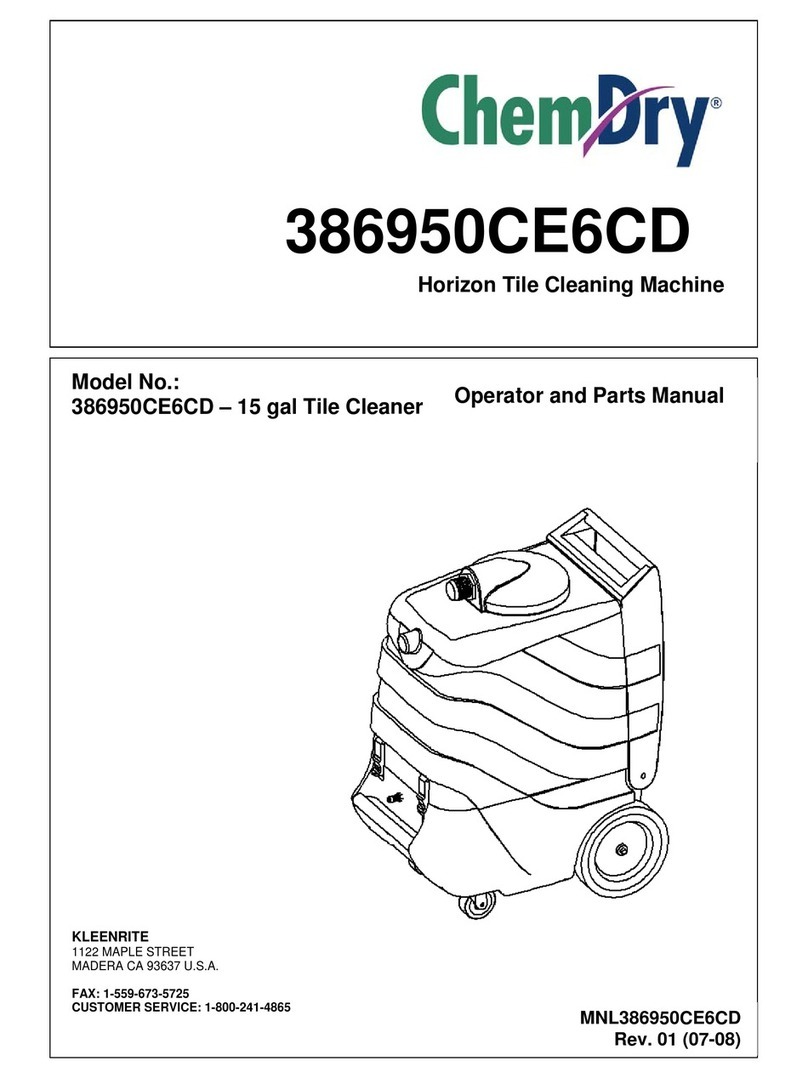

ChemDry 3869506CD Product manual

3869506CD

Horizon Tile Cleaning Machine

Operator and Parts Manual

Model No.:

3869506CD – 15 gal Tile Cleaner

KLEENRITE

1122 MAPLE STREET

MADERA CA 93637 U.S.A.

FAX: 1-559-673-5725 MNL3869506CD

Rev. 01 (07-07)

CUSTOMER SERVICE: 1-800-241-4865

OPERATION

This manual is furnished with each new model. It

provides necessary operation and maintenance

instructions and an illustrated parts list.

3869506CD (05-07)

2

Please fill out at time of installation for future reference.

Model No.- _____________________________________

Install. Date- ____________________________________

Serial No.- _____________________________________

Read this manual completely and understand the

machine before operating or servicing it.

Use the illustrated Parts Lists to order parts. Before

ordering parts or supplies, be sure to have your

machine model number and serial number handy.

Parts and supplies may be ordered by phone or mail

from any authorized parts and service center,

distributor or directly from Kleenrite.

This machine will provide excellent service. However,

the best results will be obtained at minimum costs if:

•The machine is operated with reasonable care.

•The machine is maintained regularly – per the

maintenance instructions provided.

•The machine is maintained with manufacturer

supplied or equivalent parts.

MACHINE DATA

© Kleenrite Printed in U.S.A.

Kleenrite Equipment is a registered United States trademark

TABLE OF CONTENTS

SAFETY PRECAUTIONS ................................. 3

MACHINE COMPONENTS ............................... 4

MACHINE SETUP ............................................. 4

MACHINE OPERATION ................................... 5

FREEZE PROTACTION.................................... 6

MACHINE MAINTENANCE .............................. 6

STORING MACHINE......................................... 7

RECOMMENDED STOCK ITEMS .................... 7

TROUBLE SHOOTING ..................................... 8

SPECIFICATIONS............................................. 9

ELECTRICAL DIAGRAM.................................. 10

PARTS LIST...................................................... 11

WARRANTY POLICY ....................................... 15

OPERATION

SAFETY PRECAUTIONS

This machine is intended for commercial use. It is

designed to clean tile, grout and hard surfaces and

then pump recovered solution away from the machine.

It is not constructed for any other use.

All operators must read, understand and practice the

following safety precautions.

The following safety alert symbols are used throughout

this manual as indicated in their description:

WARNING: To warn of hazards or unsafe

practices which could result in severe personal

injury or death.

FOR SAFETY: To identify actions which must be

followed for safe operation of equipment.

The following information signals potentially dangerous

conditions to the operator or equipment.

FOR SAFETY:

1. Do not operate machine:

– Unless trained and authorized.

– Unless operator manual is read and

understood.

– Around explosive or flammable vapors.

– To extract flammable or explosive liquids.

– With damaged cord or plug.

–If not in proper operating condition.

–Unless cord is properly grounded.

– As a dry vacuum.

– In standing water.

– With the use of an extension cord.

2. Before operating machine:

– Make sure all safety devices are in place

and operate properly.

3. When using machine:

– Do not run machine over cord.

– Do not pull machine by plug or cord.

– Do not pull cord around sharp edges or

corners.

– Do not unplug by pulling on cord.

– Do not stretch cord.

–Do not handle plugs with wet hands.

–Do not allow water or foam to enter

vacuum. Float ball is not activated by foam.

Damage not covered by warranty will

result.

– Keep cord away from heated surfaces.

–Report machine damage or faulty operation

immediately.

–Use defoamer to protect vacuums. If foam

exits machine turn it off immediately.

–Be certain submersible pump is secured in

bottom of tank.

–Connect hoses before turning on pump.

4. Before leaving or servicing machine:

–Turn off machine.

–Unplug cord from wall outlet.

–Drain all recovered solution from tank.

5. When servicing machine:

–Unplug cord from wall outlet.

–Avoid moving parts. Do not wear loose

jackets, shirts, or sleeves.

–Use manufacturer supplied or approved

replacement parts.

–Have service performed by authorized

service person.

WARNING: Hazardous Voltage. Shock or

electrocution can result. Always unplug machine

before servicing.

WARNING: Flammable materials can cause

an explosion or fire. Do not vacuum into tank.

WARNING: Flammable materials or reactive

metals can cause an explosion or fire. Do not pick

up.

WARNING: Contents of solution hoses may

be under pressure even after pump is off.

GROUNDING INSTRUCTIONS

Machine must be grounded. If it should

malfunction or breakdown, grounding provides a

path of least resistance for electrical current to

reduce the risk of electrical shock. This machine is

equipped with a cord having an equipment-

grounding connector and grounding plug. The

plug must be plugged into an appropriate outlet

that is properly installed in accordance with all

local codes and ordinances. Do not remove

ground pin; if missing, replace plug before use.

International models will have different cord ends.

GROUNDED OUTLET

(

3 HOLE

)

GROUNDING

PIN

3869506CD (05—07) 3

OPERATION

MACHINE COMPONENTS

1. Vacuum Inlet

2. Solution Hose Connector

3. Discharge Connector

4. Manual Drain

5. 12” Wheels

6. Vacuum Lid

7. Handle

8. Recovery Tank

9. Separate Circuit Indicator Light

10. Discharge Pump Switch

11. Vacuum #1 Switch

12. Vacuum #2 Switch

13. Freeze Protection Drain Nozzle

14. Pressure Adjustment Valve

15. Water Input Connector

16. Pressure Pump Switch

MACHINE SETUP

1. Carefully check carton for signs of damage.

Report damages at once to carrier. The machine

is shipped fully assembled and is ready for use.

2. Connect hoses and tool to be used. Attach a ¾”

garden hose to the discharge connector on the

back of the machine. An inline filter is

recommended to prevent excessive lint and

debris from entering tank and fouling discharge

pump. Attach a second garden hose to the input

connector (Figure 1).

3. Look inside recovery tank and be certain that

submersible pump is secured properly to bracket

on the bottom of the tank (Figure 2). Take note of

the space between the case of the flood pump

and the attached stainless steel bracket. Lower

the pump so this space engages the bracket

mounted in the bottom of the recovery tank. Also

be certain that nothing is obstructing the free

movement of the float switch.

WARNING: Do not vacuum up flammable

materials as they could cause an explosion or

fire.

Fig. 1

Fig. 2

1

3

6

8

2

9

11

4

5

7

1016

12

13

15

14

3869506CD (05-07)

4

OPERATION

4. Plug machine’s power cords into grounded wall

outlets on separate circuits (Figure 3). Green

circuit indicator light on switch panel illuminated

confirms connection to separate circuits.

Fig. 6

FOR SAFETY: Do not operate machine unless

cord is properly grounded.

FOR SAFETY: Do not operate machine with the

use of an extension cord.

5. Secure recovery tank lid in place.

MACHINE OPERATION

FOR SAFETY: Do not operate machine unless

entire operator manual is read and understood.

PRE-OPERATION

1. Inspect power cord for damage.

2. Turn on empty-out pump (Figure 4). The

discharge pump will not come on until the level

inside the recovery tank activates the float switch.

Note: the “Auto Discharge” switch must be turned

on in order for the discharge pump to cycle on

and off.

3. Turn on water faucet supplying water to the

machine.

CLEANING TILE

1. Activate the pressure pump and both vacuum

switches (Figure 5).

2. Apply cleaning chemicals to the surface to be

cleaned with a separate application sprayer.

Follow chemical manufacturers instructions for

selection of chemical and dwell time before

pressure rinsing with this machine.

GROUNDED OUTLET

(3 hole) ATTENTION: This machine is designed to deliver

high pressure fresh water to the tile surface and

extract emulsified soil. This model is not

designed to mix chemicals with fresh water. Any

attempt to do this could damage fresh water

pump.

3. Take hard surface or tile cleaning tool in hand

and move in the direction that compliments tool

design intermittently spraying rinsing solution.

GROUNDING

PIN

Fi

g

. 3

WHILE OPERATING

1. Periodically check for excessive foam buildup in

recovery tank. Use a recommended foam control

solution to prevent vacuum motor damage.

Warning: Flammable materials or reactive

metals can cause an explosion or fire. Do not

pick up.

ATTENTION: Excessive foam buildup will not

activate the float shut-off screen.

ATTENTION: Discharge pump will not pump foam.

Use a defoamer.

DRAINING RECOVERY TANK

1. Turn off machine after majority of water has been

pumped out by discharge pump.

2. Insert supplied 45º elbow in drain valve. Place a

bucket below it and slowly pull up on handle

(Figure 6).

3869506CD (05—07) 5

Fig. 5

Fig. 4

OPERATION

FREEZE PROTECTION

3869506CD (05-07)

6

1. Disconnect garden hose from input connector

2. Connect empty out nozzle to end of solution,

insert in end of vacuum hose and seal with hand

Figure 7).

3. Turn on vacuum and pump for 15 seconds. This

will fill the pump and hoses with air and prevent

freezing

4. Replace freeze protection drain nozzle to its

storage place.

5. Open machine and drain water from filter bowl.

MACHINE MAINTENANCE

To keep machine in good working condition simply

follow machine’s daily, weekly, and monthly

maintenance procedures.

For Safety: When servicing machine unplug cords

from wall outlet.

DAILY MAINTENANCE

(Every 4 hours of operation)

1. Empty and rinse out recovery tank thoroughly.

2. Remove float shut off screen from recovery tank

and clean (Figure 8, 9).

3. Wipe off power cord and check for damage.

Replace if necessary. Coil cord neatly after use.

4. Clean machine with an all purpose cleaner and

damp cloth.

5. Unlatch locking arms of bayonet coupler attached

to pump (Figure 10).

6. Lift flood pump off mounting bracket located in

the bottom of recovery tank. Note its position so it

can be returned to this location.

7. Guide float switch and discharge pump through

hole in top of waste tank (Figure 11).

8. Remove lint and debris from filter on bottom of

pump (Figure 12). Remove base filter and clean.

Fig. 8 Fig. 9

Fig. 10

Fig. 7

Fig. 11

Fig. 12

OPERATION

WEEKLY MAINTENANCE

(Every 20 hours of operation)

1. Inspect vacuum hoses for holes and loose cuffs.

2. Lubricate metal shaft on recovery tank drain.

MONTHLY MAINTENANCE

(Every 80 hours of operation)

1. Lubricate wheels with water resistant oil.

2. Inspect machine for water leaks and loose

hardware.

3. Open machine and inspect wiring and replace

wiring harness if signs of corrosion or heat.

4. Unscrew clear bowl on incoming water filter and

clean filter screen. Reassumble filter assembly.

STORING MACHINE

1. Before storing machine, be certain to drain and

rinse tank

2. Store machine in a dry area in an upright position.

3. Open recovery tank lid to promote air circulation.

RECOMMENDED STOCK ITEMS

Refer to Parts List section for recommended stock

items. Stock items are clearly identified with a bullet

preceding the part number. See example below.

PART # DESCRIPTION QTY.

J-30. LID, DOME 1

•J-38GRANITE TOP,SOL TANK ROTO GRANITE 1

J-39.5GRANITE HANDLE,WASTE TANK ROTO GRANI 1

J-39GRANITE WASTE TANK, ROTO GRANITE 1

3869506CD (05—07) 7

OPERATION

TROUBLE SHOOTING

PROBLEM CAUSE SOLUTION

Faulty switches or wiring. Contact Service Center.

Faulty power cord. Contact Service Center.

Machine does not operate.

Building circuit breaker tripped. Reset Breaker.

Loose or broken wiring. Contact Service Center.

Faulty vacuum switch. Contact Service Center.

Defective vacuum motor. Contact Service Center.

Vacuum motor does not

operate.

Worn carbon brushes. Contact Service Center.

Faulty switch or wiring. Contact Service Center.

Faulty solution pump motor. Contact Service Center.

Trigger on wand not pulled. Pull Solution Trigger.

Quick couplers not fully engaged. Connect quick couplers.

Solution pump does not operate.

Faulty pump head. Contact Service Center.

Faulty switch or wiring. Contact Service Center.

Float switch tangled in cord. Untangle cord in vacuum tank.

Filter screen clogged Clean filter screen under flood pump.

Flood pump does not work

Output of flood pump disconnected. Connect quick coupler in waste tank.

Small diameter garden hose Use ¾” minimum diameter garden hose.

Pump filter screen plugged with debris. Clean filter screen

Flood pump does not discharge

fast enough

Check valve plugged with debris Clean or replace check valve.

Recovery tank drain valve open. Close valve.

Defective recovery tank lid gasket. Replace gasket.

Clogged float shut-off screen. Remove recovery tank lid and clean

screen.

Loose vacuum hose connections. Secure cuffs to hose.

Poor solution pick-up.

Defective vacuum hose. Replace hose.

3869506CD (05-07)

8

OPERATION

SPECIFICATIONS

Model 3869506

LENGTH 711 mm (28 in)

WIDTH 450 mm (17.7 in)

HEIGHT 965 mm (38 in)

WEIGHT 67 Kg (148lbs)

RECOVERY TANK CAPACITY 56.7 L (15 gal)

SOLUTION PUMP 120V, 82.7 BAR (1200 PSI), 12.3A

DISCHARGE PUMP 120 V, 94.6 LPM (25 GPM), 5 A

VACUUM MOTOR – 2- 2 STAGE PARALLEL 2 @ 120V, 8.5 A, 1020W.

SEALED WATER LIFT 2337 mm (92 in) 5.66CMM (200 CFM)

TOTAL POWER CONSUMPTION CIR 1– 120V,17.7A, 2124W CIR 2– 120V, 16.3A, 1956W

POWER CORDS 2 @ 7.6m (25 ft) 3/12

DECIBEL RATING 3 METERS (10 FT) FROM

MACHINE ON CARPET

<68 db(A)

MACHINE DIMENSIONS

3869506CD (05—07) 9

787 mm

(31 in) 450 mm

(17.7 in)

939 mm

(37 in)

978 mm

(38.5 in)

ELECTRICAL DIAGRAM 3869506CD

120 V WIRING DIAGRAM

3869506CD (05-07)

10

PARTS LIST 3869506CD

TANK GROUP

3869506CD (05—07) 11

PARTS LIST 3869506CD

TANK GROUP

Part # Description Qty

B-17.2 8-32 X 1/2 PHXSS 4

B-21 10-32 X 5/16 PHXSS 8

B-22 10-32 X 7/16 PHXSS 2

B-23.7 10-32 X 5/8 PHXSS 1

B-24 10-32 X 3/4 PHXSS 3

B-26.7 10-32 X 1 1/2 PHXZINC 2

B-28.01 NUT 10-32 HEX ZINC 2

B-28.02 NUT, 10-32 SS NYLOCK 4

B-40.91 3/8-16 X 1 1/2 HEX ZINC 2

B-40.95 3/8-16 X 3 1/2 HEX ZINC 1

B-40.96 3/8-16 X 4 HEX ZINC 1

B-41.5 WASHER, 3/8 FLAT ZINC 3

C-01.25 BUSHING,HOLDER EMPTY-OUT 1

C-03.02 CLAMP, HOSE 1/4" #4 2

C-03.13 CLAMP, HOSE 1 3/4 #20 2

C-03.3 CLAMP, HOSE 2 1/4 #32 3

C-04.3 COUPLER, QC SHANK 1" HOSE 1

C-04.35 COUPLER,QC SHANK 1" X 1"FPT 1

C-04.4 COUPLER, QC MALE 1" HOSE 1

C-05.029 ELBOW, 90 2"INSERT X 2 MPT PVC 1

C-07.6 GASKET,LID FLD WATER RMVL&EDGE3 1

C-13.5 PLUG, HOLE NYLON .562 2

C-26 FLOAT,VAC SHUT OFF ROTO 1

C-30.4 GASKET, 1"ID FLAT RUBBER 1

C-30.5 GASKET, 2"ID RUBBER 1

C-35.6 HOSE BARB, 2"MPT X 2"BARB 1

C-46 LOCKNUT, 2" METAL 1

C-95 VELCRO, ONE WRAP STRAP 1/2" X 12" 2

D-13.36 COUPLING, BELL 1" X 3/4" GALVANIZED 1

D-44.085 NIPPLE 3/4" CLOSE PVC 1

E-14.65 CUFF, 1 1/2 SLIP 1 1/2 HOSE 4

J-41HZN/EXTRACT-CD TANK,EDGE HZN ROTO CHEM-DRY 1

J-49BLUGRNT LID,MEGA/E3 ROTO BLUGRNT 1

Part # Description Qty

J-57 SPACER, ROTO 1.5"OD X 1.0"ID 1

J-57.5 SPACER,ROTO 3"OD X 2.4"ID 1

K-13.2 LIGHT, GREEN ROUND 1

K-16.92 BUSHING, RELIEF 3/8 NPT 1

K-16.96 BUSHING,RELIEF 1/2 NPT 2

K-16.97 NUT,NYLON BUSHING REL.1/2 2

K-17.5 CLAMPS, NYLON CABLE 3/8 2

•K-21W SWITCH, SPST WATER RESIS 4

K-28.05 TIE, WIRE NYLON #10 SCREW 1

K-28.1 TIE WRAP,8" LONG NATURAL 1

M-0791.03 BRACKET,SF-09 HOLDER EDGE 1

M-0791.05 BRACKET,DUMP VAL MNT EDGE 1

M-0792.1 PLATE,HANDLE SW COVR EDGE 1

M-09.2 BRACKET, SUB PUMP CORD SUPPORT MEGA 1

M-09.4 BRACKET, SIDE PUMPT MOUNT MEGA 1

M-09.45 BRACKET, BASE PUMP MOUNT MEGA 1

M-10.5 COUPLER, 1.5" VAC HOSE 1

N-30.320 PNL, SW HORIZON V V C1 P D 1

SC-04.4 COUPLER,QC MALE 1" 5/64 PRIME HOLE 1

SC-05.028 ELBOW, PVC ASSY MEGA LID COMPLETE 1

•SD-94.6 CHECK VALVE, COMPLETE ASM MEGA 1

SE-09.6/28 HOSE,1 3/8 TYGON CLR BRD 28"LONG 1

SE-10.6/25 HOSE, VAC 1 1/2 GREY 25' 2

SE-10.61 HOSE,VAC 1 1/2X25'W/1.5 1

SE-12/2.25 HOSE,2" VINYL X 2.25" 1

SF-09 NOZZEL, EMPTY OUT MALE 1

•SG-16 VALVE,DUMP 1.5 W/PVC EXT 1

SJ-42HZN.3-CD HNDL,ED 4 SWT & 1 CI LIGHT HZN CD 1

SJ-46.9 MANIFOLD, ASM FILTER SHUT OFF 2" 1

SJ-49HZN-CD LID, VAC CHEM-DRY TILE MACHINE 1

SK-09.2B CORD, 25' 12/3 SJT W/TREM APPL 2

SK-84HZN1/HNDL HARNESS, HZN HNDL C2VV CI C1PD 1

•SL-23.25 PUMP, SUBMSBLE 115V W/FLT TRMNTED 1

•RECOMMENDED STOCK ITEMS

3869506CD (05-07)

12

PARTS LIST 3869506CD

BASE GROUP

B-23.17

M-0606 B-42.4

K-17.4 (2X)

C-05.10

B-36.01 (8X)

C-11.9 (2X)

B-18.02 (4X)

B-32 (8X)

C-02.45 (2X)

B-38.5 (8X)

SK-84HZN1/BASE

B-14 (4X)

J-45BLK

B-38.5 (4X)

B-32 (4X)

M-0792.7

SJ-40.5BLK101209210

C-51

B-10 (4X)

M-0792.6

B-10 (4X)

K-17.3 (2X)

B-14 (4X)

D-17

F-11

M-72

B-17.6 (4X)

E-04.11

B-42.5 (2X)

M-0790.4

C-23.9(2X)

3869506

05/25/07

C-60(2X)

C-03.2(X2)

B-22

D-17.1 (2X)

C-95

C-04.1 (2X)

M-0790.5

M-0791.3 (2X)

M-0563.8

PUMP REF

E

D

SE-09.1/4.5

B

F

D-17

G-46.12

C-30.3

D-15.2

B-31.5(4X)

B-31.5(4X)

B-38.5(4X)

D-17.1(4X)

C-13.5 (2X)

E-04.14

E-04.10 B

SL-28.1200

E-04.12

SE-09.1/16

E

D-04.005

F-14.5

D-11.84

F-12

3869506CD (05—07) 13

PARTSLIST 3869506CD

BASE GROUP

Part # Description Qty

B-10 6-32 X 1/2 PHXSS 8

B-14 NUT 6-32 HEX SS 8

B-17.6 8-32 X 3/4PHX ZINC 4

B-18.02 NUT 8-32 NYLOK, ZINC 4

B-21 10-32 X 5/16 PHXSS 1

B-22 10-32 X 7/16 PHXSS 1

B-23.17 10 X 1/2 SELF TAP HEX 1

B-23.7 10-32 X 5/8 PHXSS 1

B-26.7 10-32 X 1 1/2 PHXZINC 2

B-28.01 NUT 10-32 HEX ZINC 7

B-29.1 WASHER,#10 SS 6

B-31.5 1/4-20 X 1/2 HEX CP 8

B-32 1/4-20 X 3/4 HEX HD CP 12

B-33.38 1/4-20 X 3 HEX HD CP 6

B-36.01 NUT 1/4-20 NYLOK ZINK 14

B-38.5 WASHER, 1/4 FLAT CP 32

B-42.4 WASHER,5/8 FLAT BLKHD CP 1

B-42.5 WASHER, 3/4 FLAT CP 2

C-02.45 CASTER, 5" SWIVEL 2

C-03.2 CLAMP, HOSE 2" #24 2

C-03.3 CLAMP, HOSE 2 1/4 #32 5

C-04.1 COTTER, HAIRPIN 7/16-9/16 2

•C-05.10 FILTER, IN-LINE ASM 1/2BRB X 1/2BRD 1

C-06 GASKET, BLOWER/ARLON 1/4" 2

C-07.3 GASKET,VAC SEAL EDGE BASE 1

C-11.9 LATCH, SOFT DRAW BLACK 2

C-13.5 PLUG, HOLE NYLON .562 2

C-23.9 WHEEL, 12" W/ 1/2 BORE 2

C-30.3 GAUGE, PRESSURE 0-2000 PSI 1

C-51 MUFFLER, FOAM EDGE 1

C-60 RETAINER,PUSH-ON 3/4"ZINC 2

C-95 VELCRO, ONE WRAP STRAP 1/2" X 12" 1

D-04.005 BUSHING 3/8 X 1/2 NPT BR. 1

D-11.84 COUP, 1/2"FPT X 3/4"FIPSVL GARDEN H 1

D-15.2 45 ST ELBOW 1/4 NPT 1

D-17 90 ST ELBOW 1/4" NPT 2

D-17.1 ELBOW,ST 3/8" NPT 6

D-43 NIPPLE, 1/4 HEX BRASS 2

E-04.10 HOSE,PLS 34" 3/8MSVX1/4FP 1

E-04.11 HOSE,PLS 34" 1/4MSVX3/8MSV 1

Part # Description Qty

E-04.14 HOSE, PLS 38 1/2" - 1/4MSVx3/8MSV 1

E-04.12 HOSE,PLS 34" 3/8MSVX3/8MSV 1

F-09 Q/C 1/4" PLUG BR SHUT OFF 3

F-11 Q/C 1/4" SOC BR SHUT OFF 3

F-11INSUL/BLUE 71/4"QC SOC BR S/O INSUL BLUE 1

F-12 QC 3/8 PLUG BR ST TH X 3/8FPT 1

F-14.5 QC 3/8 SOC BR ST TH X 3/8MPT 1

G-25.15 VALVE, BALL 2-WAY 1/4"FPT 1

G-37 VALVE,VAC SHUT OFF DUAL 1

•G-46.12 VALVE, UNLOADER 1200 PSI 1

J-45BLK PMP MNT,DRLD 2 VAC SILNCE BLCK ROTO 1

J-46.5BLK MANFLD, BLWR INTAKE 2" ROTO 1

K-17.3 CLAMP,NYLON CABLE 3/16" 2

K-17.4 CLAMP,NYLON CABLE 1/4" 2

M-0563.8 BRACKET, MTR STARTER CAP 1

M-0606 BRACKET, MOTOR MOUNT 1200PSI 1

M-0790.4 AXLE, ROD 1/2 EDGE 18.75"-12 WHEEL 1

M-0790.5 AXIL, ROD 1/2 EDGE ECONO 1

M-0791.3 PIVOT, TUBE EDGE 3.400" 2

M-0792.015NH PLATE,VAC MNT PAR,QT,LARGE BASE 1

M-0792.51 PLATE,FLAPPER VALVE-EDGE 1

M-0792.6 PLATE, MUFFLER/PMP MOUNT COVER 1

M-0792.7 BRACKET, MANIFOLD DIV 1

M-31.17 STANDOFF, 5.7 EDGE 2.260" 6

M-72 SPACER, QUICK CONNECT 1

SC-16.69 SCREEN,BLOWER GUARD 2

SE-06.7/25-7HPEXT HOSE, 1/4 SOL 25'W/M&FMQC'S HI-PRES 1

SE-06.7/25-7HPINSUL HOSE, 1/4 SOL 25'W/QC HP M&FINSULQC 1

SE-06.7/25HP HOSE,1/4 SOL 25'NPT HP NO/QC 2

SE-09.1/16 HOSE, 1/2GPH 16" 3/8NPTX1/2FPT 1

SE-09.1/4.5 HOSE, 1/2GPH 4.5" 3/8NPTx1/2FPT 1

SE-12.5/3 HOSE,2"FLEX EXH 3" LONG 1

SE-12.5/6 HOSE, 2" FLEX EXH 6" 1

SE-12.6/24 HOSE, 2" CLR WIRE SUPPORT 24"LONG 1

SG-25.15 VALVE 2-WAY SHUT OFF ASM W/QC'S 1

SG-37 VALVE,DUAL FLPR MODI EDGE 1

SJ-40.5BLK101209210 BASE,DRLD PAR W/QT HRZN BLK 1

•SK-84HZN1/BASE HARNESS, HZN BASE C2VV CI C1PD 1

•SL-004 BLOWER,2STG 120V 5.7COMP #116392-00 2

•SL-28.1200 PUMP, 1200PSI CMP 110V 1

•RECOMMENDED STOCK ITEMS

3869506CD (05-07)

14

HORIZON WARRANTY POLICY

LABOR & PARTS POLICY

For the first 12 months from the date of original purchase, upon Kleenrite’s determination, product manufacturing

defects will be repaired or replaced at no charge for labor and/or parts provided that the machine or part(s) is

delivered or shipped freight prepaid to Kleenrite or its designated repair center and provided that a Return

Authorization is obtained from Kleenrite prior to machine or part(s) being shipped. (See “How to Obtain a Return

Authorization”.)

Kleenrite is not responsible to pay for parts supplied by or labor performed by any of its distributors or any general

service companies.

PARTS ONLY – STANDARD REPLACEMENT POLICY

For the first 12 months from the date of original purchase, in the event that a part believed to be under warranty fails,

simply call Kleenrite to obtain a Return Authorization, ship the part freight prepaid to Kleenrite and, Kleenrite will

either repair or replace the part at no charge if it is determined that failure was a manufacturing defect. Kleenrite will

then ship the repaired or replaced part back to you freight collect. Our service department can usually talk a person

through any part replacement procedure in a matter of minutes. There is no charge for this nationwide toll-free

service.

PARTS ONLY – EMERGENCY REPLACEMENT POLICY

For the first 12 months from the date of original purchase, in the event that a part believed by the registered owner to

be under warranty fails and an immediate replacement part is requested before Kleenrite can inspect the part that is

suspected to be faulty or have a chance to repair it, Kleenrite will ship the requested part on a COD basis (part plus

freight) or if credit has been established prior to the request the part will be shipped on an Open Account basis (part

plus freight). A Return Authorization must be requested at the time of order so that the suspected defective part can

be returned freight prepaid to Kleenrite for warranty consideration. If after receiving the part, Kleenrite determines

that the part has a manufacturing defect and can be repaired, the part will be repaired to normal working condition

and returned (freight collect) to the original registered owner as a spare part and no refund will be made. Should

Kleenrite determine that the part is covered by warranty and cannot be repaired, Kleenrite will credit an open

account customer the same amount as was charged when the replacement part was sent less freight and will refund

a COD customer the same way. However, should Kleenrite determine that the part received was not a

manufacturing defect, you will be informed of such and credit will not be given nor will the damaged part be returned

unless requested specifically to the registered owner.

HOW TO OBTAIN A RETURN AUTHORIZATION

Prior to shipping any part, assembly or machine to Kleenrite a Return Authorization Number must be requested from

Kleenrite and displayed prominently on the outside of all packages containing parts or machines for warranty

consideration to be processed and in effect. A Return Authorization can be obtained by calling Kleenrite Service

Department at 1-800-241-4865 or 1-559-673-5700. The machine and/or part serial number must be communicated

to Kleenrite Customer Service to receive a Return Authorization Number. Any machine, part or assembly must be

returned with its original serial number as affixed by Kleenrite for warranty consideration to be in effect. All returns

will be sent to Kleenrite at 1122 Maple Street, Madera Ca. 93637. Fax communications can be sent to

1-559-673-5725 and emails sent to kleenritemfg.com.

3869506CD (05—07) 15

WARRANTY

Kleenrite Equipment, Inc. warrants the HORIZON Cleaning Machine against defects in material and workmanship

under normal use and service. Kleenrite, hereby, extends a limited three-year warranty on the polyethylene

machine housing of the HORIZON against cracking or leaking and a one-year warranty on the rest of the machine

against manufacturing defect or workmanship subject to the terms and conditions that follow.

TERMS AND CONDITIONS

The warranty obligation extends only to the repair or replacement of parts, assemblies or machine housing found

upon examination by Kleenrite to be defective in manufacturing or workmanship, and Kleenrite reserves the right

to make that determination. Any adjustment or replacement of defective parts made under this warranty does not

void the warranty; neither does it extend the original warranty beyond its term.

Repair or replacements of any machine component(s) with any part(s) other than genuine Kleenrite parts will

immediately void this and all warranties.

Filters, brass fittings, seals, o-rings and quick disconnects are considered expendable in normal use and are not

covered by this warranty.

Dry cleaning solvents cannot be used in the HORIZON.

This warranty shall not cover any HORIZON machine housing, part or assembly if there is evidence of misuse,

alteration, owner neglect, lack of proper maintenance, improper chemical use, improper voltage, abuse, accident,

freezing, flood, fire, etc. and any and all circumstances beyond Kleenrite’s control.

In no event shall Kleenrite be liable for loss of use, incidental or consequential damages or any damages to

persons or property.

1122 MAPLE STREET, MADERA CA 93637 USA

Phone 800-241-4865, 559-673-5700; Fax 559-673-5725; Email kleenritemfg.com

PLEASE RETURN REGISTRATION WITHIN 10 DAYS OF RECEIVING YOUR HORIZON CLEANING MACHINE.

SPECIALS: Check our web site at: kleenritemfg.com for parts and equipment price specials.

KEEP THIS COPY FOR YOUR RECORDS

Date Received

Registered Owner(s)

Address

Phone Number

Fax Number

Email Address

Machine Serial Number

Purchased From (Distributor)

WARRANTY

REGISTRATION

3869506CD (05-07)

16

WARRANTY

Kleenrite Equipment, Inc. warrants the HORIZON Cleaning Machine against defects in material and workmanship

under normal use and service. Kleenrite, hereby, extends a limited three-year warranty on the polyethylene

machine housing of the HORIZON against cracking or leaking and a one-year warranty on the rest of the machine

against manufacturing defect or workmanship subject to the terms and conditions that follow.

TERMS AND CONDITIONS

The warranty obligation extends only to the repair or replacement of parts, assemblies or machine housing found

upon examination by Kleenrite to be defective in manufacturing or workmanship, and Kleenrite reserves the right

to make that determination. Any adjustment or replacement of defective parts made under this warranty does not

void the warranty; neither does it extend the original warranty beyond its term.

Repair or replacements of any machine component(s) with any part(s) other than genuine Kleenrite parts will

immediately void this and all warranties.

Filters, brass fittings, seals, o-rings and quick disconnects are considered expendable in normal use and are not

covered by this warranty.

Dry cleaning solvents cannot be used in the HORIZON.

This warranty shall not cover any HORIZON machine housing, part or assembly if there is evidence of misuse,

alteration, owner neglect, lack of proper maintenance, improper chemical use, improper voltage, abuse, accident,

freezing, flood, fire, etc. and any and all circumstances beyond Kleenrite’s control.

In no event shall Kleenrite be liable for loss of use, incidental or consequential damages or any damages to

persons or property.

1122 MAPLE STREET, MADERA CA 93637 USA

Phone 800-241-4865, 559-673-5700; Fax 559-673-5725; Email kleenritemfg.com

PLEASE RETURN REGISTRATION WITHIN 10 DAYS OF RECEIVING YOUR HORIZON CLEANING MACHINE.

SPECIALS: Check our web site at: kleenritemfg.com for parts and equipment price specials.

PLEASE RETURN THIS ENTIRE SHEET

Date Received

Registered Owner(s)

Address

Phone Number

Fax Number

Email Address

Machine Serial Number

Purchased From (Distributor)

WARRANTY

REGISTRATION

3869506CD (05—07) 17

Table of contents

Other ChemDry Cleaning Equipment manuals

Popular Cleaning Equipment manuals by other brands

Alfalaval

Alfalaval Toftejorg SaniJet 25 instruction manual

Silvercrest

Silvercrest SRB 6 A1 Operating instructions and safety instructions

Good Way

Good Way GVC-BP-1700 Operating and maintenance instructions

Belanger

Belanger DuoScrubber HP owner's manual

LEHMANN

LEHMANN QLEEN Q Station User information

i-team

i-team i-suit user manual