer mod. 30 - 40

1

2 1 2

3

FIG. n.7

10

5.2 - LOADING THE PRODUCT

The goods to be mixed must be loaded into the bowl exclusively with the motor still, paying

attention to the tool.

ATTENTION! Do not introduce solid products!

The procedure is the following:

1. Lower the lever (Fig.1 - ref.10) clockwise.

2. Insert the tool suitable for the work to be carried out;

3. Insert the bowl in the appropriate supports and fix it with the hooks present in the supports

(Fig.1 - ref.3).

4. (ATTENTION) place the product into the bowl paying attention to the inserted tool;

5. Lift the lever (Fig.1 - ref.10) anti-clockwise, in order to bring the bowl in working position;

6. Assume a correct position in order to avoid accidents (see FIG. n.9): the body must be

perpendicular to the work surface; the hands must not force the machine components or

obstruct the movements of the same.

In any case, do not lean on to the machine, avoiding assuming positions which

might entail direct contact with the machine.

ATTENTION!

Please use the planetary mixer for maximum 30 minutes ON

and then leave it 10 minutes OFF

7. Start the machine by pressing the “I” button.

8. To change speed, turn power off, select the desired speed then turn power on,

9. At the end of the work stop the machine by pressing stop button “0”;

10. Lower the lever (Fig.1 - ref.10) clockwise, the bowl lowers, therefore cautiously remove the

bowl.

FIG. n.9 - Correct position

3

CHAP. 1 - INFORMATION ON THE MACHINE

1.1 - GENERAL PRECAUTIONS

The machine must only be used by trained staff who must be perfectly aware of the safety

rules contained in this manual.

In case of personnel turnover, provide training in time.

Disconnect the machine from the mains before cleaning and maintaining.

When intervening for machine maintenance or cleaning (and therefore protections are

removed), carefully evaluate the residue risks.

During maintenance or cleaning, keep concentrated on the operations in progress.

Periodically check the state of the power supply cable; a worn cable or not intact,

represents a serious electrical danger.

Should the machine give reason to presume or show a malfunctioning, do not use it and do

not try to repair it; but call the “After-Sales Centre”.

Do not use the machine for frozen products, products with bones and, however, non-food

products.

Do not try to place your hands or other objects in the container whilst the machine is

working.

The manufacturer is lifted of every responsibility in the following cases:

the machine is tampered with by unauthorised personnel;

components are replaced with other non originals;

the instructions in this annual are not attentively followed;

the machine surfaces are treated with unsuitable products.

1.2 - SAFETY DEVICES INSTALLED ON THE MACHINE

1.2.1 - mechanical safety devices

With regard to mechanical safety, the machine described in this manual is in compliance with

Directive EEC 2006/42.

1.2.2 - electrical safety devices

With regard to mechanical safety, the machine described in this manual is in compliance with

Directive EEC 2006/95, 2004/108.

Therefore, the machine is provided with micro which causes the machine to stop in case the

protection grid on the bowl is removed (see FIG. n.1).

Despite the machine being equipped with the electrical and mechanical protections (both

during functioning and during cleaning and maintenance), RESIDUE RISKS do however exist,

which cannot be completely removed, recalled in this manual with ATTENTION.They refer to

the danger of bruising during cleaning of the machine and of accessories.

1.3 - DESCRIPTION OF THE MACHINE

1.3.1 - general description

Planetary mixer has been designed and realised by our company, with the precise aim to

homogenise, emulsify, whip-up food products like eggs, flour, cream and, however, not

particularly hard or consistent, and guarantee:

2

PREMISE

This manual has been edited to supply the client with information on the machine and on the rules

connected to it, as well as the use and maintenance instructions for a better use of the mean,

keeping its efficiency intact in time.

This manual must be handed over to the persons in charge of using the machine and its periodic

maintenance.

INDEX OF CHAPTERS

CHAP. 1 - INFORMATION ON THE MACHINE page 3

1.1 - GENERAL PRECAUTIONS

1.2 - SAFETY DEVICES INSTALLED ON THE MACHINE

1.2.1 - mechanical safety devices

1.2.2 - electrical safety devices

1.3 - DESCRIPTION OF THE MACHINE

1.3.1 - general description

1.3.2 - constructive features

1.3.3 - machine composition

CHAP. 2 - TECHNICAL DATA page 6

2.1 - SIZE, WEIGHT, FEATURES ...

CHAP. 3 - RECEIVING THE MACHINE page 7

3.1 - SHIPPING THE MACHINE

3.2 - CHECKING THE PACKAGE UPON RECEIPT

3.3 - DISPOSAL OF PACKAGING

CHAP. 4 - INSTALLATION page 8

4.1 - PLACING THE MACHINE

4.2 - SINGLE PHASE ELECTRICAL CONNECTION

4.2.1 - THREE PHASE ELECTRICAL CONNECTION

4.2.2 - tools rotation direction

4.3 - ELECTRICAL LAYOUT

4.3.1 - Electrical system layout mod. 10-20-30

4.4 - FUNCTIONING CHECK

CHAP. 5 - USE OF MACHINE page 9

5.1 - CONTROLS

5.2 - LOADING THE PRODUCT

CHAP. 6 - ROUTINE CLEANING page 10

6.1 - GENERALITY

6.2 - PROCEDURE TO FOLLOW WHEN CLEANING MACHINE

6.2.1 - cleaning the tools and bowl

6.2.2 - general cleaning

CHAP. 7 - MAINTENANCE page 12

7.1 - GENERALITY

7.2 - POWER SUPPLY CABLE

7.3 - TOOLS

CHAP. 8 - DISMANTLING page 12

8.1 - DECOMMISSIONING

8.2 - RAEE Waste of Electrical and Electronic Appliances

11

CHAP. 6 - ROUTINE CLEANING

6.1 - GENERALITY

The machine must be cleaned at least once a day or, if necessary, more frequently.

All parts of the machine which come into direct or indirect contact with the product to be

worked, must be scrupulously cleaned.

The machine must not be cleaned with high pressure cleaners or water jets but with water

and neutral detergents. Tools, scrubbers and anything else which might superficially

damage the machine must not be used.

Before carrying out any cleaning operation it is necessary to:

a) Disconnect the mains to completely isolate the machine from the rest of the plant;

6.2 - PROCEDURE TO FOLLOW WHEN CLEANING THE MACHINE

6.2.1 - cleaning the tools and bowl

To clean the tools holder it is necessary to:

a) Remove the bowl from the machine body;

b) CAREFULLY dismantle the tool.

Once the components have been removed, clean them with warn water and a neutral

detergent.

The bowl and tool used must be washed with hot water and neutral detergents every time they

are to be left unused for more than two hours or at least once a day.

ATTENTION! Do not wash any Planetaria component in the dishwasher.

6.2.2 - general cleaning

NB.: Disconnect the power supply

The body of the machine can be cleaned with a neutral detergent and a damp cloth, frequently

rinsed with warm water.

When finished, accurately dry all parts.

FIG. n.10

12

CHAP. 7 - MAINTENANCE

7.1 - GENERALITY

Before carrying out any maintenance operation it is necessary to:

Disconnect the power supply from the mains to completely isolate the machine from the

rest of the plant.

7.2 - POWER SUPPLY CABLE

Periodically check the wear of the cable and eventually call the “AFTER-SALES CENTRE” to

replace it.

7.3 - TOOLS

If the tools should not work the product correctly, call the “AFTER-SALES CENTRE”.

CHAP. 8 - DISMANTLING

8.1 - DECOMMISSIONING

If, for any reason it should be decided to place the machine out of order, ensure it cannot be

used by any other person: disconnect and cut the electrical connections.

8.2 - RAEE Waste of Electrical and Electronic Appliances

According to art.13 of Legislative Decree 25 July 2005, n.151 ”Implementation of

Directives 2002/95/EC, 2002/96/EC and 2003/108/EC, concerning the restriction on the

use of certain hazardous substances in electrical and electronic equipment, as well as

the disposal of waste”.

The symbol of the crossed out wheeled bin on the appliance or on its packaging indicates that,

at the end of its life-span, the product must be collected separately from other waste.

Once reached the end of its life-span, the differential collection of this appliance is arranged

and managed by the manufacturer. The user wanting to dispose of this appliance will therefore

have to contact the manufacturer and follow the system adopted by him to allow the separate

collection of the appliance that has reached the end of its life-span.

The adequate differential collection for the subsequent start of the appliance dismantled for

recycling, treatment and compatible environmental disposal, contributes to avoid possible

negative effects on the environment and on health, and favours the re-use and/or recycle of

the materials composing the machine.

The unlawful disposal of the product on behalf of the owner, involves the application of

administrative sanctions provided by the normative in force.

1

USE AND MAINTENANCE

INSTRUCTIONS MANUAL

Planetary mixers 10-20-30-40

Ed. 04/2021 - ver.002

This manual suits for next models

3

Table of contents

Other CHEFOOK Mixer manuals