| 7

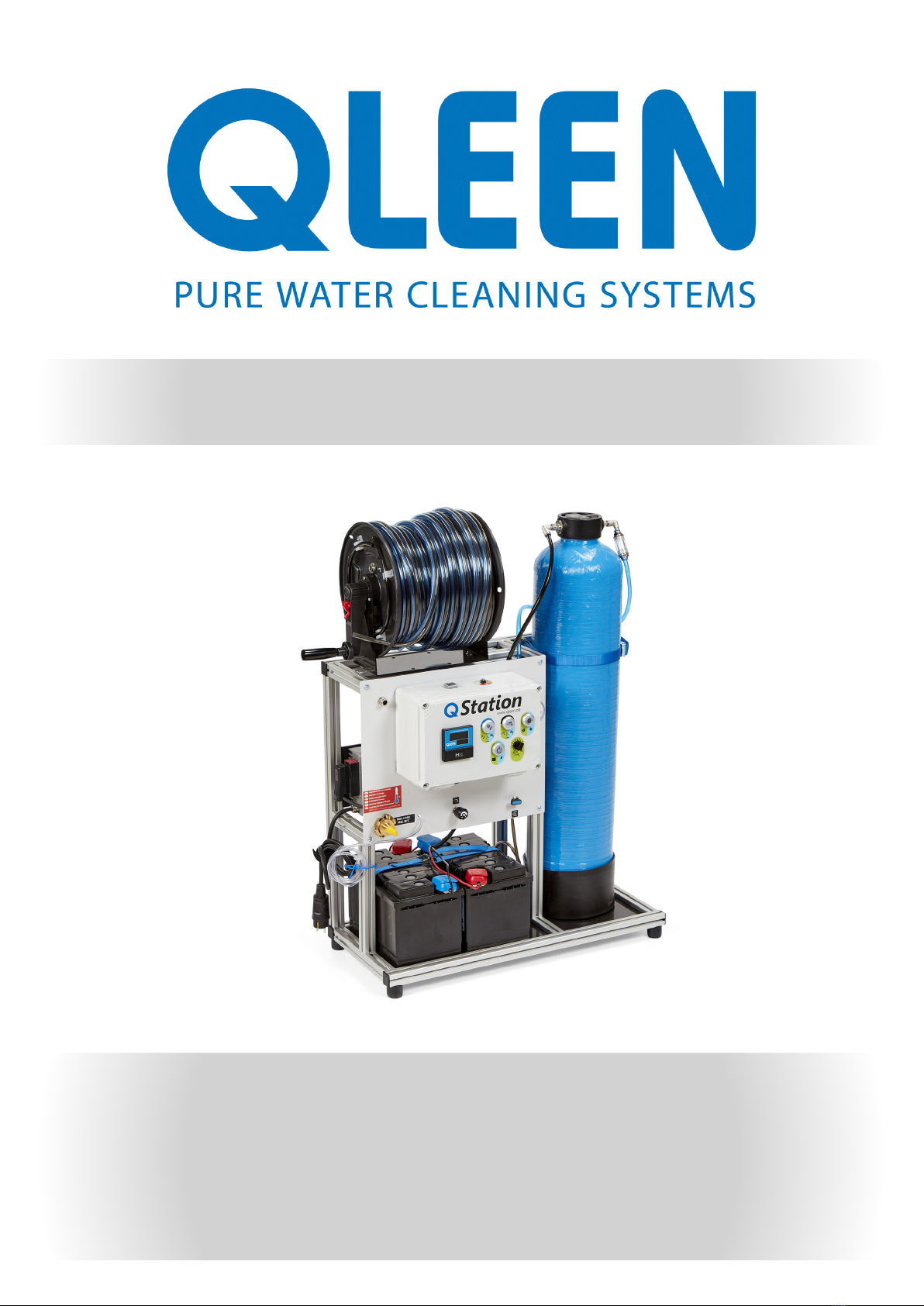

Description of the QLEEN Q-Station

3 Description of the QLEEN Q-Station

3.1 The PUREWATER principle - cleaning with pure water

The high chemical-free cleaning power of PUREWATER is the basis on which the

PURAQLEEN principle for cleaning glass, solar and facade surfaces.

In this process, tap water is passed through a granulate bottle. The minerals contained in the tap water

accumulate in the mixed bed resin and all salts are removed from the water.

The tap water is demineralized by pre-pressurization in the granulate bottle and reaches the cleaning head as

PUREWATER.

PUREWATER not only has a very good wetting capacity, but also dries without stains or streaks, even in strong

sunlight.

This means that in many cases the use of cleaning solutions can be dispensed with.

(exception: greasy, oily or very heavy soiling).

3.2 Sustainability

Our system contributes to the careful and sustainable use of resources for cleaning in times of dwindling resources.

In contrast to the reverse osmosis process, our devices operate in the energy-saving low-pressure range; the

pressure of the domestic water supply is suicient to operate our devices.

In addition, our systems convert 100% of the supplied water into PUREWATER, which can be used for cleaning.

3.3 Water hardness and productivity of the mixed bed resin

The water hardness at the place of use can be obtained from the local water supplier.

This allows you to estimate the yield of the granulate bottle.

Depending on the measured value, the following values result for the maximum PUREWATER quantity and

cleaning time with a granulate bottle (at a maximum initial value of 50 µS, approximate data):

* Based on a flow rate of 200 l/h with the brush bow Vario

German hardness level Corresponds

approximately to

conductance Estimated total quantity Estimated total cleaning

time*

2,8 °dH 100 µS 10200 l 51,0 h

5,6 °dH 200 µS 5100 l 25,5 h

8,4 °dH 300 µS 3400 l 17,0 h

11,2 °dH 400 µS 2500 l 12,5 h

14,0 °dH 500 µS 2000 l 10,0 h

16,8 °dH 600 µS 1700 l 8,5 h

19,7 °dH 700 µS 1650 l 8,25 h

22,5 °dH 800 µS 1200 l 6,0 h

25,3 °dH 900 µS 1100 l 5,5 h

28,0 °dH 1000 µS 1000 l 5,0 h