8

ON

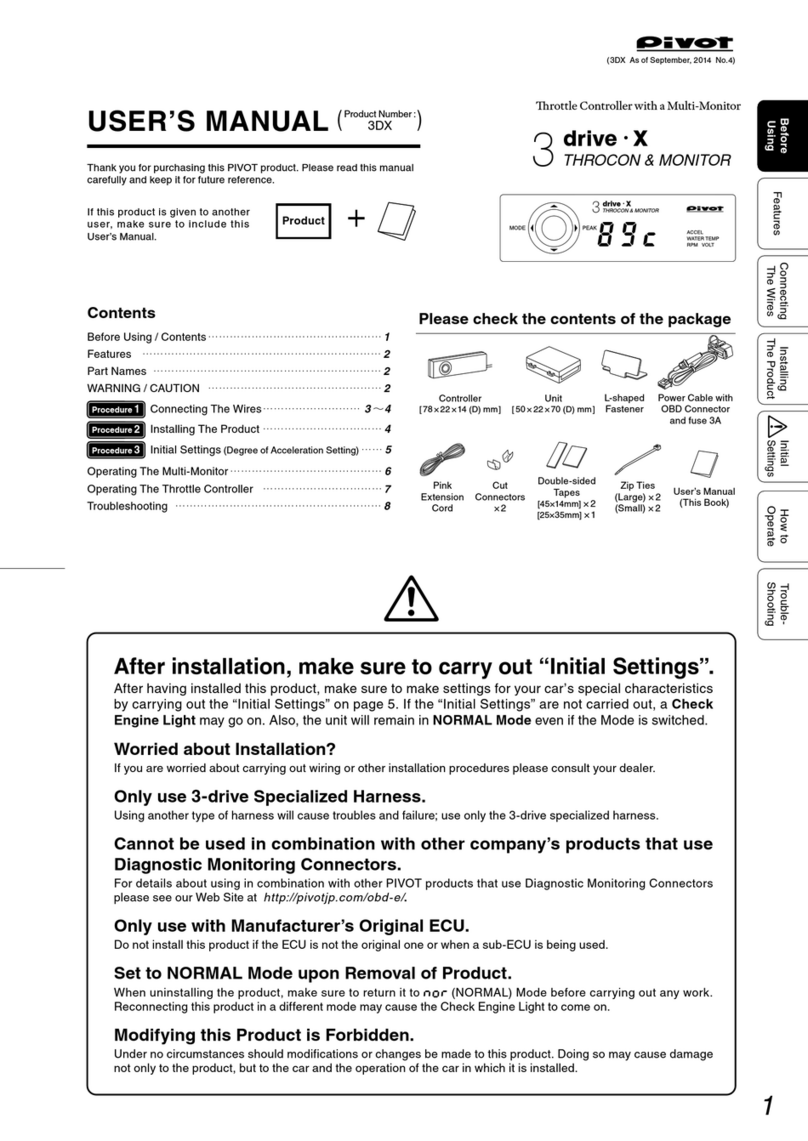

R

Troubleshooting

Poor connection of OBD2 connector.

Trouble Possible Causes Possible Solutions

The key switch is set to ON but

the display will not light up.

.

Specialized Harness

Poor connection of

Red

Black

If wiring has been direct to power the

and wires may have been improperly

wired or there is a poor connection.

Please reconfirm whether wiring and connections are

correct or not.

The accelerator connector was discon-

nected within 15 minutes after having turned

the key to OFF.

Re-connect the disconnected connector and follow the

directions “How to Turn Off the CHECK Lamp” as bellow to

turn off the lamp.

Follow the instructions in this Manual (⇒Page 3) to

connect to Accelerator Connector, and follow the direc-

tions “How to Turn Off the CHECK Lamp” as bellow to turn

off the lamp.

With the key switch in the ON position dis-

connect the accelerator connector or the

connector attached to the unit.

The “Initial Settings” have not been properly

carried out.

A CHECK lamp in vehicle has

gone on.

The “Initial Settings” have not been properly

carried out.

Make the settings by following the directions under

“Initial Settings” found on Page 5 of this Manual.

While making “Initial Settings”

an appears

in the display.

The “Initial Settings” have not been properly

carried out.

Even if the Mode is changed,

the changes cannot be felt.

Set the change ratio under ECO Mode to a smaller value.

The change ratio under ECO Mode is too

great.

The engine seems to stall easily.

While in SPORTS Mode, when

put into reverse (dot

blink) does not appear in the

display. The unit is connected to the reverse wire of

a navigation system from another company.

The backup lights have been changed to

LED lamps.

Please reconfirm whether wiring and connections are

correct or not.

Follow the instructions for wiring to reverse found in this

Manual (⇒Page 4).

●Replace the backup lights with the car maker’s original

lights.

●Do not carry out wiring for Reverse Gear.

The wiring to reverse was carried out im-

properly or there is a bad connection.

The key has been turned OFF immediately

after having finished the setting of change

ratios or changing the Mode.

The Mode and/or the setting of

change ratios can not be saved.

After having made settings of change ratios or changing

the Mode, wait for at least 2 seconds before turning the

key OFF.

※Our products have already been recognized as our Industrial Property or are in the process of receiving Industrial Property status.

※We plan in the near future to take all possible legal measures to protect against unfair competition from look-alike products using similar

designs, regulating characteristics, circuitry and circuitry layout.

※We strictly prohibit the unlicensed use of the PIVOT trademark and the unauthorized use of PIVOT User’ s Manual.

How to Turn Off the CHECK Lamp

CHECK Lamp is

ON

① Under normal conditions, start and stop the engine several times.

② If that does not turn off the lamp, disconnect the cable from

-

terminal of the battery for about 10 minutes.

③ If that does not turn off the lamp, please consult your local car dealer and have them turn it off.

Note

If the CHECK Lamp comes on due to some operational mistake, please follow the directions below to turn it off.

Features

Connecting

The Wires

Installing

The Product

How to

Operate

Before

Using

Trouble-

Shooting

Initial

Settings

PIVOT CORPORATION 87-3, Shimookada Okada, Matsumoto-shi, Nagano, 390-0313 Japan TEL0263-46-5901

Make the settings by following the directions under

“Initial Settings” found on Page 5 of this Manual,

and follow the directions “How to Turn Off the CHECK

Lamp” as bellow to turn off the lamp.

Make the settings by following the directions under

“Initial Settings” found on Page 5 of this Manual.